当前位置:网站首页>Practical example of propeller easydl: automatic scratch recognition of industrial parts

Practical example of propeller easydl: automatic scratch recognition of industrial parts

2022-07-07 12:58:00 【Paddlepaddle】

Baidu Flying propeller EasyDL Provide zero threshold for enterprise developers AI Development platform , One stop support for smart tagging 、 model training 、 Service deployment and other functions , Built in rich pre training model , Support for public clouds / Local server / Flexible deployment on the device side , It has been used in industry 、 retail 、 manufacture 、 Medical treatment and other fields .

Automatic scratch recognition of industrial parts

Through training object detection customization AI Model , To achieve for “ Scratches on industrial parts ” Intelligent recognition of , It is widely used in industrial quality inspection 、 Intelligent manufacturing and other fields .

Project description

Business background

A factory is mainly engaged in the production and processing of various workpieces , Because the factory production environment is complex , There are scratches in the production process of the workpiece 、 Bump 、 Possibility of making omissions , Defective goods should be treated as defective products , Do not enter the market .

Business difficulties

The precision of defect quality inspection is required to be high , Defects are usually subtle and difficult to find , The traditional manual quality inspection method is inefficient , Long time operation is prone to visual fatigue and false detection 、 Phenomenon of missing inspection . Low quality inspection efficiency will directly affect the factory's production capacity and delivery efficiency .

Solutions

To improve production capacity and quality inspection accuracy , The factory decided to intelligently empower the quality inspection production line , adopt AI Realize automatic identification of defects + Manual review method , Improve the efficiency of ex factory quality inspection . come to know Flying propeller EasyDL Provides zero threshold AI Development function , Model training can be completed quickly without knowing the basis of the algorithm , The factory passed EasyDL The object detection task type provided by the platform is quickly trained in the following steps , High precision scratch quality inspection of production workpiece is obtained AI Model and put it into practical business application , Based on this intelligent quality inspection scheme , The quality inspection manpower invested by the enterprise every year is reduced 60%, The efficiency and accuracy of quality inspection have been greatly improved .

Tips : For workpiece surface scratch recognition scene , Multiple scratch defects may appear in a single picture , The number of scratches needs to be identified , Therefore, the object detection model is selected .

Data preparation

Data collection and import

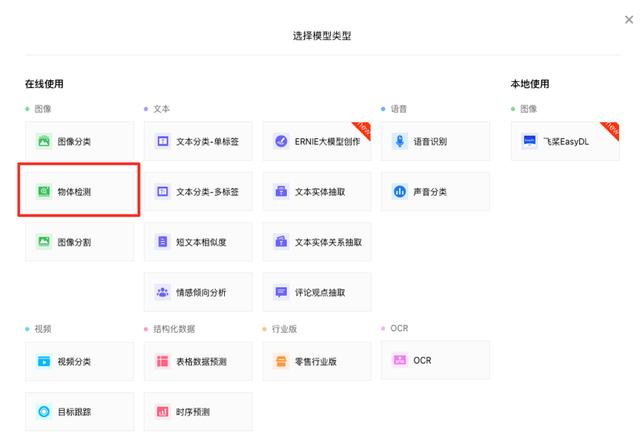

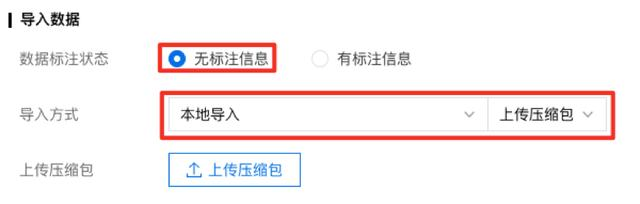

The factory selects historical defect data from the original production environment, about 300 Zhang , When preparing training data, we should pay attention to keeping consistent with the data generated by the actual production scene as far as possible , Like light 、 brightness 、 Shooting angle, etc , Only when the objective factors are consistent, the trained model will have higher applicability and effect in practical application . for example , The angle of the camera deployed in the actual quality inspection production line to the parts is overhead , that , When collecting data, you also need to collect the original pictures from the same angle . If the original data obtained by the enterprise has no annotation information , You can choose to import unmarked information in the platform and then press one key to import , for example , You can type the original image into a compressed package , The specific import path is as follows :

meanwhile EasyDL It also provides a variety of other data import methods , You can choose different import methods according to your usage habits , for example , You can upload the picture to the network address first ( for example , Baidu SkyDrive 、 Baidu BOS etc. ), Copy the corresponding address link to complete the quick import , It is suitable for cases with large data magnitude , Help you shorten the import time .

Data tagging

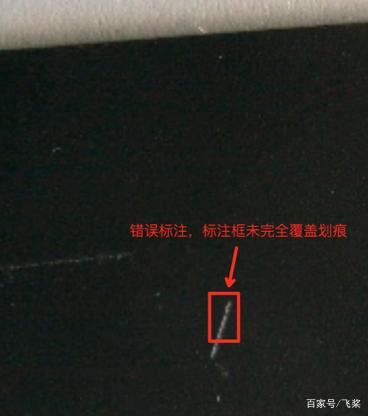

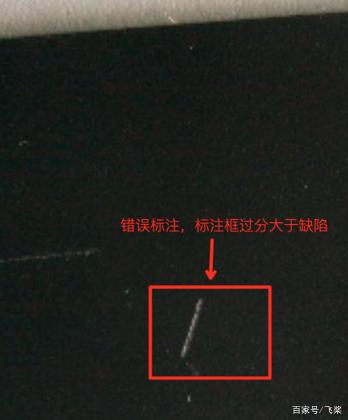

The original image needs to be marked , Before model training . The data marking process should be as close to the defect characteristics of scratches as possible , Make sure that all defects are contained in the rectangular box and that the rectangular box is not too large than the defect size , The following are examples of correct annotation and wrong annotation .

Tips : When your annotation workload is large , You can choose to turn on smart annotation , That is, you only need to mark 30% Pictures of the , The remaining 70% The picture of will automatically label you .

model training

After training data preparation , You can create it by clicking 【 Creating models 】 Enter the basic information and complete the model creation , Click on 【 Training models 】 Start training . A model can cover multiple versions , One training produces one version , You can customize the version management according to your business needs . Considering that industrial quality inspection scenarios usually pay more attention to prediction efficiency , The prediction efficiency of the model will directly affect the quality inspection efficiency , Therefore, it is recommended that you choose EasyEdge Local deployment - The server - Ultra high precision algorithm . The advantages of this scheme are : The local deployment method can effectively save the time required for the upload of prediction data and the distribution of prediction results , Greatly improve the prediction efficiency and then increase the production capacity , Ultra high precision algorithm can maximize the effect of the model , Here's the picture :

Model deployment

Local deployment requires local computing power to carry the model deployment and prediction process , To ensure the prediction performance of the model , The factory chose the one with sufficient computing power T4 Server as local computing power , Therefore, it is necessary to publish the model as a model suitable for the hardware SDK. meanwhile EasyDL The platform still supports many other hardware types , You can choose the corresponding operating system and chip type according to your actual business needs , Here's the picture :

After the model is released , Can be found in 【 Pure offline service 】 Found published models in SDK, Download and 【 Get the serial number 】 After activation, it can be deployed in the terminal application .

The enterprise will AI The model is applied to the actual scene, hoping to realize the automatic sorting of defective workpieces , In the quality inspection production line, each workpiece is photographed by a professional camera , The captured pictures are transferred to the prediction server for quality inspection , When defects are detected in the current workpiece picture , The defective workpiece is grabbed by the mechanical arm and stored in a specific area for manual review .

Effect optimization

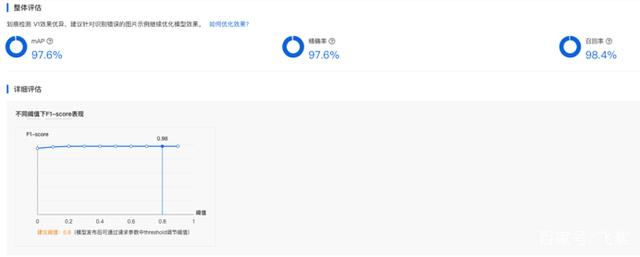

After model training , adopt EasyDL The overall effect of the model can be viewed in the automatically produced evaluation report , In this factory scenario, the defect characteristics are relatively consistent and the scenario is fixed , The overall effect is better . If the effect is not good, you can check the error examples of different labels to locate the reasons for the poor performance under this label . for example , By looking at the error examples , Pictures with wrong predictions are usually taken during periods of insufficient light , For optimization suggestions, we need to supplement the data in the case of insufficient lighting Improve model effect , Here's the picture :

common problem

problem 1:EasyDL Images provide a variety of training tasks , Why choose the object detection task type in this scenario ?

at present EasyDL Images provide image classification 、 Object detection 、 There are three types of tasks in image segmentation : Image classification is applicable to scenes with a single subject or state in the picture ; Object detection is applicable to scenes with multiple subjects and the need to identify the location of the subjects ; Image segmentation can locate multiple subjects and needs to be located at the pixel level of the subject . For the scratch inspection scenario , Multiple defects may appear in a single picture , Defects do not need to be located at the pixel level , Therefore, it is more appropriate to select object detection .

problem 2: How to collect industrial quality inspection scene data ?

The data is AI Prerequisites for model training , The training data in the industrial quality inspection scene usually comes from the historical stock data of the image acquisition equipment on the industrial production line , therefore , If image acquisition equipment has not been built on the production line, priority should be given to the construction of image acquisition equipment , Based on the collected image data AI model training .

problem 3: How to solve the problem of too few defect samples ? EasyDL The platform provides data enhancement strategies , in the light of EasyDL The platform provides data imbalance strategies , The existing defect pictures can be expanded by data enhancement strategy , And then maximize the utilization of limited data , Complete the configuration on your model training page .

This article is shared in Blog “ Flying propeller PaddlePaddle”(CSDN).

If there is any infringement , Please contact the [email protected] Delete .

Participation of this paper “OSC Source creation plan ”, You are welcome to join us , share .

边栏推荐

- Conversion from non partitioned table to partitioned table and precautions

- 详解ThinkPHP支持的URL模式有四种普通模式、PATHINFO、REWRITE和兼容模式

- 明星企业普渡科技大裁员:曾募资超10亿 腾讯红杉是股东

- 3D content generation based on nerf

- Layer pop-up layer closing problem

- regular expression

- Four functions of opencv

- 聊聊Redis缓存4种集群方案、及优缺点对比

- About IPSec

- Leetcode skimming: binary tree 25 (the nearest common ancestor of binary search tree)

猜你喜欢

共创软硬件协同生态:Graphcore IPU与百度飞桨的“联合提交”亮相MLPerf

ICLR 2022 | 基于对抗自注意力机制的预训练语言模型

Practical example of propeller easydl: automatic scratch recognition of industrial parts

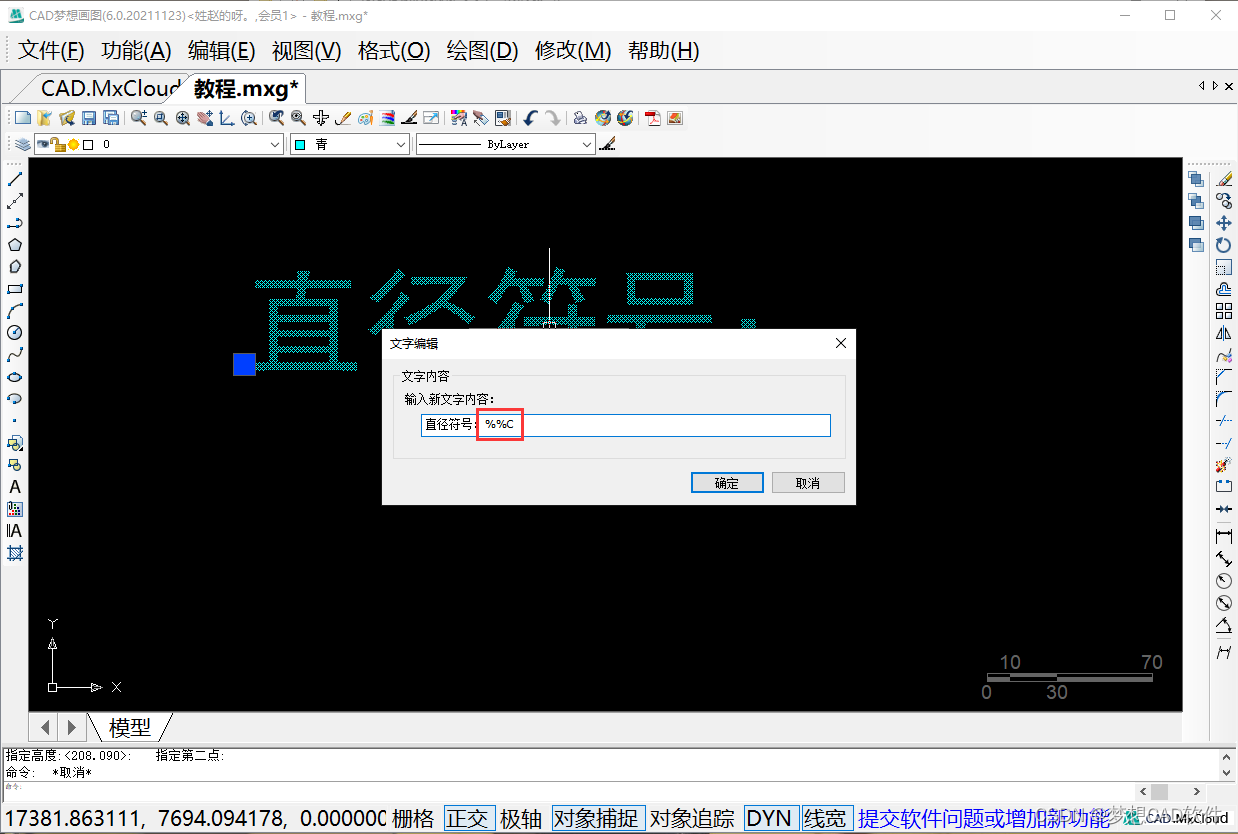

AUTOCAD——大于180度的角度标注、CAD直径符号怎么输入?

Day-15 common APIs and exception mechanisms

Master formula. (used to calculate the time complexity of recursion.)

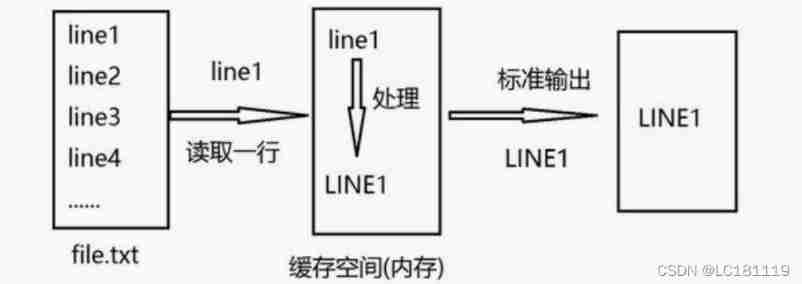

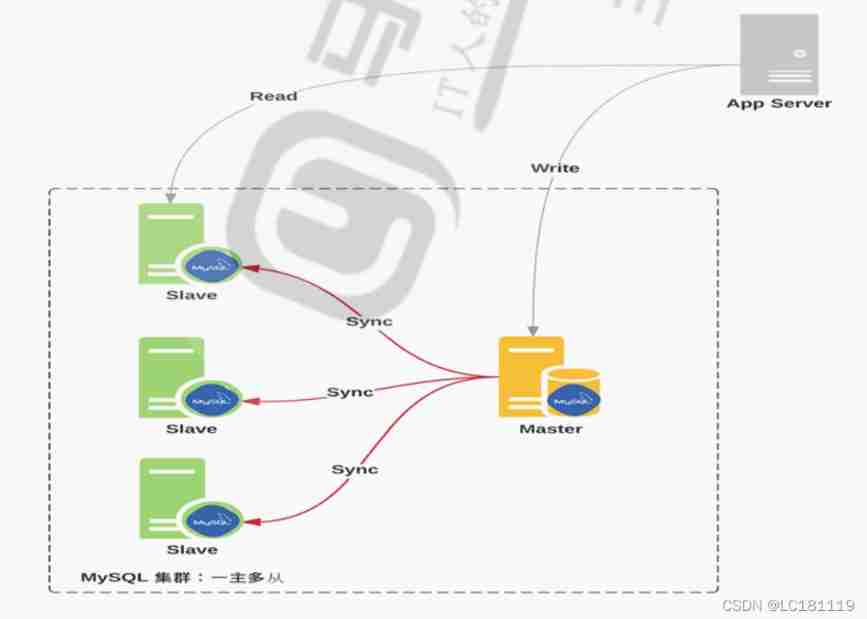

Sed of three swordsmen in text processing

MySQL master-slave replication

关于 appium 启动 app 后闪退的问题 - (已解决)

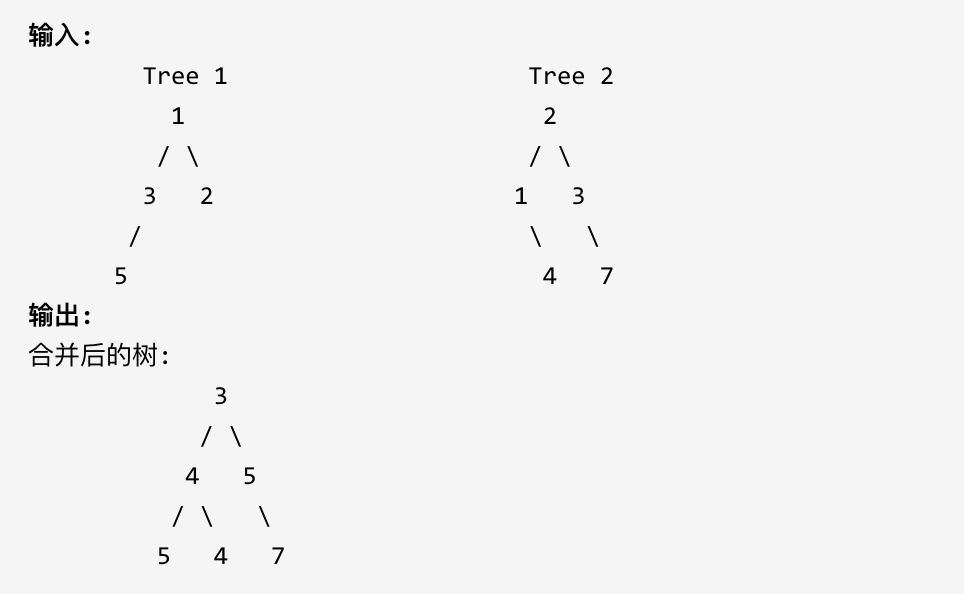

Leetcode brush questions: binary tree 19 (merge binary tree)

随机推荐

【从 0 开始学微服务】【02】从单体应用走向服务化

The difference between cache and buffer

MySQL导入SQL文件及常用命令

Aosikang biological sprint scientific innovation board of Hillhouse Investment: annual revenue of 450million yuan, lost cooperation with kangxinuo

【从 0 开始学微服务】【03】初探微服务架构

2022a special equipment related management (boiler, pressure vessel and pressure pipeline) simulated examination question bank simulated examination platform operation

PHP调用纯真IP数据库返回具体地址

.Net下极限生产力之efcore分表分库全自动化迁移CodeFirst

Day-24 UDP, regular expression

Sorting, dichotomy

3D content generation based on nerf

[learn microservices from 0] [03] explore the microservice architecture

PHP calls the pure IP database to return the specific address

How to continue after handling chain interruption / sub chain error removed from scheduling

Cookie

Master formula. (used to calculate the time complexity of recursion.)

通过Keil如何查看MCU的RAM与ROM使用情况

Layer pop-up layer closing problem

How to reset Google browser? Google Chrome restore default settings?

Day-15 common APIs and exception mechanisms