当前位置:网站首页>MES system is different from traditional management in industry application

MES system is different from traditional management in industry application

2020-11-09 14:34:00 【Hongyun Zhizao】

MES System , Whether from the function model or information model and related technology , Both of them cover the process manufacturing industry and the discrete manufacturing industry , however , No matter in terms of process flow or production organization form , There are great differences between process manufacturing and discrete manufacturing , therefore , stay MES In terms of concrete implementation , We should treat it differently according to the characteristics of the manufacturing industry .

Because as the core of enterprise value MES The system software is not integrated into the management information system , If the manufacturing factory can't produce high quality products on time , If the manufacturing information can't be delivered to the people who need it at the required time , that Enterprise level management decisions are based on guesswork , This will certainly affect the business efficiency of the whole enterprise .

1. Real time monitoring system production site , Make the production site transparent .

According to the basic definition , Users only need to confirm the product when organizing production MES System , The system automatically confirms the relevant material information and production route , All the operation information in the production process is also recorded by the system , Greatly reduce the number of work orders , Ensure the accuracy of information transmission , The system provides workshop managers to arrange materials or semi-finished products to specific equipment for operation , And in the operation to provide specific guidance , Prompt staff to work steps , The data collection function of the system can collect the quality of the site in real time , Material information , And automatically record the operating personnel and operation time and other operation information , Abnormal phenomena in production operations are also recorded in the system , To ensure future statistical analysis .

2. Improve the effect of quality management , Improve product quality .

MES The system can control the use of equipment , Set user permissions for the device , Avoid mistakes based on human judgment and the operation of unauthorized personnel The device used is wrong , Abnormal products inconsistent with the target appear in the production operation , The system can be based on WIP management , Immediately stop all potential lot number operations on site , Reduce the loss , Handle the bundle according to the exception , The system will prohibit operations beyond the tube bundle .

Demand differences between manufacturing industries , Process manufacturing industry , It's mainly based on mixing raw materials , Separate , smash , A physical or chemical method, such as heating , Add value to raw materials , commonly , They produce in batch or continuous form , The discrete industry is mainly based on the change of the physical shape of raw materials , assemble , Become a product , Add value to it , stay MES demand , Application environment and so on , There's a big difference between the two .

Product structure difference , The product structure of discrete manufacturing enterprises , It can be used “ Trees ” To describe the concept of —— The final product must consist of a fixed number of parts or components , These relationships are very well established and fixed , The product structure of process enterprises , There's a big difference ,MES They're not usually very fixed — The quantity relationship between superior material and subordinate material , Maybe with the temperature , pressure , humidity , season , Technical level of personnel , The technological conditions are different .

In the process manufacturing industry MES in , The concept of formula is generally used to describe this dynamic product structure relationship , second , In the process manufacturing industry, in every process , It's not just the product or the intermediate product that comes with it , It may also be subdivided into main products , By-product , Coproduct , Backflow and waste ,MES In describing the formulation of this product structure , There should also be a lot of , Requirements on validity period, etc .

Hongyun intelligent manufacturing is a leading intelligent manufacturing solution provider in China , stay MES/WMS System development 、 Production automation has 14 Years of industry experience , It is one of the top three intelligent manufacturing solution providers in China .

Hongyun Zhizao has an experienced professional consultant team , The technical team accounts for 70%, And absorbed a number of university professors and doctors , As a high-level intellectual resource support . future , Hongyun Zhizao will be ready to go , Focus on intelligent manufacturing and control , Realize information 、 equipment 、 Intelligent integration of three aspects of Logistics , Promote industry in an all-round way 4.0 manufacture , help “ Made in China ” March towards “ China smart ”.

版权声明

本文为[Hongyun Zhizao]所创,转载请带上原文链接,感谢

边栏推荐

- MES系统在工厂生产管理起到9大很重要的作用

- 「代码整洁之道-程序员的职业素养」读书笔记

- Viewing PDB files from the angle of assembly

- 一款基于.NET Core的认证授权解决方案-葫芦藤1.0开源啦

- Clock service Android implementation of alarm clock

- Application and practice of native map and web fusion technology

- 写给我自己的一封信

- Several methods of initializing singleton variable in go language

- 7-10x write performance improvement: analysis of wiredtiger data page lock free and compression black Technology

- Python loading voice class custom dataset

猜你喜欢

彩虹排序 | 荷兰旗问题

我叫Mongo,收了「查询基础篇」,值得你拥有

A letter to myself

7-10倍写入性能提升:剖析WiredTiger数据页无锁及压缩黑科技

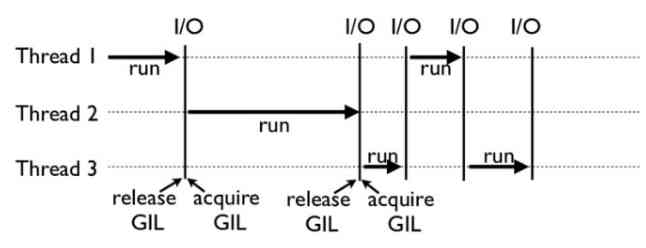

多线程真的比单线程快?

MES系统在行业应用里区别于传统式管理

Application of EMQ X in the Internet of things platform of China Construction Bank

Use treeview tree menu bar (recursively call database to create menu automatically)

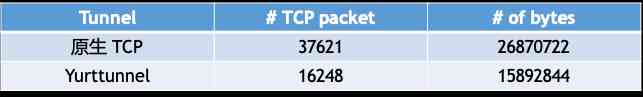

OpenYurt 深度解读:如何构建 Kubernetes 原生云边高效协同网络?

移动安全加固助力 App 实现全面、有效的安全防护

随机推荐

Where should wild card SSL certificate register and apply

Arthas Install 快速安装文档

c语言(循环链表)实现贪吃蛇的基本功能

CCF BDCI hot topic: privacy information recognition in unstructured business text information

乘风破浪的技术大咖再次集结 | 腾讯云TVP持续航行中

导师制Processing网课 双十一优惠进行中

Is multithreading really faster than single threading?

除了解析域名,DNS还能干吗?

The way of a million year salary Architect: on the architecture design of application system

AE(After Effects)的简单使用——记一次模板套用的过程

Reduce of Flink

详解三种不同的身份验证协议

I interviewed a 33 year old Android programmer, who could only program for Baidu, but wanted 25K, which was met by me

It's amazing! Ali senior architect 20 years of experience, collate and share servicemesh actual combat documents, pay rise is bad for this article!

你这么不努力,怎么做年薪40W的大数据打工人?

EMQ X 在中国建设银行物联网平台中的应用EMQ X 在中国建设银行物联网平台中的应用

The use of Android studio Aidl

嘉宾专访|2020 PostgreSQL亚洲大会阿里云数据库专场:王健

JS design pattern

Four steps of Android integrated payment