当前位置:网站首页>What are the key points of turnover box management in warehouse management

What are the key points of turnover box management in warehouse management

2022-06-26 07:37:00 【Dark blue easy net】

Use of turnover box , It can greatly ensure the standardized implementation of cargo transportation , Provide sufficient quality for the product 、 Safety guarantee . At the same time, good turnover box management can reduce logistics costs .

So now more and more enterprises use turnover boxes ( The turnover box referred to here , Standard plastic boxes are included 、 Tray 、 Station apparatus, etc ).

At the same time, as the supply chain management becomes more and more close , The management of turnover boxes has also been raised to a new level , A well functioning turnover box system enables suppliers' turnover boxes to be directly put into the production process of the factory , It improves the timeliness and accuracy of material supply , At the same time, it can effectively improve the overall efficiency of the supply chain .

Warehouse , As the receiving and sending party of materials , It is bound to be the direct face of turnover box management .

Therefore, it is appropriate for the warehouse to take the lead in implementing a reasonable turnover box management scheme .

Turnover box management is generally based on objects , Sub supplier weekly box transfer management and customer turnover box management .

Supplier weekly transfer management

Before managing the turnover box , We need to do a calculation . Calculate in order to ensure supply , How many turnover boxes are needed on a complete chain .

The formula should be like this :“ Total investment = Supplier inventory + Quantity of goods in transit + Company inventory ( safety stock + Normal use )+ Quantity of empty containers returned in transit ”. Both parties must agree on this calculation method , To ensure that there are enough turnover boxes put into use .

Then we can start making plans :

1. Make sure the turnover box meets the packaging specification .

2. Determine that the property belongs to the supplier , The factory is only responsible for keeping .

3. Confirm the receiving method of turnover box , A delivery note of turnover box can be attached with the goods , Or on the delivery note . Both parties sign and confirm the number of goods received each time .

4. Confirm the delivery method of turnover box . Generally, the supplier delivers the goods , Take away the empty box . The factory provides the receipt .

5. Confirm the time node and Reconciliation Method of account creation and reconciliation .

6. Confirm the responsibility of the factory for the storage of the supplier's weekly transfer boxes stored at the factory site . Including whether there are quantitative restrictions .

7. Confirm the supplier's responsibilities for the turnover boxes stored at the factory site . Including how to cooperate with the site management of the factory .

8. Determine how to deal with the turnover boxes that are damaged or do not meet the packaging specifications , Including responsibility identification , Handover , Insufficient quantity and other links .

9. Determine the corresponding counting process , Including time nodes , Counting method , Variance confirmation 、 Treatment methods, etc .

10. Confirm the difference loss of turnover box — If lost — Liability assumption and compensation scheme after occurrence .

11. Confirm the contact information of relevant responsible person .

Customer turnover box management

If your customer is still a supplier , Then reverse the above scheme .

It is to protect the real right of the turnover box . Regular inventory , Don't let wear and tear grow .

in addition , As mentioned earlier , Now, more and more suppliers are directly launching weekly box transfer , Circulate in the factory .

So we will also face the management of turnover boxes in the factory , Management of turnover boxes in the field , We need to make the following adjustments :

1. Plan the storage place of turnover boxes in the plant

One is the empty box storage area beside the line , It must be ensured that a certain number of turnover boxes can be stored beside the production line . The second is the empty container storage area in the factory . The area should be sufficient . It's better to have an area for each supplier .

To facilitate the supplier to pick up the empty containers . At the same time, it can limit the maximum empty container inventory , It is convenient to monitor whether the supplier picks up empty containers actively and effectively , Meet site management requirements .

2. Site management specifications for turnover boxes shall be determined

Who is responsible for pulling away the empty boxes beside the line ? Warehouse personnel or production line personnel ? How often ? What if they pile up ? What are the stacking rules for empty containers ? In particular, large cases and small cases shall be prevented . How to mark the supplier ? How to distinguish ? Prevent confusion when the supplier is carrying the case .

3. Turnover box cleaning

There are cleaning requirements for turnover boxes and working position instruments , Must be met in a certain way . Put an end to dirty boxes , Eliminate label residue . The supplier's turnover box should also have corresponding cleaning requirements , To ensure the quality of raw materials .

Stacking of turnover boxes

1、 Record in detail the goods storage turnover box , If there is a change , The information clerk must be informed of the change in time , So that the storage location of goods is consistent with that in the computer system .

2、 The goods are stacked and displayed in the warehouse , Rows should be neat , When stacking, the identification of turnover boxes or goods shall face outward , For example, product name 、 Commodity code or article number .

3、 During the storage of goods , Follow the principle of putting goods together according to the classification in . The shipment rate will be high 、 Goods with large shipments are placed close to the shipping area , Easy to ship .

4、 The storage and stacking of commodities must comply with the regulations on commodity storage , No superelevation 、 overweight 、 The horse 、 Side storage . If there are special storage requirements , Place as required . Because the price of storage land is generally too high , The problem of high stacking of goods is also serious , This often brings more unsafe factors to the storage of goods .

5、 The product content recorded on the label of the part box shall be accurate and detailed , Use the article number paper to record the article number of the commodity 、 Due time 、 The quantity of this batch of goods , The whole plate of goods shall be pasted on the shelf , It is required to be one side of the pallet fork .

Note the above points , I believe I can manage the turnover boxes in the whole supply chain better .

边栏推荐

- Cloud native integration data warehouse heavy release

- Two models of OSPF planning: double tower Raider and dog tooth crisscross

- Introduction to mapping in ES

- JMeter stress test web agent local interface test [teaching]

- 执行npm install -g serve时报错权限权限问题解决方案

- 5,10,15,20-tetraphenylporphyrin (TPP) and metal complexes fetpp/mntpp/cutpp/zntpp/nitpp/cotpp/pttpp/pdtpp/cdtpp supplied by Qiyue

- Is it legal to open an account for compass stock trading software? Is it safe?

- Liquid crystal texture diagram of purple solid mm-tpp-10c methacrylic acid decanoxy tetraphenyl porphyrin and mm-tpp-12c methacrylic acid dodecanoxy tetraphenyl porphyrin - Qi Yue display

- Ppbpi-h-cr, ppbpimn Cr, ppbpi Fe Cr alkynyl crosslinked porphyrin based polyimide material Qiyue porphyrin reagent

- 手机开户哪个证券公司佣金最低?网上开户是否安全么?

猜你喜欢

快速找到优质对象的5种渠道,赶紧收藏少走弯路

Google Earth Engine(GEE) 02-基本了解和学习资源

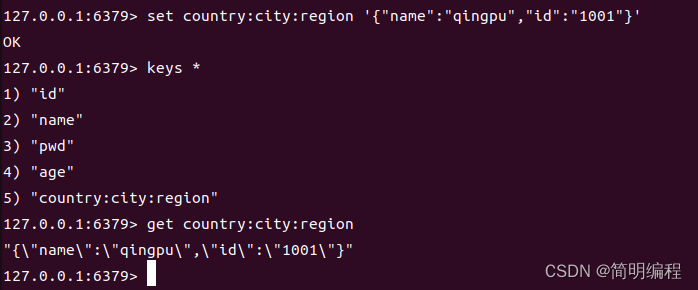

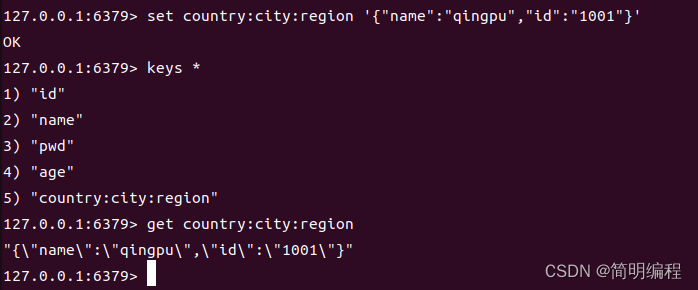

Redis系列——5种常见数据类型day1-3

![Jemter stress test - visualization tool support - [installation]](/img/e9/9acda4e37c98cc21df9499684205c6.png)

Jemter stress test - visualization tool support - [installation]

Redis series - five common data types day1-3

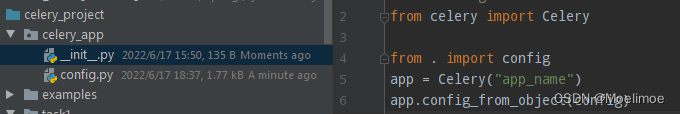

Sanic based services use celery to complete dynamic modification timing tasks

Multisensor fusion sensing

数据中心灾难恢复的重要参考指标:RTO和RPO

This article will take you to learn in detail what is FTTH

![[North Asia data recovery] a server data recovery method in which the partitions in the RAID5 array are formatted due to the misoperation of the NTFS file system](/img/4d/01310b489ca6a599a125e849ae4856.jpg)

[North Asia data recovery] a server data recovery method in which the partitions in the RAID5 array are formatted due to the misoperation of the NTFS file system

随机推荐

快速找到优质对象的5种渠道,赶紧收藏少走弯路

Redis series - five common data types day1-3

3D porphyrin MOF (mof-p5) / 3D porphyrin MOF (mof-p4) / 2D cobalt porphyrin MOF (ppf-1-co) / 2D porphyrin COF (POR COF) / supplied by Qiyue

[NLP] vector retrieval model landing: Bottleneck and solution!

Shengshi Haotong enterprise wechat sector creates a digital ecological community

Oracle中计算除法——解决除数为零报错

Encapsulating ranging and surface class based on leaflet

Jmeter压力测试-Web代理本地接口测试【教学篇】

Tetradecanoxy tetraphenylporphyrin methacrylate mm-tpp-14c; Cetanoxy tetraphenyl porphyrin methacrylate mm-tpp-16c; Purple solid; Qiyue supply

The first screen time, you said you optimized it, then you calculated it and showed it to me!

蓝桥杯嵌入式学习总结(新版)

[recommend an entity class conversion tool mapstruct, which is powerful and easy to use]

Tsinghua Yaoban chendanqi won Sloan award! He is a classmate with last year's winner Ma Tengyu. His doctoral thesis is one of the hottest in the past decade

Introduction to mapping in ES

Yyds dry inventory kubernetes easy service discovery and load balancing (11)

Important reference indicators for data center disaster recovery: RTO and RPO

Jemter 压力测试 -可视化工具支持-【安装篇】

Scratch program learning

[UVM practice] Chapter 2: a simple UVM verification platform (3) add various components to the verification platform

[SystemVerilog basics] post_ Randomize function record

http://www.gdblue.com/q_news/shownews.php?lang=cn&id=614

http://www.gdblue.com/q_news/shownews.php?lang=cn&id=614