当前位置:网站首页>Practice of production control | dilemma on assembly rack

Practice of production control | dilemma on assembly rack

2022-06-26 09:15:00 【Merrill Lynch data tempodata】

Demolition & Don't dismantle ? It's all problems

On the final assembly rack , The last step of product assembly , When assembling core components , It is found that the number of pipes and supports is missing , The components cannot be installed , Overall assembly downtime .

Through level by level communication and coordination , The complete set of pipe union and support requires 3 Days time , At this time, the product is close to the completion of assembly , Such as disassembly from the assembly rack , It will take nearly a week ; If not disassembled , Then this general rack cannot be used to assemble other products , The supporting components of subsequent products have been sent to the assembly workshop .

The impact of this accident on production is as follows :

The assembly progress of the current product is stagnant , Delayed delivery ;

The current total rack is occupied , No product can be assembled ;

There is no general rack for subsequent product assembly , Delayed delivery ;

The supporting components of subsequent products continue to accumulate in the assembly workshop , Occupy the space resources of the site ;

The material distribution plan of the enterprise 、 Assembly plan 、 The test plan and product delivery plan shall be adjusted accordingly .

This production anomaly causes the progress of multiple products to lag . End product downtime 3 God , The total rack is occupied 3 God , Production tempo is disrupted . Test plan change adjustment , The delivery date of the three products was delayed , total 11 God , Comprehensive estimation brings about 18 The economic loss of 10000 yuan and the negative impact of customer trust .

Typical pain points of traditional manufacturing industry

The production side is often , According to the market demand from 0 level BOM Gradually unfolding downward “ Pull plan ”; On one side, , Already know in advance when to produce what , However, the actual production is limited by the availability of upstream resources “ Push production ”, Any minor change in upstream links will affect subsequent production and delivery .

The contradiction between the single point management of the fragmented information system and the production link is linked

Used in information construction ERP、CRM、MES、WMS The data of information systems with equal fragmentation are independent of each other , And these data breakpoints become enterprise efficiency “ Running, running, dripping ” The place of .

Island style 、 Single point 、 Local production control , Independent authority management , This makes the production management lack of integrated control of the whole process and coordination and optimization at all levels , Collaboration is inefficient .

Isolated information flow and material flow , Make just in time production repeatedly blocked

Before production execution , Information flow oriented , The planning department formulates the production plan according to the market demand , There is often a lack of consideration of the matching of resources in the production process .

The production plan is being implemented , Dominated by material flow , However, the existing information system and work order execution cannot respond to and transmit the underlying changes in time , This makes it difficult for the risk information to be fed back to the planning department in time , And affect the follow-up process .

When abnormal production is found , Due to the lack of complete and unified production data , It makes problem tracing and decision optimization lack accurate and reliable information .

The production capacity of outsourcing manufacturers is insufficient , As a result, the pipe coupling and support are not fully set in accordance with the agreed time ; The purchasing personnel did not follow up the supply progress of outsourced materials in real time , The production management personnel failed to identify the risk of complete set of materials in advance .

This problem is not found until the final assembly process ( Lagging information flow ), Have a serious impact on production .

The guarantee of balanced production and on-time delivery : Abnormal perception and intelligent processing scheme for production control

The core idea of the production control platform is to take production delivery as the goal , To open up the main value chain , Based on the business data of production process , Early warning of potential risks 、 Timely alarm for abnormal production 、 The mechanism of rapid response to problem events , Realize efficient production problem solving and fast closed loop .

Many problems of manufacturing industry , The solution lies in " Perception and acquisition of anomalies ".

Holographic modeling , Real-time monitoring : Get through the main value chain , Based on the business data of production process , Build panoramic modeling of plant and workshop , Realize vertical and horizontal connection of information and transparent visualization of information flow in physical space . Through holographic monitoring , Pay real-time attention to all kinds of abnormal risk information and changes .

chart 1: Workshop risk monitoring

chart 2: Plant risk monitoring

“ In the face of hidden dangers in production , It is urgent to establish an early warning mechanism , Find problems ahead of time , solve the problem .”

Early warning and alarm mechanism for full link monitoring : Combine alarm trigger logic with message push rules and problem supervision functions . Based on the pre configured logic decision rules, the production hidden danger of each link can automatically trigger the alarm function , Visualize problems and risks online , And push the message to relevant personnel for online command, dispatching and control .

Alarm point reference : The production plan is delayed 、 The process stops for a long time 、 The equipment is overdue and not repaired 、 The instrument fails to be rechecked after expiration 、 Raw material inventory is lower than safety stock 、 Scheduling instruction delay 、 The task is not released on time / starts 、 The supervision decision is delayed 、 Tooling validity alarm 、 Two gold indicators early warning, etc .

chart 3: Early warning and alarm mechanism

After building a digital production control platform , A manufacturing enterprise has established a daily risk warning and alarm mechanism , All kinds of early warning events have occurred in the year 700 More , Alarm events 500 More . Exposure ahead of time , Discover problems in time , Avoid problems from small to large , It is estimated that the losses avoided by the enterprise in the past year are nearly ten million .

边栏推荐

- 小程序首页加载之前加载其他相关资源或配置(小程序的promise应用)

- Uniapp uses uparse to parse the content of the background rich text editor and modify the uparse style

- ThreadLocal

- Modify coco evaluation index maxdets=[10,15,20]

- How to convert wechat applet into Baidu applet

- 【开源】使用PhenoCV-WeedCam进行更智能、更精确的杂草管理

- Self taught machine learning series - 1 basic framework of machine learning

- Phpcms V9 mobile phone access computer station one-to-one jump to the corresponding mobile phone station page plug-in

- Section IV HQL execution process

- Phpcms mobile station module implements custom pseudo static settings

猜你喜欢

行为树 文件说明

Principle and application of single chip microcomputer -- Overview

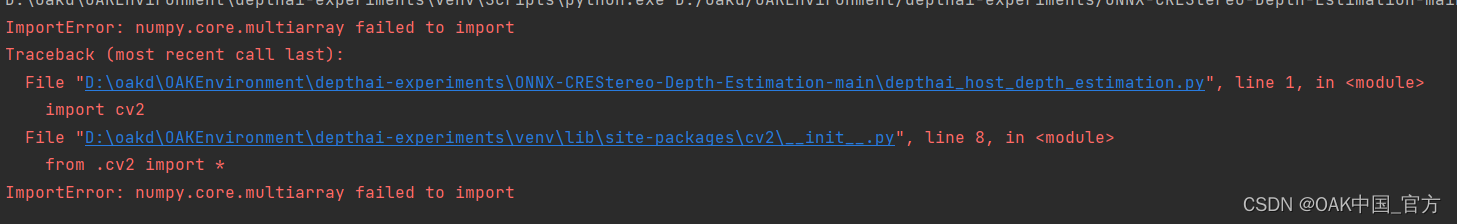

Error importerror: numpy core. multiarray failed to import

External sorting and heap size knowledge

![Modify coco evaluation index maxdets=[10,15,20]](/img/f6/a0fbf601371aa51ec5b0136574c756.jpg)

Modify coco evaluation index maxdets=[10,15,20]

phpcms v9后台文章列表增加一键推送到百度功能

Self learning neural network series - 7 feedforward neural network pre knowledge

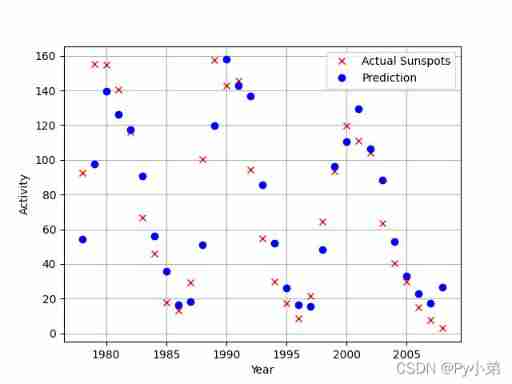

Autoregressive model of Lantern Festival

phpcms小程序插件教程网站正式上线

Live review | smardaten lihongfei interprets the Research Report on China's low / no code industry: the wind direction has changed

随机推荐

How to handle the small program tabbar that does not support parameter transfer

外部排序和大小堆相关知识

commonJS和ES6模块化的区别

Differences between commonjs and ES6 modularity

行为树的基本概念及进阶

Yolov5 advanced zero environment rapid creation and testing

Phpcms applet plug-in version 4.0 was officially launched

phpcms v9去掉phpsso模块

Fast construction of neural network

MATLAB basic operation command

Edit type information

Srv6---is-is extension

[qnx hypervisor 2.2 user manual]12.2 terminology (II)

微信小程序如何转换成百度小程序

Jetson TX2 installing the SciPy Library

Phpcms applet plug-in tutorial website officially launched

百度小程序富文本解析工具bdParse

Basic concept and advanced level of behavior tree

【微积分】拉格朗日乘子法

Self taught neural network series - 9 convolutional neural network CNN