当前位置:网站首页>Are you ready for the Internet of things to revolutionize manufacturing?

Are you ready for the Internet of things to revolutionize manufacturing?

2022-07-27 01:17:00 【Come to new media】

Digitalization is the main driving force of our age , Change our world constantly . Intelligent and interconnected systems are increasingly penetrating into all types of applications . The Internet of things (IoT) It has begun to affect various environments , Family, for example , City , tourism , logistics , Retail and pharmaceutical , But its development will not stop at the current scientific research achievements and the fields involved .

According to a report of McKinsey & Company in the United States, it is estimated that ,2025 The potential economic impact of IOT applications in 3.9 Million to 11.1 Between trillions of dollars , among 1.2 to 3.7 Trillion dollars will be allocated to IOT applications in factory environments . Also known as intelligent manufacturing or German industry 4.0, These are fully networked manufacturing ecosystems driven by the Internet of things .

some time , all “ Factory object ” Will be integrated into the network , The traditional control hierarchy will be product , Decentralized self-organization of field equipment and machines . The production process must become flexible , Even the smallest batch can be produced cost effectively , And timely meet the personalized needs of customers . meanwhile , Customers are also promoting this development , Because they can design and order products with the click of a mouse . They can also expect their products to be delivered in a few days or even hours . Because of the Internet of things , These become easy to implement .

Despite the huge potential , However, the introduction of IOT technology in the quite traditional manufacturing field will not work quickly . Long investment cycle , The requirements for process and technical stability exceed the speed of innovation , There are many problems .

With the Internet of things technology more and more in-depth, now the factory , Even the smallest equipment , Technology providers and plant planners must also find solutions to four major problems :

- How to ensure the interoperability of the system

- When thousands of devices communicate at the same time , How to ensure real-time control and predictability

- How to prevent subversives or competitors from controlling highly networked production systems

- How to determine the investment income or return of Internet of things technology

To compensate for technical uncertainty and financial risks , Appropriate pilot environment is needed . In the pilot environment , Intelligent manufacturing technology and strategy can be implemented for the first time , Evaluate and demonstrate . This is why almost every large IT Or automation technology providers have established their own intelligent manufacturing laboratories , There you can test and demonstrate proprietary solutions . But they missed an important point , Intelligent manufacturing is actually a network paradigm , It affects everything from automation to IT, From digital planning of products to recycling , From intelligent sensors to business applications and other fields .

Providers who can only provide a single solution cannot cover all these aspects at the same time . therefore , In order to achieve the overall solution , Technology providers must form a network to unite , Develop compatible solution modules suitable for the future needs of technology users .

For the center of developing comprehensive solutions for Intelligent Manufacturing , The general configuration comes from the association of manufacturing and research institutions . Such networks can include large multinational enterprises 、 Small and medium-sized companies and experienced research centers . An important goal of this collaborative model is to test the innovative Factory Technology under real conditions , And promote it from the laboratory to the market as soon as possible .

The advantage of this association is that it acts as a “ neutral ” platform , You can connect technology providers and users , No matter how they compete in the business world . This means that companies with overlapping business and capability areas can work together , No matter how big or small , What is the historical and economic situation . ad locum , They can set independent general standards , Therefore, it is not linked to specific companies or brands , They can provide proprietary technology and business models , For open ecosystems .

Technology providers with complementary businesses or capabilities can also benefit from network opportunities when different areas are interconnected , for example , In traditional automation technology and IT Interfaces between systems , Such as the digitalization of big data application or maintenance process . The network is complemented by research partners . Their role is to engage in necessary research projects , And apply the results . Besides , They will also coordinate the cooperation between all partners .

since 2005 Since then , Kaiserslautern, Germany SmartFactoryKL Smart factory has realized such a cooperation mode . They are based on industry 4.0 Highly modular production line for standard implementation , It can be considered as the first best practice case of multi vendor collaboration . The example of intelligent manufacturing awakens the pursuit of efficiency 、 The vision of a customer-oriented factory , These factories can be seamlessly connected with intelligent ecosystems . however , Before that , We still face many challenges . Proving the feasibility of intelligent manufacturing solutions from a technical point of view is only half of the work .

One of the biggest problems today is the lack of technical acceptance and interoperability between systems . Widely accepted standards are the key requirements of the next industrial era , But they are far from easy to achieve . First , It needs a lot of market demand driven by customer demand , This is also called market pulling force . secondly , It needs a sufficient number of companies , Collaborate and reach agreement on common and marketable solutions , This is the driving force of Technology .

Of course , Never has an industrial revolution occurred in a hurry . contrary , These changes have developed in decades of evolutionary transformation driven by technological progress and market demand . The current shift to intelligent manufacturing is likely to eventually become an evolution that will last for decades . If we want to accelerate these developments , We need to build more Inter Organizational Networks and test environments as catalysts .

边栏推荐

- Jenkins--基础--5.2--系统配置--系统配置

- 短视频App开发有哪些必备的功能?

- Naive Bayes Multiclass训练模型

- 深度学习笔记

- 玩客云搭配zerotier保姆级教学,保证学废

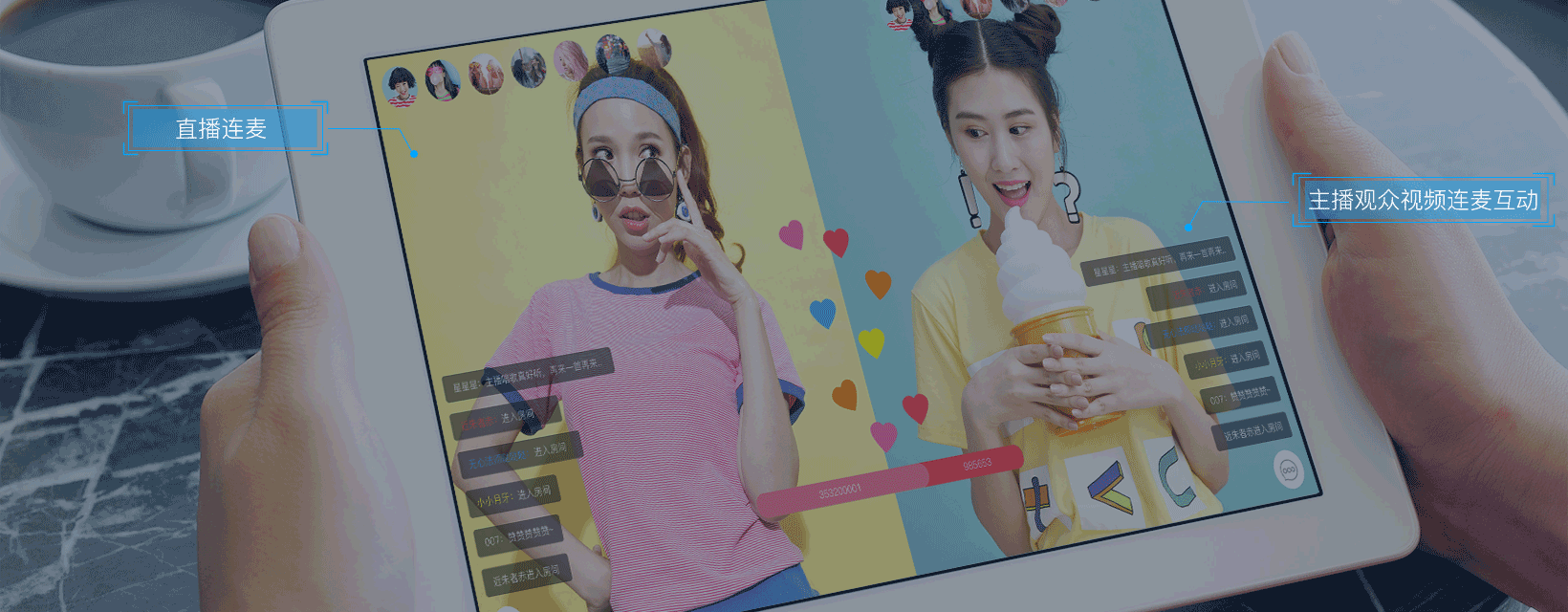

- Tencent upgrades the live broadcast function of video Number applet. Tencent's foundation for continuous promotion of live broadcast is this technology called visual cube (mlvb)

- 腾讯云直播插件MLVB如何借助这些优势成为主播直播推拉流的神助攻?

- 李宏毅机器学习(2021版)_P7-9:训练技巧

- 什么是数字经济,它是如何改变商业模式的?

- SQL关系代数——除法

猜你喜欢

Doris or starrocks JMeter pressure measurement

When a transaction encounters a distributed lock

进入2022年,移动互联网的小程序和短视频直播赛道还有机会吗?

小程序直播、连线直播、直播打赏:腾讯云移动直播组件MLVB多场景直播拓展

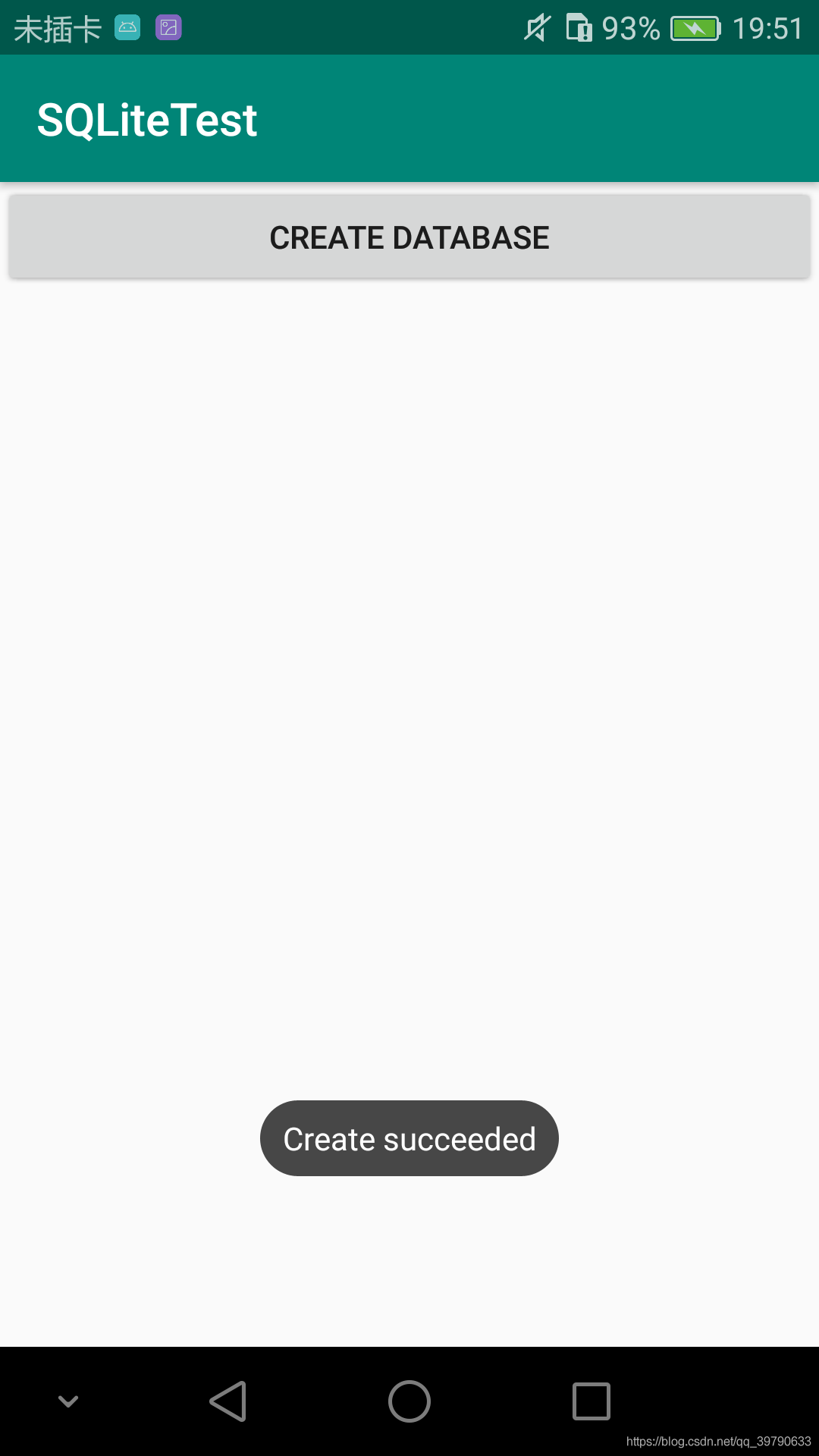

Android——数据持久化技术(三) 数据库存储

Deep understanding of pod objects: basic management

Understanding of Flink interval join source code

Li Hongyi machine learning (2017 Edition)_ P5: error

Jenkins--基础--04--安装中文插件

Redis -- cache avalanche, cache penetration, cache breakdown

随机推荐

Android——LitePal数据库框架的基本用法

In depth learning report (1)

MTCNN

Uni-app 小程序 App 的广告变现之路:Banner 信息流广告

Li Hongyi machine learning (2017 Edition)_ P5: error

adb. Exe stopped working popup problem

Android -- Data Persistence Technology (III) database storage

Solve the problem that rsyslog service occupies too much memory

Jenkins -- Basic -- 5.3 -- system configuration -- global security configuration

25 common questions in Flink interview (no answer)

无重复字符的最长子串

Jenkins--基础--5.1--系统配置--插件管理

Redisson working principle - source code analysis

Li Hongyi machine learning (2017 Edition)_ P21: convolutional neural network CNN

快来:鼓励高校毕业生返乡创业就业,助力乡村振兴

Cannot find a valid baseurl for repo: HDP-3.1-repo-1

Simple explanation of database table connection

Flink1.11 multi parallelism watermark test

VSCode2015下编译darknet生成darknet.ext时error MSB3721:XXX已退出,返回代码为 1。

IDEA导入外部项目时pom文件的依赖无效问题解决