当前位置:网站首页>A bit of knowledge - folding forging and Damascus steel

A bit of knowledge - folding forging and Damascus steel

2022-06-23 05:41:00 【Night drift ice】

Folding forging technology was widely spread in ancient times . Many weapons are full of folding and forging links in the manufacturing process . so to speak , Folding forging process is one of the most top hand-made knife processes in ancient times .

Folding forging is to combine two or more different chemical components ( Hardness and other characteristics are different ) The steel is forged into strips , Then they are stacked together and heated for melting and forging , Then fold or twist it into a fried dough twist , Then forge it into a knife shape . Can break a single steel “ The harder it is, the crisper it is ” The physical properties of , So as to obtain high hardness 、 Peerless Sabre with low brittleness . Two materials with different chemical compositions can be combined to form visible knife marks , In addition, the hardness of the two materials is different and a micro saw blade is formed at the blade , Not only does it feel sharp , The blade toughness is also good .

The purpose of forging is to shape and modify , Including the improvement of mechanical properties and internal organization . Ancient craftsmen shaped swords by forging , Developed to remove excess impurities in steel by repeated forging . The ancient metallurgical technology is not up to standard , Uneven distribution of impurity bubbles in metal , Remove some impurities and bubbles by folding and forging , Make the inside of the tool blank more dense and balanced , Finally, it is developed into a kind of composite alloy steel by folding forging technology , Improve steel properties . In the process of folding and forging , Same piece of iron , It will also form patterns due to repeated folding . So later, someone used iron with different carbon content to fold and forge repeatedly , Form more complex patterns . This pattern is a welded pattern . Obtain patterns by folding and forging , That is what we call patterned steel .

meanwhile , The swords made with this technology are also very valuable , There are records in history books that say , A treasured knife made by folding and forging is worth four people a year's rations , Ordinary people can't afford .

According to the forging temperature, it can be divided into hot forging 、 Warm and cold forging . It is generally used 800 Degree is the dividing line , higher than 800 Degree is called hot forging ; stay 300~800 It is called warm forging or semi hot forging , Forging at room temperature is called cold forging . The most common type of forging is hot forging or warm forging .

for instance , The master first arranges the steel blocks with different carbon content at random and then stacks them in layers , Different knife making schools have different arrangement methods , In this way, different forging textures of different schools can be obtained .

The stacked steel blocks are then heated .

Then forge a whole steel block with a sledgehammer .

Then fold the steel block .

In addition to the folding method , There is also a way of twisting , Fix one end of the iron bar after burning it red , Screw the steel bar in one direction at the other end , Twist the steel like a fried dough twist , A lamellar structure can also be obtained .

Then continue heating , Forge again .

Just keep folding in half 、 heating 、 Forging , Fold it in half again , Forge again . As the ancients said , One half fold is called one refining , Baisteelmaking is named after folding forging .

meanwhile , The impurities contained in the steel are also folded repeatedly — During forging , Oxidize in the air , The inclusions in the steel are greatly reduced and eliminated , So as to make its composition more uniform , The tissue tends to be dense , Grain refinement , Improve the properties of steel .

When the steel is folded in half 7 To 8 Later , The high carbon and low carbon parts permeate each other , Make the carbon content basically uniform and reach an appropriate proportion , The forgings have good hardness and toughness , meanwhile , It also presents irregular patterns due to repeated folding .

The pattern is the precipitated banded iron carbon body or carbide .

But after quenching , On the micro level , There is still a structure with uneven carbon content , So there are micro serrations , And it is this sawtooth structure , And greatly increase the cutting force , Make it sharper .

Of course , Folding forging also has disadvantages , That is a waste of labor and materials . Because a part of the iron will be oxidized every time it is folded in half , And will lose about 0.07% Our carbon , After a large piece of billet iron has been broken for several times, only a small piece of iron remains , And it is quite laborious to use a sledgehammer to strike iron by manpower .

It's really not easy to get a folding forged sword , In addition to labor and labor consumption , There are many other factors to pay attention to in the production :

First , Because different temperatures have completely different deformation capacity for steel , When the temperature is too high or too low , May break , Therefore, temperature control is a very important part in the metal forming process . in addition , The processing temperature of the material also depends on the structure of the material , Because many different steels have different carbon content , The melting point is also different , A slight oversight , Will become scrap iron . The master of the craftsman workshop should not only master the material structure of Damascus steel with professional knowledge , It is also necessary to master the furnace temperature and sintering time by experience .

secondly , The internal structure of steel is also closely related to the quality of Baodao . Because metal deforms during forging , There will be a lot of dislocation motion , Deform large grains into small grains , It will cause shrinkage cavity in the metal 、 Segregation and other defects , Each of these subtle movements plays a vital role in success , therefore , The craftsman and workshop master are folding the steel in half — During forging , In addition to enough professionalism , We should also have great patience and serious attitude .

Segregation : Different parts of the alloy form the phenomenon of uneven chemical composition during solidification and crystallization .

Shrinkage cavity : Macroporous defect structure formed in alloy during condensation crystallization .

Damascus steel

Use Damascus steel for folding forging , It is the Damascus knife with the highest name .

Damascus steel is actually 19 At the beginning of the th century, it was called wootz steel , It is produced in Uzi, India .

Wootz Steel is produced into about 2.3 Kilograms of steel ingots , It is often called a cake , Solidify in a closed crucible . This is a relatively high purity iron steel , Carbonaceous 1.5%. These cakes were transported to Damascus, Syria , There? , The sabers learned to forge them into swords with beautiful surface patterns . The hypereutectic of these steels (hypereutectoid) Carbon content plays a key role in producing characteristic surface patterns , Because the pattern is formed in this kind of steel when it is cooled Fe3C Arranged by particles . When Western Europeans first encountered weapons with these designs , They used the name Damascus steel . With the highest quality Damascus pattern Wootz It is made in 16-17 Produced in the th century .

Why the Damascus forging art is lost ?

One of the big mysteries of woods Damascus steel is why the manufacturing technology is lost . The content of vanadium provides the basis for a theory . According to our research , Obviously , To make the Damascus pattern of woods Damascus at the museum level , A blacksmith must meet at least three requirements .

First , Woods ingots must come from deposits that provide large amounts of trace elements , Especially chromium 、 molybdenum 、 Niobium 、 Manganese or vanadium . This idea is consistent with the theory of some authors , They believe that blades with good patterns are only produced by Woods ingots in southern India , Apparently near Hyderabad .

second , Experimental data confirm previous knowledge , That is, woods Damascus with good pattern is characterized by high phosphorus content . This means that the ingots of these blades will have severe heat shortness (hot short), This explains why in Paris 19 Blacksmiths of the th century cannot forge wootz Ingot . Therefore, successful forging requires the development of heat treatment technology , Decarburize the surface , To produce a ductile surface edge sufficient to accommodate a short area of internal heat .

Third , If the blacksmith developed a heat treatment technique , Enable hot short ingots to be forged , Then he may still have not learned how to produce surface patterns , Because only after the decarburization zone on the surface is worn off ; This grinding process is not a simple thing .

Blacksmiths who can make high-quality works are likely to keep the process of making these works a close secret , Only to their apprentices . The blacksmith can teach the apprentice the second and third points , But the first thing they don't know . There is no difference in physical appearance between ingots with appropriate minor elements and ingots without minor elements . Suppose for several generations , All ingots from India come from ore bodies containing an appropriate amount of minor elements , And produce works with good patterns . then , After centuries , The ore source may have been exhausted , Or the blacksmith community is out of reach ; therefore , This technique is no longer effective . as time goes on , Blacksmiths who knew this technique died without passing it on to their apprentices ( Because it no longer works ), So even if a similar source is found later , There is no more knowledge to use . If there are data on the content of carbide forming elements in various deposits used in the production of woods steel in India , We can study the possible validity of this theory .

Reference resources :

Folding forging _ Baidu Encyclopedia

The Key Role of Impurities in Ancient Damascus Steel Blades

Talk about whether it is necessary to use folding forging technology for your knife - Bili, Bili

边栏推荐

- 英集芯推出4串锂电池100W移动电源升降压方案SoC芯片IP5389

- What is the reason for the black screen of the computer monitor when the computer is turned on? What should I do about the black screen of the computer monitor

- The road of architects starts from "storage selection"

- fastjson中的@JSONField注解

- Composite API

- [proteus simulation] Arduino uno+pcf8574+lcd1602+mpx4250 electronic scale

- Introduction to MySQL (I) grammar

- 【斯坦福计网CS144项目】Lab2: TCPReceiver

- 人脸识别 确定阈值

- 抽奖 ddd 代码

猜你喜欢

How to move the software downloaded from win11 app store to the desktop

Lihongyi, machine learning 5 Tips for neural network design

Win software - (net framework) processed the certificate chain but terminated in a root certificate that is not trusted by the trusted provider

Konva series tutorial 1:what is konva?

Cloud native database is the world of future databases

GDB data reading in GDAL (III) of GIS

Mathematical analysis_ Notes_ Chapter 1: set and mapping

Heimdall Database Proxy横向扩展提高20倍

Differences between fs4059a and fs5080e charging chips

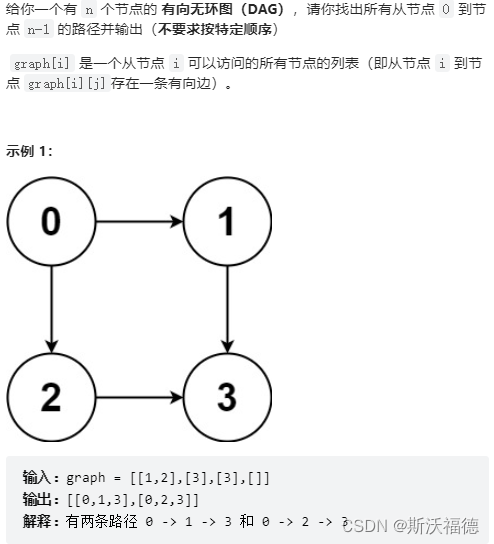

Leetcode 797: all possible paths

随机推荐

Spark 离线开发框架设计与实现

After the idea code is developed, the code is submitted. If the branch is found to be incorrect after submission, how can I withdraw it

账号多开是什么意思?为什么要账号多开?如何安全实现?

制造业数字化转型存在问题及原因分析

数字藏品赋能实体产业释放了哪些利好?

啊哈C语言 第7章 有了它你能做更多的事(第27-28讲)

sprintf 格式代码使用不规范在不同平台下的表现

About dos/ddos attack and defense

手机无线充电双线圈15W方案SOC英集芯IP6809

高等数学(第七版)同济大学 习题1-7 个人解答

When I was young, I thought my father was omnipotent

MySQL面试真题(二十五)——常见的分组比较场景

[opencv450] image subtraction, binarization, threshold segmentation

GO语言-自定义error

Wechat applet: Puzzle toolbox

MySQL面试真题(二十八)——案例-通讯运营商指标分析

Mobile power fast charging qc3.0 scheme chip ip5318 fast charging scheme

Wechat applet: wechat can also send flash photos to create wechat applet source code download and customize flash time

WebRTC[47] - WebRTC 保存 YUV 数据的常用方式

Pkav simple blasting