当前位置:网站首页>What is the five levels of cultivation of MES management system

What is the five levels of cultivation of MES management system

2022-06-26 07:41:00 【Dark blue easy net】

Combined with enterprise application MES The workshop management system summarizes MES Deepen the application of the five level maturity model ( abbreviation MES Five level cultivation ).

1、 Initial level

Initially realize the closed-loop management of the production site , An information management system centered on the production task list has been established , Including the release of production plan 、 Production process control 、 Completion has been incorporated into information system management , But management is limited to materials 、 Equipment and other key resources . Such as :

Data acquisition tools are applied , Be able to feed back the completion of production plan in time .

Quality management system is applied , Be able to control the quality in the production process in real time .

Part of workshop production management is applied , Be able to clearly know the detailed progress of production tasks .

The traceability management of key parts is realized .

2、 Specification level

The core resources of the production workshop cover information management , Such as equipment 、 Technical documents 、 work clothes 、 Personnel, etc , Production personnel can clearly control the use of various core resources in the workshop 、 Idle situation, etc , So that the various elements in the workshop can be effectively coordinated and managed . Such as :

It realizes the control of equipment 、 personnel 、 work clothes 、 Automatic data collection of energy and other resources .

Integration with equipment , It realizes the management of the real-time state of the equipment , Such as shutdown 、 Maintenance, etc. can be fed back to the system in real time .

The production scheduling system has been preliminarily applied , Be able to get the preliminary optimized production plan and guide the production .

According to the characteristics of different industries, the management of production process is realized , Such as error proofing in electronic industry .

A complete production traceability management system has been established .

A document management system covering the production process is established .

3、 Fine level

The main resources of the production workshop have been included in the information system management , The integrated management is realized , And fine management of main resources , And according to the existing resources , Preliminary optimization . Such as :

According to the existing resources , Optimize the production schedule to minutes , And established the integration relationship with other resources , For example, when the production scheduling plan is obtained , Release tooling plan 、 Equipment operation plan, etc .

In the production preparation stage , The realization of the technical documents 、 materiel 、 equipment 、 Process tooling 、 personnel 、 Integrated management of energy and mo .

The management of equipment and other aspects is more in-depth , Management of equipment maintenance , Including maintenance plan 、 Maintenance tasks 、 The maintenance cost is included in the system management .

It has established a multi-faceted early warning management and electronic Kanban management system at the production site .

4、 Optimization level

On the basis of fine level , The optimized utilization of various resources is realized , The system can effectively guide the on-site production operation , Such as :

On the device , It realizes the partial integration of equipment and capability plan , For example, the maintenance plan of the equipment is considered when calculating the capacity plan , Get the optimal production plan .

On personnel , According to the qualification of workshop staff 、 Production capacity and other factors , Automatic production scheduling .

In terms of energy , Be able to optimize energy , Reduce energy costs .

5、 Intelligent level

Established coverage of underlying devices 、 process control 、 Workshop execution 、 Management control and other seamless integrated information systems , Realize the release of production plan 、 Schedule production 、 Production and processing 、 The process of completion feedback is unmanned or less personalized . Such as :

Equipment suitable for automatic production is applied , Including CNC machine tools 、 robot 、 Automatic addressing device 、 Storage device 、 Flexible automatic fixture 、 Inspection tool 、 Switching device and replacement device 、 Interfaces, etc. .

The connection technology is applied , It can be designed according to the process , Connect various equipment , Form an organic whole of automatic production , Include SFC、DNC、MDC、FMS、FML、FA etc. , Realize the connection with the equipment 、 And MES Real time communication and control of production execution system .

Applied automatic control and management technology , Including distributed digital control technology 、 Production rules and dynamic scheduling control technology 、 Production system simulation technology, etc .

边栏推荐

- Nine hours, nine people and nine doors (01 backpack deformation) - Niuke

- Yyds dry inventory kubernetes easy service discovery and load balancing (11)

- Encapsulating ranging and surface class based on leaflet

- Okhttp3 source code explanation (IV) cache strategy, disadvantages of Android mixed development

- A bold sounding and awesome operation - remake a Netflix

- This article will take you to learn in detail what is FTTH

- Request&Response

- Calculate division in Oracle - solve the error report when the divisor is zero

- 少年,你可知 Kotlin 协程最初的样子?

- Iron / zinc / copper / platinum metal complexes such as 5,10,15,20-tetra (4-hydroxyphenyl) porphyrin (THPP) / (thppfe) / (thppzn) / (thppcu) / (thpppt) - Qiyue R & D

猜你喜欢

一文搞懂Glide,不懂来打我

5,10,15,20-tetraphenylporphyrin (TPP) and metal complexes fetpp/mntpp/cutpp/zntpp/nitpp/cotpp/pttpp/pdtpp/cdtpp supplied by Qiyue

Redis(4)----浅谈整数集合

Oracle creates stored procedures with return values and executes SQL calls

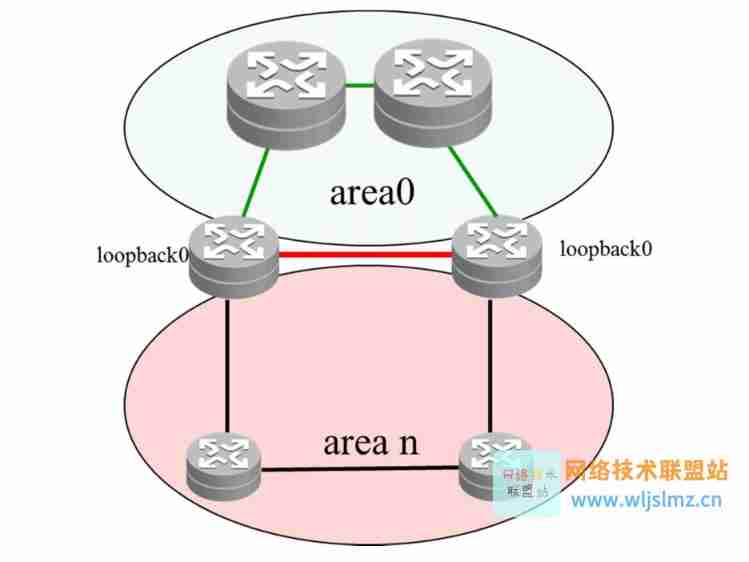

Two models of OSPF planning: double tower Raider and dog tooth crisscross

Niuniu looks at the cloud (greedy, hash, push formula) - the first session of Niuke winter vacation training camp

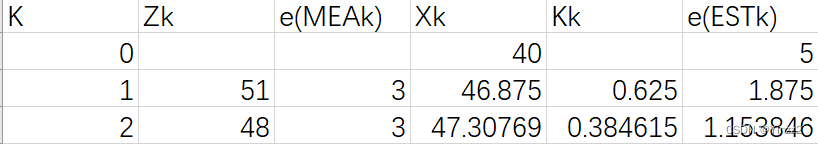

Kalman filter_ Recursive Processing

Apache inlong graduated as a top-level project with a million billion level data stream processing capability!

Take you three minutes to get started typescript

Cloud native integration data warehouse heavy release

随机推荐

5,10,15,20-tetraphenylporphyrin (TPP) and metal complexes fetpp/mntpp/cutpp/zntpp/nitpp/cotpp/pttpp/pdtpp/cdtpp supplied by Qiyue

The long path of Xiao Sha (graph theory, Euler diagram)

[UVM basics] connect of UVM_ Phase execution sequence

How can I find the completely deleted photos in Apple mobile phone?

少年,你可知 Kotlin 协程最初的样子?

数据中心灾难恢复的重要参考指标:RTO和RPO

Systemctl PHP configuration file

记一次开发 pgadmin 时执行 Building the Web Assets 遇到的依赖安装问题

Jemter 壓力測試 -基礎請求-【教學篇】

Here is the command to display the disk space usage. Go ahead and pay attention to more wonderful things!

Iron / zinc / copper / platinum metal complexes such as 5,10,15,20-tetra (4-hydroxyphenyl) porphyrin (THPP) / (thppfe) / (thppzn) / (thppcu) / (thpppt) - Qiyue R & D

Request&Response

一文搞懂Glide,不懂来打我

Two models of OSPF planning: double tower Raider and dog tooth crisscross

Google Earth Engine(GEE) 01-中输入提示快捷键Ctrl+space无法使用的问题

[UVM basics] TLM common data receiving and sending and data receiving examples

Jemter stress test - visualization tool - [usage]

The difference between insert ignore and insert into

一文分析EventBus-事件总线的使用方法和实现原理

Oracle creates stored procedures with return values and executes SQL calls

http://www.gdblue.com/q_news/shownews.php?lang=cn&id=617

http://www.gdblue.com/q_news/shownews.php?lang=cn&id=617