当前位置:网站首页>5 trends brought to us by customers

5 trends brought to us by customers

2022-06-23 02:29:00 【Huangjunlei】

Based on numerous in-depth cooperation projects in the past year , We have been exposed to the opportunities and challenges faced by manufacturing enterprises in North China , It also gives us more knowledge and understanding of the market and industry .

The big trend is like a grey rhinoceros , determine , Break in in full fury , On the way . For most businesses , How to deal with important and non urgent matters , It is often the most challenging topic .

future , We will work with our customers 、 Ecological partners should comply with the general trend , Explore the development path of manufacturing enterprises .

trend 1. Higher supply chain collaboration efficiency

(1) OEMs have taken great strides in implementing digital transformation .

CRRC 、 faw 、 beauty 、 Sany Heavy Industry and other main engine plants are required by competition and national development , Tens of billions have been invested in exploring digital transformation , They don't think about turning , But how to gain greater competitive advantage by continuously deepening the digital transformation .

By 2021 year 10 month , China “ Lighthouse factory ” The number has reached 31 home , Is to have “ Lighthouse factory ” Most countries , Mainly distributed in 3C Electronics 、 Home appliance 、 automobile 、 Iron and steel 、 New energy and other industries .

(2) The basic level of the parts factory is not complete .

Compared with the main engine factory , No matter the capital of the parts factory 、 technology 、 personnel 、 There is a huge gap in equipment .

Many enterprises still rely on handwritten forms for information collection , Sign the pledge . How much stock is there , Rely on estimates ; When can we deliver , Rely on estimates ; There is a quality problem , Rely on discussion .

Some enterprises have done a good job in digital management , But it depends heavily on the efforts of entrepreneurs , The top leaders of entrepreneurs need to look at their watches every day to control production and operation , The autonomy of ordinary employees is not activated , There is also the problem of lagging management and control .

(3) The supply chain needs to transition from supply to collaboration .

Traditional supply chain management is based on the timely delivery of goods 、 Accurate distribution is the core , The best one is Toyota's just in time production method JIT.

Now when the main engine factory encounters problems in the assembly process , The parts factory should be able to analyze the problem at the first time , Develop solutions , Instead of kicking the ball and sending messages back and forth .

In case of quality problems , Quality traceability system is required , Be able to quickly define the affected batches , Define the scope of the problem , So as to provide reliable decision-making basis for quality improvement .

The OEMs need to know the production progress of spare parts in time , Just like understanding the e-commerce logistics distribution progress , Instead of simply an agreed delivery time .

(4) OEMs are already expanding the scope of digitalization .

Haier's CAOS industrial Internet 、 Beautiful cloud wisdom number 、 The tree roots of Trinity are interconnected 、 Foxconn's industrial Fulian is not only its own practice , Has expanded its practical experience and capabilities into new business lines , That is to help other enterprises achieve digital transformation and upgrading .

trend 2. More competitive electricity costs

Is the electricity cost the same for businesses in the same block ?

(1) The development of electricity marketization .

2022 At the beginning of the year, the national development and Reform Commission 、 The National Energy Administration issued the guiding opinions on accelerating the construction of the national unified power market system .

According to the opinion , To 2025 year , The national unified power market system has been preliminarily completed , National market and province ( District 、 City )/ Regional markets work together , Medium and long term electricity 、 The spot 、 Integrated design of auxiliary service market 、 Joint operations , The market-oriented allocation of resources across provinces and regions and the scale of green power transactions have been significantly increased , Conducive to new energy 、 The market trading and pricing mechanism for energy storage and other development has taken shape .

Affected by this , The electricity purchase price of each enterprise will no longer be unified , Enterprises need to build their own power supply system .

(2) The gradual popularization of new energy technologies .

In photovoltaic 、 Distributed energy represented by wind energy , As the product matures 、 Cost reduction , Gradually become an enterprise to reduce costs 、 An important means to deal with fluctuations in the electricity market .

The energy storage system also receives emergency power from key equipment , Gradually expand to more application scenarios .

(3) Refinement of energy management .

The traditional enterprise internal power management is to read the weekly report 、 Monthly report , The granularity of energy management is coarse , The relationship between cost and capacity is not clear .

Now based on industrial Internet of things technology , Energy consumption data can be recorded in real time , And then the equipment 、 Workshop 、 output value 、 Energy, etc , Find out the high energy consumption 、 Focus on improving the links with low output value .

trend 3. Faster market response

(1) Faster market perception .

The traditional production mode is mainly based on orders , Active customer expansion in need of sales , Or advertising gets customers , Market perception is slow , Low efficiency of market demand transmission .

More and more enterprises are building a perception system that is deeply integrated with customer applications , Apple from consumer electronics 、 millet , To Sany Heavy Industry of heavy equipment 、 Episode II , And then to the electricity meters promoted by the State Grid 、App, And more attempts at predictive maintenance .

(2) Faster delivery .

The challenge for small and medium-sized enterprises is to have more models 、 Less batch 、 Urgent customer demand and competitive challenges .

And the other side , The busy level of the production line varies , The value of assets cannot be brought into full play ; Delivery efficiency meets the test of market changes , Lead to inventory accumulation 、 Capital takes up .

(3) Faster internal evolution .

Natural selection , The survival of the fittest .

In the face of changes in the market , Enterprises need more flexibility and flexibility , To adapt to the market . Although the flexibility of machinery and equipment is difficult to change in the short term , But human ability 、 The flexibility of collaborative systems can be adjusted quickly .

The low code platform appeared in recent two years 、SaaS Software is born to meet the needs of enterprises' rapid and flexible changes . With these tools, enterprises can quickly explore change paths , Avoid high costs 、 High risk investment in fixed assets .

trend 4. From products to services

(1) Consumer goods manufacturers 、 OEMs are experiencing the transformation from selling products to providing services .

The traditional transaction centered model has increasingly become a service model centered on use .

Experience 、 Iteration is the core of the service pattern , It is also gradually transferred to the upstream materials 、 Accessories enterprises .

(2) How to go from physical delivery to continuous feedback and iteration .

Consumer goods manufacturers 、 The OEMs have the customer data , Its products need continuous upgrading ; material 、 Accessory enterprises also need product usage data to iterate . How to get through the data , Taking into account data security has become an important issue .

Digital products 、 Product software is a recognized direction of evolution , But specific areas require different solutions . Such as power distribution , From purchasing distribution equipment to purchasing distribution services , From self built 、 Self management to trusteeship is an industrial practice .

The challenge is , Customers' recognition of the hardware brand , Transition to recognition of service brand .

trend 5. Recruitment challenge

(1) Recruitment difficulties .

Manufacturing factory recruitment is a continuously challenging sector , It is the result of the evolution of population structure , It is also the result of changes in the employment concept of young people .

This problem is not caused by the enterprise brand 、 There are differences in the promotion of treatment , Even if the world 500 Strong factories also face this challenge .

(2) Reduce the demand for inefficient jobs .

In addition to supply and tapping potential , Reducing labor demand is also a problem-solving path that needs to be explored synchronously .

For example, machine vision has a good application practice in the field of quality inspection of production lines , Liberate valuable industrial workers from repetitive work , To do something more challenging and valuable .

Last words

One of the keys to enterprise competition is how enterprises can be more than their competitors 、 Make better use of the competitive means provided by the times .

At present, the productivity factors in front of enterprises include : land 、 Labour 、 capital 、 technology 、 data .

Digital consulting services The author Huangjunlei Data driven value Love to achieve extraordinary

边栏推荐

- Problem thinking and analysis process

- Microservice Optimization: internal communication of microservices using grpc

- Ch340 and PL2303 installation (with link)

- [target tracking] open source | polytrack: use boundary polygons to quickly track and segment multiple targets, instead of bounding box and mask tracking

- Mobile communication Overview - Architecture

- //1.11 basic operators

- Anaconda creates a new environment encounter pit

- 1. Mx6u bare metal program (1) - Lighting master

- Call rest port to implement nailing notification

- For Xiaobai who just learned to crawl, you can understand it after reading it

猜你喜欢

C language series - Section 4 - arrays

1. Mx6u bare metal program (2) - Lighting master (imitating 32 register version)

JS to realize the rotation chart (riding light). Pictures can be switched left and right. Moving the mouse will stop the rotation

1. Mx6u bare metal program (5) - external interrupt

Analog Electronic Technology

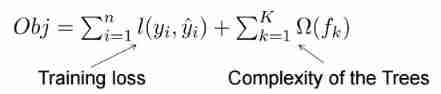

Xgboost principle

pd. read_ CSV and np Differences between loadtext

Lying in the trough, write it yourself if you can't grab it. Use code to realize a Bing Dwen Dwen. It's so beautiful

Stop automatically after MySQL starts (unable to start)

Xgboost Guide

随机推荐

Phpexcel export with picture Excel

Exploit format string vulnerability in CDE

How to customize a finished label template

Unity official case nightmare shooter development summary < I > realization of the role's attack function

What is a smart farm?

Performance test -- Jenkins environment construction for 15jmeter performance test

method

Data analysis method - user group analysis

The practice of traffic and data isolation in vivo Reviews

1. Mx6u bare metal program (5) - external interrupt

Salesforce fileUpload (I) how to configure the file upload function

Why is BeanUtils not recommended?

Gorilla/mux framework (RK boot): add swagger UI

Solve the problem that QQ flash photos cannot be saved

Xgboost Guide

Source code analysis | activity setcontentview I don't flash

Digital circuit logic design

JS advanced part

Three ways to get class

Nfv and SDN