当前位置:网站首页>Implementation of common function blocks for Beifu twincat3 servo control

Implementation of common function blocks for Beifu twincat3 servo control

2022-06-22 03:42:00 【Dusk and starry sky】

2、 servo PTP Function block definitions

2.1 Define axis variables

_axis1: AXIS_REF; // Axis variable

2.2 Add axis control command

Define function block variables :

MC_POWER_0: MC_POWER; // Shaft enable

MC_Reset_0: MC_Reset; // Axis reset

MC_Stop_0: MC_Stop; // The shaft stops

MC_Jog_0: MC_Jog;

MC_MoveAdditive_0: MC_MoveAdditive;

MC_MoveRelative_0: MC_MoveRelative;

MC_MoveAbsolute_0: MC_MoveAbsolute;

MC_MoveVelocity_0: MC_MoveVelocity;

MC_SetOverride_0: MC_SetOverride; // Set the axis speed scaling factor

MC_SetPosition_0: MC_SetPosition; // Set the current position

MC_ReadActualPosition_0: MC_ReadActualPosition;

MC_ReadActualVelocity_0: MC_ReadActualVelocity;

MC_ReadStatus_0: MC_ReadStatus;

2.3 Add global variable

Define global variables for control :

// Axis control command

bi_Power: BOOL; // Can make

bi_Reset: BOOL; // Reset

bi_Stop: BOOL; // stop it

bi_JogForward: BOOL; // Positive inching

bi_JogBackwards: BOOL; // Reverse inching

bi_MoveAdditive: BOOL; // Incremental position movement

bi_MoveRelative: BOOL; // Relative position motion

bi_MoveAbsolute: BOOL; // Absolute position motion

bi_MoveVelocity: BOOL; // Speed mode movement

bi_SetOverride: BOOL; // Axis speed scaling enabled

bi_SetPosition: BOOL; // Incremental servo , Set the current position value

bi_AxisRead: BOOL; // Read the state of the shaft

Define the input control parameter variables :

// Axis motion parameter setting

di_Stop_Deceleration: LREAL:=4000; // Stop speed (MC_Stop)

di_SetPosition: LREAL:=0; //

di_Jog_Velocity: LREAL;

di_Jog_Acceleration: LREAL:=3000;

di_Jog_Deceleration: LREAL:=3000;

di_Jog_Jerk: LREAL:=0; // Speed up .

di_MoveAdditive_Distance: LREAL:=0;

di_MoveAdditive_Velocity: LREAL:=100;

di_MoveAdditive_Acceleration: LREAL:=500;

di_MoveAdditive_Deceleration: LREAL:=500;

di_MoveAdditive_Jerk: LREAL:=0;

di_MoveRelative_Distance: LREAL:=0;

di_MoveRelative_Velocity: LREAL:=100;

di_MoveRelative_Acceleration: LREAL:=500;

di_MoveRelative_Deceleration: LREAL:=500;

di_MoveRelative_Jerk: LREAL:=0;

di_MoveAbsolute_Position: LREAL:=0;

di_MoveAbsolute_Velocity: LREAL:=100;

di_MoveAbsolute_Acceleration: LREAL:=500;

di_MoveAbsolute_Deceleration: LREAL:=500;

di_MoveAbsolute_Jerk: LREAL:=0;

di_MoveVelocity_Velocity: LREAL:=100;

di_MoveVelocity_Acceleration: LREAL:=500;

di_MoveVelocity_Deceleration: LREAL:=500;

di_MoveVelocity_Jerk: LREAL:=0;

di_MoveVelocity_Direction: MC_Direction:=1; //1:Positive 3:Negative

di_VelFactor: LREAL:=1.0; //1.0=100% Range :0.01-1.0

Define the axis state variables that store feedback

// Shaft status feedback

bo_AxisError: BOOL;

bo_ErrorStop: BOOL; // When the fault is not reset, rotate the motor again to output the fault stop signal

bo_Homing: BOOL; // Axis return to origin in progress

bo_Homed: BOOL; // The axis has returned to the original point

bo_Moving: BOOL; // Axis in motion

bo_Disabled: BOOL;

bo_Stopping: BOOL; // Stop signal output once

bo_StandStill: BOOL; // Standby

bo_DiscreteMotion: BOOL; // Discontinuous motion

bo_ContinuousMotion: BOOL; // Continuous motion

bo_SynchronizedMotion: BOOL; // Synchronous motion

bo_ConstantVelocity: BOOL; // In constant speed operation

bo_Accelerating: BOOL; // Accelerating

bo_Decelerating: BOOL; // Slowing down

//

do_ActualPosition: LREAL; // Axis current position

do_ActualVelocity: LREAL; // Current speed of axis

do_AxisErroID: DWORD; // Fault code

dg_ActualTorque AT%I*: INT; // Axises's Actual Torque

2.4 Axis control function block ST Language implementation

//* Shaft enable

MC_POWER_0(

Axis:= _axis1,

Enable:= bi_Power, //TRUE Can make ,FALSE To enable

Enable_Positive:= TRUE,

Enable_Negative:= TRUE,

Override:= ,

BufferMode:= ,

Options:= ,

Status=> ,

Busy=> ,

Active=> ,

Error=> ,

ErrorID=> );

//* Axis reset

MC_Reset_0(

Axis:= _axis1,

Execute:= bi_Reset, // The rising edge signal triggers

Done=> ,

Busy=> ,

Error=> ,

ErrorID=> );

//* Shaft shutdown

MC_Stop_0(

Axis:= _axis1,

Execute:= bi_Stop, // The rising edge signal triggers

Deceleration:= di_Stop_Deceleration,

Jerk:= ,

Options:= ,

Done=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

//Jog Inching

MC_Jog_0(

Axis:= _axis1,

JogForward:= bi_JogForward,

JogBackwards:= bi_JogBackwards,

Mode:= MC_JOGMODE_CONTINOUS, // Jog mode

Position:= ,

Velocity:= di_Jog_Velocity,

Acceleration:=di_Jog_Acceleration ,

Deceleration:= di_Jog_Deceleration,

Jerk:= di_Jog_Jerk,

Done=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

//* Relative positioning of the shaft -MoveAdd //

MC_MoveAdditive_0(

Axis:= _axis1,

Execute:= bi_MoveAdditive, // The rising edge signal triggers

Distance:= di_MoveAdditive_Distance,

Velocity:= di_MoveAdditive_Velocity,

Acceleration:= di_MoveAdditive_Acceleration,

Deceleration:= di_MoveAdditive_Deceleration,

Jerk:= di_MoveAdditive_Jerk,

BufferMode:= ,

Options:= ,

Done=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

//* Relative positioning of the shaft -MoveRela //

MC_MoveRelative_0(

Axis:= _axis1,

Execute:= bi_MoveRelative, // The rising edge signal triggers

Distance:= di_MoveRelative_Distance,

Velocity:= di_MoveRelative_Velocity,

Acceleration:= di_MoveRelative_Acceleration,

Deceleration:= di_MoveRelative_Deceleration,

Jerk:= di_MoveRelative_Jerk,

BufferMode:= ,

Options:= ,

Done=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

//** The shaft absolute positioning starts

MC_MoveAbsolute_0(

Axis:= _axis1,

Execute:= bi_MoveAbsolute, // The rising edge signal triggers

Position:= di_MoveAbsolute_Position,

Velocity:= di_MoveAbsolute_Velocity,

Acceleration:= di_MoveAbsolute_Acceleration,

Deceleration:= di_MoveAbsolute_Deceleration,

Jerk:= di_MoveAbsolute_Jerk,

BufferMode:= ,

Options:= ,

Done=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

//** Run at speed

MC_MoveVelocity_0(

Axis:= _axis1,

Execute:= bi_MoveVelocity, // The rising edge signal triggers

Velocity:=di_MoveVelocity_Velocity ,

Acceleration:= di_MoveVelocity_Acceleration,

Deceleration:= di_MoveVelocity_Deceleration,

Jerk:= di_MoveVelocity_Jerk,

Direction:= di_MoveVelocity_Direction, //MC_Negative_Direction -> reverse MC_Positive_Direction -> positive

BufferMode:= ,

Options:= ,

InVelocity=> ,

Busy=> ,

Active=> ,

CommandAborted=> ,

Error=> ,

ErrorID=> );

//** Axis speed scaling factor setting

MC_SetOverride_0(

Axis:= _axis1,

Enable:= bi_SetOverride, //TRUE take effect ,FALSE Invalid

VelFactor:= di_VelFactor, //1.0=100% 0.01-1.0

AccFactor:= ,

JerkFactor:= ,

Enabled=> ,

Busy=> ,

Error=> ,

ErrorID=> );

//* Current axis position setting ( Incremental encoder motor )

MC_SetPosition_0(

Axis:= _axis1,

Execute:= bi_SetPosition, //TRUE take effect ,FALSE Invalid

Position:= 0,

Mode:= ,

Options:= ,

Done=> ,

Busy=> ,

Error=> ,

ErrorID=> );

IF MC_SetPosition_0.Done THEN

bi_SetPosition:=FALSE;

END_IF

//* Read axis position

MC_ReadActualPosition_0(

Axis:= _axis1,

Enable:= bi_AxisRead, //TRUE take effect ,FALSE Invalid

Valid=> ,

Busy=> ,

Error=> ,

ErrorID=> ,

Position=> do_ActualPosition);

//* Shaft reading speed

MC_ReadActualVelocity_0(

Axis:= _axis1,

Enable:= bi_AxisRead, //TRUE take effect ,FALSE Invalid

Valid=> ,

Busy=> ,

Error=> ,

ErrorID=> ,

ActualVelocity=>do_ActualVelocity );

//* Axis reading status

MC_ReadStatus_0(

Axis:= _axis1,

Enable:= bi_AxisRead, //TRUE take effect ,FALSE Invalid

Valid=> ,

Busy=> ,

Error=> bo_AxisError,

ErrorID=>do_AxisErroID ,

ErrorStop=> bo_ErrorStop,

Disabled=> bo_Disabled,

Stopping=> bo_Stopping,

StandStill=> bo_StandStill,

DiscreteMotion=> bo_DiscreteMotion,

ContinuousMotion=> bo_ContinuousMotion,

SynchronizedMotion=> bo_SynchronizedMotion,

Homing=> bo_Homing,

ConstantVelocity=> bo_ConstantVelocity,

Accelerating=> bo_Accelerating,

Decelerating=> bo_Decelerating,

Status=> );

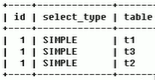

2.5 Ladder diagram of axis control function block (LD) Realization

1

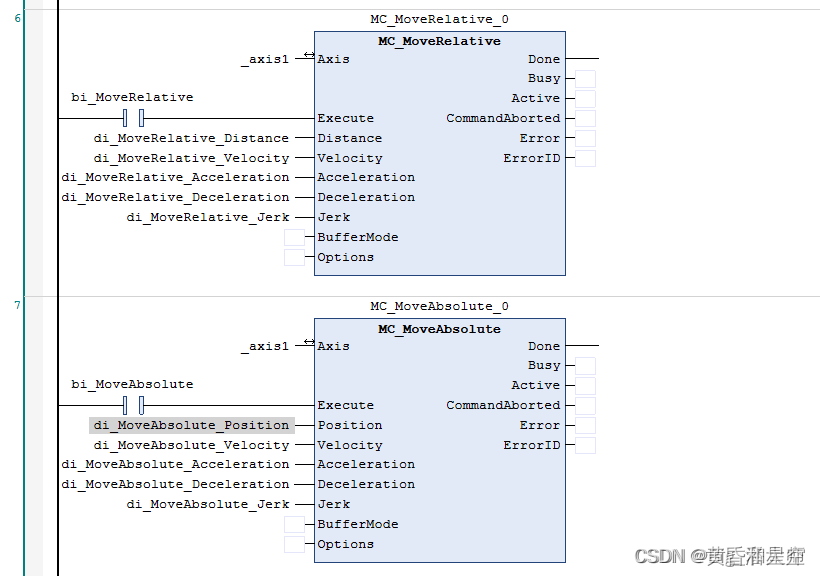

2.6 Program online monitoring

ST Program online

advantage : The notes and procedures are clear at a glance

Ladder program online

advantage : The logic function is clear , The inputs and outputs of the function block are clear

3、 Other functions of third-party servo

3.1 Torque reading

Read the torque of the third-party servo , You need to associate PDO Maping The output of is read , Some manufacturers servo in IO Scan it out PDO Mapping in Torque, Some servo manufacturers did not scan it ,PDO Maping There is no Torque You need to add it manually . Delta A2 Hehuichuan IS620N Give examples :

First, in the PLC Add variables to the program :

hmi_ActualTorque AT%I*: INT; // Axises’s Actual Torque

After adding variables ,PLC Program engineering recompile .

Huichuan IS620N

3.2 Incremental servo return to zero

There are mainly two ways for the third-party incremental servo return to zero

The way 1:DS402 Inside the agreement PDO Mode returns to zero .

advantage : The servo operates by itself 、 High positioning accuracy

shortcoming : The program logic is complex 、 Different manufacturers have different data protocols

Please refer to :

TwinCAT3 Zhongtaida A2 Incremental encoder servo uses PDO Mode returns to zero _panjinliang066333 The blog of -CSDN Blog

The way 2: Use the servo function block MC_Jog and MC_SetPosition

advantage : It can be used by different manufacturers 、 The program logic is simple

shortcoming : Low positioning accuracy

usage : The zero return command starts , Servo to Jog The movement mode moves slowly to zero , When the zero point sensor detects the servo arrival signal Jog The movement stopped , And then use MC_SetPosition Set the current position to 0, That is, the servo return to zero is completed . If the servo is on the zero point sensor at the beginning , be Jog No movement , The servo position is directly set to zero .

Please refer to :

( Be careful : Because servo zeroing is moving in one direction , So no matter which way to return to zero , Make sure that the zero point sensor is at... When returning to zero for the first time Jog Within the direction of motion )

————————————————

Copyright notice : This paper is about CSDN Blogger 「Big_ Master pan 」 The original article of , follow CC 4.0 BY-SA Copyright agreement , For reprint, please attach the original source link and this statement .

Link to the original text :https://blog.csdn.net/panjinliang066333/article/details/123423911

边栏推荐

- 平衡二叉树——调整变换规则

- WPF 实现星空效果

- Cloud native architecture (02) - what is cloud native

- 系统漏洞利用与提权

- 基于51的超声波测距仪代码(截图版)

- [qnx hypervisor 2.2 user manual]5.5 starting and using guest

- R data analysis: significance and practice of calibration curve and DCA curve in clinical prediction model

- Flutter-状态管理

- Sword finger offer 68 - ii Nearest common ancestor of binary tree

- DM达梦数据的关键字与表的字段冲突的解决办法

猜你喜欢

随机推荐

MySQL 45 lecture learning notes (IV) index

Zombie process and orphan process

ES next 新特性

剑指 Offer 68 - I. 二叉搜索树的最近公共祖先

DM达梦数据的关键字与表的字段冲突的解决办法

L'avenir est venu: l'âge du nuage

未来已来:云原生时代

MySQL 45 lecture learning notes (III) execution of SQL update statements

rabbmitMQ 简单模式<一>

WPF 实现星空效果

mysql 查询表的字段的属性、注释、字段信息

云原生架构(03)-架构

Float floating point number understanding

Mysql 45讲学习笔记(四)索引

1690. 石子游戏 VII-动态规划法

基于.NetCore开发博客项目 StarBlog - (12) Razor页面动态编译

How to break through the sales dilemma of clothing stores

1299. replace each element with the largest element on the right

Threejs realizes the fluctuation hot spot effect, fluctuation mark and fluctuation label display

C51的一些日记