当前位置:网站首页>Course design of supply chain modeling and simulation based on Flexsim

Course design of supply chain modeling and simulation based on Flexsim

2022-06-21 07:06:00 【Socialphobia_ FOGO】

Model download :flexsim Model download

One 、 Purpose and requirements of course design

1.1 The purpose of the course design is

FlexSim It's based on Windows Of , Object oriented simulation environment , Used to establish discrete event process .FlexSim Simulation systems are engineers 、 Managers and decision-makers are responding to " About operation 、 technological process 、 The scheme of dynamic system " Carry out experiments 、 assessment 、 Visual tools .

We learn about flexsim Software , Cultivate our ability to find and solve problems by applying the theoretical knowledge learned in class . Use flexsim The software simulates the actual production logistics model , Thus, the logistics process , Analyze and improve the process flow , Get a reasonable operation management production . This course is designed to ×× The existing problems of post it notes are found through simulation in the process of parts warehousing and assembly outbound , Reduce waste at work , Improve operational efficiency .

1.2 Course design business description and requirements

1.2.1 Course design business description

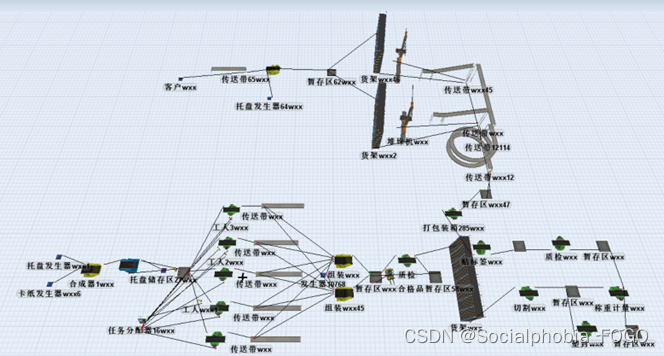

Paper jam receiving area received A、B、C、D、E Five materials , The generator sends out pallets to load five materials into pallets and send them to the synthesizer in batches , Then unpack , The goods are handled by a worker to the temporary storage area , The remaining pallets are placed in the pallet storage area for storage . Through task allocator , Assign the task to four workers , The workers moved the goods to the processor , Five processors dye five materials respectively , All dyed in different colors , Dyed red respectively 、 blue 、 green 、 yellow 、 powder . It is transported to two assembled processors by conveyor belt , Assemble five materials , The five product combinations are put into one pallet by a pallet generator , Storage staging area , Then let the forklift move a pallet of goods to the quality inspection processor for inspection and put them on the shelf . Pass the inspection processor to check whether the product is qualified or not , according to 90% Percent of pass and 10% Classification of non-conforming rate , Put the unqualified products into the unqualified area . A worker will transport the qualified products to the qualified product temporary storage area , Then the semi-finished post it notes are put on the shelf by the forklift , Proceed to the next step . The semi-finished post it notes will be finished next 7 Process , Each process must be carried out on the designated machine according to the predetermined process sequence . First , For cutting , Cut the product into the same size and put it into the temporary storage area , Carry out the weighing and measuring link , After the goods reach the specified weight, they shall be plastic sealed , After another weighing and measuring , Enter the staging area when there is no problem , Then the quality inspection is carried out , Steps for labeling goods , Finally, the goods are packed and stacked in the temporary storage area , The product is packed for a fixed time 10 second . Then a worker carries the goods onto the conveyor belt , The stacker puts the goods on the shelf from the conveyor belt . By setting up a global table , Deliver according to the customer's order , The rest of the goods are put in the warehouse , Send the goods to the customer when the customer needs them . Different packages use different pallets , Co recording 5 Kind of , It is discharged by the tray generator in different time periods , Suppose an empty pallet marked with a type value represents an order from a customer . When another order comes , Ready to ship . Products are transported on pallets .

1.2.2 Course design business requirements

1、 Master the basic principle of system simulation ;

2、 Master the construction of transportation system simulation model ;

3、 Master the selection and use of transportation system simulation software ;

4、 Be able to input and analyze data , The system can be optimized and improved by using the simulation data .

Two 、 Course design implementation process

1. Build a conceptual model

2. establish Flexsim6 Model of :

(1) Establish the model entity of each element in the conceptual model ;

(2) Add model entities to the new model ;

(3) Establish connections according to the relationships between various model entities ;

(4) Set corresponding parameters for different model entities according to the system data required by the topic , The purpose of controlling each process has been achieved ;

① Paper jam generator : The arrival interval is set to 0. When creating trigger setting type , by duniform(1,5)

② Tray generator : Create trigger setting type , by duniform(1,5)

③ Synthesizer : The processing time is 0

④ processor : Five processors dyed in five different colors , Set the color in the entry trigger in the trigger . The preset time is set to 6, The processing time is 16

⑤ Conveyor belt : The speed is set to 2

⑥ Generator : Arrival mode is arrival time interval , Set to exponential(0, 100, 0), The type of temporary entity is Pallet

⑦ Synthesizer : Assemble the product , The processing time is 10, The component lists are all set to 3

⑧ processor : cutting , Just started processing products , The processing time is 7; And pass by 6 The product after the first process , The processing time is 10

⑨ processor : Plastic encapsulation , The processing time is 5, The processing batch is 5

⑩ processor : Label , The processing time is 20 minute , The processing batch is 10 Pieces of

11 Synthesizer : Set up a global table , Deliver according to the customer's order

3. After the model is established , Operation and analysis of the model ;

4. Output report after running , View simple statistics for each model entity ;

5. Analyze the production process according to the output data , Find out the bottleneck process , And reasonably plan the process flow , Reasonable operation management .

The simulation cycle is set to 1 Hours , Repeat method is used to do several independent simulation tests , Then by observing 、 Statistics 、 Analyze the real-time state diagram and the derived simulation experiment data , Get the final simulation results .

3、 ... and 、 Experience of course design

Through this supply chain modeling and simulation course , I learned a lot , This is an interesting course , So I am also engaged in this course design . I find flexsim It can not only simulate our real things , And you can also create some new process reengineering , Simulate some situations that cannot be realized in reality . This kind of simulation does not require a lot of manpower and material resources , It has greatly helped the production and development of the company . We can boldly simulate various scenarios on the computer , This can open up our minds , Exercise our ability .

On the network and B I found a lot about flexsim And studied it carefully , Roughly know how to run effectively flexsim . When dealing with simple entities , Be able to model with software , And data analysis , Draw a general conclusion . But in the process of operation , I still encountered many difficulties , Some parameters and settings that cannot be fully understood are not understood in time , As a result, the later setting work is carried out slowly . After systematically understanding the relevant parameters 、 Set the name 、 After function , The course design was successfully completed . In the design process , By looking up a lot of relevant information , I also have the experience of exchanging with my classmates , And discuss with each other , Let's take our classmate relationship a step further , Students help each other , Discuss the problem together , Listening to different opinions is also of great help to my own curriculum design , So I have to learn from my classmates .

Although the final design is not very good , But the knowledge and experience learned in the production process , Let me think independently in my work in the future , Build confidence in your ability to work , I believe this will have a very important impact on my future study and work . This will be my greatest wealth in this course design , It will benefit me all my life .

Four 、 Result analysis of business modeling and simulation

4.1 Business model diagram

4.2 The running state and simulation results of simulation

4.2.1 Analysis of the running state of the output simulation run time ( With screenshots )

4.2.2 Analysis of output data after simulation operation ( Attached data sheet , Only statistics proportion , The fourth part is an in-depth analysis )

Flexsim Summary Report

Time: 10450.91131

Object Class idle processing blocked

Temporary storage area 4 Queue 0 0 0

dyeing wxx Processor 5008.417941 2512 764.744645

dyeing wxx Processor 4460.823606 2528 1745.149725

dyeing wxx Processor 6854.180531 2192 0

dyeing wxx Processor 3501.123611 2528 2623.736807

dyeing wxx Processor 3723.324264 2512 2089.570827

Conveyor belt wxx Conveyor 0 0 9109.553484

Conveyor belt wxx Conveyor 0 0 7962.935684

Conveyor belt wxx Conveyor 0 0 418.95069

Conveyor belt wxx Conveyor 0 0 10274.11442

Conveyor belt wxx Conveyor 0 0 9095.70144

assemble wxx Combiner 944.461846 420 0

Temporary storage area wxx Queue 0 0 0

shelves wxx Rack 0 0 0

Task allocator 16wxx Dispatcher 10450.91131 0

Forklift wxx Transporter 10180.18735 0 0

Worker wxx1 Operator 3846.605334 0 0

Worker wxx4 Operator 4687.193098 0 0

Worker 2wxx Operator 6205.957583 0 0

cutting wxx Processor 10135.91131 315 0

Temporary storage area wxx Queue 0 0 0

Weighing and metering wxx Processor 9820.911312 630 0

Temporary storage area wxx Queue 0 0 0

Plastic encapsulation wxx Processor 10225.91131 225 0

Temporary storage area wxx Queue 0 0 0

testing wxx Processor 10000.91131 450 0

Temporary storage area wxx Queue 0 0 0

Label wxx Processor 9550.911312 900 0

Worker 5wxx Operator 10144.86446 0 0

Worker 3wxx Operator 7958.581878 0 0

Conveyor belt wxx Conveyor 0 0 0

Stacker wxx ASRSvehicle 9771.025056 0 0

shelves wxx2 Rack 10450.91131 0 0

Conveyor belt wxx12 Conveyor 0 0 0

Tray generator wxx1 Source 0 0 8887.61808

unpacking wxx Separator 22.43028 1010 333.870868

operator 46689 Operator 698.971476 0 0

Temporary storage area wxx47 Queue 0 0 0

assemble wxx45 Combiner 943.826545 30 0

Generator 10768 Source 0 0 5409.089552

Conveyor belt wxx45 Conveyor 0 0 0

Stacker wxx45 ASRSvehicle 9971.480158 0 0

shelves wxx46 Rack 10450.91131 0 0

Conveyor belt 12114 Conveyor 0 0 0

Synthesizer 1wxx Combiner 44.456896 0 10406.45442

Paper jam generator wxx6 Source 0 0 10450.91131

Pallet storage area 27wxx Sink 0 0 0

Quality testing wxx Processor 9950.911312 500 0

Qualified product staging area 58wxx Queue 0 0 0

Temporary storage area 62wxx Queue 0 0 0

Synthesizer 63 Combiner 5.558577 150 0

Tray generator 64wxx Source 0 0 10260.71038

Conveyor belt 65wxx Conveyor 0 0 0

Customer wxx Sink 0 0 0

Packing and packing 285wxx Processor 10003.2357 447.675617 0

4.2.3 According to the output data , Compare the processing and idle time of each entity , Make a pie chart to observe the working state of each process

① The first synthesizer :

② Unpacker :

③ Dyeing apparatus :

④ Quality inspector :

⑤ The second synthesizer :

4.2.4 Output result analysis

For the above simulation , The optimization process of the inspection system is to cut the personnel , It turns out that the people who moved the goods to the dyeing machine were 4 personal , use 3 One person can complete , So cut out a worker , make the best of 3 workers . If this factory wants to process more products , It is necessary to improve the working efficiency of the assembler . It can be concluded from the analysis that some temporary storage areas are congested , If the tester is not modified , More and more products to be processed will be accumulated in the model , The capacity of the staging area will continue to increase until it can no longer be added . To solve this problem , We must not add an assembler , Because the assembler is one of the bottlenecks of the whole system .

In addition, you can find out that the workload of some equipment is too low , Idle for a long time . The discovery of the above problems can play a good guiding role in the optimization of the whole system .

边栏推荐

- [JS] intercepting string

- 使用cell ranger进行单细胞转录组定量分析

- ADEX governance voting: pledge reward halved

- Introduction to exceptions

- Yield Guild Games 与 Discord 上的第一款 MMORPG ——Tatsumeeko 达成合作

- Debezium error report processing series 18: solve the problem that the table structure cannot be obtained

- [flutter special topic] 72 graphic minimalist custom running lamp acemarquee yyds dry goods inventory

- Product manager proficient in Axure tools

- Summary of each layer of the five layer reference model

- Introduction to missing data filling dataset (1) -- Introduction to multiple datasets and dataset preprocessing (beast, covertype, credit, EEG, iris and letter)

猜你喜欢

随机推荐

156 rust and Solana environment configuration

缺失数据填补数据集介绍(1)——多种数据集介绍及数据集预处理(breast、covertype、credit、eeg、iris和letter)

Debezium报错处理系列之十八:解决无法获取表结构问题

June translation of CET-6 in 2022

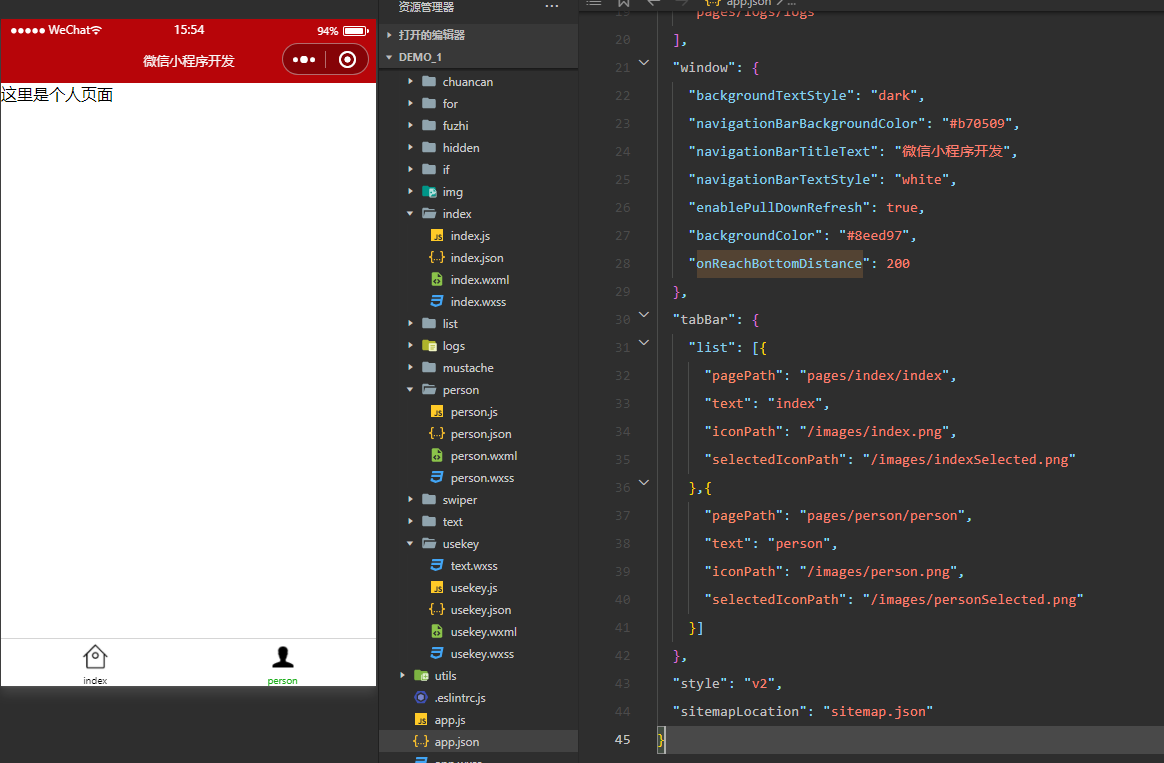

Small program [phase I]

數據分析之:不同行業的常見指標

【FPGA小波变换】基于FPGA的图像9/7整数小波变换verilog实现

2022 operation and maintenance failure case experience

Pyg tutorial (4): Customizing datasets

MySQL MHA

微信小程序_3,WXML模板语法

June training (day 21) - heap (priority queue)

Modbus poll v9.9.2 build 1690 MODBUS test tool single file version

六月集训(第21天) —— 堆(优先队列)

Do you know all the extension racks of ThinkPHP?

Kubernetes cluster setup detailed tutorial

Weather forecast applet source code / weather wechat applet source code

【正则表达式每日一技】逃逸正则表达式中具有特殊含义的字符

The origin of Butler Volmer formula

Pyg tutorial (2): graph data