当前位置:网站首页>Four necessary steps for building a digital factory

Four necessary steps for building a digital factory

2022-06-21 07:05:00 【Dark blue easy net】

How to build a good digital factory management system , Not only does it need to have an adequate budget , More scientific planning and Design , Generally do a good job in digital construction , The following steps must be followed :

First of all : Planning and design of information system

Many factories will purchase many independent information systems , Such as CRM( Customer relationship management system )、PLM( Product life management system )、ERP( Enterprise resource plan )、HR( human resources )、QMS( Quality management system )、OA( Office automation ) etc. , But because the top-level design is not done well , Poor system integration , And software selection 、 Online procedures are unscientific , Cause a lot of money 、 Waste of time and human resources .

therefore , We should do a good job in the construction of digital chemical plants , We must do a good job in the planning and design of informatization , Include at least the following :

1、 The future of information systems 3-5 The overall direction and objectives of the year ( Match the company's strategy ).

2、 The overall design of the hardware system , Including network architecture 、 Network security 、 The overall design of the storage system .

3、 Overall design of software system and subsystem 、 Subsystem supplier requirements and online logical sequence .

second : Good launch ERP This data platform

Achieve business - Financial integration ERP, It is also the standard cost 、 actual cost 、 receivable / To cope with 、 The only choice for inventory accounting and general ledger , It is an information system that cannot be evaded .

therefore ,ERP Is the foundation of all information systems , Is the inevitable foundation , You have to do well , Do a solid job .

Third : Choose a professional MES System

stay ERP On the basis of , Choose a professional MES The system becomes the key .MES The characteristics of the industry are quite obvious , Such as machining industry , Focus on the management of processing process , Process report 、 property master 、 WIP management is the key . The electronic materials of the electronic industry are foolproof 、 Complete set of materials is the key . Data tracing of auto parts industry ( batch 、 Pieces of ) Is the core , Different industries need different MES Solution , and MES The suppliers are also different : Auto background 、 Data collection and material network 、ERP Software manufacturer 、 Lean production consultant transformation, etc , Different suppliers 、 Different industries face different customers .

Fourth : Be sure to go to APS And choose the right supplier

current MES Software , Generally, it does not include two MES Core functions : Detailed scheduling 、 Operation work order assignment , But these two functions are the key to the operation of the plant : Determine the optimal release of the operation work order , Achieve customer delivery satisfaction and internal effective output 、 Maximize resource efficiency .

“ Detailed scheduling ”、“ Operation work order assignment ” The function of has more professional APS Advanced planning and scheduling software implementation , therefore , In general ERP、MES After the launch , High complexity 、 Highly variable factory business scenarios , There must be APS Implementation and launch of advanced planning and scheduling , Only in this way can we achieve ERP and MES The effective function of .

边栏推荐

猜你喜欢

Use the loupe cell browser to view the results of 10x single cell transcriptome analysis

使用cell ranger进行单细胞转录组定量分析

【毕业季-进击的技术er】:即将大四在校生的技术分享,未来共勉

Lnc2meth: methylation sites on disease-related lncrna

Understand this point

Pyg tutorial (5): analyzing the message propagation mechanism in GNN

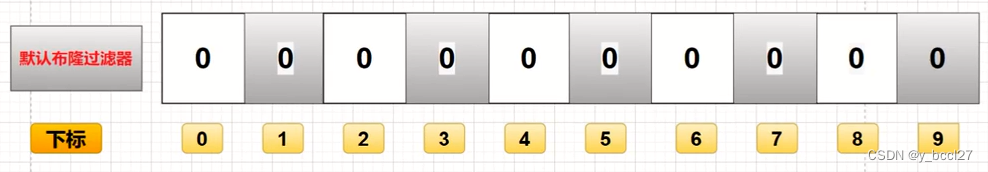

布隆過濾器

【转】刘润:不要和没有逻辑的人讨论业务

建设数字化工厂的四个必要步骤

Google Earth Engine(GEE)——全球农田有机土壤碳和氮排放(1992-2018年度)数据集

随机推荐

win10上vs2017配置Eigen3开发环境

如何利用MES管理系统实现防错和预警

2022年6月13日面试被问到面试题目

Geo2r: difference analysis of data in geo database

Understanding generics mechanism

数据分析之:不同行业的常见指标

flutter jpush

lombok之@NonNull注解

微信小程序_5,全局配置

0-1 knapsack problem (violent recursion / dynamic programming)

0-1背包问题 (暴力递归 / 动态规划)

工作那点事

Yield guild games and Walken reach cooperation

2022 运维故障案例经验

153 Solana create PDA and storage

五层参考模型各层总结

Superparameters and model parameters

easyUI的combox下拉列表的远程数据的绑定方法

ADEX governance voting: pledge reward halved

kubernetes集群搭建详细教程