当前位置:网站首页>MES, APS and ERP are essential to realize fine production

MES, APS and ERP are essential to realize fine production

2022-07-06 07:37:00 【Huidu technology intelligent manufacturing】

ERP,APS And MES System integration , Realizable plan → perform → supervise → Cycle of plan modification , Timely adjust the abnormalities on site , Make the operation of the whole enterprise more orderly .

ERP The production part of is generally composed of the following modules :MPS( Main production plan )、MRP ( Material requirements plan )、MOM( Production order management )、SFC( Workshop site management ). because ERP It's based on unlimited capacity , And it's back in order “ Introduction ” The plan for , Therefore, it is impossible to give a detailed production plan, accurate delivery date, detailed production scheduling and material requirements .

ERP Production management module (MPS、MRP、MOM、SFC) It provides a very rough planning and production process data collection and statistics function , Can not meet the actual production process control of users . therefore , The task of production management is, of course, determined by MES( manufacturing execution system ) Here we go .

Connecting the preceding and the following depends on MES System

MES(Manufacturing Execution System) The concept of manufacturing execution system originated in the last century 90 years ,MES Software has only matured in recent years .MES The system is when the whole resources of the company are managed according to its business objectives , Provide the company with the execution means to achieve the execution goal , Connect the theoretical data of the basic information system with the actual data of the factory through the real-time database , It also provides the communication function between business planning system and manufacturing control system .

A workshop or factory with complete automation at the bottom of the factory , The implementation of MES Relatively easy . But at present, the bottom automation of Chinese manufacturing enterprises is not perfect , It is impossible to control production by automatic return information in one step , Must be based on the improvement of the level of underlying Automation , Partial perfection . At present MES The real-time production information must be collected and input manually . We should give full play to the executive level MES The role of , We must strengthen the infrastructure at the bottom .

When a customer complains about a product , Can you trace all the production process information of this batch of products according to the product number ? Can you find out immediately : Raw material supplier 、 Operate the machine 、 The operator 、 The process that went through 、 Production time, date and key process parameters ?

When the same production line needs to mix and assemble multiple models of products , Whether it can prevent workers from assembling wrong parts 、 The production process is wrong 、 Product mix ?

In the past 12 There are the most... On the production line in hours 5 What are the defects of products ? What are the quantity of defective products ?

Current warehouse and pre process 、 Middle process 、 What is the quantity of each product on the post process line ? Which suppliers to supply separately ? When can we deliver the goods in time ?

How much time does the production line and processing equipment have in production , How much time is it stalling and idling ? The main reason that affects the production potential of the equipment is : Equipment failure ? Scheduling error ? The supply of materials is not timely ? The training of workers is not enough ? Or the process index is unreasonable ?

Can the quality inspection data of products be automatically counted and analyzed , Accurately distinguish the random fluctuation and abnormal fluctuation of product quality , Eliminate potential quality problems in the bud ?

Can we abolish the manual report , Automatically count the production quantity of each process 、 Pass rate and defect code ?

These are the needs MES Main problems solved by the system .

The goal of modern enterprises is to pursue lean production , That is to say, by reducing the waste of resources, the production concept of achieving the maximum output with the minimum input and the products with the best quality and the lowest cost , The concept of the fastest response to market demand .MES System is a necessary environmental condition for implementing lean production . In order to achieve lean production ,MES It has to be monitored in real time 、 control 、 Statistics 、 Analyze all the details of each production process , This is also MES The main function of the system .

Planning and scheduling is the key to lean production , quite a lot MES The production planning and scheduling module of the system has very limited functions , Can't effectively resolve , So many companies have to use Excle Form to deal with the task of accurate scheduling .

The first is the randomness of production demand , When production demand changes , Manual production scheduling will be very difficult ; meanwhile , When production bottlenecks are unpredictable , Manual scheduling is very difficult to operate , Resources cannot be fully utilized , The order can't be delivered on time . In especial , When it comes to small quantities 、 Many varieties 、 The contradictions of discrete manufacturing enterprises with complex processes are extremely prominent . People are eager to turn to more powerful lean production solutions :APS.

ERP,APS And MES System integration , Realizable plan → perform → supervise → Cycle of plan modification , Timely adjust the abnormalities on site , Make the operation of the whole enterprise more orderly .

If you have MES/APS System related requirements , Pay attention to me , Get more details about smart manufacturing , Welcome to communicate !

边栏推荐

猜你喜欢

【mysql学习笔记30】锁(非教程)

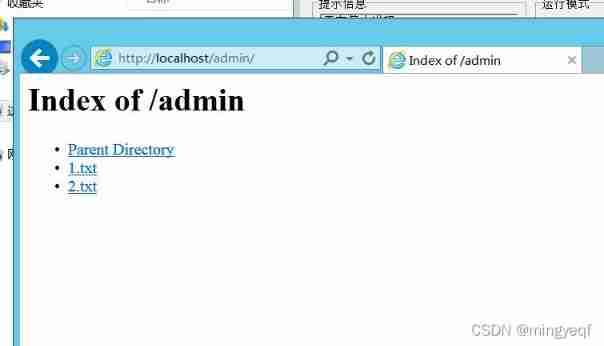

Apache middleware vulnerability recurrence

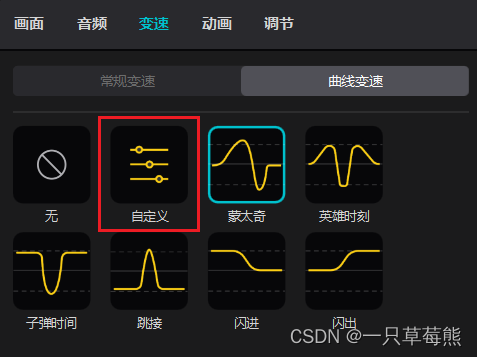

剪映的相关介绍

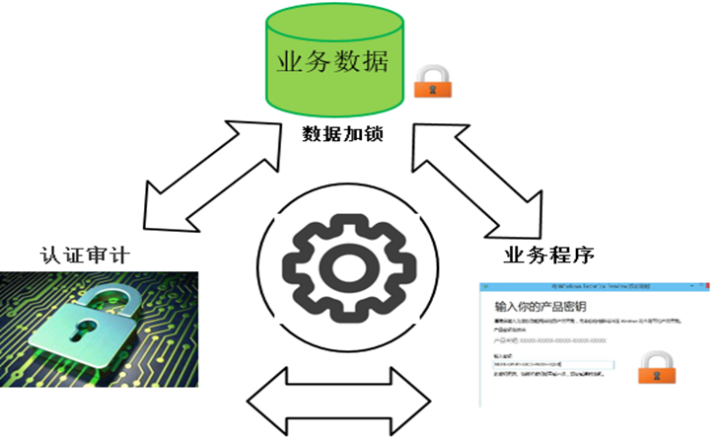

Significance and measures of encryption protection for intelligent terminal equipment

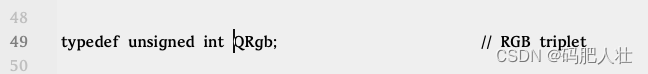

qt颜色与字符串、uint相互转换

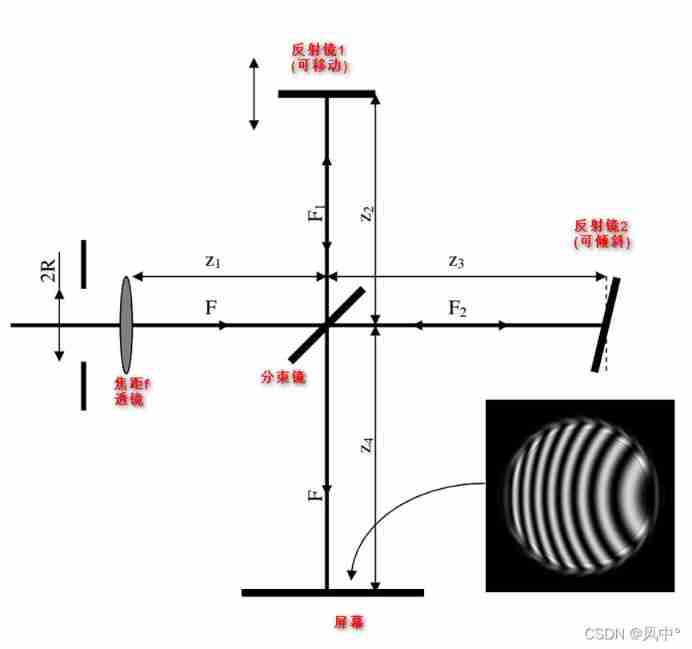

Simulation of Michelson interferometer based on MATLAB

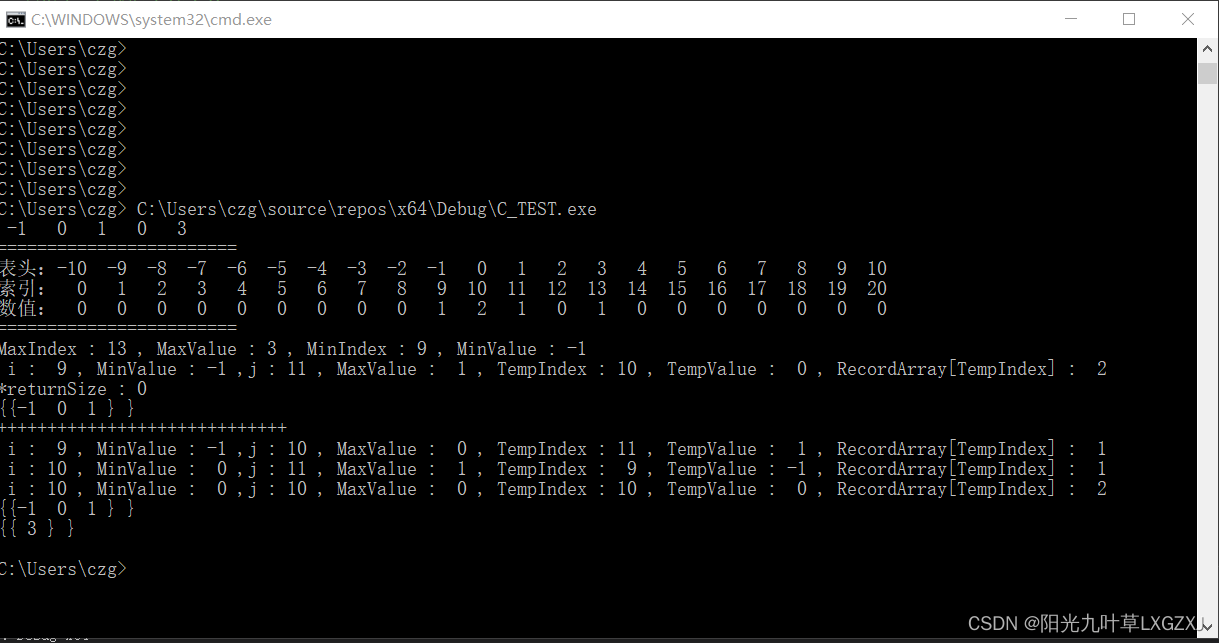

Leecode-c language implementation -15 Sum of three ----- ideas to be improved

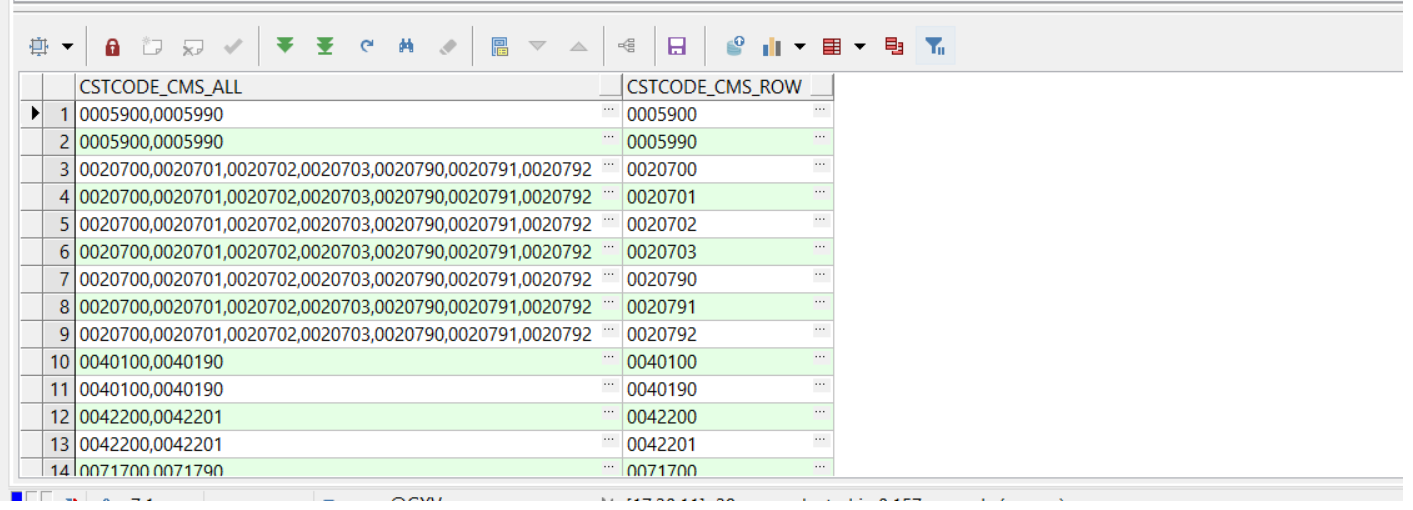

Oracle column to row -- a field is converted to multiple rows according to the specified separator

![Ble of Jerry [chapter]](/img/ce/127b597cdd238bb0c37326f5cf8265.png)

Ble of Jerry [chapter]

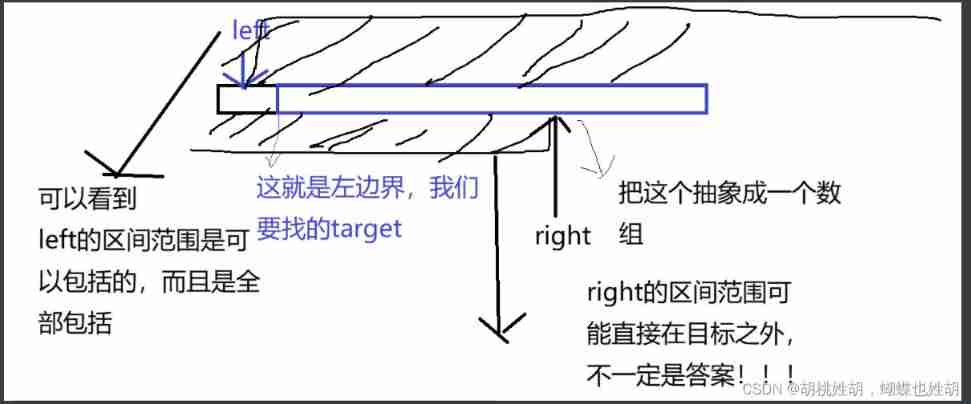

Do you really think binary search is easy

随机推荐

Database addition, deletion, modification and query

杰理之普通透传测试---做数传搭配 APP 通信【篇】

Detailed explanation | detailed explanation of internal mechanism of industrial robot

Ali's redis interview question is too difficult, isn't it? I was pressed on the ground and rubbed

【MySQL学习笔记32】mvcc

杰理之AD 系列 MIDI 功能说明【篇】

Bugku CTF daily question: do you want seeds? Blackmailed

Jerry needs to modify the profile definition of GATT [chapter]

http缓存,强制缓存,协商缓存

Go learning --- use reflection to judge whether the value is valid

The ECU of 21 Audi q5l 45tfsi brushes is upgraded to master special adjustment, and the horsepower is safely and stably increased to 305 horsepower

JMeter performance test steps practical tutorial

Significance and measures of encryption protection for intelligent terminal equipment

合规、高效,加快药企数字化转型,全新打造药企文档资源中心

可变参数重载时的内存错误

Ble of Jerry [chapter]

数字IC设计笔试题汇总(一)

Sharing of source code anti disclosure scheme under burning scenario

TS 类型体操 之 循环中的键值判断,as 关键字使用

Select all the lines with a symbol in word and change them to titles