当前位置:网站首页>What do SMT operators do? operating duty?

What do SMT operators do? operating duty?

2022-06-26 00:17:00 【Mounter】

SMT What do operators do ? operating duty ?

This article was written by Jiangxi yingteli

www.intelli40.cn

SMT Operator's job responsibilities

Purpose : Control quality , Achieve efficiency , Supervise the operation of employees .

requirement : Do not accept bad , Do not create defects , No bad output

Premise :

1: Be familiar with the size indicated by the material number of each customer , specifications , Error equivalence .…

2: Familiar with various material units , Code , Conversion, such as resistance : English abbreviation R,PCB Mark ( Such as :R10) Indicates that it is in PCB Position on , The unit is Ohm , Conversion method :1M o =10000k o =10000000 o ;

3: Be familiar with the polarity components in PCB The direction indicated by the silk screen on the .

4: Be familiar with the job responsibilities of each station and have the skills of printing intermediate inspection

Work content guidance

1: When changing lines , The operator selects the correct material according to the specifications Feeder, Will be installed Feeder The materials shall be installed on the corresponding station of the machine according to the station table of the model provided by the project . After all materials are installed, it must be called after self inspection IPQC Check all the data . Prepare the refueling record sheet and daily production report .

2: Technicians debug the mounter OK after , Trial production of a first piece , Write the first article inspection sheet for IPQC For the first piece , First piece OK After mass production . The engineering personnel shall not pass the furnace until they are informed that it is possible to pass the furnace . The first ten boards must be carefully checked for any poor quality, such as : Side up 、 The offset 、 Missing stickers 、 Wrong parts 、 Reverse pasting 、 Polarity element reverse, etc .

3: Midway refueling , The chip mounter can receive the material belt FEEDER It must be refuelled in the form of a receiving strip ( Such as : Yamaha series ,JUKI Machine series ) Do not wait until the material has been used up for standby refueling . When a station is running out of materials, it is necessary to prepare materials in advance and write a refueling record , To improve productivity . During refueling, the material tray must be checked with the replaced material tray , Whether the specifications are consistent with the station position table . Also called IPQC Take a piece of material and paste it on the refueling record sheet to make a refueling record . When changing the plate and loading the tube , There has to be IPQC Confirm the direction of the material and then confirm the direction for refueling . It is not allowed to remove materials from two stations for refueling at the same time , So as not to change it by mistake . All refuelling must go through IPQC Confirm on the spot .

4: Use of bulk materials , When using bulk materials , All bulk materials must be sorted to the bulk tray and marked with the finished material number and location . Write the application form for hand release , to IPQC After confirming the signature , Find out the materials to be pasted by hand in the machine and confirm them before jumping materials . During the intermediate inspection of the manual sticker , It is necessary to supervise the operation method , Pay attention to the direction of the polar elements 、 Trowel 、 Wrong posting, etc , To ensure quality . Always pay attention to the quality after intermediate inspection and drawing , If there is any problem, immediately improve it

5: Near the end of the clearance , Must budget in advance whether there will be less material , And inform the foreman to assist in finding materials . Try to avoid waiting for materials , Reduce productivity . All bulk materials must be found out and pasted during tail cleaning , Do not leave it to be repaired afterwards , If there are still empty plates , The vented materials must be completely and correctly written on the venting sheet , Don't write wrong , fail to write down . After writing it, hand it over to the foreman for confirmation and signature before emptying . In order to avoid the same work order applying for replenishment more than once . After clearing the tail , Take the initiative to ask the foreman on duty whether to remove the materials and return them to the warehouse .

6: Before handover , It is necessary to coordinate with the printer or intermediate inspection personnel to transfer the machines of this line , Clean the floor garbage . Know the production quantity of the shift during handover ( It must be checked with the printing position for consistency ) And problems in production . Valuable materials 、 Station tables and tools ,7S, The handover must be clear . If the handover is not clear , Inform the foreman to go to the site to find the problem and deal with it , The handover record form must be signed by the foreman on duty before going off duty . After completing the production of a model , The station position table must be returned to the foreman for safekeeping , For the next time .

7: The operator is the length of one line , Be responsible for paying attention to problems actively and dealing with problems in time during production , To improve production efficiency and control quality . Gradually improve their own professional skills and knowledge at work, and actively teach and supervise the operation of other employees . Make them cooperate with themselves to achieve the production efficiency and quality objectives of the line .

8: Machine maintenance must be done every day .《 Refuelling record sheet 》、《SMT Daily report of production status 》 and 《 Productivity Kanban 》 Such forms must be filled in in real time and standardized , Neat handwriting . Do not resort to fraud , Do things carelessly .

9: Anti static is SMT Principles , Be aware of static electricity when working , You should know that the friction of objects will also generate static electricity , Empty PCB The board may also store static electricity . So in contact with PCB Wear static electricity ring or gloves when using the board . Electrostatic clothes and hats should be neatly dressed , Do not expose your hair . Check whether the anti-static measures of each station are normal at work and supervise the employees of the line .

This article was written by Jiangxi yingteli

More technical and product information , Click to see

www.intelli40.cn

边栏推荐

- Redis之哨兵

- How postman tests interfaces that require login

- [advanced ROS] Lecture 1 Introduction to common APIs

- 【ROS进阶篇】第一讲 常用API介绍

- 10.2.2、Kylin_kylin的安装,上传解压,验证环境变量,启动,访问

- Use js to obtain the last quarter based on the current quarter

- 元宇宙中的法律与自我监管

- Darkent2ncnn error

- Research and development practice of Kwai real-time data warehouse support system

- MongoDB的一些基础用法

猜你喜欢

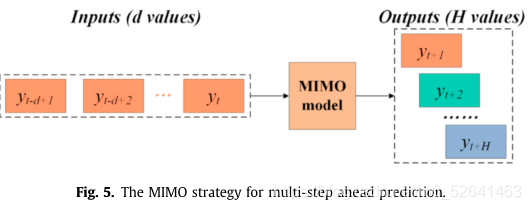

文献调研(二):基于短期能源预测的建筑节能性能定量评估

ASA如何配置端口映射及PAT

Daily question brushing record (IV)

EBS r12.2.0 to r12.2.6

EBS R12.2.0升级到R12.2.6

ValueError: color kwarg must have one color per data set. 9 data sets and 1 colors were provided

Thrift入门学习

小红书微服务框架及治理等云原生业务架构演进案例

Xiaohongshu microservice framework and governance and other cloud native business architecture evolution cases

【ROS进阶篇】第一讲 常用API介绍

随机推荐

小红书微服务框架及治理等云原生业务架构演进案例

Ffmpeg version switching

Darkent2ncnn error

Recommended system design

redux工作流程+小例子的完整代码

防抖和节流

2021-04-28

Redux workflow explanation + small examples

EasyConnect连接后显示未分配虚拟地址

DNS review

dhcp复习

Redis之常见问题

【ROS进阶篇】第一讲 常用API介绍

Topic36——53. Maximum subarray and

EBS r12.2.0 to r12.2.6

正则表达式介绍及一些语法

Reading notes on how to connect the network - hubs, routers and routers (III)

11.1.2、flink概述_Wordcount案例

PCB生产为什么要做拼板和板边

电路板去板边—V-Cut分板机注意事项