当前位置:网站首页>[industrial control old horse] detailed explanation of the design scheme of the running lamp control system based on Siemens S7-200PLC

[industrial control old horse] detailed explanation of the design scheme of the running lamp control system based on Siemens S7-200PLC

2022-06-29 07:43:00 【Industrial control old horse】

Based on Siemens S7-200PLC The design scheme of the control system of the running lamp based on

1、 Design background

application S7-200 PLC The hardware circuit of the lantern design , And make use of OB1 Ladder diagram control program design . By controlling S7-200 PLC The function of the timing relay is to realize that each color lamp lights up and goes out according to a certain law .

Turn on the delay timer SD Characteristics ( If RLO There is a positive jump edge , Then turn on the delay timer start command , Start the timer of the command with the set time value ). This control circuit has a simple structure , High reliability , Strong applicability ; The software program has a wide range of applications , The control of lighting and extinguishing the colored lights according to certain rules , Just change the time of the corresponding timer .

2、 Basic requirements of the system

2.1. The operation of the system is controlled by a switch :

Start switch “ON” The system works ; Start switch “OFF” The system stops working ;

2.2. S7-200 The command system of :

Turn on the delay timer SD, If RLO There is a positive jump edge , The on delay timer starts , Start the specified timer with the set time value . After reaching the set time , The dynamic contact of the timer is closed and maintained , until RLO Turn into 0 when , The timer is reset . If the timer runs for (RLO by 1 when ) Less than the timer time setting , Then when RLO from 1 Change to 0 when , The timer is also reset .

2.3. The law of control :

L1L7 common 7 A light-emitting diode , Ask to press the start button to run the lantern L1L7 Every... In positive order 1 Seconds turn on , When L7 After light , stop 2 second , then , Reverse reverse sequence 1 Seconds turn on , When L1 After re lighting , stop 5 second , Repeat the process . Press the stop button , The running lamp stops working .

2.4. Design principle

(1) Shift instructions

Shift instructions include unsigned number shift and signed number shift . The unsigned shift contains the word shift left instruction 、 Word shift right instruction 、 Doubleword left shift instruction and doubleword right shift instruction ; Signed number shift includes integer shift right instruction and double integer shift right instruction .* Unsigned number shift instruction .

Word shift left instruction

When it is allowed to enter EN Bit is high “1” when , The word shift left instruction will be executed , take IN The content specified by the end is sent to the accumulator 1 In low words , And left N The number of bits specified at the end , And then write OUT.Word shift right instruction

When it is allowed to enter EN The status of is “1.

(2) Sequential control design method

The so-called sequence control , That is, according to the predetermined sequence of production process , Under the action of each input signal, according to the internal state and time sequence , In the production process, each actuator operates automatically and orderly . Generally, sequential control design method is used , The sequence function diagram shall be drawn , The structure of the sequential function diagram has a single sequence 、 Select sequence and parallel sequence . A single sequence has no branches or merges , Branches of the selection sequence cannot be activated at the same time , Branches of parallel sequences can be activated at the same time .

2.5. Hardware selection

S7-200 Programming software based on STEP 7-MicroWIN32 Equipped with a large number of programming wizards , Such as PID、 Network reading and writing 、 Programming wizard for high-speed counters and high-speed output instructions , Position control module 、 Text display TD200、 Modem module 、 Ethernet Module 、 Internet module 、AS-i Programming wizard of communication module, etc . When using these programming wizards , Just enter the required data or determine the options , Programming software can automatically generate user programs .

With programming software and simulation function , yes , we have PLC The manufacturer provides the software to run on the computer , Can be used instead of PLC Hardware debugging user program simulation software , For example, Siemens and STEP 7 The programming software is used together S7-PLCSIM Simulation software 、 Mitsubishi Corporation and SW3D5C-GPPW-C Programming software SW3D5C-LLT-C Simulation software , Omron and CX-Programmer Simulation software for programming software CX-Simulator etc. , Siemens “LOGO! ” The programming software of the programmable logic module also has the simulation function .

PLC The simulation software is also a good learning tool for beginners to learn programming and program debugging methods .

2.6. The project design

The trend of the running lantern is as follows : When the start button is pressed ,L1、L2、L3、L4、L5、L6、L7 In order of 1 The second interval is lit ; When L7 After light , Pause 2 second , Reverse reverse sequence 1 Seconds turn on , When L1 After re lighting , stop 5 second , Repeat the process . For emergency stop, press the stop button , The running lamp stops working .

2.7. Element list

surface 2-1 List of components for multi period intersection traffic lights

3、 PLC control system design

From the definition of programmable controller ,PLC It is also a kind of computer , It has a structure similar to that of a general-purpose computer , The programmable controller is also controlled by the central processing unit (CPU)、 Memory 、 Input / Output (I/O) Interface and power supply . However, it has stronger interface ability to connect industrial processes and more direct programming language to meet control requirements than general-purpose computers .

3.1. I/O Assignment and numbering of points

surface 3-1 System I/O Address assignment table

3.2. PLC External terminal wiring diagram

PLC The working time reference is provided by the circuit of the running lamp . stay PLC The end of the output of , Connecting a resistor and a light-emitting diode or connecting two light-emitting diodes in parallel with a resistor constitutes PLC The circuit of the running lantern , Pictured 3-1 Shown .

The device selection in the circuit can be determined by calculation and experiment , You can also refer to some typical circuit parameters . In circuit , Resistance has partial voltage function , The resistance value is about 13KΩ , The voltage borne by one and two parallel LED is 3V about , PLC The operating voltage of the is +24V, This can make the running lamp work normally .

The switch is PLC Signal input port . The switch at the input end is used to control the operation of the output end and the operation of turning off the traffic lights , Start switch sd1, I0. 0 Power on (“1” state ), The traffic lights operate according to the designed procedure , sd2 closed , I0. 1 power failure (“0” state ) The system stops working .

chart 3-1 The design diagram of the hardware circuit of the running lantern

边栏推荐

- Blue Bridge Cup -- Analysis of the second batch of test questions of the 13th session

- 关于KingbaseES临时文件过大问题

- Swin Transformer理论讲解

- golang 修改 结构体切片的值

- Compiling principle: the king's way

- 101. 对称二叉树(递归与迭代方法)

- Listen to textarea input through Keyup to change button style

- About the problem that the kingbasees temporary file is too large

- from xx import*等价于from xx import *,不一定要加空格

- systemd 管理node-exporter

猜你喜欢

Use of parameter in Simulink for AUTOSAR SWC

[translation] swarmed out. Design methods for building modern applications

Perceiving healthy life, enabling boundless connection -- contributing to openharmony 3.1 ecological construction

蓝桥杯——最小框架

matlab simulink 电网扫频仿真和分析

systemd 管理node-exporter

Wechat applet learning notes (summer vacation)

Detailed explanation of top and free commands

Problem solving -- > online OJ (13)

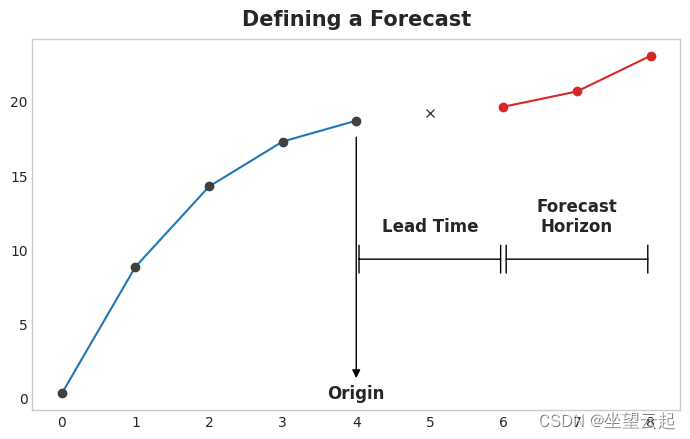

Machine learning notes - time series prediction using machine learning

随机推荐

postman预处理/前置条件Pre-request

flutter 仿照 uiswitch

1183: patient queue

SQL 注入绕过(六)

施努卡:轮胎自动抓取安装,3D视觉定位,机器人自动抓取

【工控老马】PLC六路抢答器系统设计详解

tf. to_ int64

cv2.cvtColor

The table cannot be vacuumed because the cursor is open for a long time

解题-->在线OJ(十三)

How to select CRM brand suppliers in garment industry?

golang 修改 结构体切片的值

Markdown skill tree (7): separator and reference

tf.compat.v1.global_variables

Schnuka: 3D visual inspection scheme 3D visual inspection application industry

ShapeShifter: Robust Physical Adversarial Attack on Faster R-CNN Object Detector

KingbaseES 中select distinct on 语句

[translation] E-Cloud. Large scale CDN using kubeedge

Markdown skill tree (4): link

IMX6DL4.1.15支持EIM总线(下)——配置原理分析。

![[translation] swarmed out. Design methods for building modern applications](/img/95/47b0b073c0f2f2631e39981274a079)