当前位置:网站首页>EDI project cases of customers in medical device industry

EDI project cases of customers in medical device industry

2022-06-23 02:13:00 【Knowledge and action software EDI】

Project background

The development of the medical device industry is directly restricted by the upstream and downstream development of its supply chain ,“ The upstream ” The support of component suppliers plays an important role . How to ensure cooperation with the supply chain “ The upstream ” Establish a long-term and stable cooperative relationship , It is very important for enterprises in the medical device industry . A domestic medical device industry customer ( hereinafter referred to as M company ) It has nearly 30 years of industry experience in the domestic market , In addition to the continuous huge R & D investment , adopt EDI technology , Effectively strengthen and “ The upstream ” Supplier partnership .

Project introduction

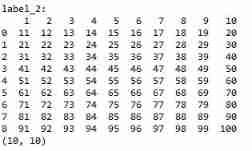

In the near future , Medical device industry M The company has reached cooperation with Zhixing software , Deploy... Locally EDI System , And with “ The upstream ” supplier TI establish EDI Connect , Realize the automation of business data receiving and sending process . adopt EDI System to TI Place the order , And load balancing is applied to this EDI project , High availability . The plan reached by both parties is as follows :

1.EDI Platform deployment , Data security and high availability should be considered 2.EDI Platform docking TI EDI

EDI Platform deployment scheme

Bridge of knowing and doing EDI A single instance of the system can easily meet the automatic transmission needs of most enterprises , This time M company EDI During deployment , Considering the huge amount of data processed by customers every day , And has long-term data processing needs , Our project manager will include load balancing, highly available shared storage services and highly available database services in this project EDI Deployment plan , To achieve a higher level of availability and scalability . The picture below is EDI Example of platform deployment scheme :

For the sake of data security , Our consultants helped our clients deploy Nginx The server . Use Nginx Load balancing as a reverse proxy , Distribute all requests equally to each deployment EDI Server for , To ensure the M Security of the company's intranet , At the same time, reduce memory consumption , Improve concurrency , The high availability concurrency requirement is realized . As shown in the figure above , Applications Server1 and Server2 Indicates deployment EDI Two servers of the platform , Through shared storage services , Realization EDI Platform configuration sharing , All transaction logs of the platform are realized through database services 、 Access log sharing .

EDI After the platform deployment scheme is agreed , combination TI EDI demand , Through the bridge of knowledge and action EDI platform , Realization AS2 signal communication , At the same time EDI International standard message format conversion , adopt tRFC Connect SAP With IDOC Form to synchronize data to M The company's SAP System .

EDI Platform docking scheme

1. transport

adopt AS2 Port implementation and TI EDI Communication for .

2. Message standard

TI Supported message standards include EDIFACT、X12 as well as RNIF. This project M The company chose X12 standard , be based on TI Of PO & POC Pattern , The business level involves the following five types of business documents ;

Message code | Business implications | Transmission direction |

|---|---|---|

850 | Order | M The company sent to TI |

855 | Order response | TI Send to M company |

860 | Order change | M The company sent to TI |

865 | Order change reply | TI Send to M company |

856 | Delivery notice | TI Send to M company |

This time EDI Project common use 5 A service message , If the enterprise still needs to adopt JIT Pattern , You need to add 830 Material demand forecast and 830R Material demand forecast reply and other messages .

3. Data format conversion

Will receive X12 A message through X12 The port is converted to EDI XML, Then you will get EDI XML adopt XML Map Port mapping , Convert to IDoc XML. adopt SAP IDoc The port is connected to the customer's SAP System , transmission IDoc file .

How to connect the bridge of knowing and doing SAP What about the system? ? You can refer to the article :SAP(IDoc) port configuration

EDI The overview of the platform docking scheme is shown in the figure below :

Through the overview of the scheme, we can clearly see , This time EDI In the project ,M The company with TI Between EDI The project needs to complete the following links :

- M Local deployment of the company EDI System

- And TI adopt AS2 establish EDI Connect

- M The company's EDI System and SAP System integration

- M The company's EDI System and TI Of EDI Exchange business files between systems

Project plan

Our project manager will arrange in advance according to the actual situation of the project EDI Deployment process and project cycle . Usually , Due to docking with trading partners and EDI Different degrees of difficulty of the project , Project cycles also vary . docking TI Of EDI project , Usually , The project cycle is two to three months . The project plan details are shown in the figure below :

We need to pay attention to , And TI Conduct the business scenario test phase , As a whole EDI The part of the project with the largest proportion of time . This part needs to complete the above mentioned PO&POC Mode or JIT Pattern testing . The business scenario test process is short 4-6 Zhou , Long needs 6-8 Zhou . At this stage, business scenarios and business details need to be communicated , Therefore, multi-party participation is required . If the enterprise wants to speed up the project progress in this link , Then the enterprise needs to follow up the project in time , More coordination and cooperation can ensure the efficient implementation of the project .

Project review

stay EDI During the implementation of the project , In order to make business data more suitable for data transmission between enterprises , Our consultant is based on M The needs of the company and TI EDI Characteristics of the project , Yes, this time EDI The project has been targeted :

The estimated arrival time does not match the actual arrival time

There will be a time difference between the expected arrival date and the actual arrival date , The problem is not only M In the customer case , For other customers, there may also be such problems . If you need to eliminate this time difference , Get the actual arrival date , How to deal with the problem of delivery date in the actual project ? There are two options :

The demand date is advanced

M The company can choose to advance the delivery date when placing an order , It is estimated that the arrival time is early , But the actual arrival time meets the actual demand .

The estimated arrival date is delayed

M The company is receiving TI After the delivery notice , Process the estimated arrival time , Add a period of time in transit or from the transit warehouse to the actual warehouse , In this way, the estimated arrival time is more accurate .

Data splitting processing

Although in EDI The specification has strict requirements for data , But the actual situation is far more complicated than expected . Like data splitting , How to deal with it ?

for example , Supplier transmitted XML The file contains a batch of data , For example, multiple orders 、 When there are multiple line items or multiple customer records , Want to place every order / project / Record from this “ Batch ” Of XML Split the data . You can use the bridge of knowledge and action Split port , Realization XML File Division . The effect is shown in the figure below :

Demand like this happens almost every day , While meeting the needs of our customers , They are also constantly learning about the bridge of knowledge and action EDI Optimize and upgrade the functions of the system .

边栏推荐

- Bc113 small leloding alarm clock

- 1.3-1.4 web page data capture

- Lying in the trough, write it yourself if you can't grab it. Use code to realize a Bing Dwen Dwen. It's so beautiful

- Common mistakes in C language (sizeof and strlen)

- Xgboost Guide

- 1. Mx6u bare metal program (1) - Lighting master

- You must know the type and method of urllib

- Get the structure of the class through reflection, little chestnut

- Performance test -- 14 detailed explanation of performance test report and precautions

- Evolution history of mobile communication

猜你喜欢

Branch and loop statements (including goto statements) -part1

JS rotation chart (Netease cloud rotation chart)

pd. read_ CSV and np Differences between loadtext

Circuit analysis (circuit principle)

1. Mx6u image burning principle (no specific process)

Unity official case nightmare shooter development summary < I > realization of the role's attack function

Cmake configuration error, error configuration process, Preject files may be invalid

![Buuctf misc-[bjdctf2020] Nani](/img/4e/ac6bf2f64cb68136581814da73db66.jpg)

Buuctf misc-[bjdctf2020] Nani

Constexpr keyword

Byte order: big endian vs little endian

随机推荐

Buuctf misc-[bjdctf2020] Nani

Garbled code of SecureCRT, double lines, double characters, unable to input (personal detection)

Quick sort method

Circuit analysis (circuit principle)

Bc110 tic tac toe chess

"First knowledge of C language" (Part 3)

Cut! 39 year old Ali P9 saved 150million

Rebirth -- millimeter wave radar and some things I have to say

Game (sanziqi & minesweeping)

pd. read_ CSV and np Differences between loadtext

5g core network and core network evolution

Browser independent way to detect when image has been loaded

Microservice Optimization: internal communication of microservices using grpc

Cmake configuration error, error configuration process, Preject files may be invalid

You can be what you want to be

Bc113 small leloding alarm clock

WebService details

Uint8 serializing and deserializing pits using stringstream

278. digital combination

Chapter 3 tensorflow linear regression