当前位置:网站首页>[cloud based co creation] intelligent supply chain plan: improve the decision-making level of the supply chain and help enterprises reduce costs and increase efficiency

[cloud based co creation] intelligent supply chain plan: improve the decision-making level of the supply chain and help enterprises reduce costs and increase efficiency

2022-06-23 14:59:00 【Hua Weiyun】

Abstract : This article mainly starts with the brief introduction of youhualin , Further to intelligence SCP+ APS Basic knowledge , Finally, its solution and specific application scenarios are described , To improve the decision-making level of the supply chain , The effect of helping enterprises reduce costs and increase efficiency .

One . Introduction to you Hualin

Youhualin was founded in 2016 year , Formerly known as Decision Making TechnologyL.L.C., It is an operation research company 、 Artificial intelligence 、 Big data technology is the core driver , Technology companies that provide a package of intelligent decision-making overall solutions such as data strategy consulting and software implementation . The company is headquartered in Shanghai , In Beijing, 、 Shenzhen 、 Chengdu has branches , Near scale 200 people . You Hualin has been committed to promoting intelligent decision-making technology based on massive data (Data Driven Decision) Promotion in China , Help Chinese enterprises realize the strategic transformation from automation to digital intelligence , Designed to help enterprises improve operational efficiency , Enhance international competitiveness .

The development course of Youhua forest

2016 year

Youhualin was established

It breaks the monopoly of foreign technology related to intelligent decision-making , Officially enter the Chinese market

2017 year

Since the research Deloris Algorithm platform , Solve large-scale mixed integer programming , Flexible business rule constraint matching and management , Quick solution .

a “ China has the most investment value 50 strong ” complete A Round of funding

2018 year

Build an intelligent supply chain plan SCP +APS The product is the first in China to use operational research + AI Algorithm based intelligent supply chain planning products .

2019 year

intelligence SCP + APS Recognized by leading enterprises in the industry , signing BOSCH、 haier 、 saic 、 Leading enterprises in Taiji and other industries .

Deep ploughing auto parts 、 Consumer electronics industry , Set up the business 、 product 、 Service team , Form perfect solutions and service capabilities .

2020 year

The intelligent supply chain plan is completed 3.0 Version release , formation ” product + Industry solutions " Provide professional services for industry customers , And guarantee 100% Delivery rate .

2021 year

Sign a contract with Ningde new energy 、 State - precision 、 oakes 、 Daikin air-conditioning 、 COFCO Coca Cola 、 Unilever and other leading enterprises .

2022 year - future

Sign a contract with Ningde times , Further deepen the new energy market and tree root interconnection 、 Baidu 、 Ali signed a long-term strategic cooperation agreement , Deepen the reform of China's manufacturing industry

I have learned about the brief introduction and development of Youhua forest , Next, let's take a look at some problems encountered in the current supply chain plan .

Two . The difficulty of supply chain planning

The difficulty of current supply chain planning is mainly reflected in the delivery time , capacity , Three aspects of inventory , Reflected in the data , plan , System and response .

The dilemma of supply chain planning

Delivery date : The production cycle is too long , Too few products are delivered per unit time .

capacity : Poor enforceability forces workers to work overtime , Uneven production scheduling leads to uneven working hours .

stock : Supply does not match demand , raw material 、 Partially Prepared Products 、 The finished products are sluggish .

data

Data sources are scattered : Scattered in different departments / System ; Maintain online / Offline

Poor reliability : materiel BOM, Process data , Device data , Untimely capacity data , unreliable

plan

The manual table plan is broken down layer by layer

Capacity rules are complex , It is difficult to calculate the plan

Lack of material integrity inspection

The delivery date of the order cannot be promised

All decisions depend entirely on human experience and cannot quantify the quality of the plan

System

department / The co-ordination between plants is poor

The lack of a unified information management platform is difficult to promote the comprehensive digital transformation of enterprises

The group is responsible for each order , Lack of visibility into the operation of each manufacturing unit

Respond to

Process change cannot adjust the plan in time

In the face of an emergency , Limited response time , The degree of impact cannot be considered comprehensively

The essence of supply chain planning is supply-demand balance

Of course Common features of production planning work , It is applicable to enterprises in all industries :

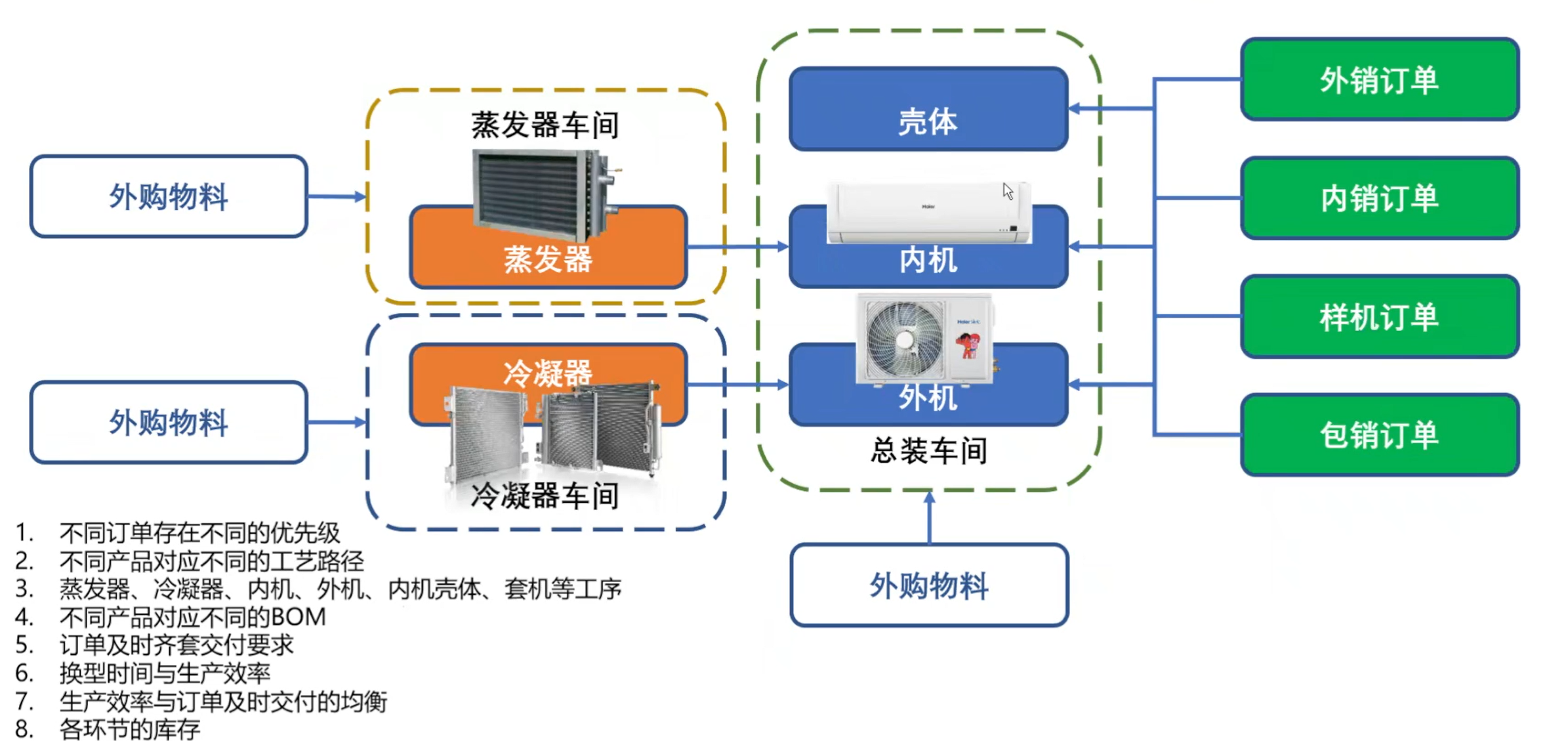

Different orders 、 Different products have different priorities

Different products correspond to different process paths

Different processes and equipment have different processing requirements

Different products correspond to different BOM

Timely order delivery requirements

Production efficiency of each link

Inventory of each link

Energy consumption and emission of various equipment

Finish talking about the difficulties encountered , Next is intelligence SCP+ APS overview , And the corresponding youhualin solution and youhualin application scenarios .

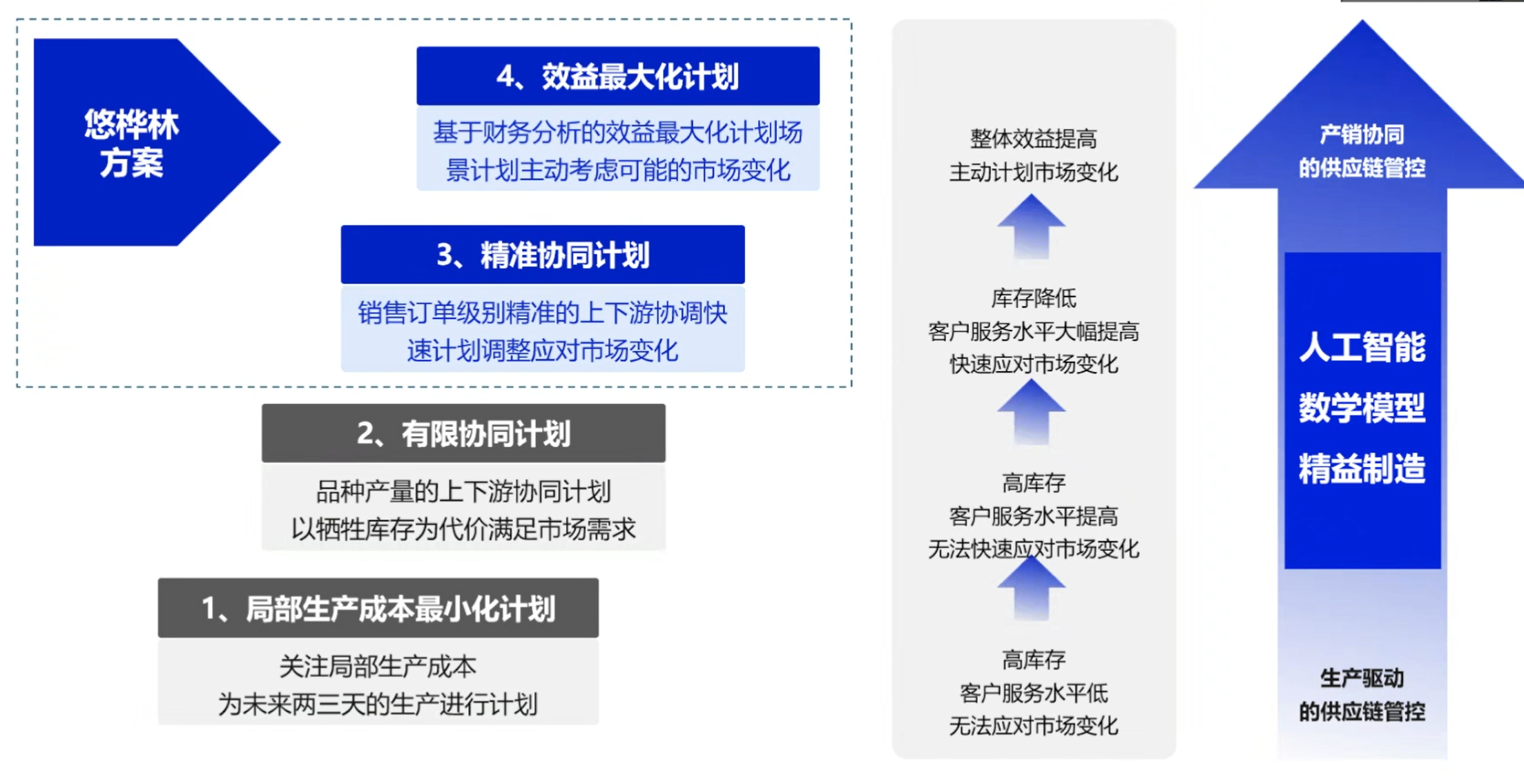

3、 ... and . The evolution route of intelligent supply chain

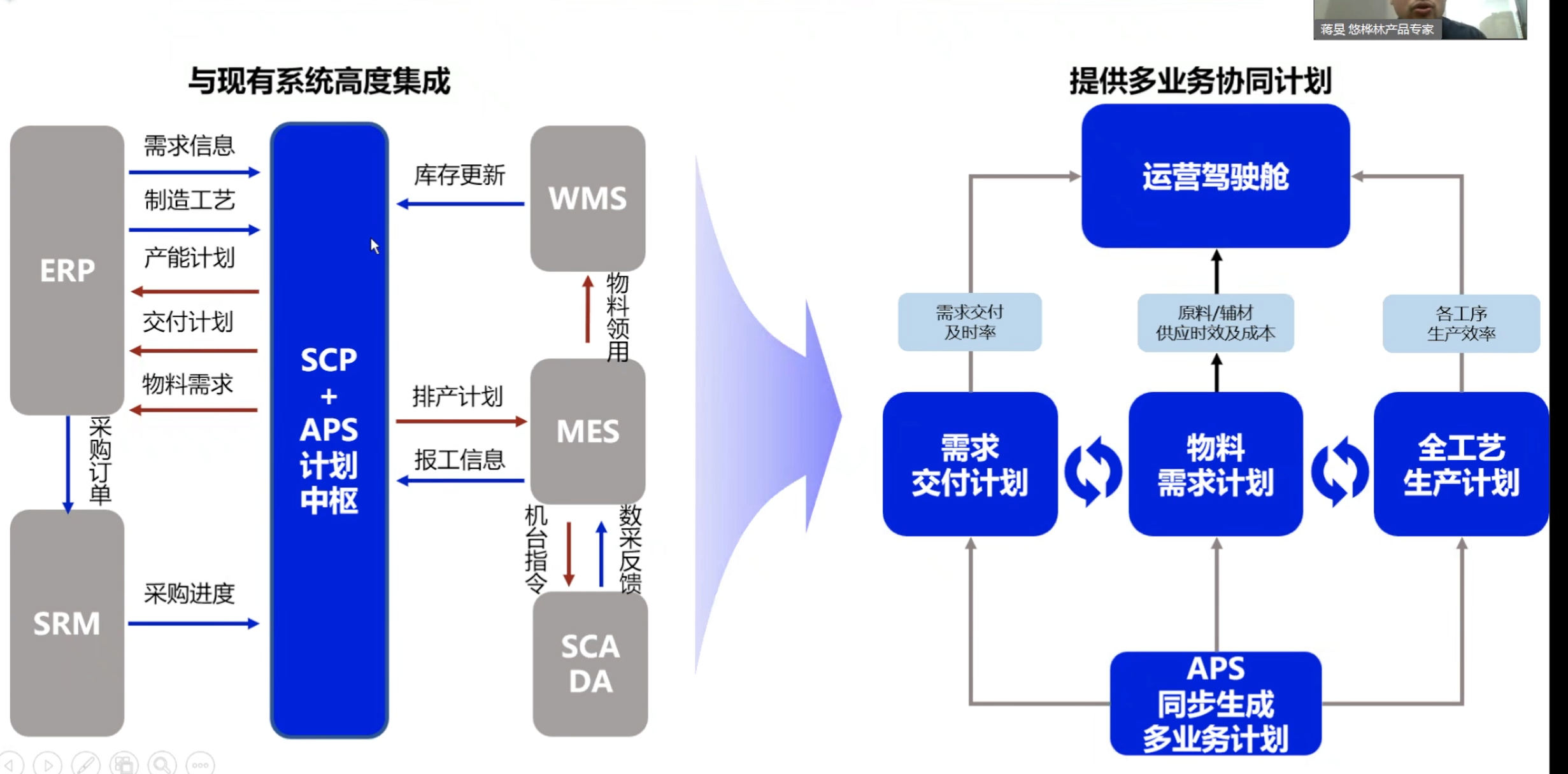

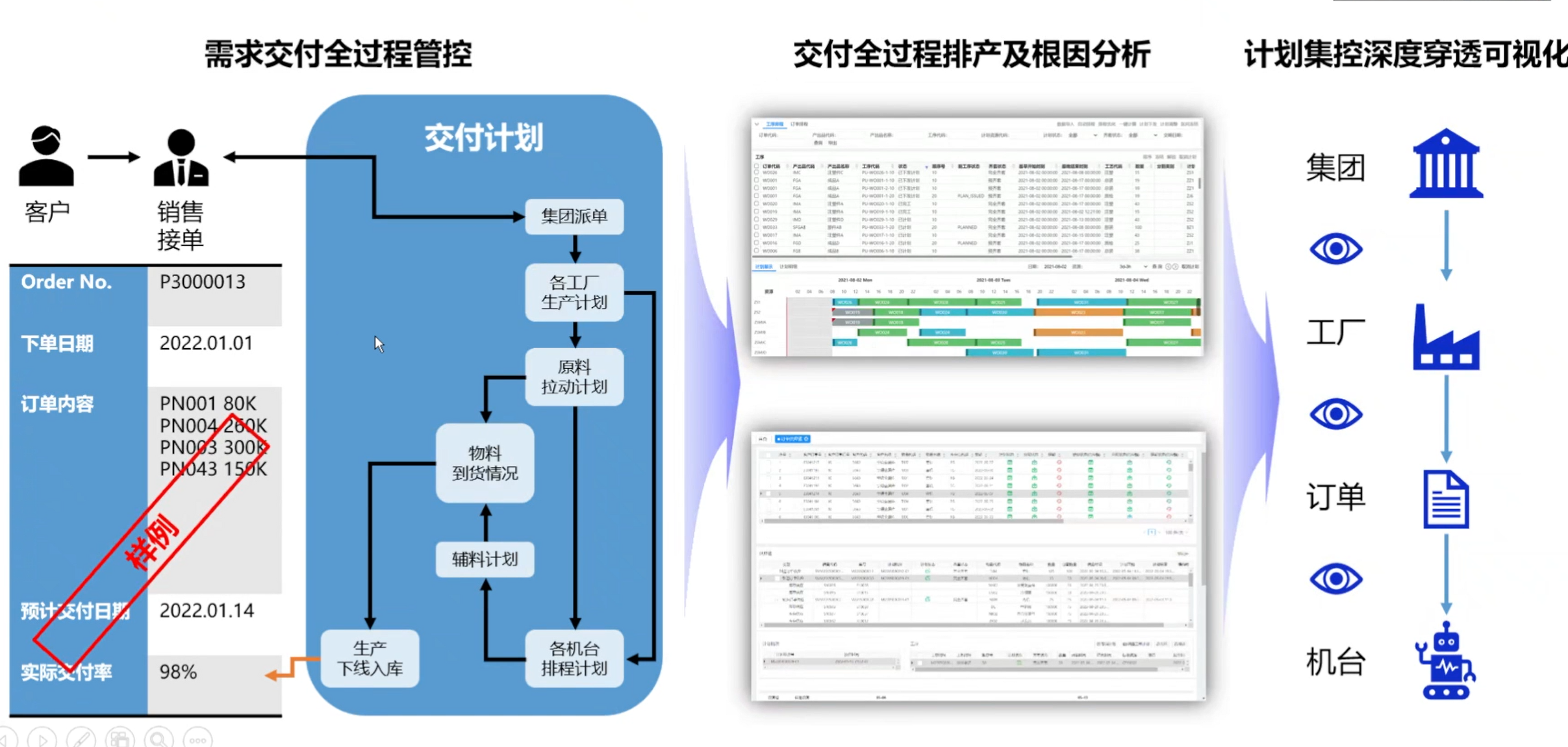

Multi business collaboration plan

The delivery process is visible

Through visualization , The whole process can be controlled .

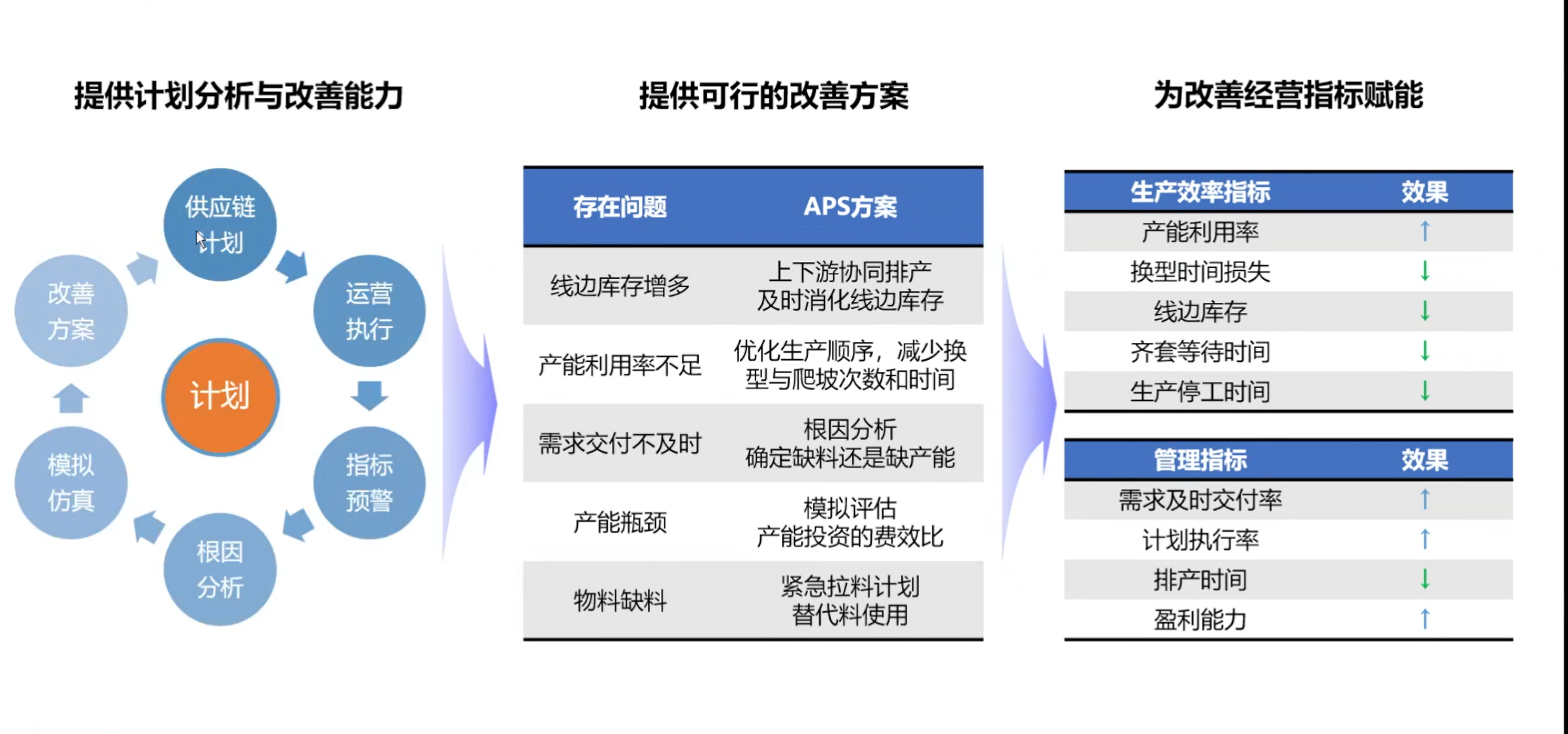

Empowering efficiency improvements

Capability combination of youhualin intelligent supply chain planning system

SCP+APS Relationship between modules of the product

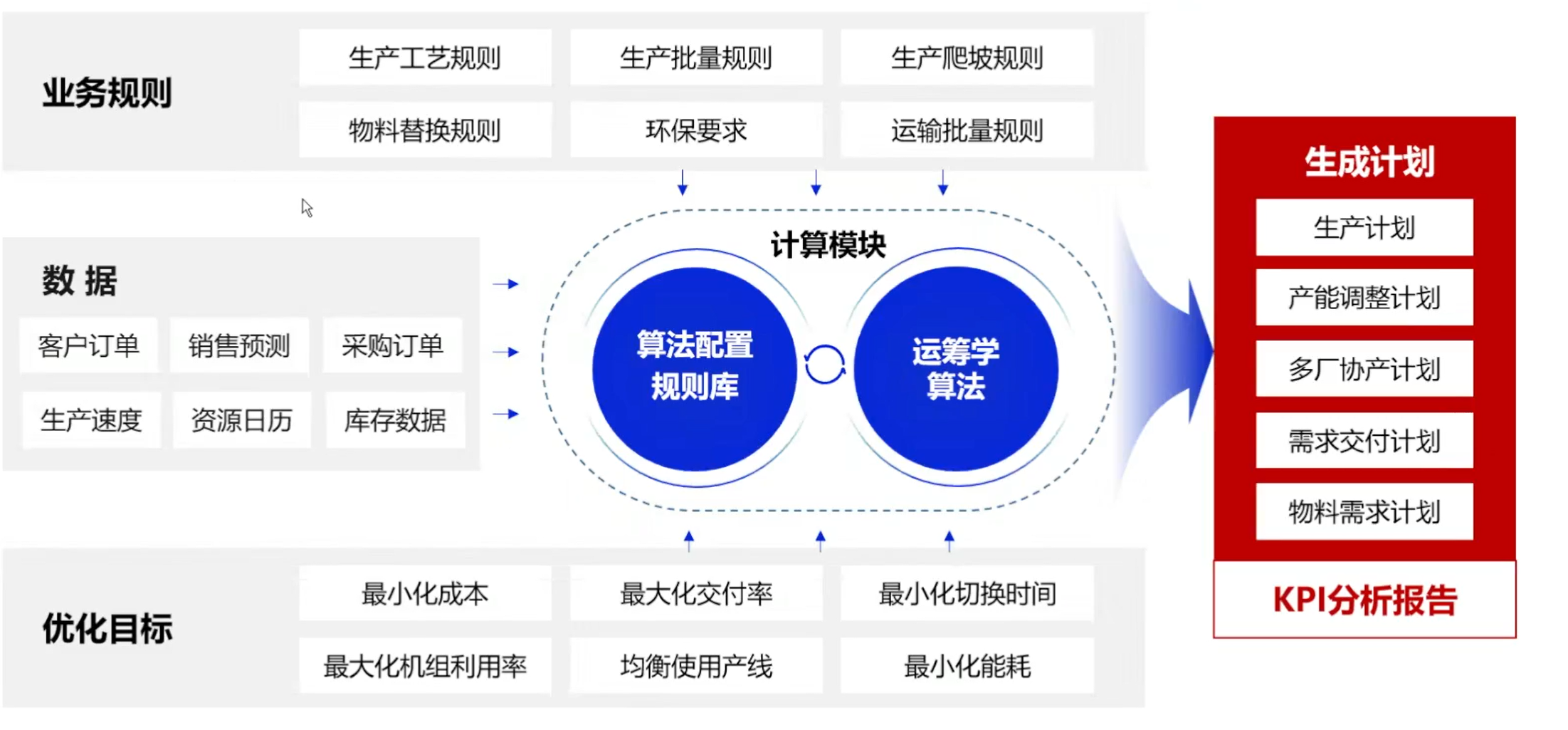

The technical framework with operations research as the core

One model generates all the rules 、 Data and optimization objectives

Business rules ( Can be described quantitatively ): Production process rules 、 Material replacement rules 、 Production lot rules 、 Environmental requirements 、 Production ramp rules 、 Transportation lot rules .

data ( The system automatically completes docking ): Customer order 、 Sales forecast 、 Purchase order 、 Production speed 、 Resource Calendar 、 Inventory data .

Optimization objectives : Minimize costs 、 Minimize energy consumption 、 Maximize delivery 、 Minimize switching time 、 Maximize unit utilization .

All business rules 、 data 、 Optimization objectives , stay A series of plans are generated at one time in a model : Production plan 、 Capacity adjustment plan 、 Multi plant co production plan 、 Requirements delivery plan 、 Material requirements plan , Are equipped with corresponding KPI Analysis report , Used to analyze the production status .

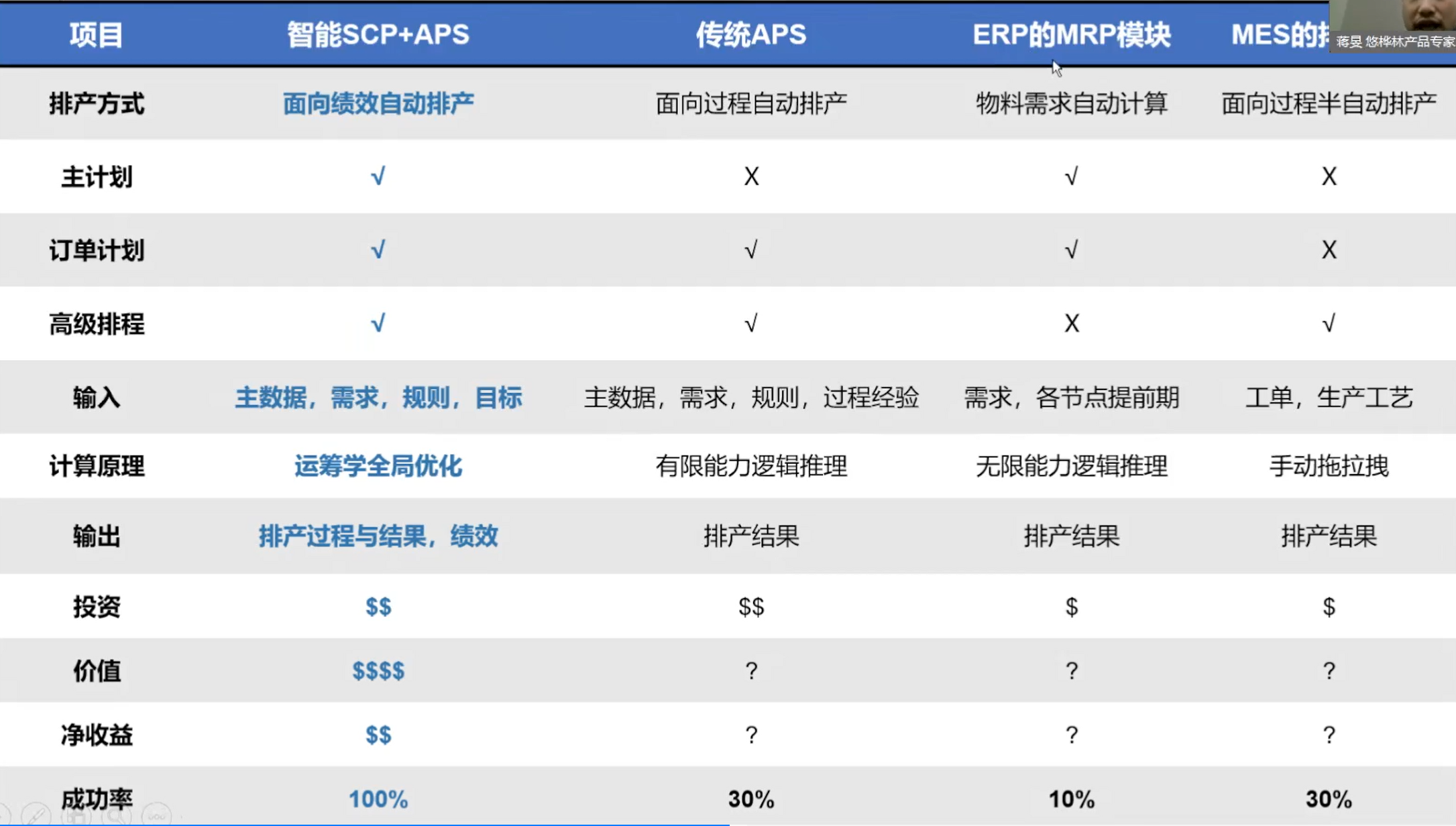

Four . You Hualin SCP+ APS Introduction to

You Hualin SCP+ APS location

You Hualin SCP+APS Product advantage

SCP+ APS Implementation value

5、 ... and . You Hualin application scenario

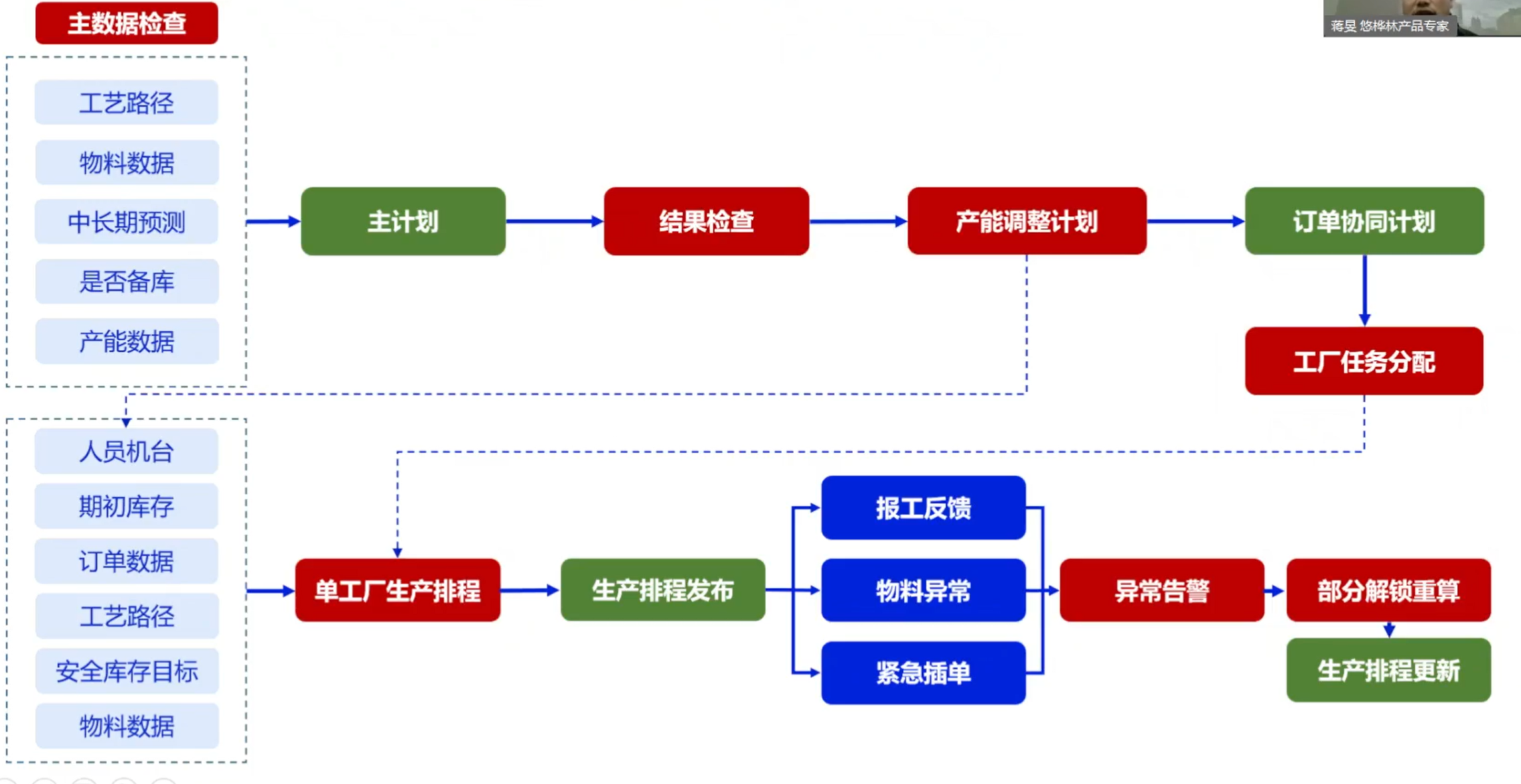

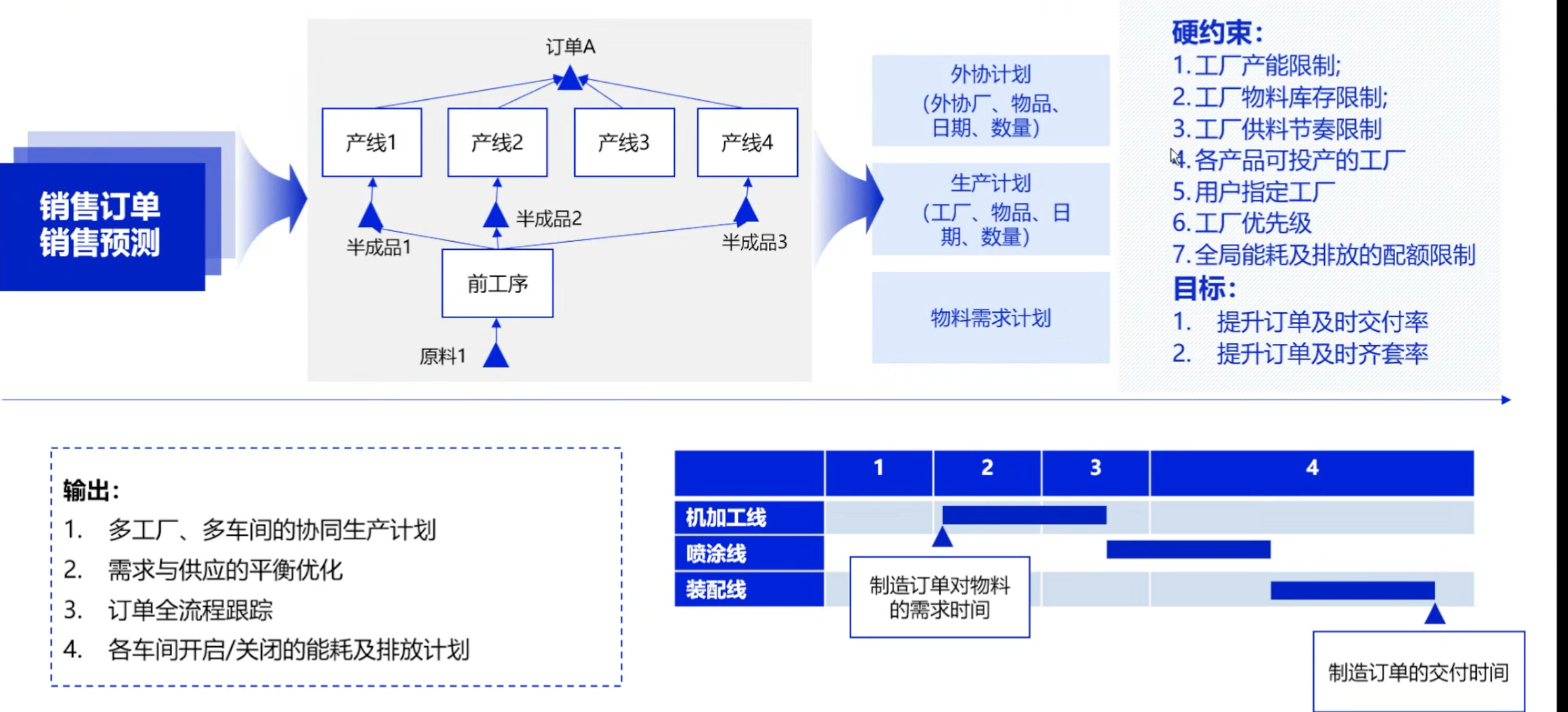

New production scheduling process

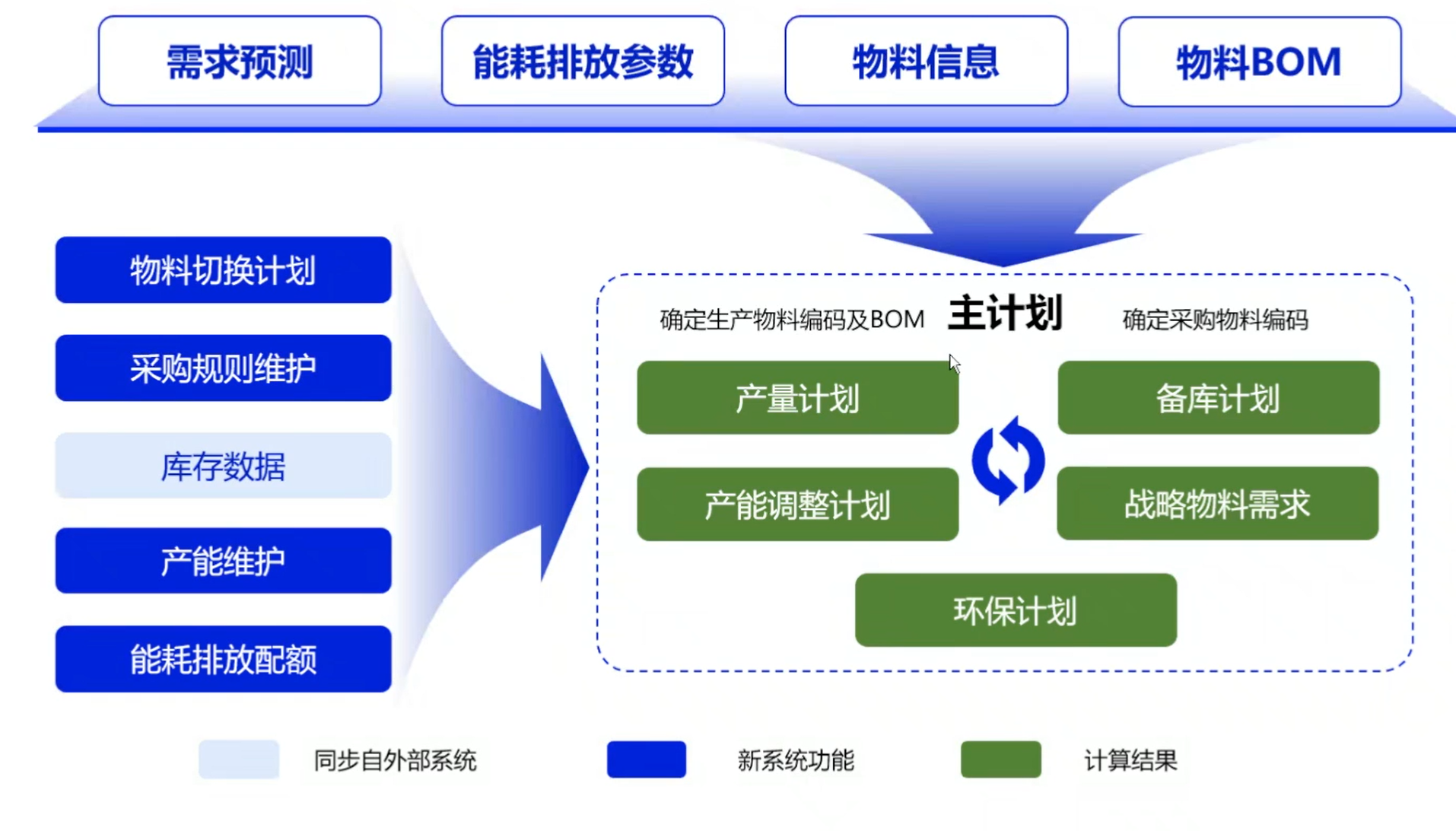

Master plan MP: Generate multiple key plans synchronously

Master plan MP: Capacity adjustment and active standby

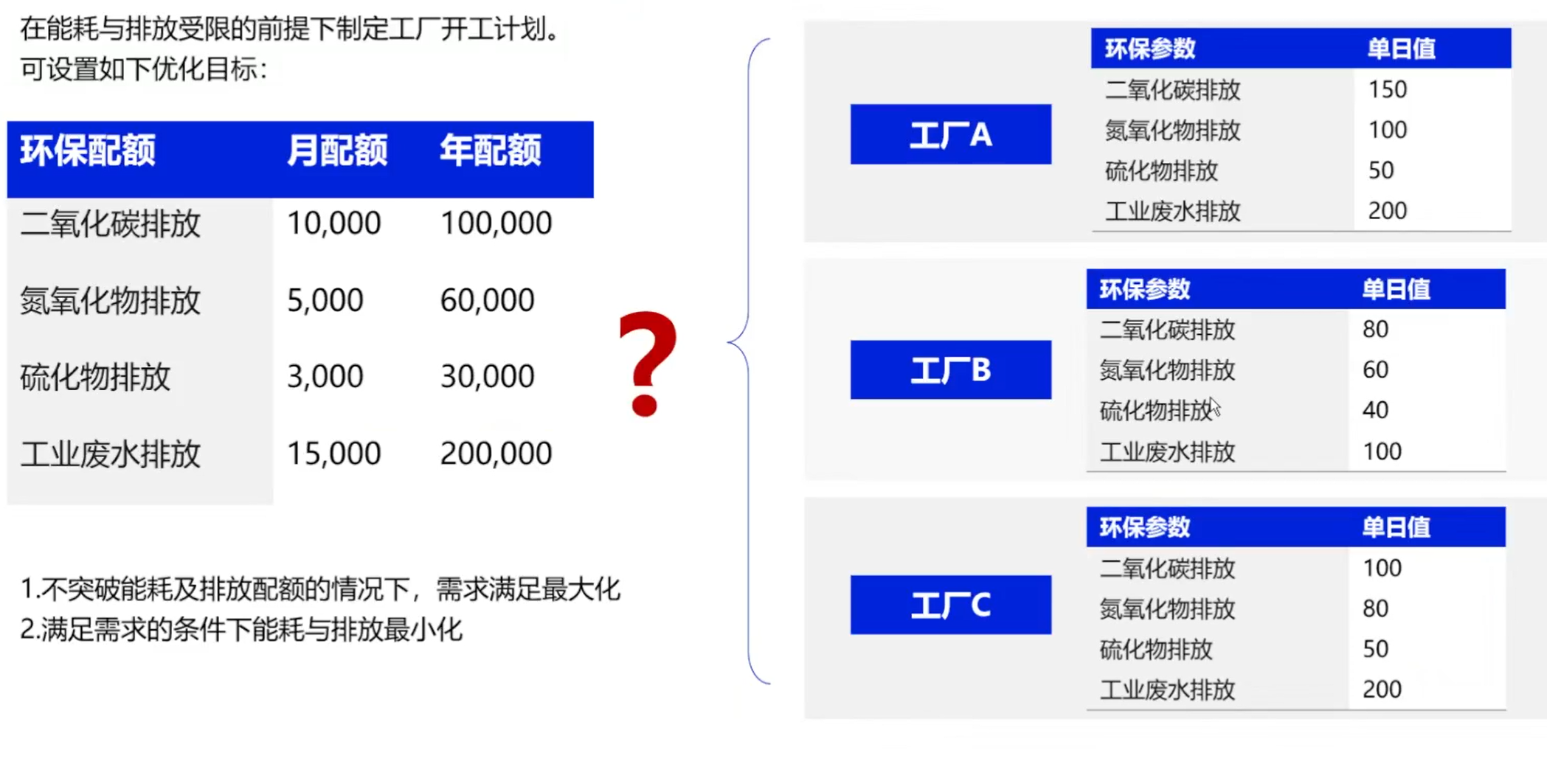

Master plan MP: Commencement plan under environmental protection quota

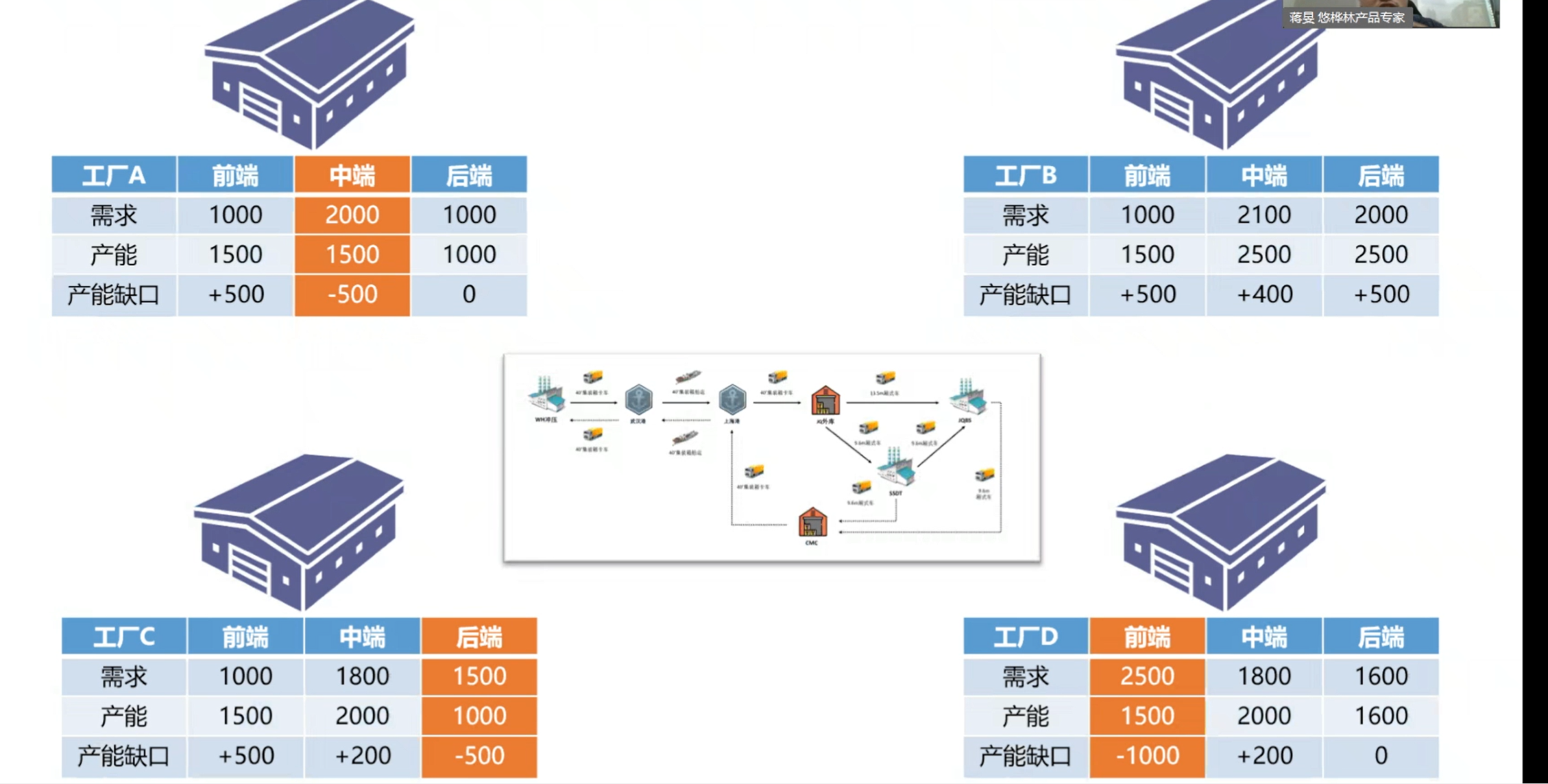

Master plan , Multi factory allocation

Order collaboration planning OCP: Multi plant demand allocation and order progress tracking

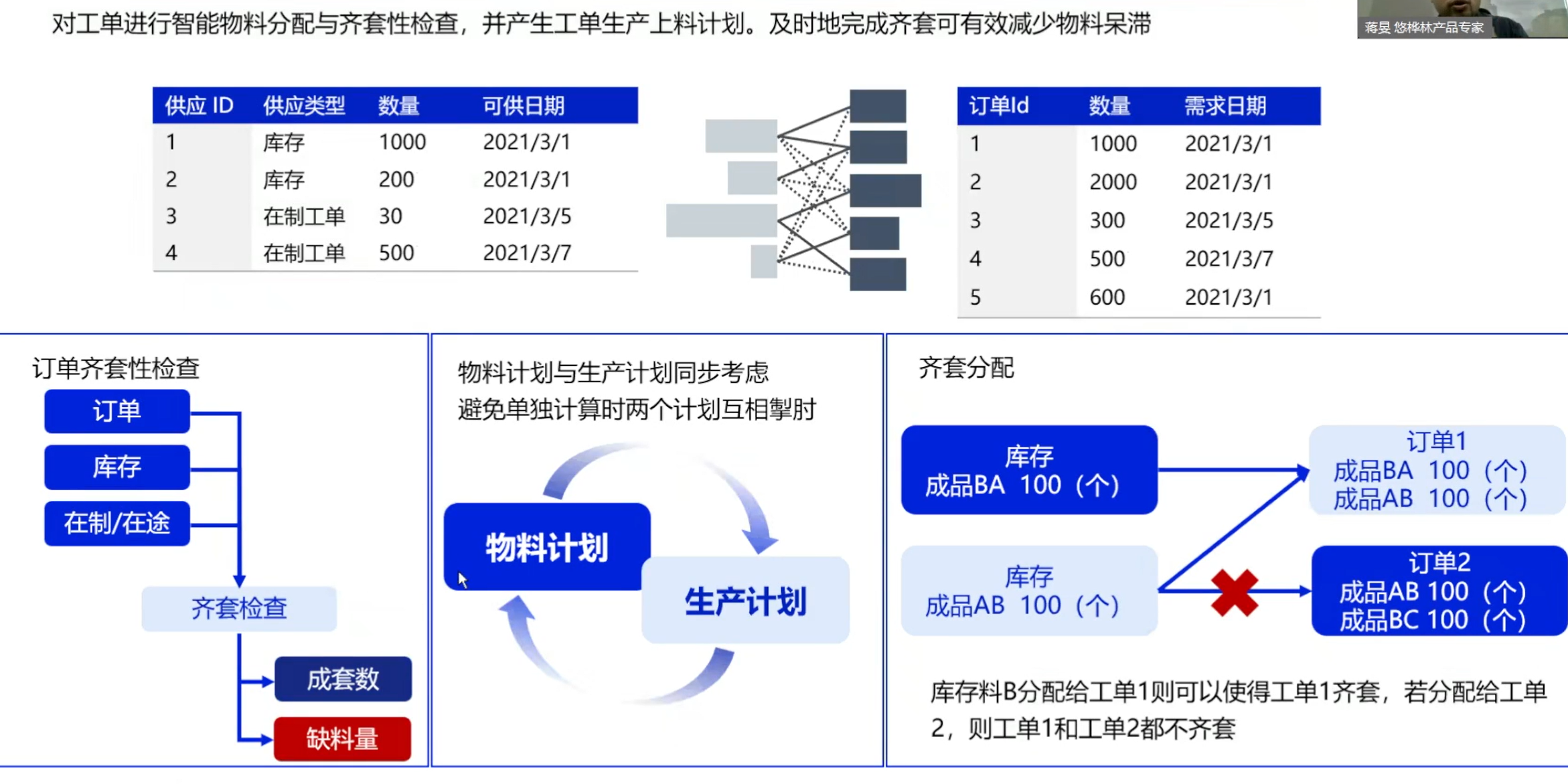

Order collaboration planning OCP: Material allocation and completeness check

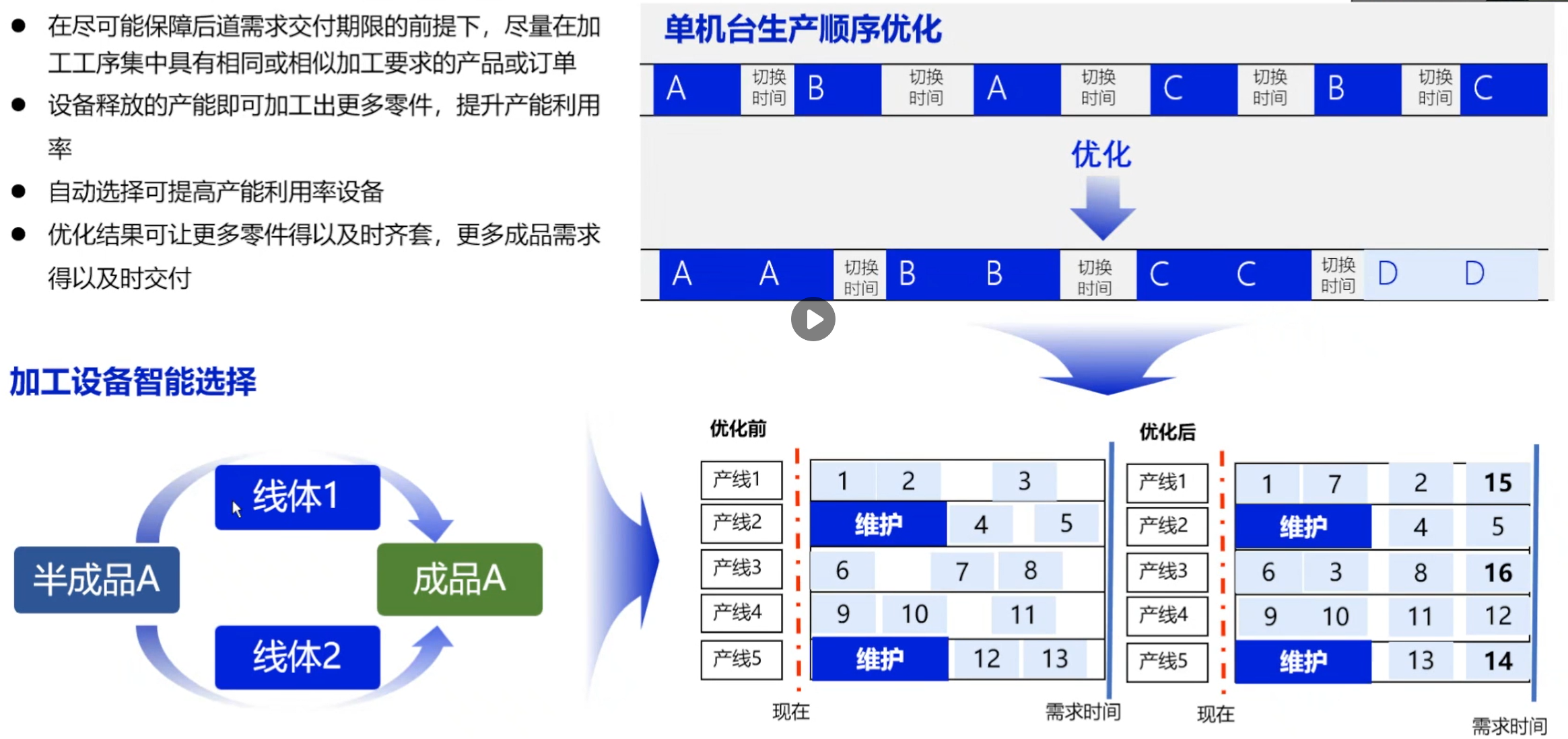

Advanced scheduling AMS: Optimize production sequence to release capacity

On the premise of ensuring the delivery deadline of subsequent requirements as much as possible , Try to set products or orders with the same or similar processing requirements in the processing process

The capacity released by the equipment can produce more parts , Improve capacity utilization

Automatic selection of equipment to improve capacity utilization

The optimization results can make more parts complete in time , More finished products need to be delivered on time

Advanced scheduling AMS: Intelligent disassembly of process flow

AMS Able to split work orders , To achieve flexible production , Meet the production line 、 Number of sites, etc , Shorten manufacturing lead time .

Split by batch

A work order can be split into multiple production batches , Each production batch can be transferred independently

Split by process

A work order can be split on each operation / Merge , To meet the capacity and process constraints of different production equipment

Advanced scheduling AMS: Overall optimization of multiple processes

According to the time required for the next process , Optimize the production scheduling sequence of the previous operation , Complete sets of parts required for timely completion of each process

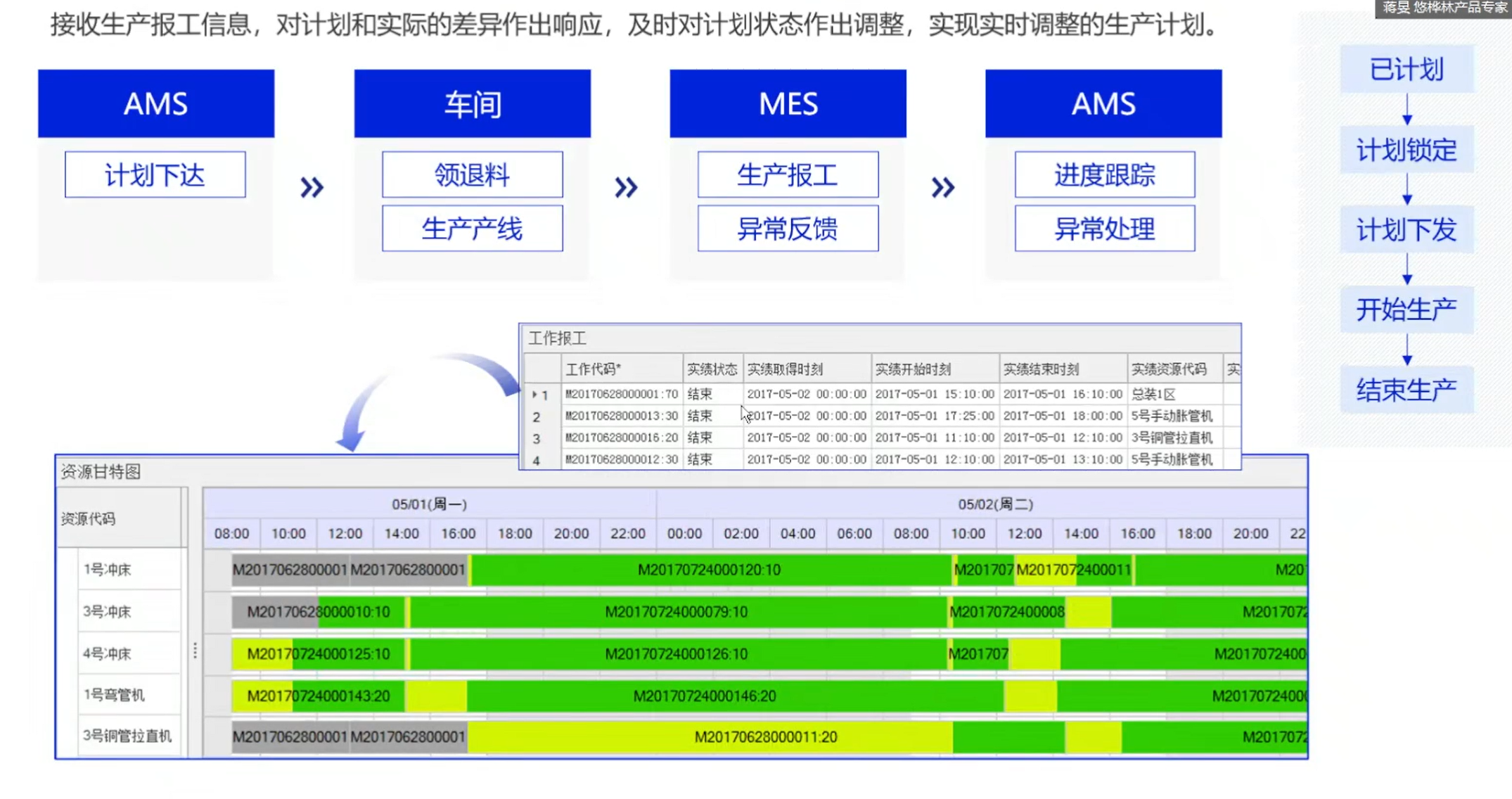

Advanced scheduling AMS: Production execution monitoring and status tracking

Receive production work report information , Respond to planned and actual variances , Adjust the plan status in time , Realize real-time adjustment of production plan .

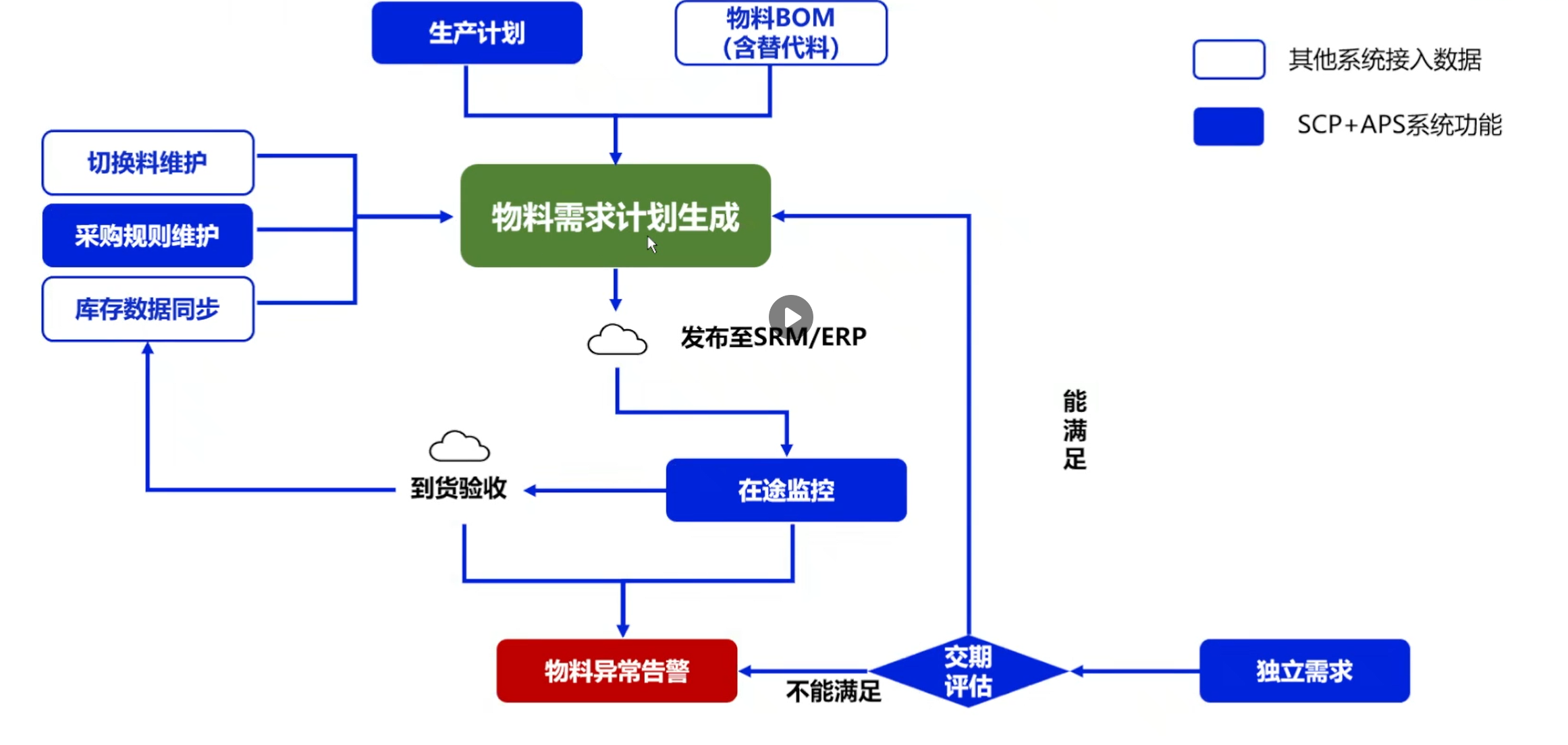

MRP Intelligent purchasing plan

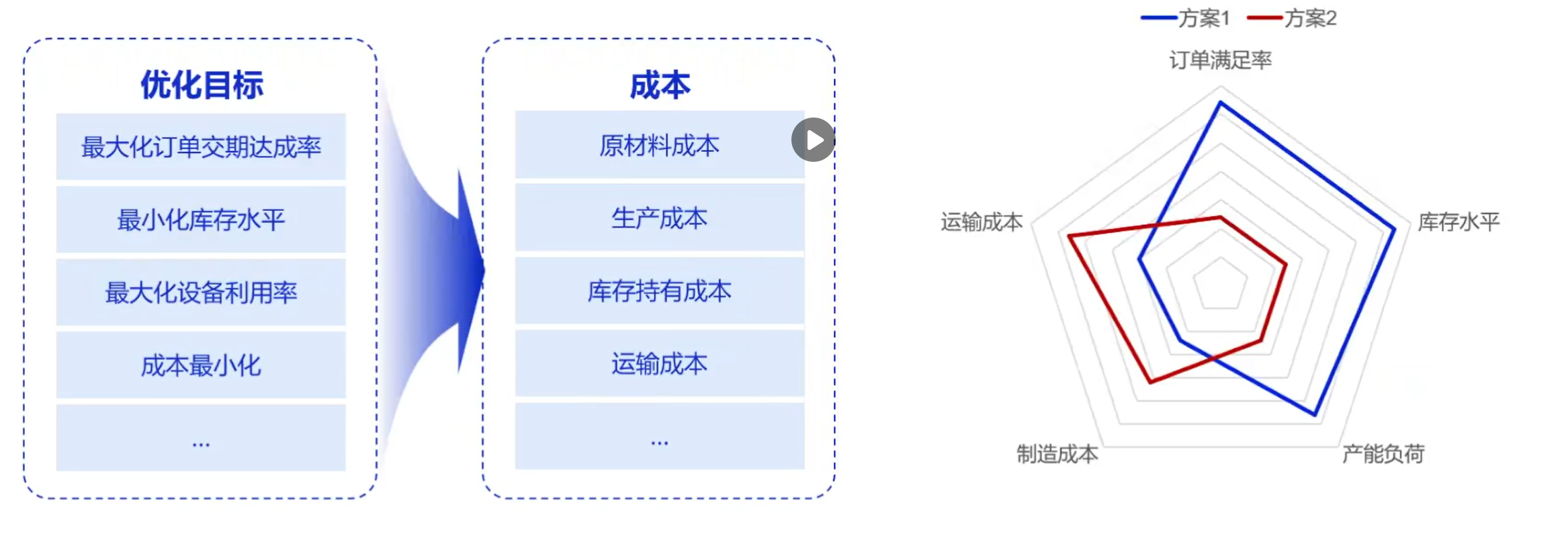

Simulation analysis and multi version comparison ( Plans at all levels support )

Users can use the same data , Create multiple scenarios (Scenario) , And set different planning rules , Compare the output results of different planning rules . It can also be set Reserve capacity 、 supply 、 Demand, etc , Understand the impact of these adjustments on overall optimization performance . A very important application of simulation analysis is , In order to solve the multi-objective optimization problem . Optimization goals are often conflicting . For example, in order to guarantee the delivery time of the order , It may be necessary to choose a factory with higher cost to produce, etc .

Production planning

Scheduling optimization

Demand based planning - Key to generate output plan of each cycle

Prerequisite : 100% deliver

Optimization objectives : The cost of standby storage is the lowest / Maximize output

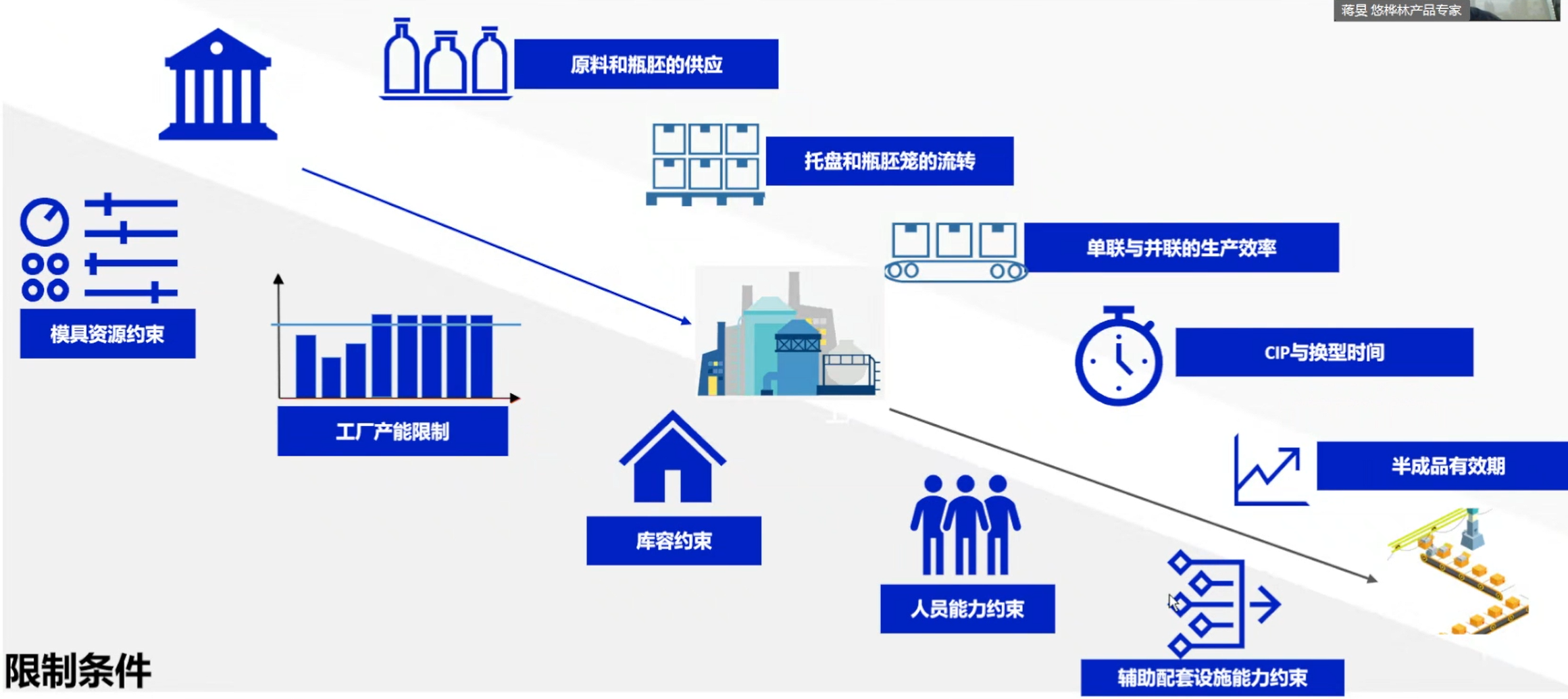

constraint condition

The planned output of each product in the current week shall not exceed its total demand ( customer demand + Reserve capacity )

The man hours consumed by each production line in the current week shall not exceed its available man hours

Key benefits

Quantitative decision-making can significantly reduce the cost of standby storage

One key production scheduling eliminates manual operation errors

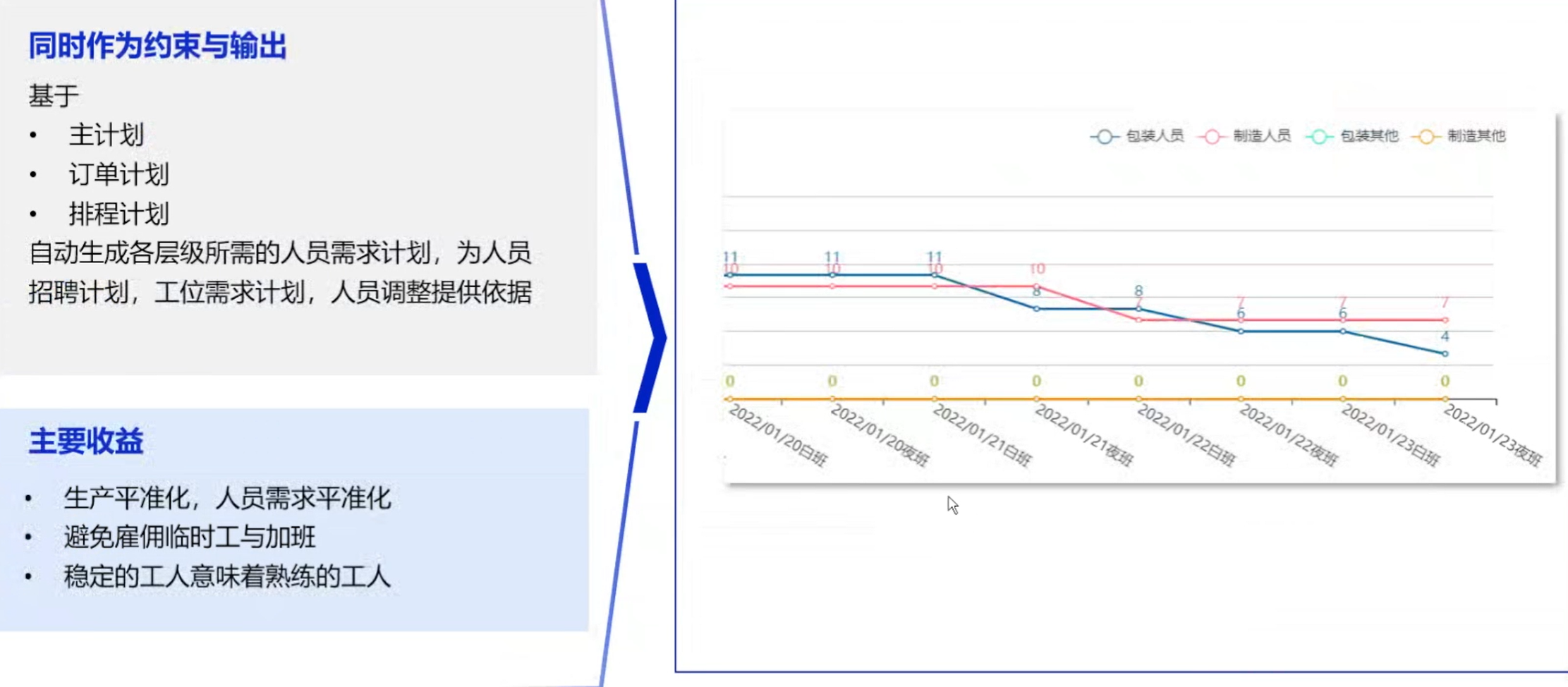

Personnel requirements plan

Inventory plan Inventory optimization Demand based planning 、 Customer order 、 Safety stock demand and production The production preparation warehouse plan generates the corresponding weekly and daily inventory plans With master plan and / Or the scheduling plan is generated synchronously Prerequisite : Not exceeding the storage capacity Optimization objectives : Minimum inventory Key benefits The medium - and long-term plan will significantly reduce the level of reserve Short term plan balance multi-objective optimization of inventory cost

Food processing industry

Issues considered in the master plan

factory :

Whether the long-term capacity meets the overall demand

Maximize demand satisfaction 、 Minimize costs, etc

Optimize the climbing rate 、 Material and personnel constraints

Shared resource constraints in the same factory and across factories

Warehouse :

Optimize transportation capacity constraints

Flexible pre built inventory settings

Safety stock demand and flexible inventory strategy

Customer :

Flexible allocation of supply schemes in priority order

Horizontal cross region transfer of warehouse , Meet temporary demand adjustment

Arrange the best delivery warehouse in different regions in the light and peak seasons

The core objectives of the master production plan

1. Maximize demand fulfillment

2. Supply chain cost optimization

The validity period of semi-finished food is short , How to manage ?

The rule algorithm of traditional planning software is to set indirect rules .

for example , When the production line is shut down for a long time and then restarted , Experience rules need to be set : The beverage scheduled for production on the first day shall not be arranged to produce semi-finished products, and the validity period is 24 Hours of product .

And if you use mathematical programming , Then you only need to enter the semi-finished product validity , There is no need to set indirect rules , During calculation, it can automatically determine whether the semi-finished products can be consumed within the validity period .

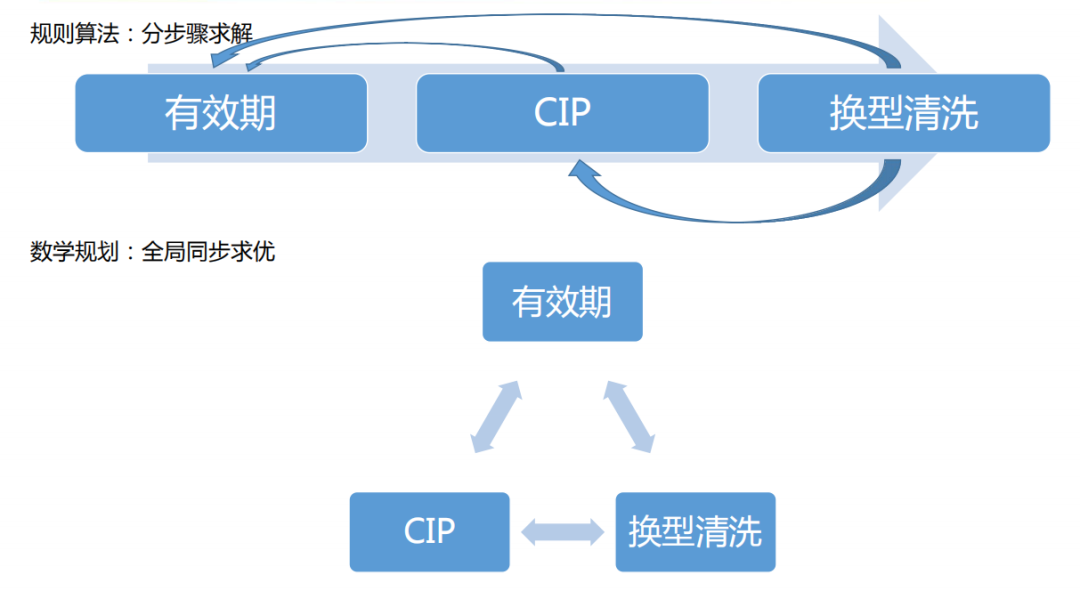

CIP And flexible type change cleaning

CIP It is a cleaning rule that defines that you must stop to force cleaning after a period of continuous production and processing .

The flexible type change cleaning is to optimize the production sequence of a single machine , Arrange production according to the order delivery order . In this way, the same product can be merged , Not only does it not affect the order delivery timeliness , It can also save cleaning time , The time saved can be used for the production of other products .

Flexible cleaning time exceeds or does not meet CIP What about the maximum duration of ?

Traditional rule algorithm : Solve in steps

Whether the product meets the product validity period , Is it satisfactory? CIP The requirements of , Produce in limited time and make the best use of production capacity , Whether type change cleaning is required to meet the timely delivery of different orders .

You Hualin mathematical programming : Global synchronization optimization

The period of validity 、CIP、 Model change cleaning is calculated in the same model , The final result satisfies all the problems considered .

Multi factory transfer plan

Allocation optimization

Generate inter factory transfer plan based on production gap

The transportation time limit generates an in transit inventory plan

Both master plan and daily plan support synchronous generation of multiple

Factory allocation plan

Key benefits

Automatically generate transfer plans based on production scheduling results and transportation time limit

Balance the fluctuation of local demand through the capacity of multiple factories nationwide

Reduce the standby database requirements , Increase delivery capacity

Order collaboration planning OCP: Household appliances

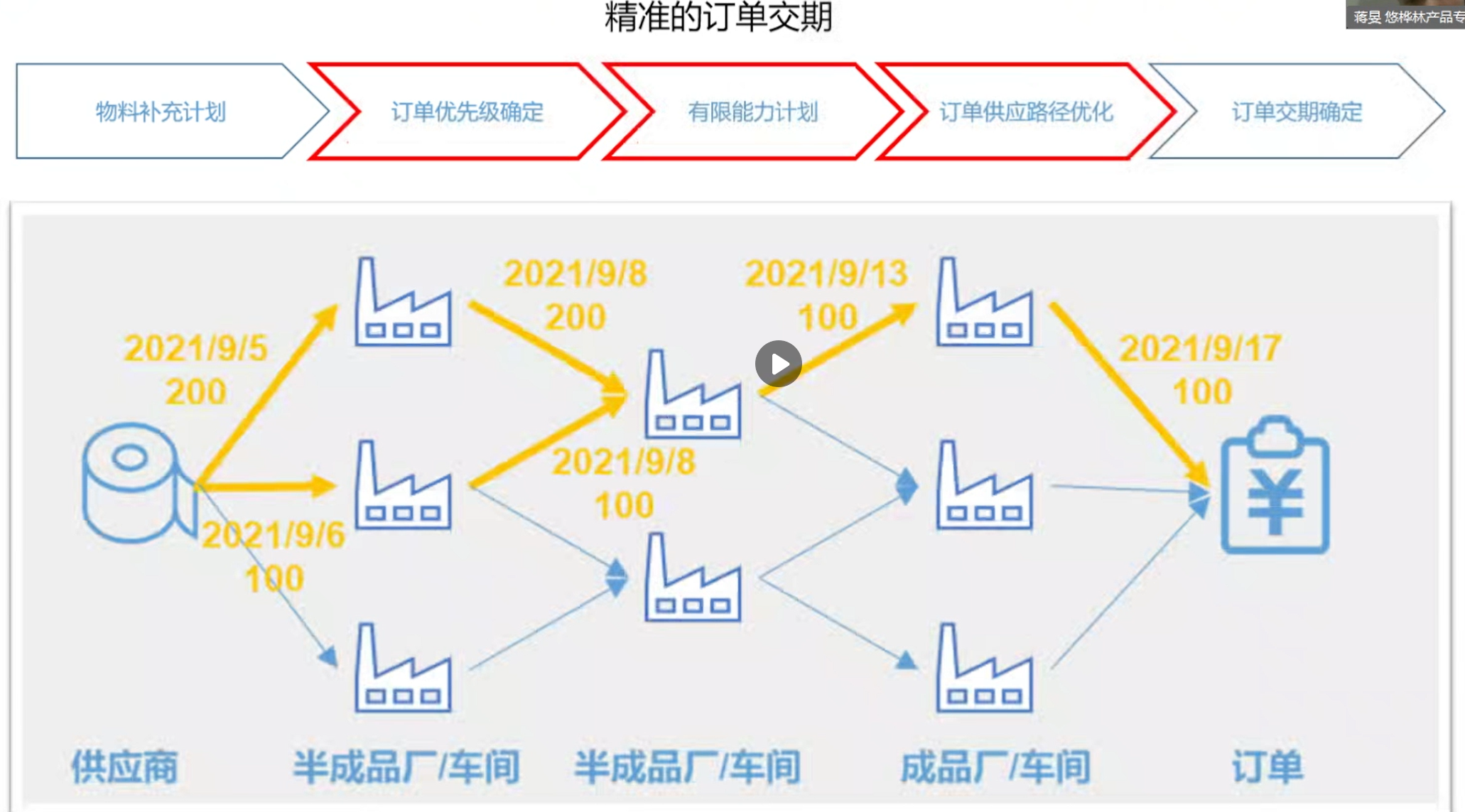

Order collaboration planning OCP: Precise order delivery based on limited capacity

Order delivery plan

Scheduling optimization

Generate an order allocation plan with one click based on the demand plan

Prerequisite : Orders are allocated according to the capacity of each factory

Optimization objectives : Lead time / Cost minimization

The process is visible

Order delivery commitment is automatically generated

Distribution plants are traceable

Whether the schedule meets the delivery requirements , Whether the order is delayed :

Key benefits

Shorten the lead time

Lower delivery costs

The delivery process is transparent

Advanced scheduling AMS: Food processing

The core business objectives of the daily production scheduling plan

Maximize demand fulfillment

Maximize total production

Maximize productivity

summary

This article mainly starts with the introduction of youhualin , And then understand his development process , Then I learned about the main problems encountered in the current supply chain , And be familiar with the evolution route of intelligent supply chain , Finally, its typical application scenarios are described , To improve the decision-making level of the supply chain , The effect of helping enterprises reduce costs and increase efficiency .

This article participates in Huawei cloud community 【 Content co creation 】 Activity number 17 period .

https://bbs.huaweicloud.com/blogs/358780

Task 24

边栏推荐

- ACM Player Illustration leetcode remove element

- mysql主从只同步部分库或表的思路与方法

- Idea view View the class file idea Class folder

- An idea plug-in for automatically generating unit tests

- MATLAB|时序数据中的稀疏辅助信号去噪和模式识别

- MySQL高级语句二

- 【云驻共创】智能供应链计划:提升供应链决策水平,帮助企业运营降本增效

- How can genetic testing help patients fight disease?

- JSR303数据校验

- SQL injection vulnerability (principle)

猜你喜欢

2021-05-22

图解OneFlow的学习率调整策略

As a software testing practitioner, do you understand your development direction?

JSR303数据校验

Simple tutorial of live streaming with OBS

一款自动生成单元测试的 IDEA 插件

【DataHub】LinkedIn DataHub学习笔记

港股今年最大IPO来了,660亿身家,坐在矿山上的“大王”

How to solve the problem that iterative semi supervised training is difficult to implement in ASR training? RTC dev Meetup

How to use note taking software flowus and note for interval repetition? Based on formula template

随机推荐

[datahub] LinkedIn datahub learning notes

How to solve the problem that iterative semi supervised training is difficult to implement in ASR training? RTC dev Meetup

Distributed database uses logical volume to manage storage expansion

建议自查!MySQL驱动Bug引发的事务不回滚问题,也许你正面临该风险!

Quick view of wechat applet development process

从3开始,在业务系统中增加分页功能

【深入理解TcaplusDB技术】TcaplusDB导入数据

ASP. Net C pharmacy management information system (including thesis) graduation project [demonstration video]

raspberry pi安装 wiringpi

WebService interface publishing and calling

AI talk | data imbalance refinement instance segmentation

When I went to oppo for an interview, I got numb...

百万奖金等你来拿,首届中国元宇宙创新应用大赛联合创业黑马火热招募中!

Qu'est - ce que ça veut dire? Où dois - je m'inscrire?

港股今年最大IPO来了,660亿身家,坐在矿山上的“大王”

KDD'22「阿里」推荐系统中的通用序列表征学习

Ie mode of selenium edge

Résumé de la méthode de déduction de la force 513 - trouver la valeur du coin inférieur gauche de l'arbre

ACM Player Illustration leetcode remove element

NFNet:NF-ResNet的延伸,不用BN的4096超大batch size训练 | 21年论文