当前位置:网站首页>Comparison between winding process and lamination process

Comparison between winding process and lamination process

2022-06-29 00:24:00 【Double vision】

At present, what restricts the development of pure electric vehicles is the mileage and the efficiency of supplementary energy , The core component that limits these two points is the power battery technology . At present, the mainstream power battery cells in the industry are divided according to the manufacturing process , It can be divided into winding process and lamination process . Different manufacturing processes will directly affect the core indicators of the battery, thus affecting some performance characteristics of pure electric vehicles .

As an important part of lithium battery manufacturing , Lamination and winding technology has been widely concerned by academic and commercial circles . Coating the positive and negative electrode sheets 、 dry 、 Striping 、 After slitting , The assembly process of electrode sheets will be carried out , The unpacked cell can be divided into lamination and winding processing .

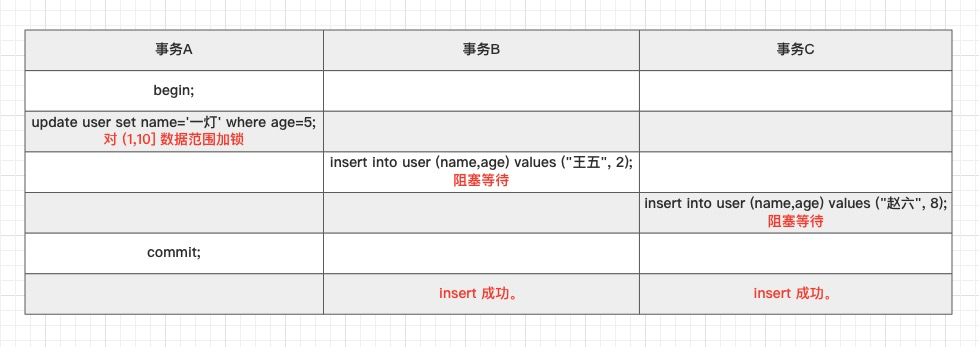

▲ Schematic diagram of comparison between winding process and lamination process

Lamination process It is to divide the coated positive and negative agent layer into initial sizes , Then, the positive bonding agent layer is deposited in sequence 、 The diaphragm 、 The negative bonding agent layer is bonded , There will be more “ Sandwich ” The structural layers are overlapped in parallel , An electrode chip core that can be encapsulated is formed . The continuity of gasket process depends on the diaphragm “Z” Zigzag bend , Put the positive and negative electrodes on the diaphragm continuously , The diaphragm “Z” The glyph goes through it , Separate the poles , Finally, wrap the shell .

One . Summary of advantages and disadvantages of lamination process

// advantage

I. High capacity density : The internal space of lithium battery is fully utilized , Therefore, compared with the winding process , Volume is higher than capacity ;

II. High energy density : The discharge platform and volume specific capacity are both higher than those of the winding lithium battery , So the energy density is relatively high ;

III. Flexible size : The size of each pole piece can be designed according to the size of lithium battery , Thus, the lithium battery can be made into any shape .

// Inferiority

I. Easy to solder : All pole pieces shall be spot welded to one spot , Difficult to operate and easy to solder ;

II. Equipment efficiency is slow : At present, the efficiency of domestic laminating machine is mostly 0.8s/ The rate of the slice , Imported laminating machine 0.17s/ There is a big difference in the efficiency of the chips .

Winding process It is winding by fixing the winding needle , The positive pole piece treated in the early stage 、 The diaphragm 、 The negative pole pieces are wound and extruded in sequence . The specific process is to press the raw material as the negative electrode 、 The diaphragm 、 Positive pole 、 The order of the diaphragms is stacked together , It is directly rolled into a cylindrical or elliptic cylinder by the winding method , Then put it in the metal shell of square shell or cylinder .

Two . Summary of advantages and disadvantages of winding process

// advantage

I. High internal resistance : Normally, the positive and negative electrodes have only a single lug ;

II. Easy electric welding : Each lithium battery only needs to be welded at two places , Easy to control ;

III. Production control is relatively simple : A lithium battery has two poles , Easy to control .

// Inferiority

I. Single shape : It can only be made into cuboid lithium battery ;

II. Poor heat dissipation effect : It is difficult to take thermal isolation measures between cells , It is easy to cause local overheating , This causes the heat to spread out of control .

It is mainly explained from two aspects of the electrical performance and processing technology of the electric core :

// Electrochemical performance

1. Internal resistance difference

Batteries manufactured by the lamination process have low internal resistance , The battery made by winding process has high internal resistance . Because the winding process of the cell usually uses a monopole ear to output current , The lamination process is a parallel welding of multiple pole lugs , This method greatly reduces the lithium ion migration path in the charge and discharge process . The lower internal resistance improves the heating condition of the cell in use , Thus, the attenuation rate of the initial energy density of the cell is optimized , Therefore, the battery capacity of the lamination process decays more slowly .

2. Cycle life difference

With the normal use of the battery, the charging and discharging process accumulates , After heat generation in the cell, the working temperature of the cell is affected . For cells manufactured by lamination process , The internal structure is uniform , It can also distribute heat evenly , Including good heat dissipation capacity ; And the winding process makes the electric core , The internal structure and mechanical performance show gradient changes , The heat dissipation direction between the pole piece and the diaphragm is uneven , This results in the temperature gradient distribution , It is easy to cause slow heat dissipation in the inner circle 、 Fast heat dissipation in the outer ring . The concentrated high temperature will also affect the phase structure and electrochemical performance of battery active materials , Resistance to lithium ion deinterlacing caused by long-term use , It also makes the battery show the phenomenon of rapid capacity decay , That is, the battery cycle is short .

3. Difference in mechanical stress of electrode piece

Two kinds of electrode sheet treatment process lead to different internal mechanical stress performance of the battery . The stress areas between the electrode sheets manufactured by the lamination process are the same , There is no obvious stress concentration point , In addition, it is not easy to damage the electrode material layer in the process of charging and discharging . The winding process produces stress concentration at the bend of the cell . According to the experience of battery analysis , The bending part of the winding is more prone to structural damage under the stimulation of electrical signals , And cause short circuit and lithium metal precipitation . The stress concentration point is the initial position that mainly causes battery failure , It also leads to short cycle life of the winding process .

4. The battery magnification performance is different

Lamination process is equivalent to multi pole pieces connected in parallel , It is easier to complete large current discharge in a short time , It is beneficial to the battery's magnification performance . The winding process is just the opposite , A single polar lug leads to slightly poor magnification performance .

5. Energy density design differences

The battery made by lamination process can support higher energy density , The main reason is that the lamination processing method can make better use of the packaging space , Increase the filling of effective materials ; And the battery made by the winding process , The electrode piece has a curved circular structure , And the double diaphragm structure used occupies a certain space , Failed to achieve higher space utilization , This will result in a lower energy effect .

// Treatment process

1. Electrode sheet manufacturing difference

Compared with the production method of laminations , The mode of winding production, the degree of automation and the suppliers of supporting equipment are in the mature stage , And at present, most of the cell manufacturers use the winding production process . However, the equipment and supporting links of the lamination process are slightly complicated , The requirements for the qualified rate of pole piece cutting are extremely strict . generally speaking , The cutting of winding mode is mainly at the two nodes of starting and ending winding of the electric core , The lamination cutting needs long-term and accurate control , Each pole piece has to undergo four knife cutting , And the cross section of the pole piece 、 Powder drop 、 Burr and other conditions need to be controlled , The requirements for pole piece consistency are quite high .

2. Battery manufacturing differences

The operation of manufacturing battery by winding process is relatively simple , Both semi-automatic equipment and full-automatic equipment can efficiently complete the assembly and packaging of electric cells . It is complicated to manufacture batteries by lamination process , A higher proportion of manual operation is required , And because the equipment industry chain is not mature , Automated production is difficult to replicate on a large scale .

in addition , In terms of battery quality control , The type of winding process is easier to control , Lamination process manufacturing is difficult to obtain good consistency because of complex process links .

In general , Battery manufacturers need to design the production process according to battery quality requirements and cost control , Before and after the optimization of electrode sheet treatment process , About pole piece cutting and welding 、 There will be great changes in the assembly process .

边栏推荐

猜你喜欢

How many locks are added to an update statement? Take you to understand the underlying principles

Easy to use free ppt template

Remove HTML tags from Oracle

MSYQL is abnormal. Don't worry. Mr. Allen will point out the puzzle

With notes: insert sort --from WCC

12.物体检测Mask-Rcnn

6.28 学习内容

Cross domain problem of canvas drawing caused by background image cache

Daily question 1: remove elements

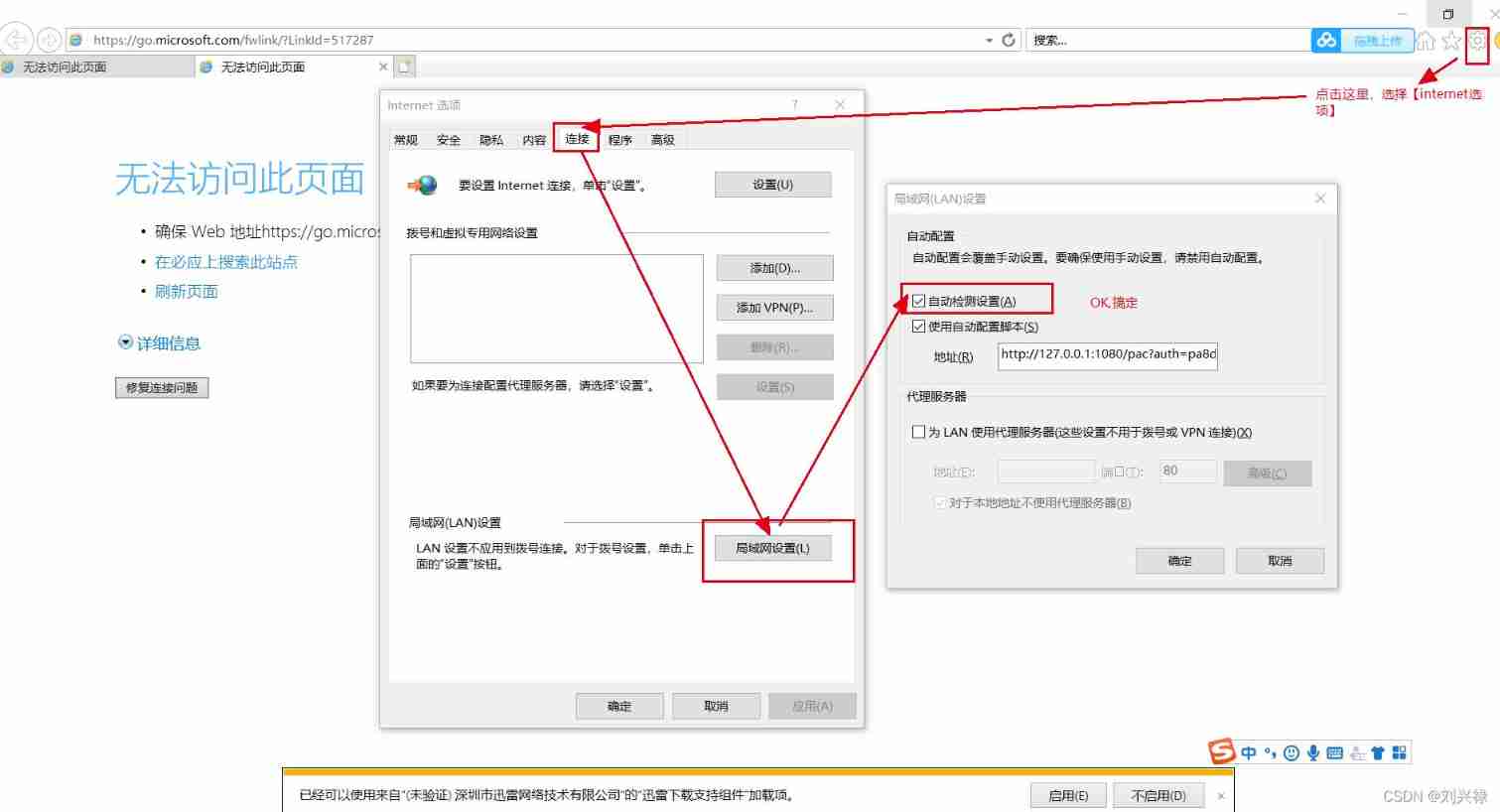

Baidu online disk login verification prompt: unable to access this page, or the QR code display fails, the pop-up window shows: unable to access this page, ensure the web address....

随机推荐

[image denoising] matlab code for removing salt and pepper noise based on fast and effective multistage selective convolution filter

TypeScript--第四节:函数

Technology sharing | software development process that you must understand if you want to get started with testing

养老年金险是理财产品吗?预期收益在哪看?

With notes: re understanding else if

Three PWN questions

Leetcode daily question: implementing strstr()

MapReduce case

Click hijack: X-FRAME-OPTIONS is not configured

Along with the notes: methods simulating array like classes

11.目标分割

TypeScript -- 第七节 枚举

[image registration] SAR image registration based on particle swarm optimization Improved SIFT with matlab code

Matrix compression

Basic use of Chrome browser

Test experience: how testers evolve from 0 to 1

SCP copy folder

由背景图缓存导致的canvas绘图跨域问题

Daily question 1: remove elements

TypeScript -- 第六节 泛型