当前位置:网站首页>What problems need to be solved by MES management system in the era of intelligent manufacturing

What problems need to be solved by MES management system in the era of intelligent manufacturing

2022-06-24 00:14:00 【Dark blue easy net】

MES The application object of the management system mainly faces the strategic management and middle management , Strategic focus on high-level data ( Such as the completion rate 、 Trends, etc ), Middle management focuses more on real-time data ( Such as planning progress 、 Production problems, etc ), The workshop execution layer pays more attention to the relatively static data ( assembly BOM、 Process data, etc ).

MES The production management system focuses on factory and enterprise customers with lean and intelligent construction needs , It is the core foundation for manufacturing enterprises to realize intelligent manufacturing management ,MES Management system for :

1、 Large domestic manufacturing enterprises 、 Foreign funded and joint-venture manufacturing enterprises and private manufacturing enterprises of various scales ;

2、 Many varieties 、 Small batch 、 An enterprise that produces to order , For example, OEM enterprises that receive orders , Tooling and mold manufacturing enterprises, etc ;

3、 The product is complex 、 Changeable 、 Enterprises with production capacity bottlenecks ;

4、 Traditional industries that produce according to market forecasts , Such as ordinary mechanical equipment manufacturing 、 Machining assembly and assembly production of electronic products ;

5、 Other manufacturing enterprises that customize products for customers .

MES Workshop management system is based on the idea of real-time collaboration , Take the implementation of lean production plan and workshop dynamic scheduling as the core , Integrating lean production concepts and methods 、 Constraint theory 、 Enterprise resource optimization theory 、 Supply chain management 、 Outsourcing management 、 Human resource management 、 Business management and other advanced management concepts , Fully absorb the experience of enterprise informatization construction of intelligent manufacturing enterprises at home and abroad 、 Lessons and research results to create a lean business management system .

MES The management system systematically manages the data of production site and business operation , Based on the results of data analysis , Let each business decision form a production plan smoothly , At the same time, the status of each production link at the manufacturing site can be displayed in real time , Expose problems , Give Way “ Problem finding ”, Easily realize the integrated intelligent management from production site to operation management .

One 、 Solve high-level management problems : Digital decision support system 、 Improve the speed and accuracy of decision-making .

Two 、 Solve the problem of enterprise talents : system optimization 、 Build talent echelons , Improve the quality of all employees .

3、 ... and 、 Solve the problem of enterprise execution : Responsibilities and rights are clear 、 Everyone has a goal , Insist on using digital performance evaluation results to realize rewards and punishments .

Four 、 Solve the problem of enterprise profitability : The system takes cost management as the main axis 、 From the budget of receiving orders 、 Process creation accounting to shipment settlement , Step by step cost control , Guarantee the profit of the company .

5、 ... and 、 Solve quality problems : The system has quality control function , Pass employee self inspection 、 Quality control patrol inspection 、 Machine precision spot check and other effective ways to control product quality , Reduce non-performing costs .

6、 ... and 、 Solve production schedule problems : The system sets the production status monitoring interface 、 Convenient and intuitive 、 real time 、 On line control of production , Control in advance , Improve the delivery rate .

边栏推荐

- Andorid development art exploration notes (2), cross platform applet development framework

- Nice input edit box

- Salesforce batch apex batch processing (V) asyncapexjob intelligence

- 混沌工程,了解一下

- Andorid 开发艺术探索笔记(2),跨平台小程序开发框架

- Chinese guide to accompanist component library - glide, hot

- Dart series: using generators in dart

- 【FreeRTOS】07 二值信号量、计数信号量

- 国内首款开源MySQL HTAP数据库即将发布,三大看点提前告知 石原子科技重磅推出

- Android AIDL:跨进程调用Service (AIDL Service),kotlininvoke函数

猜你喜欢

Windows10 security mode entry cycle blue screen repair

Use of reverse tools IDA and GDB

Andorid 开发艺术探索笔记(2),跨平台小程序开发框架

Another short video app with high imitation and eye opening

Startup process analysis of APP performance optimization

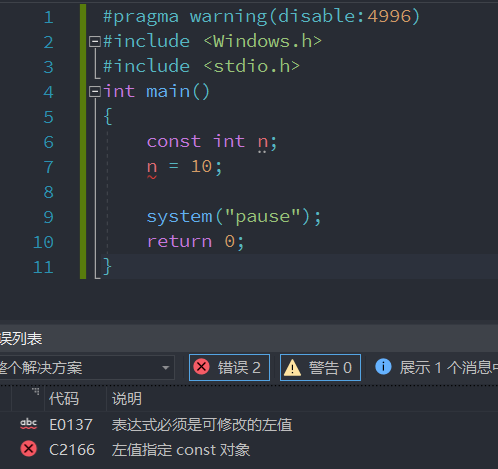

return、const、volatile关键字

【FreeRTOS】07 二值信号量、计数信号量

Solve the problem of project dependency red reporting

C语言:结构体数组实现找出最低分学生记录

Android 3年外包工面试笔记,有机会还是要去大厂学习提升,作为一个Android程序员

随机推荐

Social order in the meta universe

What is the use of AI technology in the medical field?

.NET 中的 Worker Service 介绍

How much business do you need to know to do data analysis

What is the future development of palmprint recognition technology?

UART protocol timing summary

社招面试必不可少——《1000 道互联网大厂 Android工程师面试题》

AI技术在医学领域有什么用?

如何利用数仓创建时序表

Comment utiliser l'entrepôt de données pour créer une table de synchronisation

Solve the problem of project dependency red reporting

Windows10 security mode entry cycle blue screen repair

纯js实现判断ip是否ping通

[technical grass planting] use the shared image function to realize the offline switching from CVM to LH

SAVE: 软件分析验证和测试平台

Detailed process from CPU fetching to sending control and microprogram control principle

人工智能技术岗位面试要注意什么?

Security | warm tips: security incidents on the cloud have intensified recently. Please do a good job in backup monitoring of cloud security protection!

Shutter control layout

抖音实战~密码找回