当前位置:网站首页>Single chip microcomputer: pcf8591 application program

Single chip microcomputer: pcf8591 application program

2022-06-13 03:53:00 【DC-STDIO】

List of articles

PCF8591 Applications

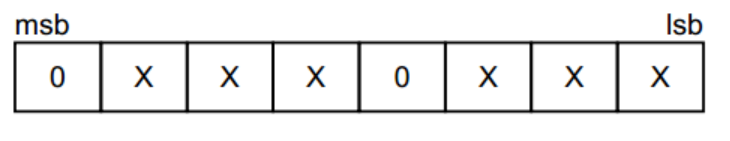

PCF8591 The communication interface is I2C, Then programming must comply with this protocol . Single chip microcomputer is right PCF8591 To initialize , Send a total of three bytes . First byte , and EEPROM similar , Is the device address byte , among 7 Bits represent the address ,1 Bits represent the reading and writing direction . Address high 4 The fixed position is 0b1001, The lower three are A2,A1,A0, All three of us are connected to the circuit GND, So that is 0b000, As shown in the figure .

Send to PCF8591 The second byte of will be stored in the control register , Used to control the PCF8591 The function of . Among them the first 3 Position and number 7 The bit is fixed 0, in addition 6 Each bit has its own role , As shown in the figure below , Senior students will introduce one by one .

The... Of the control byte 6 Is it DA Enable bit , This position 1 Express DA Output pin enable , Will produce analog voltage output function . The first 4 Position and number 5 Bit can realize PCF8591 Of 4 Analog inputs are configured into single ended mode and differential mode , The difference between single ended mode and differential mode , We have introduced it in previous articles , Here you only need to know that these two are configuration AD Enter the control bit of the mode .

The... Of the control byte 2 Bit is the automatic increment control bit , Automatic increment means , For example, we have 4 Channels , When we use it all , After reading the passage 0, Read it again next time , Will automatically enter the channel 1 To read , We don't need to specify the next channel , because A/D Every time I read the data , Are the results of the last conversion , So when students use the automatic increment function , Pay special attention to , What you are currently reading is the value of the previous channel . In order to maintain the universality of the program , Our code doesn't use this function , Directly made a general program .

The... Of the control byte 0 Position and number 1 Bit is the channel selection bit ,00、01、10、11 Represents the 0 To 3 Of 4 A channel selection .

Send to PCF8591 The third byte of D/A Data register , Express D/A Voltage value of analog output .D/A Let's introduce , You know the function of this byte . If we just use A/D Function words , You can not send the third byte .

Let's use a program , hold AIN0、AIN1、AIN3 The measured voltage value is displayed on the LCD , At the same time, you can turn the potentiometer , Will find AIN0 The value of has changed . /Lcd1602.c File program source code **/ ( Omit here , Refer to the code in the previous chapter ) /I2C.c File program source code **/

/*****************************main.c File program source code ******************************/

#include <reg52.h>

bit flag300ms = 1; //300ms Timing mark

unsigned char T0RH = 0; //T0 High byte of overloaded value

unsigned char T0RL = 0; //T0 The low byte of the overloaded value

void ConfigTimer0(unsigned int ms);

unsigned char GetADCValue(unsigned char chn);

void ValueToString(unsigned char *str, unsigned char val);

extern void I2CStart();

extern void I2CStop();

extern unsigned char I2CReadACK();

extern unsigned char I2CReadNAK();

extern bit I2CWrite(unsigned char dat);

extern void InitLcd1602();

extern void LcdShowStr(unsigned char x, unsigned char y, unsigned char *str);

void main(){

unsigned char val;

unsigned char str[10];

EA = 1; // General interruption

ConfigTimer0(10); // To configure T0 timing 10ms

InitLcd1602(); // Initialize the LCD

LcdShowStr(0, 0, "AIN0 AIN1 AIN3"); // Display channel indication

while (1){

if (flag300ms){

flag300ms = 0; // Display channel 0 The voltage of

val = GetADCValue(0); // obtain ADC passageway 0 The conversion value of

ValueToString(str, val); // Voltage value converted to string format

LcdShowStr(0, 1, str); // Display on the LCD

// Display channel 1 The voltage of

val = GetADCValue(1);

ValueToString(str, val);

LcdShowStr(6, 1, str);

// Display channel 3 The voltage of

val = GetADCValue(3);

ValueToString(str, val);

LcdShowStr(12, 1, str);

}

}

}

/* Read the current ADC Conversion value ,chn-ADC Channel number 0~3 */

unsigned char GetADCValue(unsigned char chn){

unsigned char val;

I2CStart();

if (!I2CWrite(0x48<<1)){

// Addressing PCF8591, If not answered , Stop the operation and return to 0

I2CStop();

return 0;

}

I2CWrite(0x40|chn); // Write control byte , Select the conversion channel

I2CStart();

I2CWrite((0x48<<1)|0x01); // Addressing PCF8591, Specifies the subsequent read operation

I2CReadACK(); // Read a byte empty first , Provide sample conversion time

val = I2CReadNAK(); // Read the value just converted

I2CStop();

return val;

}

/* ADC Convert the value to the string form of the actual voltage value ,str- String pointer ,val-AD Conversion value */

void ValueToString(unsigned char *str, unsigned char val){

// Voltage value = Conversion result *2.5V/255, Type in the 25 Implied one decimal decimal

val = (val*25) / 255;

str[0] = (val/10) + '0'; // Integer bit character

str[1] = '.'; // decimal point

str[2] = (val%10) + '0'; // Decimal characters

str[3] = 'V'; // Voltage unit

str[4] = '\0'; // Terminator

}

/* Configure and start T0,ms-T0 Timing time */

void ConfigTimer0(unsigned int ms){

unsigned long tmp; // Temporary variable

tmp = 11059200 / 12; // The timer counts the frequency

tmp = (tmp * ms) / 1000; // Calculate the required count

tmp = 65536 - tmp; // Calculate timer overload value

tmp = tmp + 12; // Compensate for the error caused by interrupt response delay

T0RH = (unsigned char)(tmp>>8); // The timer overload value is split into high and low bytes

T0RL = (unsigned char)tmp;

TMOD &= 0xF0; // Zero clearing T0 Control bit of

TMOD |= 0x01; // To configure T0 For mode 1

TH0 = T0RH; // load T0 Overload value

TL0 = T0RL;

ET0 = 1; // Can make T0 interrupt

TR0 = 1; // start-up T0

}

/* T0 Interrupt service function , perform 300ms timing */

void InterruptTimer0() interrupt 1{

static unsigned char tmr300ms = 0;

TH0 = T0RH; // Reload overloaded values

TL0 = T0RL;

tmr300ms++;

if (tmr300ms >= 30){

// timing 300ms

tmr300ms = 0;

flag300ms = 1;

}

}

Students who read the program carefully will find , The program is in progress A/D When reading data , Two programs were used to read 2 Bytes :I2CReadACK(); val = I2CReadNAK(); PCF8591 The conversion clock of is I2C Of SCL,8 individual SCL Cycle completes a conversion , So the current conversion result is always in the next byte 8 individual SCL Can only be read on , So the function of our first statement here is to produce a whole SCL Clock supplied to PCF8591 Conduct A/D transformation , The second time is to read the current conversion result . If we only use the second statement , Every time I read the result of the last conversion .

边栏推荐

猜你喜欢

![[note]vs2015 compilation of masm32 using MASM32 Library](/img/f5/b47336af248d1b485208ec3f9ca12b.png)

[note]vs2015 compilation of masm32 using MASM32 Library

【测试开发】自动化测试selenium(三)——unittest框架解析

单片机:红外遥控通信原理

leetcode.1 --- 两数之和

GoFrame第四天

单片机信号发生器程序

Watering artifact based on Huawei cloud Internet of things (stm32+esp8266)

Wechat payment configuration

![[笔记]vs2015 编写汇编masm32之使用MASM32库](/img/f5/b47336af248d1b485208ec3f9ca12b.png)

[笔记]vs2015 编写汇编masm32之使用MASM32库

LVS four layer load balancing cluster (5) LVS overview

随机推荐

MySQL 8.0 enables remote root user access and solves the problem of you are not allowed to create a user with Grant

[test development] automated test selenium (III) -- unittest framework analysis

5G China unicom AP:B SMS ASCII 转码要求

Lambda end operation find and match findany

Real time requirements for 5g China Unicom repeater network management protocol

Synching build your own synchronization cloud

Lambda end operation count

H5 jump to mobile app store

【愚公系列】2022年06月 .NET架构班 080-分布式中间件 ScheduleMaster的Master集群和数据库切换

Ego planner code analysis ----cmakelists Txt and package xml

Among the four common technologies for UAV obstacle avoidance, why does Dajiang prefer binocular vision

【Web】Cookie 和 Session

Jumpserver: user - system privileged user - Asset - authorization

Determine whether the file encoding format is UTF-8 or GBK

Lambda终结操作查找与匹配findFirst

Big Five personality learning records

【愚公系列】2022年06月 .NET架构班 081-分布式中间件 ScheduleMaster的API自定义任务

5g China Unicom ap:b SMS ASCII transcoding requirements

Installing MySQL 8.0.20 under Linux and ubuntu20.04 LTS

单片机/嵌入式的实时性疑问解答