当前位置:网站首页>Canoe: the fifth simulation project: simulation + test

Canoe: the fifth simulation project: simulation + test

2022-06-25 22:43:00 【picoasis】

Catalog

1-2 Detect the message length DLC

3-1 Test module entry function MainTest

3-2 CAPL The test case —— Detect message cycle

3-3 CAPL The test case —— Detect the message length DLC

3-4 CAPL The test case —— Detect undefined message undefined msg

3-5 CAPL The test case —— A functional test

5-1 System variable control message sending

5-2 IG Node sends custom message

Engineering background

The main purpose of the project is : Based on the first 3 A simulation project , be familiar with CANoe Message test function of .

Purpose of the project

The project will focus on CAN Messages in the bus , stay Test Module To realize the test function . It mainly includes :

- Detect the period of periodic message

- Check the length of the message

- Check whether there are undefined messages in the network

- Simple function test : By modifying the values of the relevant system variables , Simulate the operation of real test environment , Finally, check the change of signal value on the bus .

- Generate test reports

Message sending

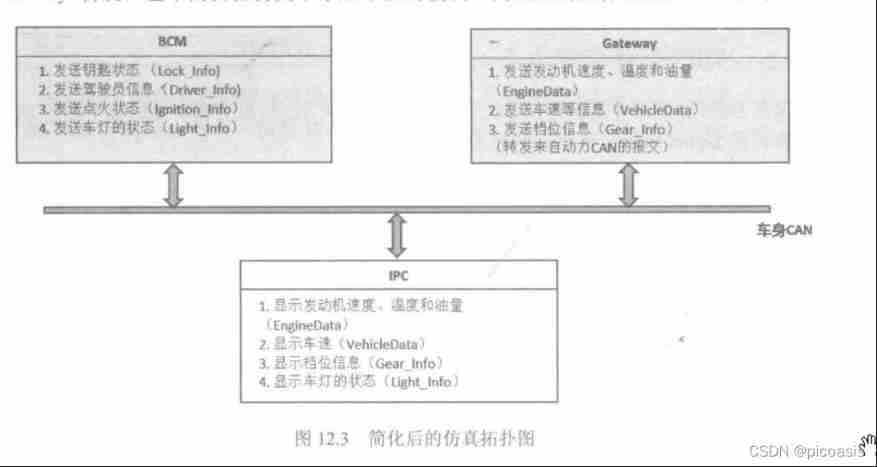

The first 3 The sending and receiving of simulation engineering messages are as follows :

The relevant attributes of the message are summarized in the following table :

The signal attributes in the message are shown in the following table :

Project realization

Overview of Engineering steps

The examples in this chapter are based on 12 Chapter simulation engineering , For the convenience of distinction , You need to copy the folder of the original project and be known as Vehicle_System_Simulation_Test, The project name is also saved as Vehicle_System_CAN_Test.cfg, Create a project folder named Testmodul Folder , Used to store relevant test code .

Next , On this basis, test modules and fault injection panels will be added .

The project includes the following key steps :

- Test method analysis

- add to Test Module,

- CAPL Test case writing ,

- Operation engineering , Run test cases .

- fault injection , Run test cases .

- View test report .

1 Test method analysis

The purpose of this project is to test the sending cycle of different messages 、 packet length DLC; A functional test ( Check whether the signal value is within the expected value range ); Undefined message .

1-1 Detect message cycle

The method of detecting the message cycle is to designate a specific time , Select the first message to be tested in the time period as the start timestamp , Observe the time interval of subsequent repetition of the message to be tested .

TSL function —— Detection function

Detection function 1:

ChkStart_MsgAbsCycleTimeViolation ( Message aObservedMessage,duration aMinCycleTime, duration aMaxCycleTime)

The functionality : Observe the bus periodic message aObservedMessage Every occurrence of , If the interval of the message does not meet the specification requirements , A special event representing the occurrence of an exception will be triggered .

Return value :>0, Return to one IDaCheckedId, That is, observe the event of the message to be tested ;=0 Report errors .

TSL function —— Status report function

Status report function 1:long ChKQuery_NumEvents(dword aCheckId)

The functionality : Query the number of exceptional special events in this time period

Status report function 2:double ChkQuery_StatProbeIntervalAvg(dword aCheckId)

Return to the time period , The average cycle interval of the message

Status report function 3: double ChkQuery_StatProbeIntervalMin(dword aCheckId)

Return to the time period , The minimum cycle interval of the message

Status report function 4: double ChkQuery_StatProbeIntervalMax(dword aCheckId)

Return to the time period , The maximum cycle interval of the message

TSL function —— Detect the control function

Detect the control function 1: long ChkControl_Destroy(Check aCheckId)

Used at the end of the test , Destroy the event object aCheckId, Release resources . return 0 Successful operation ,<0 Report errors .

1-2 Detect the message length DLC

function :

Status report function ChkQuery_NumEvents

Detect the control function ChkControl_Destroy

Detection function :dword ChkStart_InconsistentDLC(Message aMessage,char [] aCallback)

Check whether the length of the specified message sent to the bus is the same as DBC The definitions in the database are consistent

aMessage Message to be tested ;char [] aCallback Callback function name , Optional parameters

Return value :>0: Returns an event object aCheckId;=0 Report errors

1-3 A functional test

Function test used CAPL Program logic to set the value of a signal , And then use ChkStart_MsgSignalValueInvalid Function to detect whether the signal value is within the expected value range .

dword ChkStart_MsgSignalValueInvalid (Signal aObservedSignal,double aMinValue, double aMaxValue, Callback aCallback)

Function parameter : Signal to be tested , Must be set at DBC Signal in , Minimum signal value , Maximum signal value , Callback CAPL Function name , Optional .

Return value : Returns an event object aCheckId, That is, to detect events of undefined messages

1-4 Detect undefined message

Detection function :dword ChkStart_UndefinedMessageReceived (char [] CaplCallback)

effect : Observe whether there are undefined messages on the current bus

Return value :>0: Returns an event object aCheckId, That is, the event of the message to be observed ;=0 Report errors .

Status report function :long ChkQuery_EventMessageId (dword aCheckId)

effect : Returns the message that triggered the event MessageId

Return value :>0 Return the message that triggers this event ID;<0 Report errors .

2 add to Test Module

2-1 Create test environment

Create test environment , Name it NetworkTester.

2-2 Insert CAPL Test Module

Insert CAPL Test Module, And configure this module Configuration Dialog box

To configure Module Of Name by :Network Tester, stay TestModule Create under folder CAPL file NetworkTester.can

3 CAPL Write test cases

Choose TestModule, Right click to select Edit, Can edit NetworkTester.can .

3-1 Test module entry function MainTest

CAPL In the test module can Documentation requirements :- Must contain MainTest function , All test cases enter from this interface

- add to TestModule describe :Title,DisCription.

- Simulation project initialization , Ensure the normal sending of messages ; In this project, the door is unlocked , Set up CarDriver, And the key position is set to 2.

- Group test cases testGroupBegin, Test case function name calls ,testGroupEnd.

void MainTest()

{

testModuleTitle("NetworkTester");

testModuleDescription("Message Specification Test and Function Test Demo.");

testGroupBegin("Check msg cycle time","Check the differ mesage cycle time");

Init_Test_Condition();

CheckMsgEngineData();

CheckMsgVehicleData();

CheckMsgGear_Info();

CheckMsgIgnition_Info();

CheckMsgLight_Info();

testGroupEnd();

testGroupBegin("Check msg DLC","Check DLC of a message");

CheckDLCLock_Info();

testGroupEnd();

testGroupBegin("Check undefined msg","Check the undefined message");

CheckUndefinedMessage();

testGroupEnd();

testGroupBegin("Fucntion Test","Check the engine speed after setup");

CheckEngine_Speed();

testGroupEnd();

}

// Initialize simulation engineering status , Ensure that each module is in Online

Init_Test_Condition()

{

@Vehicle_Key::Unlock_Car = 1;

@Vehicle_Key::Car_Driver = 0;

@Vehicle_Key::Key_State = 2;

testWaitForTimeout(500);

}3-2 CAPL The test case —— Detect message cycle

The test respectively EngineData(50),VehicleData(50),Gear_Info(50),Ignition_Info(50) ,Light_Info(500) Message cycle .

With EngineData For example ,CAPL The program logic is as follows :

- First declare the detection event gCycCheckId

- Define constants :

- Maximum and minimum range value of the cycle :[lCycMinCycleTime,lCycMaxCycleTime] by [40,60]

- Light_Info Period range of :[Light_MIN_CYCLE_TIME,Light_MAX_CYCLE_TIME] by [490,510].

- Write test cases :

- Define test report prompt information : use testCaseTitle Define test report prompt information , With EngineData For example testCaseTitle("TC-1","TC-1:Check cycle time of msg EngineData");

- Observe the message to be measured , Whether the cycle is within the scope requirements : Use ChkStart_MsgAbsCycleTimeViolation Observe whether the message to be tested is within the set interval . Normal return message detection event ID——aCheckedId . If aCheckedId Greater than 0 It means that the test runs normally , If =0 It means there is an error in the measurement process .

- Test case results , After outputting the test report , Destroy the test event

- Set the time for use case testing KTIMEOUT, Observe the period of the message to be measured in this observation period .

- Run the test case to the result aCheckedId As test Conditions ——testAddCondition, This means that the test case run results will be presented in the report

- Wait for the test time to end ,

- After the observation , Count the period average value of the message in the test case 、 Maximum 、 minimum value .

- Run the result according to the use case aCheckedId Print report , If aCheckedId Is greater than 0, That is, detect that the message cycle is not within the range , Then use snprintf+TestStepFail Describe the test steps that caused the error , The decision of the test case is automatically set to fail here . Otherwise, use snprintf+TestStepPass Describe the test results , The report will show the test steps performed as expected , pass with flying colors .

- Finally, destroy the detection event gCycCheckId.

Other messages only need to be sent in 3 Test case part , Change to the corresponding message name .1 Declare detection events ,4 Use case test results ,5 Destruction detection events are common functions .

The specific code example is as follows :

variables

{

//TC1

dword gCycCheckId;// Declare the... Of the detection event ID

int gUndefinedMsgCheckResult;// Declare the detection result of undefined message

const long kMIN_CYCLE_TIME = 40;// General minimum cycle time constant

const long kMAX_CYCLE_TIME = 60;// General maximum cycle time constant

const long Light_MIN_CYCLE_TIME = 490;// Define message Light_Info Minimum cycle time constant

const long Light_MAX_CYCLE_TIME = 510;// Define message Light_Info Maximum cycle time constant

const long kTIMEOUT = 4000;// Define the test wait time constant

// Custom message —— Use IG modular

}

// Cycle time detection result function

CheckMsgCyc(float aCycMinCycleTime, float aCycMaxCycleTime)

{

long lQueryResultProbeAvg;// Average declaration time

long lQueryResultProbeMin;// Declare the minimum measurement time

long lQueryResultProbeMax;// Declare the maximum measurement time

char lbuffer[100];

testAddCondition(gCycCheckId);// Add an event to this function

testWaitForTimeout(kTIMEOUT);// Wait for the test time to end

// Statistical average time

lQueryResultProbeAvg = ChkQuery_StatProbeIntervalAvg(gCycCheckId);

// Statistics min Time

lQueryResultProbeMin = ChkQuery_StatProbeIntervalMin(gCycCheckId);

// Statistics max Time

lQueryResultProbeMax = ChkQuery_StatProbeIntervalMax(gCycCheckId);

if(ChkQuery_NumEvents(gCycCheckId)>0)

{

// Count the number of exceptions // Print report

snprintf(lbuffer,elCount(lbuffer),"Valid values %.0fms - %.0fms",aCycMinCycleTime,aCycMaxCycleTime);

testStepFail("",lbuffer);

snprintf(lbuffer,elCount(lbuffer),"Average cycle time: %dms",lQueryResultProbeAvg);

testStepFail("",lbuffer);

snprintf(lbuffer,elCount(lbuffer),"Min cycle time: %dms",lQueryResultProbeMin);

testStepFail("",lbuffer);

snprintf(lbuffer,elCount(lbuffer),"Average cycle time: %dms",lQueryResultProbeMax);

testStepFail("",lbuffer);

}

else

{

snprintf(lbuffer,elCount(lbuffer),"Valid values %.0fms - %.0fms",aCycMinCycleTime,aCycMaxCycleTime);

testStepPass("",lbuffer);

snprintf(lbuffer,elCount(lbuffer),"Average cycle time: %dms",lQueryResultProbeAvg);

testStepPass("",lbuffer);

snprintf(lbuffer,elCount(lbuffer),"Min cycle time: %dms",lQueryResultProbeMin);

testStepPass("",lbuffer);

snprintf(lbuffer,elCount(lbuffer),"Average cycle time: %dms",lQueryResultProbeMax);

testStepPass("",lbuffer);

}

ChkControl_Destroy(gCycCheckId);// Destruction event

}

//TC1:Check Cycle time of msg EngineData

testcase CheckMsgEngineData()

{

float lCycMinCycleTime;// Declare the minimum cycle time

float lCycMaxCycleTime;// Declare the maximum cycle time

lCycMinCycleTime = kMIN_CYCLE_TIME;// assignment

lCycMaxCycleTime = kMAX_CYCLE_TIME;

// Test report prompt information

testCaseTitle("TC-1","TC-1:Check cycle time of msg EngineData");

// Start to observe the message to be tested

gCycCheckId = ChkStart_MsgAbsCycleTimeViolation(EngineData,lCycMinCycleTime,lCycMaxCycleTime);

CheckMsgCyc(lCycMinCycleTime,lCycMaxCycleTime);// Cycle time detection result function

testRemoveCondition(gCycCheckId);// Remove test conditions

}

//TC-2:Check Cycle time of msg VehicleData

testcase CheckMsgVehicleData()

{

float lCycMinCycleTime;

float lCycMaxCycleTime;

lCycMinCycleTime = kMIN_CYCLE_TIME;

lCycMaxCycleTime = kMAX_CYCLE_TIME;

testCaseTitle("TC-2","TC-2:Check cycle time of msg VehicleData");

gCycCheckId = ChkStart_MsgAbsCycleTimeViolation(VehicleData,lCycMinCycleTime,lCycMaxCycleTime);

CheckMsgCyc(lCycMinCycleTime,lCycMaxCycleTime);

testRemoveCondition(gCycCheckId);

}

//TC-3:Check Cycle time of msg Gear_Info

testcase CheckMsgGear_Info()

{

float lCycMinCycleTime;

float lCycMaxCycleTime;

lCycMinCycleTime = kMIN_CYCLE_TIME;

lCycMaxCycleTime = kMAX_CYCLE_TIME;

testCaseTitle("TC-3","TC-3:Check cycle time of msg Gear_Info");

gCycCheckId = ChkStart_MsgAbsCycleTimeViolation(Gear_Info,lCycMinCycleTime,lCycMaxCycleTime);

CheckMsgCyc(lCycMinCycleTime,lCycMaxCycleTime);

testRemoveCondition(gCycCheckId);

}

//TC-4:Check Cycle time of msg Ignition_Info

testcase CheckMsgIgnition_Info()

{

float lCycMinCycleTime;

float lCycMaxCycleTime;

lCycMinCycleTime = kMIN_CYCLE_TIME;

lCycMaxCycleTime = kMAX_CYCLE_TIME;

testCaseTitle("TC-4","TC-4:Check cycle time of msg Ignition_Info");

gCycCheckId = ChkStart_MsgAbsCycleTimeViolation(Ignition_Info,lCycMinCycleTime,lCycMaxCycleTime);

CheckMsgCyc(lCycMinCycleTime,lCycMaxCycleTime);

testRemoveCondition(gCycCheckId);

}

//TC-5:Check Cycle time of msg Light_Inf

testcase CheckMsgLight_Info()

{

float lCycMinCycleTime;

float lCycMaxCycleTime;

lCycMinCycleTime = kMIN_CYCLE_TIME;

lCycMaxCycleTime = kMAX_CYCLE_TIME;

testCaseTitle("TC-5","TC-5:Check cycle time of msg Light_Info");

gCycCheckId = ChkStart_MsgAbsCycleTimeViolation(Light_Info,lCycMinCycleTime,lCycMaxCycleTime);

CheckMsgCyc(lCycMinCycleTime,lCycMaxCycleTime);

testRemoveCondition(gCycCheckId);

}

3-3 CAPL The test case —— Detect the message length DLC

//TC6:DLC Message length test

testcase CheckDLCLock_Info()

{

dword checkId;

// Test report prompt information

testCaseTitle("TC-6","TC-6:Check msg DLC of Lock_Info");

// Steward observation message Lock_Info Of DLC

checkId = ChkStart_InconsistentDlc(Lock_Info);

testAddCondition(checkId);

// Wait for the test time to end

testWaitForTimeout(kTIMEOUT);

testRemoveCondition(checkId);

}3-4 CAPL The test case —— Detect undefined message undefined msg

//TC-7: Detect undefined signals

testcase CheckUndefinedMessage()

{

long lEventUndefineMessageId;// Declare undefined message Id

char lbuffer[100];

gUndefinedMsgCheckResult = 0;//? The number of initialization undefined messages is 0

testCaseTitle("TC-7","TC-7:Check CAN channel for undefined message");

// Start observing the current bus

gCycCheckId = ChkStart_UndefinedMessageReceived("UndefinedMsgCallback");

// Time delay , That is, measure the time period

testWaitForTimeout(kTIMEOUT);

switch(gUndefinedMsgCheckResult)

{

case 1:

write("undefined message detected!");

// Get undefined message ID

lEventUndefineMessageId = ChkQuery_EventMessageId(gCycCheckId);

snprintf(lbuffer,elCount(lbuffer),"Undefined message detected: Id 0x%x",lEventUndefineMessageId);

testStepFail("",lbuffer);

break;

default:

write("Iamdefault");

testStepPass("","No undefined message detected!");

break;

}

ChkControl_Destroy(gCycCheckId);// Destruction event

}

UndefinedMsgCallback(dword aCheckId)

{

// Callback function , Call when an undefined message is detected

write("Test: undefined message finded");

ChkQuery_EventStatusToWrite(aCheckId);

gUndefinedMsgCheckResult=1;// Set the number of undefined messages to 1

}

3-5 CAPL The test case —— A functional test

testcase CheckEngine_Speed()

{

dword checkId;

testCaseTitle("TC-8","TC-8:Check Engine Speed Value");

@Vehicle_Key::Unlock_Car = 1;

@Vehicle_Key::Car_Driver = 0;

@Vehicle_Key::Key_State = 2;

@Vehicle_Control::Eng_Speed = 2000;

// Start observing , Whether the signal value is within the range

checkId = ChkStart_MsgSignalValueInvalid(EngineData::EngSpeed,1900,2100);

testWaitForTimeout(kTIMEOUT);

if(ChkQuery_EventSignalValue(checkId))

{

testStepPass("","Correct Engine Speed Value");

}

else

{

testStepFail("","Incorrect Engine Speed Value");

}

}

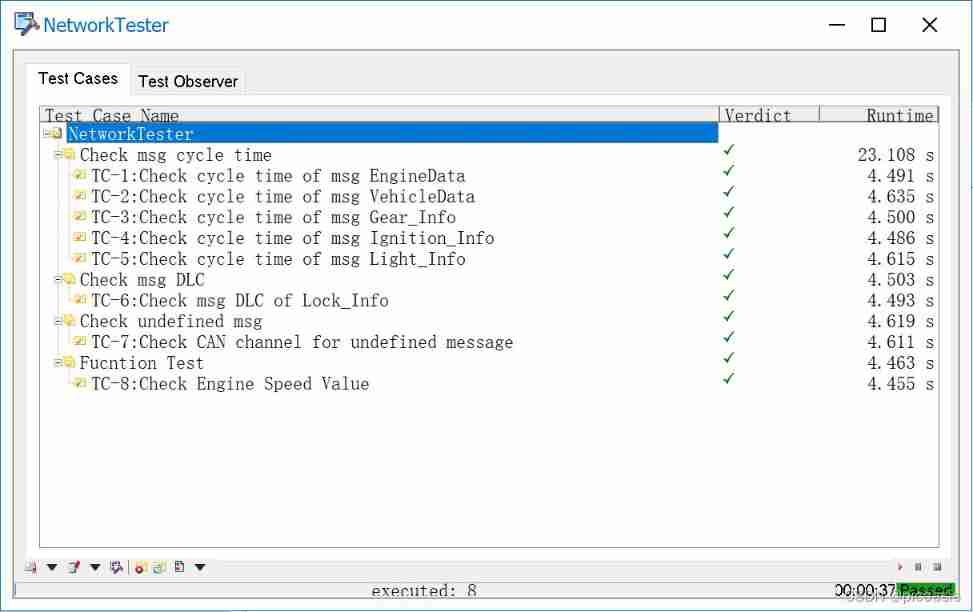

4 Project operation test

After running the project , Run the test .

The test case running results are shown in the figure ,Light_Info Message cycle detection error of .

—— see CANdb, Only messages are found Light_Info The message cycle of is 500, The detection range used in the code is 40-60, Change the cycle range to Light_MIN_CYCLE_TIME and Light_MAX_CYCLE_TIME, The following example :

//TC-5:Check Cycle time of msg Light_Info

testcase CheckMsgLight_Info()

{

float lCycMinCycleTime;

float lCycMaxCycleTime;

//lCycMinCycleTime = kMIN_CYCLE_TIME;//kMIN_CYCLE_TIME=40==>Light_MIN_CYCLE_TIME=490

//lCycMaxCycleTime = kMAX_CYCLE_TIME;//kMAX_CYCLE_TIME=60==>Light_MAX_CYCLE_TIME=510

lCycMinCycleTime = Light_MIN_CYCLE_TIME;

lCycMaxCycleTime = Light_MAX_CYCLE_TIME;

testCaseTitle("TC-5","TC-5:Check cycle time of msg Light_Info");

gCycCheckId = ChkStart_MsgAbsCycleTimeViolation(Light_Info,lCycMinCycleTime,lCycMaxCycleTime);

CheckMsgCyc(lCycMinCycleTime,lCycMaxCycleTime);

testRemoveCondition(gCycCheckId);

}Run the test case again , All pass .

5 fault injection

To verify the correctness of the test case , A variety of fault injection methods can be used to achieve fault injection , Common are : Use the fault injection function , Use network nodes CAPL Programming , And the use of IG node .

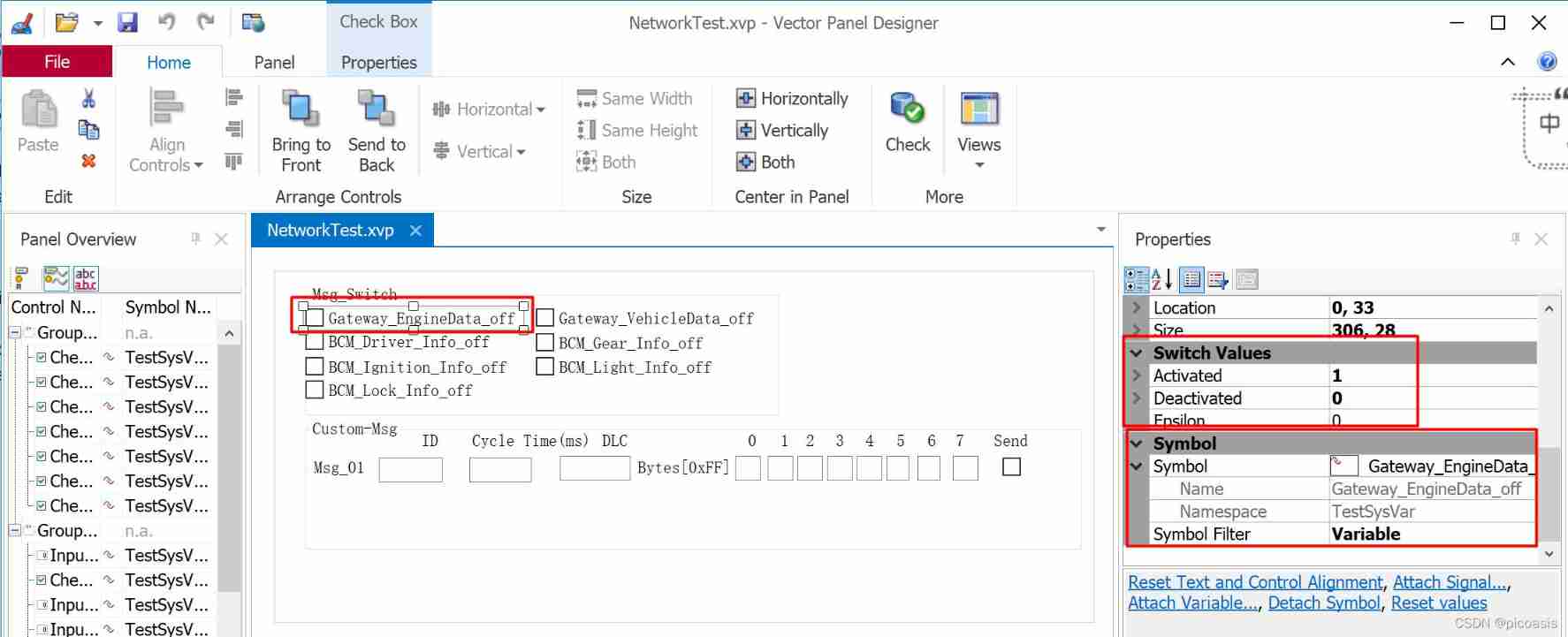

A panel is made in the book : Msg_Switch and Custom_Msg, Control the sending and closing of messages respectively , And sending customized messages .

I try to use Panel The module implements this panel : Create system variables , Associate the panel check box with the system variable , And then CAPL Read system variables in programming , Control the corresponding message function according to the variable value .

But in the end , Use Panel only Msg_Switch part .Custom_Msg No corresponding undefined message creation method is found , You are welcome to share with us . Finally using IG The node implements the sending of undefined messages .

5-1 System variable control message sending

Create system variables , Associate the panel check box with the system variable , And then CAPL Read system variables in programming , Control the corresponding message function according to the variable value .

The test case involves 7 A message , So create 7 The system variables are created as follows :

With Gateway_EngineData_off For example , The process of creating system variables is as follows .

Create a Value Table The common use . because 7 System variables have the same numerical interpretation : Check as 1 Stop message sending , If not, it means 0 It means that the message is sent normally . Use the same ValueTable It can be managed in a unified way .

Panel The creation process is as follows :

First add a Panel panel , Name it NetworkTest.

Add a check box component , Change the name and , Associate the corresponding system variable , The example below is EngineData, Other message control can be matched one by one according to the name .

Panel After creation , stay NetworkTest.can Add variables to listen for events , Control corresponding message sending .

With EngineData For example ,CAPL The programming is as follows :

on sysvar_update TestSysVar::Gateway_EngineData_off

{

if (@this==1)

{

testDisableMsg(EngineData);

write("Test: disable EngineData");

//testDisableMsg(Cluster_Info);

// ILDisableMsg("Cluster_Info");

}

else{

testEnableMsg(EngineData);

write("Test: enable EngineData");

}

}There are more than functions that control the sending and termination of messages testDisableMsg and testEnableMsg, For other functions, please refer to this article ( Put the link after improvement ).

5-2 IG Node sends custom message

IG Nodes can be divided into CAN IG and IG, The difference is that CANIG Only support CAN message , and IG Can support CAN、LIN、MOST And other messages . Besides, there are IG and PDU IG The difference between ,PDU IG It can support any network protocol , Include CAN as well as Ethernet 、FlexRay.

5-2-1 establish IG node

stay Simulation Setup Create... On the bus CAN IG modular ,CAN IG The module allows users to send customized CAN message .

5-2-2 Add custom message , And configuration

Add... As shown in the figure above 3 Custom message Msg_01,Msg_02,Msg_03, And define relevant attributes according to the following figure

5-2-3 function

After the save , Start the project , Start the test case , Send custom message .

Test results show that undefined message is detected .

6 Test report

The test report has 2 format :①CANoe TestReport Viewer( recommend )②XML/HTML Format ( Former )

As shown in the figure below , Modify it to the format you want :

The opening position of the test report is as follows

①CANoe TestReport Viewer( recommend )

②XML/HTML Format ( Former )

END

边栏推荐

- Youku IPv6 evolution and Practice Guide

- 【WPF】CAD工程图纸转WPF可直接使用的xaml代码技巧

- 2022-2028 global transmission type photoelectric circuit breaker industry research and trend analysis report

- Huasheng lithium battery IPO meeting: 9-month revenue of 690million; shenjinliang's family relationship is complex

- In depth analysis of Flink fine-grained resource management

- Interview shock 23: talk about thread life cycle and transformation process?

- 圖解棧幀運行過程

- leetcode: 49. Grouping of alphabetic words

- Fujilai pharmaceutical has passed the registration: the annual revenue is nearly 500million yuan. Xiangyun once illegally traded foreign exchange

- 数据治理,说起来容易,做起来难

猜你喜欢

What are the debugging methods for nodejs

NRM source switching tool

Obsidian basic tutorial

2022-2028 global transmission type photoelectric circuit breaker industry research and trend analysis report

This 110 year old "longevity" enterprise has been planning for the next century

![[HNU summer semester] preparation stage of database system design](/img/cf/5ff390e2662a8942fa22e2c41e0fb5.png)

[HNU summer semester] preparation stage of database system design

2022-2028 global proton exchange membrane hydrogen electrolyzer industry survey and trend analysis report

Illustration de l'exécution du cadre de pile

再突破!阿里云进入Gartner云AI开发者服务挑战者象限

2022-2028 global carbon fiber unidirectional tape industry research and trend analysis report

随机推荐

Research Report on China's new energy technology and equipment market competition analysis and marketing strategy suggestions 2022-2028

Nacos 源码分析01 代码结构

面对AI人才培养的“产学研”鸿沟,昇腾AI如何做厚产业人才黑土地?

Diagram of stack frame running process

【WPF】CAD工程图纸转WPF可直接使用的xaml代码技巧

图解栈帧运行过程

Online crudhasone Association query reports an error unabletouseinternalvariable:list

China soft magnetic material market demand status and prospect scale forecast report 2022-2028

The difference between synchronize and volatile

[WPF] XAML code skills that can be directly used for converting CAD engineering drawings to WPF

Application runtime layotto enters CNCF cloud native panorama

用idea建立第一個網站

Beyond natural motion: exploring the discontinuity of video interpolation

聊聊Adapter模式

Talk about adapter mode

Progress of the 137th MPEG Conference

[HNU summer semester] preparation stage of database system design

Hello, teacher, is it really safe to open an account in Alipay fund?

2022-2028 global cloud based remote browser isolation industry research and trend analysis report

Introduction to HNU database system ODBC