当前位置:网站首页>What is the quality traceability function of MES system pursuing?

What is the quality traceability function of MES system pursuing?

2022-06-12 08:22:00 【Intelligent manufacturing of Huidu Technology】

Today we will analyze the product quality traceability of manufacturing enterprises , as well as MES Application of product traceability in the system .

We know , Production quality management is MES A very important part of the system , Because for a long time , The workshop quality management department hopes that the processing level of the workshop will continue to be in the best state , The quality problems arising from the processing process can be found in time 、 Handle 、 feedback . This requires the workshop to timely feed back the quality information generated in the production process , For analysis and adjustment by relevant departments , So as to avoid the loss of processing quality .

So let's see MES What are the quality management modules :

1、 Quality inspection

According to the current production situation , The inspector selects the WIP to be inspected according to the WIP number under the quality management system , List inspection items and standards , And with quality BOM stored ,MES The software system will automatically judge whether the quality is qualified or not according to the quality characteristic standard , Nonconforming products will trigger the nonconforming product handling process .

2、 Quality plan

Establish quality specification information for parts to be processed , Form process level quality control specifications and control parameter table , The specification information includes the quality requirements and standards for the inspection items of parts 、 test method 、 Testing equipment, etc . This information is guided by the part process information , With BOM stored , It can be called repeatedly after being established once .

3、 Quality analysis

The statistical analysis chart can directly reflect the product quality problems ,MES The software can automatically process the relevant data hierarchically , Draw histogram , Permutation chart 、 Cause and effect diagram and scatter diagram .

4、 Data collection

Data acquisition can be divided into automatic acquisition 、 Semi automatic collection and manual collection , The system realizes the automatic collection of CMM measurement data through the interface program . The semi-automatic data acquisition system can also be composed of servers such as digital display measuring equipment , When inspecting parts , There is no need to write down the inspection results , It is automatically sent to the data processing device for storage .

5、 The quality control

By calculating the process capability index , Evaluate the process processing capacity . Control the manufacturing process , available SPC Technology to draw relevant charts .

6、 Quality report

The quality of workshop production can be checked daily 、 month 、 year 、 people 、 equipment 、 Date and other conditions or composite conditions automatically generate report files , Store or print , Submit to the superior department or other relevant departments for reference .

Many enterprises will face the following problems in the actual production process :

1、 Purchasing personnel , Workshop staff , If the warehouse management personnel only rely on paper documents to transfer , Information is easy to miss , And the information cannot be exchanged in time , Affect productivity .

2、 Generally, the production process of the production enterprise is more complex , There are many processes and personnel involved , Once something goes wrong with the product , Hard to trace , Unable to adjust in time , Have a great impact on subsequent production .

3、 There are many manual recording processes , There will be some mistakes when the efficiency is low , Have an impact on accuracy .

MES The impact of the system on Production Traceability after it is applied in the manufacturing enterprise :

1、 While optimizing the production process , Can save time , Improve work efficiency .

2、 Realize information sharing , When something goes wrong , Managers can react quickly , Make market adjustments .

3、 Improve the accuracy of data entry , Realize the timely information collection of data , Avoid errors and omissions due to data flow .

4、MES The system labels each product with ” Id card “, Including raw materials , Production process , Production equipment , Production personnel, etc , Facilitate the timely communication of information , Control of product quality and production management by management .

The final summary :

The traceability management system is MES Part of the production management system , By coding the raw materials 、 Production control 、 Barcode management 、 Management of multiple dimensions such as finished product identification , It can be realized in any link of production , Can be traced back to the material , Trace back to the destination of the finished product , To the enterprise quality tracking 、 Pinpointing the scope of a quality problem provides a solution .

factory MES Application of the system in enterprises , It is a necessary means for the development of enterprise informatization and the construction of intelligent production workshop , Significantly improve work efficiency and service level , Especially product traceability , Effectively improve product quality , Improve customer satisfaction , So as to enhance the core competitiveness of enterprises .

Establishment of traceability system , In case of quality accident, it can locate quickly , Analyze the quality causes , Be able to put forward appropriate countermeasures in time , Reduce enterprise risk , Reduce customer losses , So that the interests of customers can be guaranteed , Bring obvious value to production management .

If you have MES/APS System related requirements , You can leave a message by private mail , Get more case details , Welcome to communicate !

边栏推荐

- What should be paid attention to when establishing MES system? What benefits can it bring to the enterprise?

- Detailed explanation of Google open source sfmlearner paper combining in-depth learning slam -unsupervised learning of depth and ego motion from video

- In depth interpretation of 5g key technologies

- A brief summary of C language printf output integer formatter

- Vscade debug TS

- 网站Colab与Kaggle

- Talk about the four basic concepts of database system

- Vision Transformer | Arxiv 2205 - LiTv2: Fast Vision Transformers with HiLo Attention

- ctfshow web4

- What is an extension method- What are Extension Methods?

猜你喜欢

Derivation of Poisson distribution

三国杀周边--------猪国杀题解

ctfshow web4

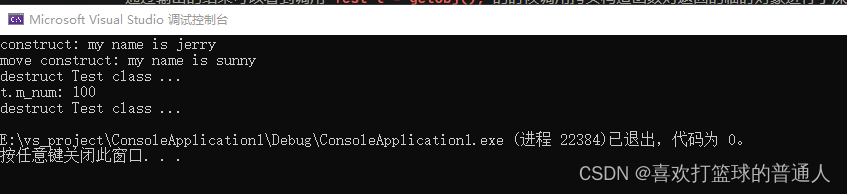

(p36-p39) right value and right value reference, role and use of right value reference, derivation of undetermined reference type, and transfer of right value reference

Vins technical route and code explanation

MATLAB image processing -- image transformation correction second-order fitting

Record the treading pit of grain Mall (I)

visual studio2019的asp.net项目添加日志功能

ctfshow web3

JVM学习笔记:垃圾回收机制

随机推荐

This article is required for the popularization of super complete MES system knowledge

call方法和apply方法

ctfshow web 1-2

(P27-P32)可调用对象、可调用对象包装器、可调用对象绑定器

超全MES系统知识普及,必读此文

Hands on deep learning -- image classification dataset fashion MNIST

ctfshow web4

(p27-p32) callable object, callable object wrapper, callable object binder

企业上MES系统的驱动力来自哪里?选型又该注意哪些问题?

Query in MySQL

Detailed explanation of Google open source sfmlearner paper combining in-depth learning slam -unsupervised learning of depth and ego motion from video

2.1 链表——移除链表元素(Leetcode 203)

Scope of bean

What is the MES system? What is the operation process of MES system?

ctfshow web3

MYSQL中的查询

(p25-p26) three details of non range based for loop and range based for loop

如何理解APS系统的生产排程?

Installation series of ROS system (II): ROS rosdep init/update error reporting solution

2.2 链表---设计链表(Leetcode 707)