当前位置:网站首页>Briefly describe the 11 core functional modules of MES system

Briefly describe the 11 core functional modules of MES system

2022-07-26 19:08:00 【Old bird who likes soy sauce】

Traditional manufacturing enterprises , The emphasis of informatization construction is generally placed on ERP Management system and field automation system . But just relying on ERP And field automation are often unable to cope with the contradiction between production and management ,ERP Mainly for upper level resource planning management , Be able to deal with what happened before , You can also predict and deal with upcoming events , But I can't cope with the events that are happening now , Traditional production site management is only regarded as black box operation . And manufacturing execution systems (mes) Emphasize the implementation of manufacturing plan , It builds a bridge between planning management and process control , It just fills the gap between the two .

As a link between the decision-making level and the basic control level of the enterprise ,MES Straighten out the information flow within the enterprise .MES It can schedule accurately 、 send out 、 track 、 Monitor workshop production information and process , At the same time, it can measure and report real-time performance , It is the basic technical means to realize the agility of workshop production .

MES share 11 The main function modules include : Detailed scheduling of processes 、 Resource allocation and state management 、 Production unit allocation 、 Document management 、 Product tracking and product list management 、 Performance analysis 、 Labor resource management 、 Maintenance Management 、 Process management 、 Quality management 、 Data collection . The functions of each module are briefly described as follows :

1、 Detailed scheduling of processes : Optimize and sort the job plan by sorting and scheduling the limited resource capacity ;

2、 Resource allocation and state management : Manage the resources needed for production , Coordinate workers 、 Production equipment 、 Optimize the allocation of tools and materials , And track its current working status and completion ;

3、 Production unit allocation : The operation of sending materials or processing orders to a processing unit through production orders to start a process or step ;

4、 Document management : Manage and distribute products 、 Process planning 、 Records and documents related to design or work order , And the preservation and maintenance of historical production data ;

5、 Product tracking and product list management : The history of each product is obtained by monitoring the position and status information of the workpiece at any time , This record can be traced up to the material component , Or trace to the end product ;

6、 Performance analysis : Provide the result report of the actual manufacturing process , And compare it with historical records and expected goals ;

7、 Labor resource management : Provide employee status information data updated by minute ( Including working hours 、 Participation rate 、 Achievement confirmation, etc ) It is convenient to guide the work of personnel ;

8、 Maintenance Management : Track the maintenance of equipment and tools , Guide maintenance work , Ensure the normal operation of machines and other assets and equipment to achieve the implementation objectives of the plant ;

9、 Process management : Monitor the production process , Guide the work flow of the factory , Improve processing efficiency and quality ;

10、 Quality management : Real time analysis of information collected from the manufacturing site , Track and analyze the quality of the processing process , Ensure product quality ;

11、 Data collection : Collect and organize people , Machine and bottom control operation data and process material information , So as to obtain the forms required for internal production operations 、 Record or parameter data .

The manufacturing workshop of an enterprise , It is the intersection of logistics and information flow , It is the economic benefit center of the enterprise . With the improvement of market economy , The role of workshop in manufacturing enterprises has gradually changed from traditional enterprise cost center to profit center , It strengthens the role of the workshop , therefore , Manufacturing execution system located in the workshop with execution function MES It plays a very important role . It not only establishes a complete traceability system for the factory , And improve the management level , Enhance the core competitiveness of enterprises .

————————————————

Copyright notice : This paper is about CSDN Blogger 「kingmax54212008」 The original article of , follow CC 4.0 BY-SA Copyright agreement , For reprint, please attach the original source link and this statement .

Link to the original text :https://blog.csdn.net/kingmax54212008/article/details/53993862

边栏推荐

- 【AUTOSAR-RTE】-1-聊一聊RTE(Run-Time Environment)

- JS刷题计划——链表

- NFT digital collection system development: fellow uncle first promoted the blessing series digital collection, which will be sold out immediately

- 这场竞赛,能读懂题目的你大有可为

- 手机申请公募reits账户安全吗?

- Brand new! Uncover the promotion route of Ali P5 Engineer ~p8 architect

- Seata 入门简介

- LeetCode简单题之验证回文字符串 Ⅱ

- MySQL exercises elementary 45 questions (Unified table)

- How far can Volvo, which has lost its "safety brand" due to declining sales and marginalization of its brand?

猜你喜欢

我酷故我在

Simulated 100 questions and simulated examination of refrigeration and air conditioning equipment operation examination in 2022

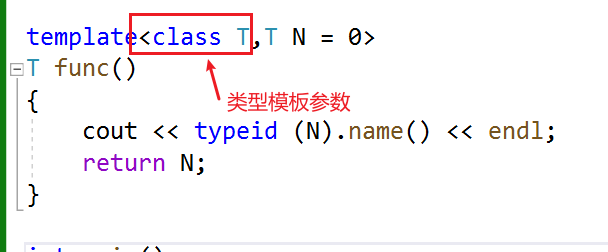

Advanced template (runner's notes)

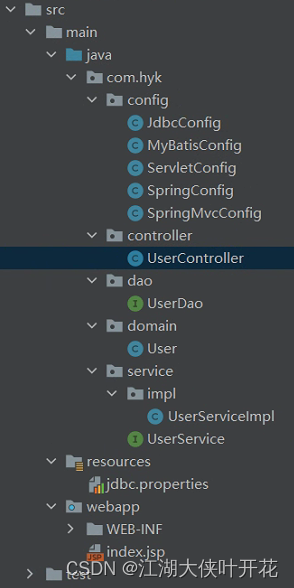

SSM integration - functional module and interface testing

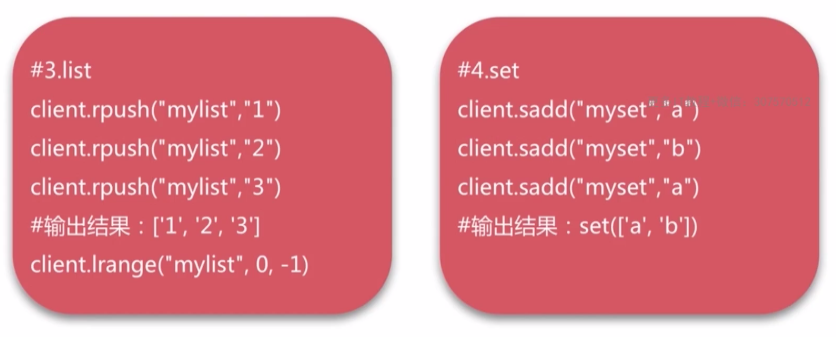

Redis学习笔记-2.客户端的使用

2022G1工业锅炉司炉上岗证题库及模拟考试

SSM integration configuration

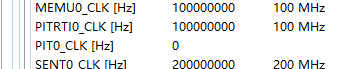

The pit of mpc5744p reports an error, RTOS cannot be started, and there is a clock source problem

2022 Shanghai safety officer C certificate operation certificate examination question bank simulated examination platform operation

如何成为一名优秀的测试/开发程序员?专注谋定而后动......

随机推荐

微软默默给 curl 捐赠一万美元,半年后才通知

.Net CLR GC 动态加载短暂堆阈值的计算及阈值超量的计算

NFT digital collection system development: sold out when online, and netizens "spike" Digital Collections

自动化测试的使用场景

.net CLR GC dynamic loading transient heap threshold calculation and threshold excess calculation

SSM integration - functional module and interface testing

5 best overseas substitutes for WPS Office

模板进阶(跑路人笔记)

Concentrate, heart to heart! The Chinese funded mobile phone Enterprises Association (CMA) of India is officially operational!

Lombok常用注解

【Swoole系列3.1】进程、线程、协程,面试你被问了吗?

MapReduce(二)

NFT数字藏品系统开发:“中国旅游日”山西首次发布古建筑数字藏品

Likeshop takeout order system is open source, 100% open source, no encryption

SSM整合-异常处理器和项目异常处理方案

Comparison of advantages and disadvantages between SD NAND and EMMC

一文详解MES系统给企业带来的5大好处,附应用场景

实用工具网站推荐

手写一个Starter

FTP protocol