当前位置:网站首页>Business logic design of physical warehouse and virtual warehouse in middle inventory

Business logic design of physical warehouse and virtual warehouse in middle inventory

2022-06-23 06:45:00 【Koikoi123】

The concepts of real warehouse and virtual warehouse are aimed at the system development itself . Simply speaking , The warehouse for cost accounting can be called physical warehouse , Those that do not account for costs can be called virtual warehouses . Virtual warehouse is the main transition function in the system .

In the midrange system , Virtual warehouse is equal to the allocation pool of inventory , Inventory of individual items in the same warehouse group , Sum of physical inventory = The sum of empty warehouse inventory .

So in the middle stage inventory management of the mall , How to design the business logic of physical warehouse and virtual warehouse ? The following issues need to be considered :

One 、 How to control the sales inventory of each store ( Commodity function )

scene : Shicang a,b,c The initial inventory is 0, It needs to be a physical warehouse a,b,c All purchase 100, That is to say 3 Purchase receipt notices , The actual warehouses are a,b,c.

In the above scenario, how do virtual warehouses allocate inventory ? here , It needs to be used " Allocation pool allocation policy " Control the proportion of inventory entering the phantom warehouse .

hypothesis 3 Each purchase receipt notice puts the inventory into the virtual warehouse a, here , Shicang a,b,c There are 100 stock , Empty warehouse a Yes 300 stock .

The store x, The store y, The store z Sell goods at the same time , The store x Available allocation pool ranges : Empty warehouse a; The store y Available allocation pool ranges : Empty warehouse b, The store z Available allocation pool ranges : Empty warehouse c.

here , The inventory is in empty warehouse a, The store y And stores z What if there is nothing to sell ? Here you need to insert a description " Move warehouse " The necessity of , That is, inventory adjustment can be performed for virtual warehouses in the same warehouse group by warehouse transfer .

Suppose from the empty warehouse a, Move 50 Inventory to virtual warehouse b, Move 20 Inventory to virtual warehouse c, here , Empty warehouse a stock =230, Empty warehouse b stock =50, Empty warehouse c stock =20.

Does that mean the store x The saleable inventory is 230, The store y The saleable inventory is 50, The store z The saleable inventory is 20 Well ? But that's not the case , We need to develop an inventory synchronization strategy to control the amount of inventory synchronized from the middle office to each platform .

hypothesis , The store x, Empty warehouse a Synchronous scale =90%, Warning number =10, Reserved number =5, The number of synchronizations at this time =2300.9=207. After a period of sales , Empty warehouse a The inventory has been reduced to 10( That is, the set alert number is reached ), The number of synchronizations at this time =( Available inventory - Reserved number ) Synchronous scale =(10-5)*0.9=4.5, Deduct the decimal point , Synchronize platform inventory =4; When empty warehouse a Available =6 when , Number of syncs =(6-5)*0.9=0.9, Less than 1, Synchronize platform inventory =0.

Two 、 The corresponding relationship between real warehouse and virtual warehouse

There is not a one-to-one correspondence between real warehouse and virtual warehouse , An order is adapted to a virtual warehouse inventory , The delivery physical warehouse may be a physical warehouse with the ordered goods . For example, order to buy goods a, Shicang a Heshicang b All have commodities a Inventory of , The order is adapted to the virtual warehouse a, Shicang a Heshicang b It is possible to ship , The midrange needs an algorithm that can adapt to the optimal ( The distance is optimal , The logistics cost is the best ) Physical warehouse delivery of .

3、 ... and 、 Virtual warehouse inventory transfer

If , The store x Good sales , Empty warehouse can be a,b,c Set to the available allocation pool range of the store profile , Set up shop x, Empty warehouse b Synchronous scale =90%, Warning number =5, Reserved number =2, Set up shop x, Empty warehouse c Synchronous scale =100%, Warning number =2, Reserved number =1, Number of syncs =2300.9+500.9+20*1=272.

give an example , Now open a new store : The store p, Available allocation pool ranges : Empty warehouse e. here , Empty warehouse e, Inventory is 0, What should the company do if it no longer purchases ? Here we need to talk about allocation , This is a document that transfers inventory from one physical warehouse to another . This needs to be clear 4 A little bit : Transfer out the physical warehouse 、 Transfer to the physical warehouse 、 Call out the empty warehouse , And allocation strategies ( Allocation pool allocation policy ).

Four 、 Circulation of goods inventory

For the circulation of goods , The actual warehouse of the middle stage = Shipping store , The purchase action is in the store system ( Most are new retail systems ).

Scenario assumption , Shicang a= store a, Shicang b= store b, Shicang c= store c

Store inventory is synchronized to the middle office , branch 2 Types : Full and incremental . Total quantity : Shicang a stock = Synchronize inventory ; The incremental : Shicang a stock = Shicang a Current stock + Synchronize inventory . give an example :

Current time physical warehouse a In stock 0, Full synchronized inventory 100, After synchronization , Shicang a In stock 100;

Current time physical warehouse a In stock 100, Incremental synchronization inventory 50, After synchronization , Shicang a In stock 100+50=150; Similarly, the incremental synchronized inventory is -50, After synchronization , Shicang a In stock 150+(-50)=150-50=100.

边栏推荐

猜你喜欢

Measurement principle and thickness measurement mode of spectral confocal

Get to know webassembly quickly

华为软件测试笔试真题之变态逻辑推理题

业务逻辑安全思路总结

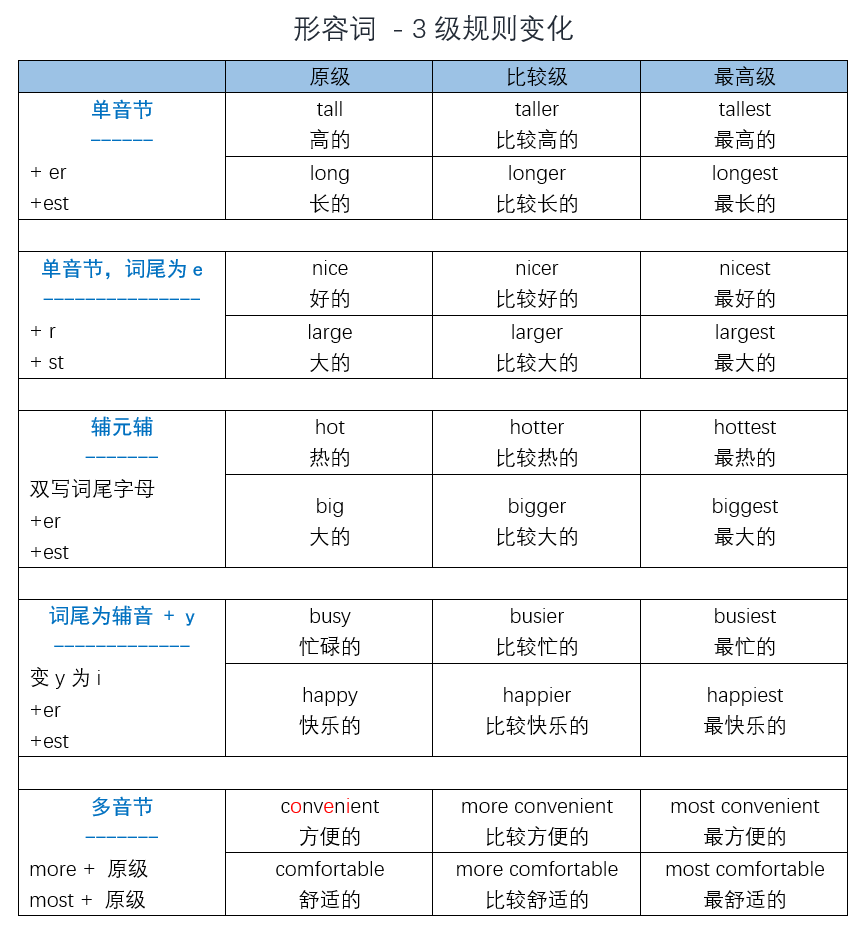

English语法_形容词比较级 - 3级变化

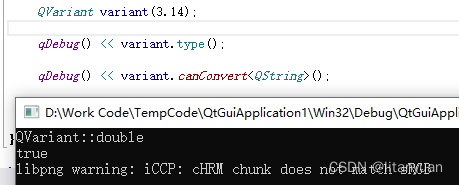

Summary of qvariant use in QT

20220621 Three Conjugates of Dual Quaternions

Explain csma/cd, token bus and token ring clearly

Open source ecology 𞓜 super practical open source license basic knowledge literacy post (Part 2)

常见设置模式(抽象工厂&责任链模式&观察者模式)

随机推荐

leetcode - 572. 另一棵树的子树

idea的去除转义的复制粘贴

SAP execution transaction code mrrl error -no message was found for partner 100065-

二叉树的遍历及相关知识

[resolved] "the unity environment took too long to respond. make sure that: \n“

20220621 Dual Quaternion

数值计算方法 Chapter7. 计算矩阵的特征值和特征向量

MySQL ON DUPLICATE KEY 和 PgSQL ON CONFLICT(主键) 处理主键冲突

开源OAuth2框架 实现SSO单点登录

设计师需要懂的数据指标与数据分析模型

如何查看本机IP

回调函数详解

如何实现与FDA保持邮件通信安全加密?

Functions and basic structure of CPU

phpStudy设置301重定向

Coordinate transformation

Add IPAD control function into shairplay

mysql如何将日期转为数字

xml schem 记录

30 data visualization tips that can not be ignored