当前位置:网站首页>How to use MES management system to realize error prevention and early warning

How to use MES management system to realize error prevention and early warning

2022-06-21 07:05:00 【Dark blue easy net】

With the development of information technology and the continuous improvement of management level , Information production management has become an important means of production management in manufacturing enterprises , How to master the production process comprehensively and in real time , Master the production progress 、 Product quality data and process specifications of production workers 、 Reasonably control product material batch 、 Matching accessory model , It is a problem faced by most Chinese manufacturing enterprises “ Soft rib ”.

MES The management system scans and compares in real time through the scanning gun , Identify whether the assembly parts meet the requirements through the all-in-one machine or touch screen , And sending the real-time data in the assembly process to the system recording server . This article will start from MES Discuss the error proofing function process of workshop management system and how to implement it , So as to help enterprises realize error prevention and stupidity prevention .

MES Management system error proof and fool proof operation process

Strictly control the assembly process according to the process flow requirements , The assembly personnel only need to follow the system prompts , Eliminate potential risks caused by human factors , Make the assembly process transparent 、 Standardization ;

According to the order type , The same terminal equipment automatically displays different assembly interfaces to guide assembly operations ;

After completing the whole process , Automatically perform and display the next assembly information 、 Order configuration ;

The assembly data must comply with the assembly part verification rules , The system verifies the barcode of each scanned part , If it does not conform to the part verification rules, it will automatically give an alarm and prohibit the next process assembly ;

adopt MES System analysis key components 、 The barcode of the re protected parts shall be matched with the process , So as to realize quality prevention and omission 、 Quality error prevention 、 Quality data is 、 Anti retroactive .

Besides automation and process design , Informatization can also prevent mistakes and stupidity , And informatization will use data statistics technology to conduct more comprehensive error proofing processing from the overall perspective . Informatization can help enterprises eliminate the causes of errors , It can also eliminate defects and avoid the expansion of defects , Provide great error proofing support to field operators !

One 、 Promote the coordination of multiple types of work with informatization , Eliminate the cause of the error

Through grasping the production plan and work order , Let production and supply 、 Logistics quality 、 The business coordination among various departments of equipment power has been realized ;

Make the production plan and work order pull the material distribution , The supply department shall cooperate with the work order to prepare materials according to the plan ;

When executing a production work order , Generate an inspection request according to the inspection process and notify the quality inspector , Feed back the inspection results to the workshop site ;

logistics 、 equipment 、 Power according to production plan / Prepare the work order , All links on site shall be executed in strict accordance with the work order sequence , When the upstream production is finished and the quality is qualified, the sequence can be transferred , The downstream party can execute .

Two 、 Eliminate the cause of error with automated checks

MES The basis of workshop management system realizes digital material management and production process , And support the process of business operation , Therefore, the on-site business operation can be standardized , And carry out various automatic inspections at each process node , Avoid all kinds of mistakes .

Electronic operation manual , Create directories and keywords , Convenient retrieval ;

Material inspection , For example, receiving materials according to work orders , Not the current work order or the next work order , Do not receive materials ; Before feeding , according to BOM The work order performs material comparison , If the inspection is unqualified, it will not be started ;

Process parameters 、 Equipment parameters 、 Environmental parameter check , For example, when a work order is started , Set up equipment inspection node , Check relevant parameters , If the inspection is unqualified, it will not be started .

Digitalization of production standards , convenient IT The system automatically checks and manages ;

3、 ... and 、 Eliminate defective products , With SPC Defect prevention and early warning

There may be no problem at the beginning of production , But after a long time of accumulation , Mistakes are inevitable , How to avoid these mistakes ? Now SPC Can help eliminate the generation of defective products :

Use automated data collection , Collect process parameters and online test data in real time ;

By analyzing the process , And formulate SPC Early warning rules ;

according to SPC Early warning rules , Carry out on-site early warning and give operation tips .

Compared with the traditional process design and automation devices , From a global perspective , More comprehensive and reliable error prevention and stupidity prevention can be realized by using information-based data statistics technology , And then support worry free production through industrial big data technology . Now , Most enterprises are facing strong market pressure , Need core competitiveness and development vision , Informatization gives enterprises a new vision , Help enterprises adapt to rapid changes , Achieve evolution and optimization .

边栏推荐

- 152 Solana getting started (16) - create a metaplexnft

- EasyUI monitors mouse press events & keyboard events [simple and detailed]

- AdEx 治理投票:质押奖励减半

- [flutter special topic] 72 graphic minimalist custom running lamp acemarquee yyds dry goods inventory

- [GNN] Application of GNN neural network toolbox and MATLAB simulation

- Pyg tutorial (1): getting to know pytorch geometry

- 五层参考模型各层总结

- Building a hard core Gateway - resume

- How to deal with the error message of concurrentmodificationexception?

- June training (day 21) - heap (priority queue)

猜你喜欢

Candy tunnel JS special effect code

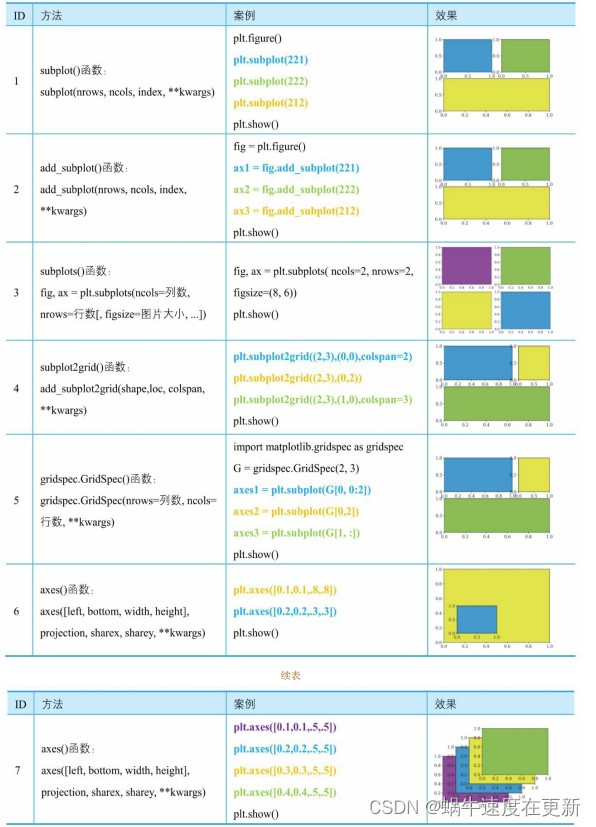

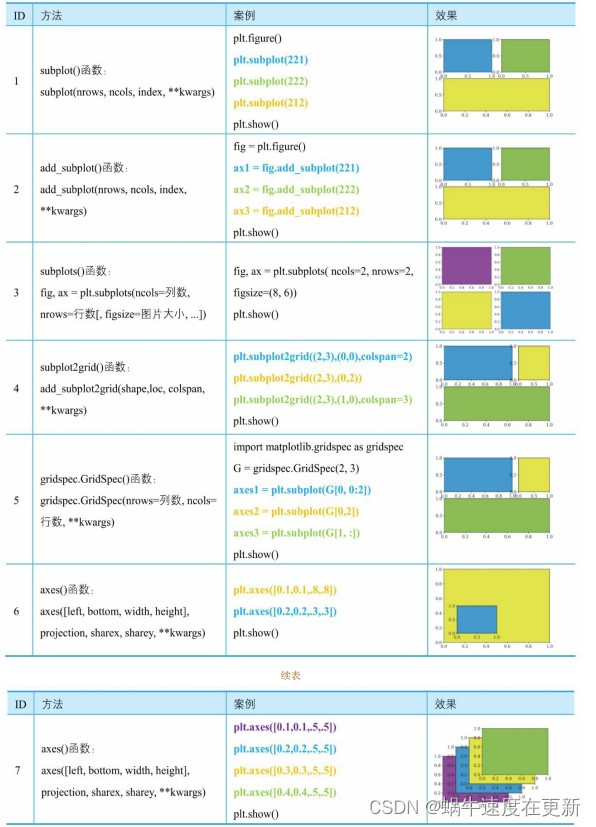

Matplotlib subgraph beautification

Google Earth Engine(GEE)——全球农田有机土壤碳和氮排放(1992-2018年度)数据集

Tweenmax oscilloscope 3D animation

flutter jpush

Eigen common operations

matplotlib子图美化操作

Yield guild games and Walken reach cooperation

Google Earth engine (GEE) - US native lithology data set

Feature scaling for machine learning

随机推荐

Eigen common operations

What is a good primary key for MySQL

微信小程序_5,全局配置

怎么看小程序是谁开发的(查看小程序开发公司方法)

【GNN】GNN图神经网络工具箱的应用和matlab仿真

Debezium error report processing series 18: solve the problem that the table structure cannot be obtained

Pyg tutorial (4): Customizing datasets

Tweenmax oscilloscope 3D animation

Old users come back and have a look

2022 运维故障案例经验

lombok之@NonNull注解

Filtre Bloom

缺失数据填补数据集介绍(2)——多种数据集介绍及数据集预处理(mushroom、news、spam、wine-red和yeast)

onnx转tensorrt学习笔记

Unittest使用

BOL波尔独创双币驱动模型 引领DeFi+NFT+Web3.0新热点

使用Loupe Cell Browser查看10X单细胞转录组分析结果

win10上vs2017配置Eigen3开发环境

Construction methods of file class and various common methods

SQL 进阶挑战(26 - 30)