Hello,

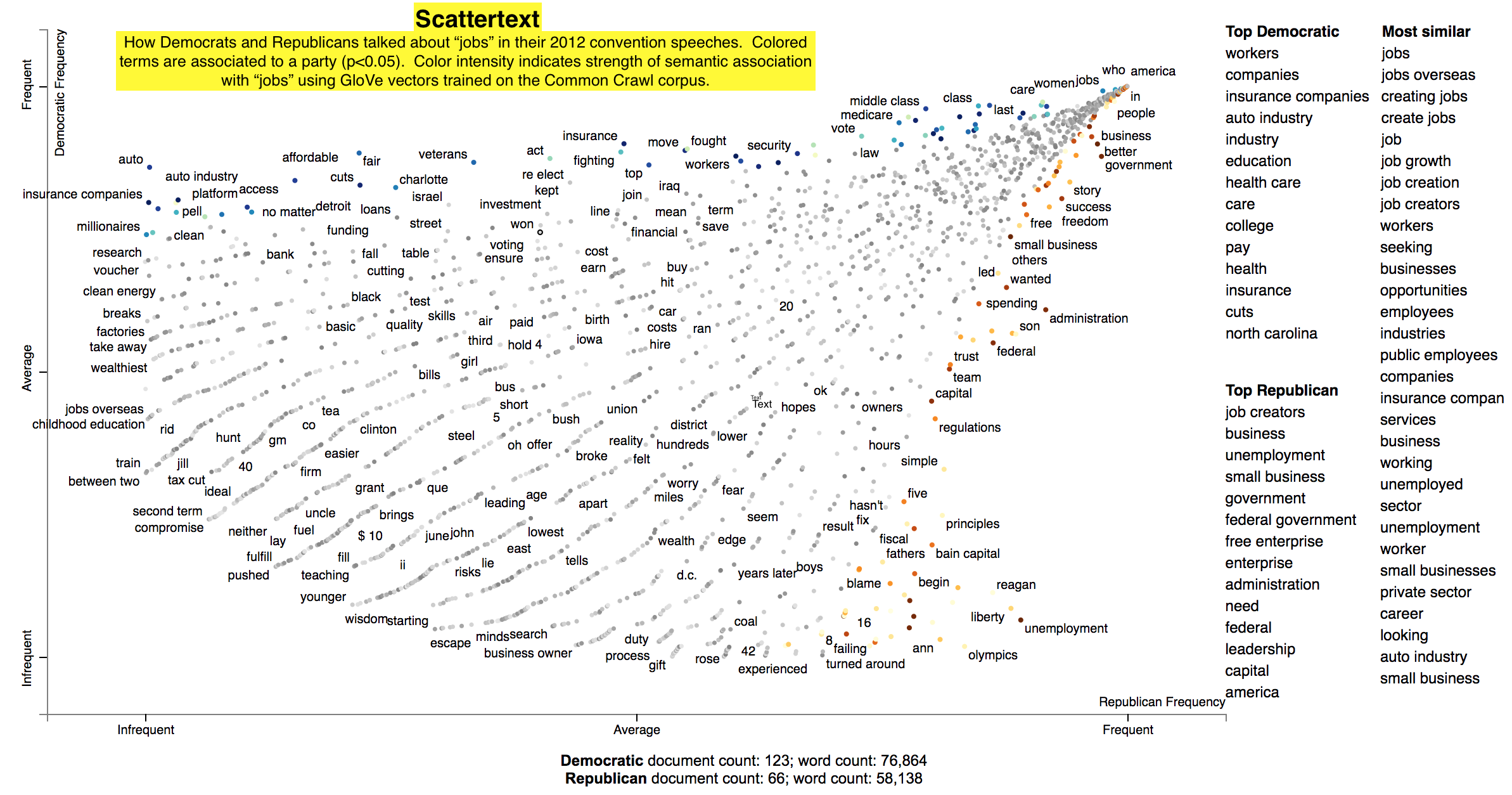

I am playing with the internals of scatter text to utilize Bokeh as the front end visualization. I found for larger corpus's the time for the javascript to load to be excessive. With Bokeh I can serve up the text on the fly and dynamically re-parse the document based on filtering and such. Right now I am using several of the internal functions to generate the term document matrix to populate the graph data.

In my case I am playing with patent text documents. The results are looking very nice so far but I have encountered an issue shown below with the set of 5 documents (I get the same error for a larger set of documents as well). I replicated the problem in Juptyer notebook with a dump of the problematic document set (embedded in issue below as well).

corpus = CorpusFromPandas(df,

category_col='category',

text_col='DESCRIPTION',

clean_function = clean_text,

nlp=nlp).build()

sc = ScatterChartBokeh(corpus)

chart_dict = sc.to_dict(category='a', category_name='a', not_category_name='b',)

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\scipy\stats\_distn_infrastructure.py:1732: RuntimeWarning: invalid value encountered in true_divide

x = np.asarray((x - loc)/scale, dtype=dtyp)

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\scipy\stats\_distn_infrastructure.py:879: RuntimeWarning: invalid value encountered in greater

return (self.a < x) & (x < self.b)

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\scipy\stats\_distn_infrastructure.py:879: RuntimeWarning: invalid value encountered in less

return (self.a < x) & (x < self.b)

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\scipy\stats\_distn_infrastructure.py:1735: RuntimeWarning: invalid value encountered in greater_equal

cond2 = (x >= self.b) & cond0

ValueError Traceback (most recent call last)

<ipython-input-284-557009ffbd72> in <module>()

1 chart_dict = sc.to_dict(category='a',

2 category_name='a',

----> 3 not_category_name='b',)

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\scattertext\ScatterChart.pyc in to_dict(self, category, category_name, not_category_name, scores, transform)

473 if self.scatterchartdata.term_significance:

474 json_df['p'] = df['p']

--> 475 self._add_term_freq_to_json_df(json_df, df, category)

476 json_df['s'] = percentile_min(df['color_scores'])

477 json_df['os'] = df['color_scores']

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\scattertext\ScatterChart.pyc in _add_term_freq_to_json_df(self, json_df, term_freq_df, category)

512 json_df['ncat25k'] = (((term_freq_df['not cat freq'] * 1.

513 / term_freq_df['not cat freq'].sum()) * 25000)

--> 514 .apply(np.round).astype(np.int))

515

516 def _get_category_names(self, category):

C:WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\pandas\util\_decorators.pyc in wrapper(*args, **kwargs)

89 else:

90 kwargs[new_arg_name] = new_arg_value

---> 91 return func(*args, **kwargs)

92 return wrapper

93 return _deprecate_kwarg

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\pandas\core\generic.pyc in astype(self, dtype, copy, errors, **kwargs)

3408 # else, only a single dtype is given

3409 new_data = self._data.astype(dtype=dtype, copy=copy, errors=errors,

-> 3410 **kwargs)

3411 return self._constructor(new_data).__finalize__(self)

3412

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\pandas\core\internals.pyc in astype(self, dtype, **kwargs)

3222

3223 def astype(self, dtype, **kwargs):

-> 3224 return self.apply('astype', dtype=dtype, **kwargs)

3225

3226 def convert(self, **kwargs):

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\pandas\core\internals.pyc in apply(self, f, axes, filter, do_integrity_check, consolidate, **kwargs)

3089

3090 kwargs['mgr'] = self

-> 3091 applied = getattr(b, f)(**kwargs)

3092 result_blocks = _extend_blocks(applied, result_blocks)

3093

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\pandas\core\internals.pyc in astype(self, dtype, copy, errors, values, **kwargs)

469 def astype(self, dtype, copy=False, errors='raise', values=None, **kwargs):

470 return self._astype(dtype, copy=copy, errors=errors, values=values,

--> 471 **kwargs)

472

473 def _astype(self, dtype, copy=False, errors='raise', values=None,

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\pandas\core\internals.pyc in _astype(self, dtype, copy, errors, values, klass, mgr, **kwargs)

519

520 # _astype_nansafe works fine with 1-d only

--> 521 values = astype_nansafe(values.ravel(), dtype, copy=True)

522 values = values.reshape(self.shape)

523

C:\WinPython-64bit-2.7.10.3\python-2.7.10.amd64\lib\site-packages\pandas\core\dtypes\cast.pyc in astype_nansafe(arr, dtype, copy)

618

619 if not np.isfinite(arr).all():

--> 620 raise ValueError('Cannot convert non-finite values (NA or inf) to '

621 'integer')

622

ValueError: Cannot convert non-finite values (NA or inf) to integer

corpus.get_texts().tolist()

[u" The invention may be more completely understood in consideration of the following detailed description of various embodiments of the invention in connection with accompanying figures, in which: is a perspective view of a conventional manual wheelchair with manually operated brake mechanism. is a front view of a conventional manual wheelchair with manually operated brake mechanism. is a rear view of a wheelchair brake mechanism according to an example embodiment of the present invention is a partial exploded rear view of a wheelchair brake mechanism according to an example embodiment of the present invention. is a side view of a wheelchair brake mechanism in an engaged position according to an example embodiment of the present invention. is a side view of a wheelchair brake mechanism in a disengaged position according to an example embodiment of the present invention. is a side view of a wheelchair brake mechanism in an engaged position and showing how portions of said mechanism move to a disengaged position according to an example embodiment of the present invention. is rear partial cross section view of a wheelchair brake mechanism in an engaged position according to an example embodiment of the present invention. is rear partial cross section view of a wheelchair brake mechanism in an engaged position and showing how portions of said mechanism move to a disengaged position according to an example embodiment of the present invention. is a side view of a wheelchair brake mechanism in an engaged position showing how portions of said mechanism move to a disengaged position according to an example embodiment of the present invention. is an enlarged view of according to an example embodiment of the present invention. is a side view of another embodiment of a wheelchair brake mechanism in a disengaged position according to an example embodiment of the present invention. is a side view of another embodiment of a wheelchair brake mechanism in an engaged position according to an example embodiment of the present invention. is a side view of an attendant controlled brake release assembly of a wheelchair brake mechanism according to an example embodiment of the present invention. is an end view of an attendant brake release assembly of a wheelchair brake mechanism according to an example embodiment of the present invention. is a cross section view of an attendant brake release assembly of a wheelchair brake mechanism according to an example embodiment of the present invention. is a side view of an attendant brake release assembly of a wheelchair brake mechanism according to an example embodiment of the present invention. is a side view of a wheelchair brake mechanism according to an example embodiment of the present invention. is a side view of a wheelchair brake mechanism according to an example embodiment of the present invention. is a rear view of a wheelchair brake mechanism according to an example embodiment of the present invention. is a top view of a wheelchair brake mechanism according to an example embodiment of the present invention. is an enlarged view of a portion of . is a side view of an attendant break release assembly and a friction brake assembly according to an example embodiment of the present invention. is a side view of an attendant break release assembly and a friction brake assembly according to an example embodiment of the present invention. is an end view of an attendant break release assembly and a friction brake assembly according to an example embodiment of the present invention. While the present invention is amenable to various modifications and alternative forms, specifics thereof have been shown by way of example in the drawings and will be described in detail. It should be understood, however, that the intention is not to limit the invention to the particular embodiments described. On the contrary, the intention is to cover all modifications, equivalents, and alternatives falling within the spirit and scope of the invention as defined by the appended claims. collectively illustrate a wheelchair with a weight-actuated brake mechanism, indicated by numeral 100, to control the free movement of the wheelchair. Referring generally to , and particularly to , typically two wheelchair brake mechanisms 100(in an exploded view) and 100are attached to a wheelchair 102. Each wheelchair brake mechanism 100and 100controls the rotational movement of each of drive wheels 110and 110respectively. The following description of the wheelchair brake mechanisms 100and 100will be discussed singularly, but it should be noted that it applies equally to both mechanisms 100and 100 The wheelchair brake mechanism 100includes at least one support structure 200 comprising an elongate bar that is pivotally coupled to a portion of the foldable frame 108. Although an elongate bar is shown and discussed as one of the example embodiments, it should also be noted that the support structure 200 may also comprise a rod or other similar component. The support structure 200 is preferably disposed generally between a respective drive wheel 110110and the foldable frame 108. At least a portion of the support structure 200 is disposed generally proximate the drive wheel 110such that it may engage the drive wheel 110and prevent rotational movement thereof as a user enters or leaves the seat 104. Referring to , 5B and 5C, the support structure 200 includes first 202 and second 204 opposed ends. Referring to , the support structure 200 is pivotally couplable to a support bracket 210 that is mountable to a portion of the foldable frame 108 of the wheelchair. In an example embodiment, the support bracket 210 is disposed on a rear portion of the foldable frame 108 defining the backrest of the wheelchair 106. The support bracket 210 is disposed generally proximate a juncture between the backrest 106 and the seat 104 (shown in ). The support bracket 210 includes a plate portion 212 that is mountable to the foldable frame 108 with at least one fastener 214, such as a screw, bolt, or like device. Fastener 214 preferably replaces existing fasteners fastened to the wheelchair 102. By using the pre-existing mounting holes or fastening points on an existing wheelchair, the present invention is easily and quickly retro-fittable to variety of wheelchairs without the need to make modifications such as drilling holes. In one example embodiment, plate portion 212 may have a generally arcuate or curved shape to accommodate the foldable frame 108 of the wheelchair 102. The support bracket 210 also includes a flange portion 216 traversing away from an outer surface of the plate portion 212. A fastener 218 and coupler 219 pivotally couples the support structure 200 to the flange portion 216 of the support bracket 210. Any fastener may be used, such as a bolt and nut that would permit pivotal movement between the support structure 200 and the flange portion 216. To facilitate locking and unlocking the drive wheels 110and 110of the wheelchair 102, the support structure 200 includes at least one braking lever 250 and at least one sensing lever assembly 300 extending away from the first 202 and second 204 ends respectively. Only one brake mechanism 100or 100is necessary to accomplish the desired braking function of the wheelchair 102. However, it is most common to pair a first 100and a second 100braking mechanism with the opposing wheels 110and 110It should be noted that the operation of braking mechanism 100is separate and not dependant on operation of braking mechanism 100and vise-versa. The independent operation is facilitated, in part, by each brake mechanism 100and 100having its own respective sensing lever assembly 300. The braking assembly has a default engaged position, as illustrated in , and disengaged position, as illustrated in . shows the engaged position with the disengaged position superimposed along with directional arrows indicating the direction of movement of the indicated components. In the engaged position, braking lever 250 is disposed adjacent to and confronts a portion of the drive wheel 110preventing it from rotating freely. In the disengaged position, the braking lever 250 is disposed sufficient distance away from the drive wheel 110to allow it to freely rotate. Sensing lever assembly 300 facilitates rotational movement or pivoting of the support structure 200 from the engaged position toward the disengaged position when a user is entering or leaving the wheelchair 102. Referring back to , braking lever 250 traverses away from the support structure 200 and extends generally toward the drive wheel 110In one example embodiment, the braking lever 250 extends away from the support structure 200 at generally a ninety-degree angle, such that the support structure 200 has a generally L-shape. Other angles and shapes such as C-shaped, J-shaped, S-shaped and other similar shapes are also envisioned to be within the spirit and scope of the invention. In one example embodiment of the invention, the braking lever 250 is integral to the support structure 200. In other embodiments of the invention the braking lever 250 may be detachably coupled to the support structure 200 to permit modification according to the wheelchair 102 being outfitted with the brake mechanism 100 Braking lever 250 comprises a generally rectangular plate or bar having a length generally greater than a width of the drive wheel 110The braking lever 250 also has an upper peripheral edge portion 252 and a lower peripheral edge portion 254. The lower peripheral edge portion 254 engages or confronts the drive wheel 110when the support structure 200 is in the engaged position. In an example embodiment, the lower peripheral edge portion 254 is generally linear however; it may also have a generally curvilinear or arcuate shape such that it mimics the arcuate shape of the drive wheel 110The generally arcuate shape provides more surface contact between the braking lever 250 and the drive wheel 110thereby increasing rotational resistance. Continuing with , the brake mechanisms 100and 100include a biasing or tension member 260 such as a coiled spring or adjustable elastomeric strap that is coupled to and extends generally between either the support structure 200 and a portion of the foldable frame 108 or between the braking lever 250 and a portion of the foldable frame 108. The biasing member 260 maintains support structure 200 in the default engaged position, as illustrated in , when a user is not seated in the seat 104 of the wheelchair 102. By having the engaged position as the default position, the drive wheels 110and 110remain locked when the user is not seated, thereby immobilizing the wheelchair 102 and providing a stable structure for the user. Since the wheelchair 102 is immobilized, a user entering or leaving the seat 104 of the wheelchair 102 will have a significantly reduced chance of falling due to the wheelchair 102 coming out from under them. Referring back to , the biasing member 260 includes a first end 262 and a second end 264. The first end 262 is detachably coupled to either the braking lever 250 or the support structure 200. In one example embodiment, the second end 264 is detachably coupled to a portion of the foldable frame 108 such as illustrated in . In this example embodiment, the second end 264 of the biasing member 260 includes a hook or S-shape hook member 265 attached thereto to facilitate detachable coupling of the biasing member 260 to a portion of the foldable frame 108. The second end 264 of the biasing member 260 may be detachably coupled to a portion of the axle assembly 275 of the drive wheel 110extending through a portion of the foldable frame 108 and secured thereto by a coupler 276 such as a nut or similar component. However, the second end 264 of the biasing member 260 may be attached anyplace on the wheelchair 102 that facilitates its ability to maintain the support structure 200 in the engaged position. In other example embodiments of the invention, the second end 264 of the biasing member 260 is coupled to an adjustable coupler 270 that is coupled to a portion of the foldable frame 108 to permit a user to adjust its length and thereby the tension that the biasing member 260 exerts upon the support structure 200. In one example embodiment of the invention, as illustrated in , the adjustable coupler 270 may include a turnbuckle portion 272 and a threaded eyelet or hook portion 274. Rotation of the threaded eyelet portion 274 in a clockwise direction shortens the length of the adjustable coupler 270, thereby requiring the biasing member 260 to be stretched in order for the threaded eyelet portion 274 to be coupled to the foldable frame 108. In another example embodiment, the biasing member 260 comprises an elongate generally elastomeric strap 260 having a plurality of spaced apertures or holes extending along a length thereof. In this example embodiment, adjustment is accomplished by changing the engagement point of the S-shaped hook 265 (or similar engagement device) to different apertures provided in the elastomeric strap. Other types of adjustable couplers 270 are also contemplated and considered to be within the spirit and scope of the present invention. As the user is seated, the support structure 200 moves from the engaged position to the disengaged position. Returning to though 5C, the sensing lever assembly 300 is operably coupled to the support structure 200 and positionable beneath the seat 104 to sense when a user is entering or leaving the wheelchair 102. In one example embodiment, as a user enters the wheelchair 102 the seat 104 travels in a downward vertical direction until it confronts and vertically displaces the sensing lever assembly 300. The downward movement of the sensing lever 300 assembly causes the support structure 200 to pivot or rotate from the engaged position toward the disengaged position. In the engaged position, the drive wheel 110is locked and not freely rotatable. With the user is seated, the support structure 200 in the disengaged position and the wheelchair 102 is freely moveable. Various configurations are contemplated for actuating the sensing lever assembly 300. In one example embodiment, as illustrated in , 6C and 7, the sensing lever assembly 300 comprises a sensor bracket 310 having leg portion 312 pivotally coupled to the support structure 200 and a foot portion 314 transversely extending therefrom that is in operable communication with the seat 104 of the wheelchair 102. The leg portion 312 is generally vertically or perpendicularly oriented with respect to a longitudinal axis of the support structure 200. The foot portion 314 is oriented at a generally ninety degree angle with respect to the leg portion 312 such that the sensor bracket 310 has a generally L-shape. However, other shapes are also contemplated for the sensor bracket 310, including but not limited to C-shaped, U-shaped, and J-shaped. Regardless of the shape utilized, the sensor bracket 310 is oriented such that the foot portion 314 extends generally beneath a portion of the foldable frame 108 defining the seat 104 of the wheelchair 102. Depending upon the weight of the user, it may be advantageous to be able to adjust the distance between the seat 104 of the wheelchair 102 and the foot portion 314. For example, a smaller user weighing less may need to decrease the distance to facilitate the seat 104 of the wheelchair 102 engaging the foot portion 314. A larger user weighing more may increase the distance to permit the user to become fully seated in the wheelchair 102 before the support structure 200 moves from the engaged position to the disengaged position. In one example embodiment of the invention, as illustrated in , 6C and 7, a seat engagement assembly 350 is operably disposed on the foot portion 314 to facilitate adjustment of the distance between the seat 104 of the wheelchair 102 and the foot portion 314. As particularly illustrated in the example embodiment of , the seat engagement assembly 350 comprises a stop 352 having a saddle portion 354 and a shaft portion 356 adjustably disposed on the foot portion 314. The saddle portion 354 has a generally arcuate or curvilinear shape to accommodate a tubular shape of the foldable frame 108. The shaft portion 356 may be threadedly coupled to the foot portion 314, such that rotation of the shaft portion 356 adjusts the height of the stop 352 and thus the distance between the seat 104 of the wheelchair 102 and the foot portion 314. At least one threaded nut, bolt or similar component 358 may be disposed on the shaft portion 356 to secure the stop 352 at a particular height with respect to the foot portion 314. As particularly illustrated in , a plurality of threaded nuts is utilized to secure the stop 352 to the foot portion 314. Other embodiments of the seat engagement assembly 350 may also be utilized. For example, a cable having a pair of opposed ends coupled to the support structures 200 of the braking mechanisms 100and 100may be used. An adjustable pneumatic cylinder and piston rod may also be utilized. shows the sensing lever assembly 300 in the position where the wheel is engaged and no movement is possible. This position corresponds with an absence of a patient seated in the chair. When the patient sits on the seat, the rails 107 of the foldable frame 108 move downward as indicated by the arrows in . The downward movement of the rails causes the seat engagement assembly 350 to move the sensing lever assembly 300 downward as shown, which, in turn, causes the wheel to be released for free movement. A wheelchair 102 with brake mechanisms 100and 100may be further enhanced by providing a means for bypassing the brake mechanism 100and 100when a user is not seated in the wheelchair 102. Such bypass means makes it easier for an attendant to transport an empty wheelchair that would otherwise have the brake mechanisms 100and 100engaged. In example embodiments, as illustrated in , 5B, 5C, 8A-12, and 17-18, a brake release assembly 400 is coupled to the foldable frame 108 and operably coupled to the support structure 200. In one of the example embodiments, the brake release assembly 400 comprises at least one hand release lever 402 pivotally couplable to handles of the wheelchair 102. A linkage 403 is coupled to and extends between the hand release lever 402 and the support structure 200 or braking lever 250. The hand release lever 402 is pivotable between a depressed position or state and released position or state. As an attendant depresses the hand release lever 402 toward the depressed state it pivots the support structure 200 from the engaged position toward the disengaged position. As an attendant releases the hand release lever 402 from the depressed state toward the released stated, the support structure 200 pivots from the disengaged position toward the engaged position. Referring now to and particularly to , the hand release lever 402 includes at least one flange 404 having an aperture or hole 405 for attaching at least one end of the linkage 403. A second end of the linkage 403 is detachably coupled to the support structure 200 or braking lever 250. In one example embodiment, the hand release lever 402 is preferably disposed generally above the handle of the wheelchair 102 to allow gravity to assist an attendant in applying the hand release lever 402. In one example embodiment of the invention, the hand release lever 402 may be manufacture from stainless steel. Additionally, the hand release lever 402 may have a generally textured outer surface and/or a contoured surface to facilitate gripping and/or comfort for an attendant grasping the hand release lever 402. Other configurations, materials and texturing are also contemplated by the present invention. Other materials may include aluminum, composite, polymer, or similar materials. The linkage 403 comprises a generally rigid rod or wire according to one embodiment. Linkage 403 may be manufactured from various other materials such as steel, aluminum, titanium, composite polymer, or fabric. Any device that would link the hand release lever 402 and the support structure 200 may be used and is contemplated by the present invention. A length adjustor 408 may be desirably disposed between a pair of linkage portions 406and 406to adjust an overall length of the linkage 403. The length adjustor 408 is used because the distance between the handles of the wheelchair 102 and the placement of the support structure 200 may vary depending upon the manufacturer of the wheelchair 102. The length adjustor 408 may comprise an elongate tube or cylinder having opposed open ends extending into an interior space thereof. Free ends of the linkage portions 406and 406may extend into the open ends of the length adjustor 408. Fasteners 410, such as screws, bolts or similar components may extend into the length adjustor 408 to engage and secure the linkage portions 406and 406in the interior of the length adjustor 408. Other devices such as turnbuckles may also be used to adjust the overall length of the linkage 403. In another example embodiment, a brake release coupling assembly 450 is provided to facilitate coupling the brake release assembly 400 to the wheelchair 102 without having to modify the wheelchair 102. In this example embodiment, as illustrated in and particularly , the brake release coupling assembly 450 comprises a pair of coupling members 460and 460detachably coupled together about the handle of the wheelchair 102. Referring to , each of the coupling members 460and 460includes a groove, recess or channel 462and 462extending into an inner surface thereof for receiving the foldable frame 108 defining the handles of the wheelchair 102. As illustrated in , when the coupling members 460and 460are coupled together grooves 462and 462define an aperture extending through at least a portion of the coupling members 460and 460As particularly illustrated in , each of the grooves 462and 462has a generally arcuate shape to accommodate the arcuate shape of the foldable frame 108. The grooves 462and 462may have various shapes, such as a generally linear or an approximately right angle depending upon the shape of the foldable frame 108. In another example embodiment, as illustrated in , each of the coupling members 460and 460may include a shoulder portion 466and 466respectively extending generally curvilinearly away therefrom. The grooves 462and 462of the coupling members 460and 460may extend along an inner surface of the shoulder portions 466and 466to accommodate a generally arcuate shape of the foldable frame 108. The coupling members 460and 460may be machined from steel, aluminum, polymers, composites and similar materials. Additionally, the hand release lever 402 and the coupling members 460and 460may have a silver ion coating, which has been shown to kill bacteria, viruses and other pathogens. To assemble the brake release assembly 400 each coupling member 460and 460is positioned adjacent to respective side of the foldable frame 108, such that the handles of the wheelchair 102 extend through the aperture defined by the coupling members 460and 460Referring again to , fasteners 424, such as screws, bolts and similar components, are utilized to couple the coupling members 460and 460together. The hand release lever 402 is pivotally coupled to the coupling members 460and 460with a fastener 426, such as a screw, bolt and similar components. Referring generally to and 8A-10B, and in particular, brake release assembly 400 may include a break release locking mechanism 500 operably coupled thereto to permit an attendant to maintain the support structure 200 in the disengaged position. In one example embodiment, a switch 510 is movably disposed to the coupling members 460and 460to selectively confront and prevent pivoting of the hand release lever 402 from the depressed state toward the released state. As discussed above, the support structure 200 is in the disengaged position when the hand release lever 402 is in the depressed state. Referring particularly to , an end of the switch is pivotally disposed in a notch 631 extending into a lower surface or bottom 632 of each of the coupling members 460and 460 Referring back to , the switch 510 is positionable between a first locked position at A, a second locked position at B, and a released position at C. While the switch 510 is in the released position C, the hand release lever 402 will move freely from the depressed state toward the released state. An attendant can temporarily hold the hand release lever 402 in the depressed state by moving the switch 510 to the first locked position A and letting the flange 404 confront the switch 510. The force exerted on the flange 404 by the biasing member 260 acting on the support structure 200 and the linkage 403 keeps the switch 510 in the first locked position A and prevents the hand release lever 402 from pivoting toward the released position. There are at least two methods for moving the switch 510 from the first locked position to the released C position. The first method occurs when a user sits in the seat 104 of the wheelchair 102. As a user sits down, the support structure 200 pivots from the engaged position toward the disengaged position causing the linkage 403 to at least slightly displace the hand release lever 402. The displacement of the hand release lever 402 reduces the pressure on the switch 510, thereby permitting gravity to act on the switch 510 and move it to the released C position. Permitting movement of switch 510 from the locked position A to the released position C when a user sits in the seat 104 ensures brake mechanism 100will move from the disengaged position toward the engaged position once the user attempts to rise up from the wheelchair 102. The second method of moving the switch 510 from the first locked position A to the released position C occurs when an attendant depresses hand release lever 402. Once the force created by the biasing member 260 acting on the support structure 200 and linkage 403 is removed from the switch 510, gravity freely moves it toward the released position C. An attendant can also keep the hand release lever 402 in the depressed stated by moving the switch 510 to the second locked position B and letting the hand release lever 402 confront switch 510. Once switch 510 is placed in the second locked position B, hand release lever 402 will not be able to move toward the released stated even if it is depressed again or a user sits in the seat 104 of the wheelchair 102. The switch 510 is maintained in the second locked position B, by a securing assembly 560 operably disposed in at least one of the coupling members 460or 460 In one example embodiment, as illustrated in , the securing assembly 560 comprises a coiled spring or other biasing member 562 disposed in a bore 566 extending through the coupling member 460or 460and into the notch 631. An engagement member 564, such as a ball bearing or similar device, is also disposed in the bore 566 and is biased against a portion of the switch 510 when it is in the second locked position B. The bore 566 may have a diameter slightly smaller than a diameter of the engagement member 564 or it may taper toward the notch 631, such that the engagement member 564 is prevented from completely escaping from the bore 566 when the switch 510 in not in the second locked position B. A fastener 568 may also be threadedly disposed in the bore 566 to facilitate removably retaining the securing assembly 560 in the bore 566. To permit the hand release lever 402 to move from the depressed state toward the released state, and simultaneously move the support structure from the disengaged position toward the engaged position, an attendant forces or pivots switch 510 toward release position C, whereby the biasing member 260 and linkage 403 force the hand release lever 402 to move from the depressed state toward the released state. In another embodiment, as illustrated in , a locking collar 570 may be tethered by a strap 572, chain or similar structure to the coupling portions 460and/or 460The locking collar 570 is operably couplable about the hand release lever 402 and the handle of the wheelchair 102 when the hand release lever 402 is in the depressed state. The locking collar 570 may comprise an annular ring or plate having an aperture extending therethrough for receiving the hand release lever 402 and the handle of the wheelchair 102. In other embodiments, the locking collar 570 may comprise a plate or ring having a C-shape, U-shape or similar shapes. In some instances it may not be advisable to have a wheelchair that can move freely when a user or patient is seated; for example, if the patient is suffering from Alzheimer's or other similar diseases that affects a patient's memory. In this instance, as illustrated in , the brake mechanisms 100and 100include only a support structure 200 and a braking lever 250 pivotally coupled to the foldable frame 108. There is no sensing lever assembly 300 to pivot the support structure 200 from the engaged position toward the disengaged position. As discussed above, the biasing member 260 extends between the support structure 200 or braking lever 250 and a portion of the foldable frame 108 to maintain the support structure 200 in the engaged position. When a user sits in the seat 104 of the wheelchair 102 it does not move the support structure 200 and braking lever 250 to the disengaged position. The brake release assembly 400 may be utilized to facilitate transport of either the patient seated in the wheelchair 102 or an empty wheelchair 102. In this example embodiment, the relationship of a user or patient's position in the seat 104 of the wheelchair 102 does not affect the brake mechanisms 100and/or 100In this particular example embodiment, securing assembly 560 may not be disposed in the bore 566 of one of the coupling members 460or 460Instead, a pin or similar structure may be securely or removably disposed therein to prevent the hand release lever 402 from being secured in the depressed state. This arrangement ensures that the wheelchair 102 is always locked unless an attendant is present. An attendant can still temporarily lock hand release lever 402 in position A to transport the wheelchair 102. However, as discussed above, as soon as a user is seated in the wheelchair 102 the switch 510 automatically moves to the released position C to ensure that the wheelchair 102 will be secured if the user attempts to rise up from the wheelchair 102. Occasionally, attendants transporting patients in wheelchairs 102 have to maneuver the wheelchairs 102 down an incline, such as a long sloping driveway, or a wheelchair access ramp of a building. Referring to , a friction brake assembly 600 may be coupled to a wheelchair 102 in conjunction with the brake mechanisms 100and 100Additionally, the friction brake assembly 600 may be used with () or without () the sensing lever assembly 300 pivotally coupled to the support structures 200. In one example embodiment, as illustrated in , the friction brake assembly 600 includes a control lever 610 comprising a plate portion 612 disposed adjacent to a top of the drive wheel 110and/or 110and an anchor portion 614. The plate portion 612 is oriented in a generally horizontal plane such that a lower surface of the plate portion 612 confronts the drive wheel 110and/or 110to slow rotation thereof while the wheelchair 102 is moving either on a flat surface or down an incline. In one embodiment, the anchor portion 614 is disposed between the drive wheel 110or 110and the foldable frame 108 and is oriented at a generally right angle to the plate portion 612. However, it is contemplated that the anchor portion 614 may be oriented at any angle with respect to the plate portion 612. As particularly illustrated in , the anchor portion 614 may be pivotally coupled to the support bracket 210, such that the support structure 200 and the anchor portion 614 have generally the same pivot point. A spacer (not shown) comprising a cylinder, washer or a similar structure, may be disposed between the anchor portion 614 and the support structure 200 to prevent operational interference. The plate portion 612 may have a front edge 620 and rear edge 622 corresponding with a front and rear of the wheelchair 102. The rear edge 622 of the plate portion 612 may have a generally smaller width than the front edge 620 such that the plate portion 612 has a generally triangular shape. The plate portion 612 may have any shape such as generally curvilinear or arcuate to accommodate the curvature of the drive wheels 110and 110Other shapes and configurations such as C-shaped, U-shaped, V-shaped are also contemplated and considered to be within the spirit and scope of the invention. As illustrated in and particularly , an attendant operated friction brake actuation lever 630 is pivotally coupled to the coupling members 460and 460to actuate the control lever 610. The brake actuation lever 630 is positioned generally below the handle of the wheelchair 102 and oriented generally parallel to the handle of the wheelchair 102. As shown in , the brake actuation lever 630 is pivotally disposed in an aperture 632 defined by grooves 634and 634extending into inner surfaces of the coupling members 460and 460 Referring to , a linkage 640 is coupled to and extends between the brake actuation lever 630 and either the plate portion 612 or the anchor portion 614 of the control lever 610. A length adjuster 408 may be disposed between a pair of linkage portions 642and 642to adjust an overall length of the linkage 640. The adjustment of the linkage 640 is identical to the adjustment of the linkage 403 described in detail above. In operation, as the wheelchair 102 accelerates down the incline, the attendant can squeeze the friction brake actuation lever 630 toward the handle of the wheelchair 102, and concurrently the linkage 640 pivots the control lever 610 causing the plate portion 612 to engage the drive wheel 110and/or 110By releasing the brake actuation lever 630, the plate portion 612 pivots away from and disengages the drive wheel 110and/or 110 In one embodiment, some or all of the components of the present invention are made from materials capable of withstanding the temperatures or harsh chemicals associated with autoclaving or sterilization. The materials capable of being autoclaved or sterilized include, but are not limited to, stainless steel, aluminum, composite polymers, and other materials known to one skilled in the art. Details of the present invention may be modified in numerous ways without departing from the spirit or scope of the present invention. For example, adjustable turnbuckles that adjust spring tension for different weight users could be replaced with a metal strap with a series of holes for different weight settings. Also, the hand release handles could utilize a clamp mounting mechanism to mount the handle on the back of the chair so that there would be no holes to drill to mount the brake system to the wheelchair. Various components of the present invention may be altered in shape or size without affecting the functionality of the device. Those skilled in the art will recognize other modifications or alternatives of the present invention without departing from the spirit or scope thereof. Although the present invention has been described with reference to particular embodiments, one skilled in the art will recognize that changes may be made in form and detail without departing from the spirit and scope of the invention. Therefore, the illustrated embodiments should be considered in all respects as illustrative and not restrictive. ",

u" The advantages of this invention will become apparent upon consideration of the following detailed disclosure of the invention, especially when taken in conjunction with the accompanying drawings wherein: is a schematic elevational view of a first embodiment of a powered running board for use on automotive vehicles, the lowered operating position of the running board and associated linkage being shown in phantom; is a schematic elevational view of a second embodiment of a powered running board for use on automotive vehicles depicting the range of movement available to such running board configurations, the lowered operating position being shown in phantom; is a schematic representation of the control mechanism for use with automotive powered running boards; and is a logic flow diagram for the process of controlling a powered running board. Referring to , a control mechanism for a powered running board on an automotive vehicle incorporating the principles of the instant invention can be seen. The powered running board 10 can be manufactured in a number of different configurations. One representative configuration for the powered running board apparatus 10 is shown in . This configuration of running board is pivotally movable between a raised stored position 12 (shown in solid lines) and a lowered operating position 13 (shown in phantom), thus defining a range of operating movement 14 therebetween. The running board 15 is connected to a pivot mechanism 17, shown in as a four bar linkage 18, to pivotally support the running board 15 throughout the range of movement 14. An actuator 19 powers the pivotal movement of the four bar linkage 18, and is typically a linear actuator 19, or an electric motor configured to convert rotary motion of the motor into linear movement of the four bar linkage 18. The four bar linkage 18 keeps the tread or step surface of the running board 15 level throughout the range of operation. Referring now to , a different embodiment of a powered running board is depicted. In this configuration, the running board 15 is supported on threaded upright members 21 that are received within corresponding threaded receivers 22. An actuator 25, typically in the form of an electric motor 26, rotates the threaded receiver to transmit translational movement of the threaded upright member 21, thus raising and lowering the running board 15 between the raised stored position 12 (shown in solid lines) and the lowered operating position 13 (shown in phantom lines), defining the range of operating movement 14 therebetween. As one of ordinary skill in the art will recognize, the threaded receivers 22 must be rotationally supported on the frame 5 of the automotive vehicle by bearings or the like (not shown) and coupled to the actuator 25. To effect parallel movement of the running board 15, all of the threaded receivers 22 will simultaneously rotated to cause translational movement of the corresponding upright members 21. The use of an electric motor 26 for the actuator 19, 25 provides the ability to have significant control of the operation of the powered running board 15. Electronic sensors can sense the position or the extent of rotation of the electric motor 26 and, thus, provide consistent repeatability of the position of the electric motor 26 whenever the actuator 19, 25 is engaged. Accordingly, the vertical position of the running board 15 within the operating range 14 can be repeated with great accuracy, irrespective of the configuration of the apparatus permitting vertical movement of the running board 15. Referring now to , a schematic diagram of the control system 30 incorporating the principles of the instant invention can best be seen. The control system 30 includes a central control module 31 operable to receive and transmit signals to the other components of the system 30. The control module 31 is electrically connected to the drive mechanism 19, 25, 26 for each of the left and right side running boards 15 independently to permit individual operation thereof. The control module 31 is also electrically connected to a position switch mechanism 33 that is used to manually operate each of the left and right side motors 26 for the corresponding running boards 15. The switch mechanism 33 can include individual switches for the left and right side operation or a single switch with a cooperative left/right operational switch. Typically, this switch mechanism 33 will include a toggle switch or the equivalent to permit use thereof in the up and down directions. The control module 30 is also connected to a memory module 35 which can be a part of the existing memory module (not shown) in modern automotive vehicle to control positions of mirrors and seats, or the memory module 35 can be a separate memory bank that is incorporated into the control module 31. Ancillary to the memory module 35 can be an optional selector switch 37 that is operative to store in the memory module 35 selected positions for multiple users or other pre-set positions that can be stored in the memory module 35. During operation, the control module 30 can provide a drive signal 41 to each respective left and right drive motor 26 to effect operation thereof to move the corresponding running board 15 in the desired direction. Each drive motor 26 is also operative to provide a feedback signal 43 to the control module 31 to indicate the rotated position of the drive motor 26 being operated, and consequently, the operating position (vertical height) of the corresponding running board 15. The control module 31 is also operable to receive input signals from various components of the vehicle to indicate status of the component to provide an operative interlock system through the control module 31. For example, the opening of a door (not shown) can initiate power to the drive motor 26 for the corresponding running board 10. A sensor can provide an input signal 44 to the control module 31 to be indicative of whether the vehicle is moving or if the transmission is in a predetermined position, thus controlling the transmission of the drive signal 41. In operation, as reflected in the logic flow diagram of , the input signal from one or more vehicle sensors at step 51, such as the signaling of the opening of a vehicle door at step 52, initiates the query as to whether all conditions permit the deployment of the running boards at step 55. For example, the opening of the door at step 52 would normally initiate the deployment of the running board 10 on the corresponding side of the vehicle; however, should another sensor indicate that the vehicle is moving, deployment of the running board 10 should not be started. Accordingly, if all of the sensed vehicle conditions at step 55 indicates that deployment should not occur, then changing vehicle conditions at step 53 would be repeated until all the preselected sensor criteria is met. At step 57, the subsequent query is whether a memory position has already been stored in memory. If not, the running board 10 would have to be manually deployed through the switch 33 at step 58 until a desired position is established and that position is then automatically stored in the memory module 35 at step 59. If the memory module 35 already has a position stored, the next query at step 60 is whether multiple positions are stored. If so, user identification needs to be inputted prior to step 61 and deployment of the running board 10 is then accomplished at step 62 according to the position selected from the memory module 35. If multiple positions are not stored in the memory module 35, the running board 10 is deployed to the last stored position at step 65. Once the vehicle door is closed at step 67, the running board 10 is then returned to the retracted position 12 at step 68. The control system 30 will also be operative to deploy the running board to the last deployed position when the vehicle door is opened from the outside, assuming that all other conditions at step 51 are satisfied. Assuming that the vehicle is parked and is not being operated, the driver would approach the vehicle and open the door in a normal manner. The process would go through the steps from step 52 with the sensor indicating the opening of the vehicle door. Since the vehicle is parked and not operating, all of the other preselected conditions should be satisfied at steps 51 and 55. Assuming further that the vehicle had been previously operated or otherwise has a pre-stored position of deployment in the memory module 35, the query at step 57 is positively answered. At step 60, no user identification would have been provided so the running board 10 would then be deployed to the previously deployed position at step 65. One skilled in the art will realize that the memory module 35 could also be used to store pre-set deployment positions, such as 50% or 100% of the movement range 14, being used in deployment of the running board 10. Such pre-established deployment positions could be used in lieu of the user defined positions inputted by the control 37 and the process at step 61. The last stored position will be saved in the memory module 35 until a new position is stored therein. Accordingly, once the position of the running board 15 is stored in the memory module 35, the control module 31 will send a drive signal 41, when properly initiated, until the feedback signal 43 indicative of the return of the running board 15 to the pre-selected position has been obtained from the corresponding drive motor 26. With the utilization of the proper vehicle input signals 44, the control module 31 can be operative to return the running board 15 to the raised stored position 12 whenever the door (not shown) is closed and automatically back to the last selected stored operative position whenever the door is opened. One skilled in the art will recognize that this control system 30 can be utilized to operate the running boards 15 on both sides of the vehicle or, alternatively, on just the driver's side of the vehicle with the passenger side being a conventional mechanical or normal powered movable running board 15. The position switches 33, 37 can be appropriately positioned for access by the proper occupant of the vehicle. It will be understood that changes in the details, materials, steps and arrangements of parts which have been described and illustrated to explain the nature of the invention will occur to and may be made by those skilled in the art upon a reading of this disclosure within the principles and scope of the invention. The foregoing description illustrates the preferred embodiment of the invention; however, concepts, as based upon the description, may be employed in other embodiments without departing from the scope of the invention. ",

u' shows a perspective view of a split bench seat incorporating the subject invention; is a view similar to but showing one seat portion in a tumbled position; is a view similar to but showing the entire seat in a tumbled position; shows a perspective view of an alternate seat configuration incorporating the subject invention; is a perspective rear view, partially broken away, of a cantilever mounted split bench seat; is a perspective view of a seat attachment structure incorporating the subject invention; is a perspective view of a striker/latch mechanism as utilized in the seat attachment structure of ; and is a perspective view of a cross member from the seat attachment structure of positioned over a fuel tank. shows a seat assembly 10 having a seat attachment structure 12 for mounting the seat assembly 10 to a vehicle underbody 14. The seat attachment structure 12 includes a seat bracket assembly that provides a common bracket configuration that can be used to mount any type of seat configuration. For example, in a second row of vehicle seats, the common bracket configuration can be used to mount either a pair of seats 16, 16separated by an aisle 18 (see ) or a split bench seat 20, as shown in . In either of these configurations, seats are unlatched and pivoted to a tumbled position to increase cargo space within a vehicle as needed. While the seat attachment structure 12 is described has being particularly beneficial to a second row configuration, it should be understood that seat attachment structure 12 could also be beneficial to other seating row configurations. The split bench seat 20 of , also referred to as a 60/40 split option, includes a first seat portion 20positioned on one lateral vehicle side, a second seat portion 20positioned on an opposite lateral vehicle side, and a third seat portion 20positioned between the first 20and second 20seat portions and supported by the second seat portion 20. As shown, the first seat portion 20is split from the second 20and third 20seat portions at 22. The first seat portion 20can be tumbled separately (see ) from the second 20and third 20seat portions to allow access to a third row of seating. The second 20and third 20seat portions can also be tumbled along with the first seat portion 20to increase cargo space, as shown in . The third seat portion 20is cantilevered mounted to the second seat portion 20at one lateral seat side 24 and is unsupported at an opposite lateral seat side 26 as indicated by gap 28. This feature allows the common bracket configuration to be used. In other words, the same bracket is used to mount a pair of seats 16, 16to the vehicle underbody 14 as is used to mount the split bench seat 20 to the vehicle underbody 14. This feature will be discussed in greater detail below. The third seat portion preferably has seat integrated restraints (SIR) 30 (see ). The SIR 30 includes a seat belt assembly having a lap belt portion and a shoulder belt portion. The SIR 30 has both lap belt and shoulder belt attachment points going directly to the third seat portion 20. This configuration makes installation of the split bench seat 20 into the vehicle more efficient and more cost effective, as well as providing an aesthetically pleasing appearance. The first 20and second 20seat portions preferably have seat restraint assemblies with attachment points supported by a vehicle frame member. The bench seat 20 with SIR 30 should include a very robust seat attachment structure 12. The seat attachment structure 12 can accommodate high seat loads including all seat loading for the third seat portion 20. The seat attachment structure 12 includes a unique seat bracket assembly 32 that effectively transfers the loads to vehicle body structures. The seat bracket assembly 32 includes a rear cross member 34 that extends in a generally lateral direction between first 36 and second 38 side rails. The first 36 and second 38 side rails extend in a generally longitudinal direction with the first side rail 36 being positioned on one lateral vehicle side 40 and the second side rail 38 being positioned at an opposite lateral vehicle side 42. The rear cross member 34 is fastened and/or welded at opposing ends to each of the first 36 and second 38 side rails. The rear cross member 34 includes a main body 50 with at least first 52 and second 54 extensions that are integrally formed within the main body 50. The first 52 and second 54 extensions extend in the longitudinal direction. A front cross member 56 extends in the lateral direction and is longitudinally spaced apart from the rear cross member 34. Thus, the front 56 and rear 34 cross members are generally parallel to each other, while the first 52 and second 54 extensions and the first 36 and second 38 side rails are generally parallel to each other. The seat bracket assembly 32 also includes first 60 and second 62 longitudinal members extending between the front 56 and rear 34 cross members. The first 60 and second 62 longitudinal members are generally parallel to the first 36 and second 38 side rails and are generally perpendicular to the front 56 and rear 34 cross members. The first longitudinal member 60 is attached at one end 64 to the first extension 52 and at an opposite end 66 to the front cross member 56. The second longitudinal member 62 is attached at one end 68 to the second extension 54 and at an opposite end 70 to the front cross member 56. A first striker 72 is mounted to the first extension 52 and a second striker 74 is mounted to the second extension 54. A third striker 76 is mounted to the first side rail 36 and a fourth striker 78 is mounted to the second side rail 38. As shown in , latches 80 (only one is shown) are mounted on the seats 16, 16, or 20, 20, 20and cooperate with the first 72, second 74, third 76, and fourth 78 strikers to selectively release the seats 16, 16or 20, 20, 20from the strikers 72, 74, 76, 78, allowing the seats 16, 16or 20, 20, 20to be moved to a tumbled position. A front mount provides pivotal movement to facilitate tumbling as known. The first extension 52 includes first 82 and second 84 mount portions that are separated by a first opening 86 and the second extension 54 includes third 88 and fourth 90 mount portions that are separated by a second opening 92. The first 86 and second 92 openings each include an apex 94 that extends into the main body 50. The first striker 72 extends across the first opening 86 and has one striker end mounted to the first mount portion 82 and an opposite striker end mounted to the second mount portion 84. The second striker 74 extends across the second opening 92 and has one striker end mounted to the third mount portion 88 and an opposite striker end mounted to the fourth mount portion 90. A transversely extending flange 96 is formed about a perimeter that defines the openings 86, 92. The transversely extending flange 96 increases structural strength. The first 86 and second 92 openings are preferably horseshoe or U-shaped openings; however, other opening shapes could also be used. The transversely extending flanges 96 preferably extend continuously about the perimeter that defines the U-shaped openings. Optionally, straps 98 could be mounted to the first 52 and second 54 extensions, respectively. shows an example of a strap 98. In this embodiment, one strap 98 would extend underneath the first longitudinal member 60. One strap end is mounted to the first mount portion 82 and an opposite strap end is mounted to the second mount portion 84. The strap ends are positioned on an opposite face of the first extension 52 from the first striker 72. A similar strap configuration would be used with the second longitudinal member 62 and second extension 54. Each strap end, as well as each striker end, is preferably bolted to the respective first 82, second 84, third 88, or fourth 90 mount portion with a single bolt 100, however, other attachment methods could also be used. The bolts 100 are also used to attach the first 72 and second 74 strikers to the first 52 and second 54 extensions. The straps 98 are preferably made from steel. The straps 98 provide an extra metal stack-up that prevents the bolts 100 that are used to attach the first 72 and second 74 strikers to the first 52 and second 54 extensions from pulling through a floor structure under high seat loads. As shown in , the rear cross member 34 is positioned vertically above, i.e. extends laterally over, a fuel tank 102. The fuel tank 102 is preferably a saddle type fuel tank that has a first lateral tank portion 104 and a second lateral tank portion 106 in fluid communication with each other via a narrower center tank portion 108. The first extension 52 is positioned on one side of the center tank portion 108 and the second extension 54 is positioned on an opposite side of the center tank portion 108. This configuration results in improved energy absorption properties. In order to further enhance the energy absorption properties of the rear cross member 34, the rear cross member 34 and first 52 and second 54 extensions are preferably formed from an ultra-high strength steel grade DP600 material. DP600 has excellent mechanical hardening properties. DP600 also has higher deformability, higher yield strength, and higher ultimate strength properties than steel materials traditionally used to form seating brackets. The high energy absorption, excellent work hardening and bake hardening properties of DP600 in combination with the structural configuration of the rear cross member provides excellent system integrity. Energy absorption is further enhanced by the vehicle underbody 14, i.e. the vehicle floor 14. The vehicle floor 14 is preferably formed from a front portion at the front of the seat assembly 10, shown most clearly in , and a rear portion at the rear of the seat assembly 10, shown most clearly in . The front portion of the vehicle floor 14 is preferably thicker than the rear portion, which assists in preventing forward seat travel during seat pull and which also minimizes local buckling. As discussed above, the seat attachment structure 12 includes the third striker mounted 76 to the first side rail 36 at one lateral vehicle side 40 and the fourth striker 78 mounted to the second side rail 38 at an opposite lateral vehicle side 42. The first 72 and second 74 strikers are positioned between the third 76 and fourth 78 strikers. In the split bench seat configuration, the first 72 and third 76 strikers provide the tumble feature for the first seat portion 20and the second 74 and fourth 78 strikers provide the tumble feature for the second 20and third 20seat portions. In the seat configuration with two separate seats 16, 16, the first 72 and third 76 strikers provide the tumble feature for one seat 16and the second 74 and fourth 78 strikers provide the tumble feature for the other seat 16 Thus, in either seating configuration, the seat bracket assembly 32 includes eight total attachment points for attaching seats 16, 16or 20, 20, 20to the vehicle underbody 14. There are four striker attachment points located at the rear of the seats 16, 16or 20, 20, 20and four pivot attachment points located at the front of the seats 16, 16or 20, 20, 20. The four striker attachment points comprise a first striker attachment point at the first strike 72, a second striker attachment point at the second striker 74, a third striker attachment point at the third striker 76, and a fourth striker attachment point at the fourth striker 78. The four pivot attachment points comprise a first pivot attachment point between one end of the front cross member 56 and the vehicle underbody 14, a second pivot attachment point between an opposite end of the front cross member 56 and the vehicle underbody, a third pivot attachment point between the front cross member 56 and the first longitudinal member 60, and a fourth pivot attachment point between the front cross member 56 and the second longitudinal member 62. As discussed above, in the split bench seat configuration, the third seat portion 20is cantilevered mounted at one lateral seat side 24 to the second seat portion 20and is unsupported at an opposite lateral seat side 26. In the configuration shown, the third seat portion 20is mounted at the one lateral seat side 24 at the second striker attachment point and at the fourth pivot attachment point. In other words, the third seat portion 20is only supported along the second longitudinal member 62. The third seat portion 20is supported at the second striker 74 mounted to the second extension 54 of the rear cross member 34, and at a pivot mount where the second longitudinal member attaches to the front cross member 56. The third seat portion 20is unsupported at the opposite lateral seat side 26 as indicated by the gap 28 between a seat bottom 110 of the third seat portion 20and a floor structure. The combination of a cantilevered SIR seat with a tumble option is very unique in the industry. Further, having the rear cross member 34 and first 52 and second 54 extensions formed from DP600 used in combination with the first 60 and second 62 longitudinal members provides a very robust seat/underbody joint that can accommodate high seating loads for this unique seating combination. It should be understood that various alternatives to the embodiments of the invention described herein may be employed in practicing the invention. It is intended that the following claims define the scope of the invention and that the method and apparatus within the scope of these claims and their equivalents be covered thereby. ',