当前位置:网站首页>Precautions for cleaning PCBA board in SMT chip processing

Precautions for cleaning PCBA board in SMT chip processing

2022-06-26 00:17:00 【Mounter】

SMT Patch processing PCBA Precautions for plate cleaning

Source of the article : Jiangxi yingteli Electronics Co., Ltd

PCBA It's an empty board (pcb) after SMT Patches and DIP The whole process completed by the plug-in ,( Extended reading :PCBA Circuit board production process flow ) In the process , Reflow soldering will occur 、 Wave soldering , Manual welding, etc , Because the electronic products are getting smaller and smaller ,PCBA The size requirements of are becoming smaller and smaller , But the requirements for quality ( Including product reliability and stability ) It is getting higher and higher ,

Therefore, many brands or solution providers require smt The patch processing plant is right pcba Apply three proofing paint , Increase the stability and reliability of the product , Ensure product quality and performance , But before the three proofing paint is applied , You have to deal with pcba Clean the plate ,

Because after welding, various flux residues will appear on the board , Some residues are acidic 、 Solubility 、 Corrosivity, etc , If you don't clean the residue , The coating will also cause great damage to the product , Next, Jiangxi Inteli electronic technology will introduce to you pcba Relevant precautions for plate cleaning .

SMT Patch processing pcba Precautions for plate cleaning

1.pcba The plate is welded , It should be cleaned as soon as possible ( Flux residues can produce corrosion over time ), cleaning pcba Residual flux and other contaminants on the plate ;

2. cleaning pcba Board time , Prevent the cleaning agent from invading the unsealed components , To avoid damage to components , After cleaning , Should be placed in 30-50 In an oven of about degrees , After about half an hour of baking , Take out after drying PCBA plate ;

3. cleaning pcba Board time , Protect the components on the board 、 identification , Otherwise, it will cost you a lot , Waste mounting and welding pcba plate .

cleaning PCBA Boards affect the life and reliability of electronic products , There are some PCBA The board is not cleaned , May cause a short circuit 、 Electric leakage , Lead to unqualified products and many failures , Increase recall and repair costs , So do not clean PCBA The gains outweigh the losses .

Jiangxi yingteli electronics is a professional smt Patch processing plant , Located in Fuzhou, Jiangxi Province , Have 24 Siemens high-speed patch line ,mpm/dek Solder Paste Printer ,KY 8030 Solder paste detector 、heller Reflow soldering , All the mounting equipment are imported , To provide customers with excellent chip quality assurance , At the same time, we provide customers with fast patch delivery and service .

边栏推荐

- Smt贴片机工作流程

- CaMKIIa和GCaMP6f是一样的嘛?

- leetcode.14 --- 最长公共前缀

- 渲云携手英特尔,共创云渲染“芯”时代

- ssh的复习

- Reading notes on how to connect the network - hubs, routers and routers (III)

- SQL中只要用到聚合函数就一定要用到group by 吗?

- My blog is 2 years old and 167 days old today. I received the pioneer blogger Badge_ Old bear passing by_ Sina blog

- Oracle RAC cluster failed to start

- 原型和原型链的理解

猜你喜欢

Redis之内存淘汰机制

What is micro service

什么是微服务

深圳台电:联合国的“沟通”之道

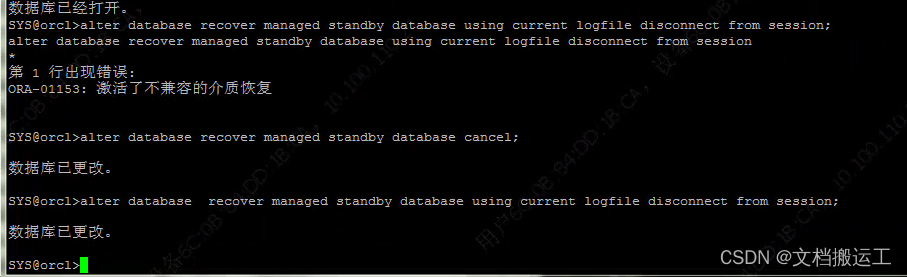

Ora-01153: incompatible media recovery activated

How postman tests interfaces that require login

Regular expression introduction and some syntax

10.2.3、Kylin_ The dimension is required for kylin

Daily question brushing record (IV)

删库跑路、“投毒”、改协议,开源有哪几大红线千万不能踩?

随机推荐

On the use of bisection and double pointer

性能领跑云原生数据库市场!英特尔携腾讯共建云上技术生态

Farsync simple test

leetcode.14 --- 最长公共前缀

Ffmpeg version switching

Thrift入门学习

Smt贴片机工作流程

EasyConnect连接后显示未分配虚拟地址

Notes on the method of passing items from the spider file to the pipeline in the case of a scratch crawler

Resolve thread concurrency security issues

SMT操作员是做什么的?工作职责?

Linux下搭建集群环境(2)-----------linux下安装Mysql

Smt贴片机保养与维护要点

DateTimeFormatter与LocalDateTime

Redis memory elimination mechanism

Datetimeformatter and localdatetime

Apache基金会正式宣布Apache InLong成为顶级项目

机器视觉:照亮“智”造新“视”界

Record some CF questions

oracle RAC 集群无法启动