Mechanical vibration is a common phenomenon in Engineering , The parts and components of mechanical equipment and the whole machine have different degrees of vibration . The vibration of mechanical equipment often affects its working accuracy , Aggravate the wear of the machine , Accelerate fatigue failure ; With the increase of wear and fatigue damage , The vibration of mechanical equipment will be more intense , Such a vicious circle , Until the equipment breaks down and is damaged . Increased vibration is often accompanied by abnormal working conditions of machine components 、 Even a physical phenomenon caused by failure . Yes 60% The above mechanical faults are reflected through vibration . No shutdown and disassembly , Through the measurement and analysis of mechanical vibration signals , The degree of deterioration and the nature of the fault can be understood . Now , The theory of vibration is quite mature , The method is simpler and easier .

Equipment failure prediction machine tool failure early warning mechanical equipment vibration monitoring machine tool failure early warning CNC Early warning of abnormal vibration of wireless monitoring equipment

www.yun-360.com

The maintenance and repair of industrial equipment can be roughly divided into 3 Means , Predictive maintenance is the general trend .

Corrective maintenance : It belongs to post maintenance , Mend the fold after the sheep have been stolen .

Preventive maintenance : It belongs to prior maintenance , Based on time 、 Regularly maintain the equipment under the conditions of performance , More depends on experience .

Predictive maintenance : It belongs to prior maintenance , Based on various sensors installed on the equipment , Real time monitoring of equipment operation state , More accurately judge when the fault occurs . If hidden trouble is found , Automatically trigger alarm or repair command .

For the most widely used auxiliary machinery in the factory , Such as motor 、 Fan 、 Air compressor 、 Water pump 、 Most of the equipment on non key process and process nodes such as reducer have not used online monitoring system . The new intelligent vibration sensing and end cloud integrated monitoring system will help significantly reduce the deployment cost of equipment online monitoring 、 Use cost and maintenance cost , It is bound to usher in a huge incremental market , At present, many equipment manufacturers are also actively promoting the use of vibration sensors for equipment condition monitoring as an optional or standard configuration of factory equipment .

The solution of intelligent vibration monitoring system mainly consists of wireless vibration sensors ( Wireless uniaxial temperature vibration sensor 、 Wireless triaxial temperature vibration sensor 、 Wireless uniaxial temperature acceleration sensor 、 Wireless three-axis temperature acceleration sensor, etc )、 Intelligent wireless acquisition instrument 、 The intelligent vibration monitoring system is composed of cloud platform and mobile phone applet . The system collects the temperature of terminal equipment through wireless vibration sensor 、 Vibration amplitude 、 Acceleration and other information , adopt LoRa/BLE/Wi-Fi/ NB-IOT( Optional ) Wait for Wireless , Use intelligent wireless acquisition instrument or operator base station , Transmit relevant information to smart .

Two 、 Program advantages

1、 Accurate detection , Real time reporting ;

2、 Ultra-low power consumption , Stable performance ;

3、 Wireless transmission , Easy to install ;

4、 Battery powered , Waterproof and explosion-proof ;

5、 Support cloud platform , Real-time query 、 Abnormal alarm , Remote monitoring ;

3、 ... and 、 The application case

Case study 1: Flywheel bearing condition monitoring project in stamping workshop of a large car factory

Demand scenarios :

Stamping shop AB The line adopts flywheel structure , Flywheel bearing installation is concealed , Its wear state cannot be observed , Replacing this bearing requires 6 A shift ,8 people / shift , If the damage degree cannot be judged in advance , Wait for its sudden failure and shutdown , It will also cause damage to the clutch brake and the main shaft , The loss is in 200 More than ten thousand yuan .

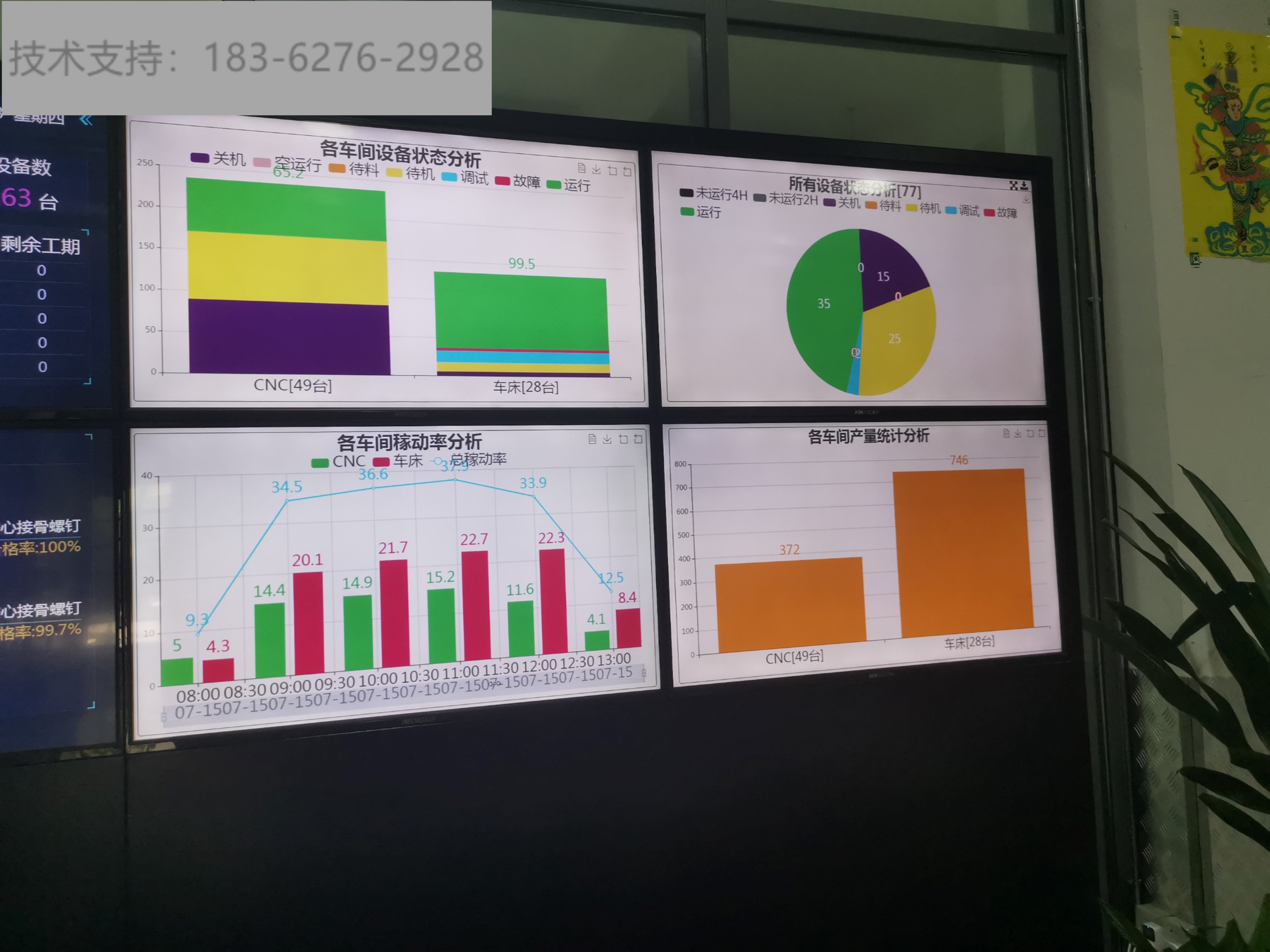

Case study 2: Intelligent monitoring system for factory equipment in a semiconductor factory in Wuxi

Demand scenarios :

Wuxi semiconductor Fab factory , Facility fans 、 Water pump 、 The motor must work reliably and stably , In case of abnormal shutdown, the loss is very huge , High requirements for equipment operation and maintenance , The cost is also high , Through the intelligent monitoring of the equipment, the abnormality of the equipment can be effectively detected in advance , Preventive maintenance can be achieved .

Case study 3: Intelligent monitoring project of a vibrating screen machine for coal sorting in Tianjin

Demand scenarios :

This application scenario has a harsh environment , There is dust outside 、 Water and high temperature , The vibration amplitude of the sorter is large , It's noisy , There is no effective monitoring means for equipment status , use Zigbee The networked wireless vibration monitoring sensor can online monitor the running state of the screen , Find fault symptoms in advance , Preventive maintenance .

Case study 4: Rolling mill fault alarm and prediction project in a steel plant in Chengde

Demand scenarios :

The rolling equipment in the rolling mill must ensure reliable and stable operation , In case of abnormal shutdown, the loss is very huge , High requirements for equipment operation and maintenance , The cost is also high , At present, it depends on personnel experience , It is time-consuming and laborious, and the failure of equipment cannot be warned in advance , Through intelligent online monitoring, the abnormality of the equipment can be effectively detected in advance , Preventive maintenance can be achieved .

Case study 5: Cooperate with a group in Shanghai to provide subway axle box intelligent monitoring system

Demand scenarios :

Subway traffic safety concerns almost every one of us , Hub monitoring 、 Maintenance and repair is a very important safety guarantee , Our company cooperates strategically with customers to develop vibration monitoring sensors with independent intellectual property rights 、 Data transmission and data analysis system . Set detection device for axle box system , Realize the monitoring of bearing temperature rise and vibration in the axle box , Realize hierarchical alarm , All test results can be displayed in the cab , And the alarm information can be sent to OCC, This system will first be installed and used in Shanghai Rail Transit 6、8 Line no. .

Case study 6: Cooperate with a listed company in the power industry to provide an intelligent monitoring system for power plant auxiliaries

Demand scenarios :

The customer is a well-known system solver in the power industry , Build a remote intelligent monitoring system , The real-time collection of equipment operation data is carried out through the temperature vibration integrated sensor , At the same time, the existing monitoring system data is integrated through the remote intelligent monitoring system , And according to the operation characteristics of power units and related auxiliary machines, configure targeted data acquisition strategies , Grasp the vibration that is effective for analyzing and locating unit faults 、 Temperature data , And with the help of intelligent alarm strategy , Discover the abnormal operation of the equipment in time , And realize automatic push SMS and mobile in abnormal state APP Alarm push . Remote diagnostic engineers conduct precise analysis of data , Issue equipment diagnosis conclusions and maintenance suggestions , And submit the diagnostic report , So as to provide targeted maintenance guidance and suggestions for the site .

Case study 7: some LCD Module water cooling system equipment status intelligent monitoring project

Demand scenarios :

The client is LCD Leading enterprises of Taiwan enterprises in the industry ,3 There are 13 All cooling water towers are 5 The top of the building , All pumps have been in service 9 In the above , Due to the failure of maintenance personnel to conduct regular and fixed-point patrol inspection of equipment points , It was found that a cooling water system had stopped working after the factory environment seriously exceeded the standard 3 God , The equipment has been seriously damaged , Direct loss 30 Ten thousand yuan . Now we are installing our wireless vibration and temperature integrated monitoring sensor 、 Gateway and upper computer system , There is no site modification and wiring construction , Realize the remote monitoring in the central control room , Instead of manual spot check and patrol inspection , Reduced labor costs and maintenance costs .

Case study 8: some A Stock listed OEM giant machine tool equipment tool life intelligent monitoring project

Demand scenarios :

The cutting tools of CNC machine tools are vulnerable parts , The wear state of the tool , It directly determines the yield of processed products . The current tool detection methods are inaccurate , Complex modeling and other issues , Unable to meet the requirements of Intelligent Manufacturing . Jiejie sensor has deep cooperation with customers , Develop intelligent tool wear detection sensor VB30, By testing the knife handle ( Tool holding device ) Vibration signal , More accurate detection of tool wear status , Implement “ Unmanned factory ” Strategies provide reliable data sources . After the implementation of the project 60% Unexpected shutdown , Quality defect rate from 6‰ Down to 3‰, save 16% Cost of .

Four 、 Product introduction

1、 Wireless vibration sensor

Wireless vibration sensors are mainly divided into : Wireless uniaxial vibration sensor 、 Wireless uniaxial temperature vibration sensor 、 Wireless triaxial vibration sensor 、 Wireless triaxial temperature vibration sensor 、 Wireless single axis acceleration sensor 、 Wireless uniaxial temperature acceleration sensor 、 Wireless three-axis acceleration sensor 、 Wireless three-axis temperature acceleration sensor, etc .

2、 Intelligent wireless vibration acquisition instrument

Intelligent wireless acquisition instrument is an intelligent 、 Specialized wireless electronic devices , Used to collect the temperature of the sensor 、 Vibration 、 Acceleration and other data information . It integrates RS232、RS485、 Ethernet 、4G And so on , With data acquisition 、 Handle 、 Storage and sending functions , It can reliably transfer device data to the cloud platform .

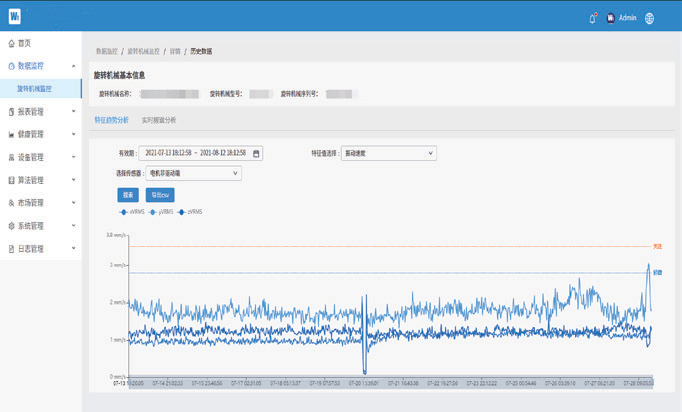

3、 Intelligent vibration monitoring system cloud platform

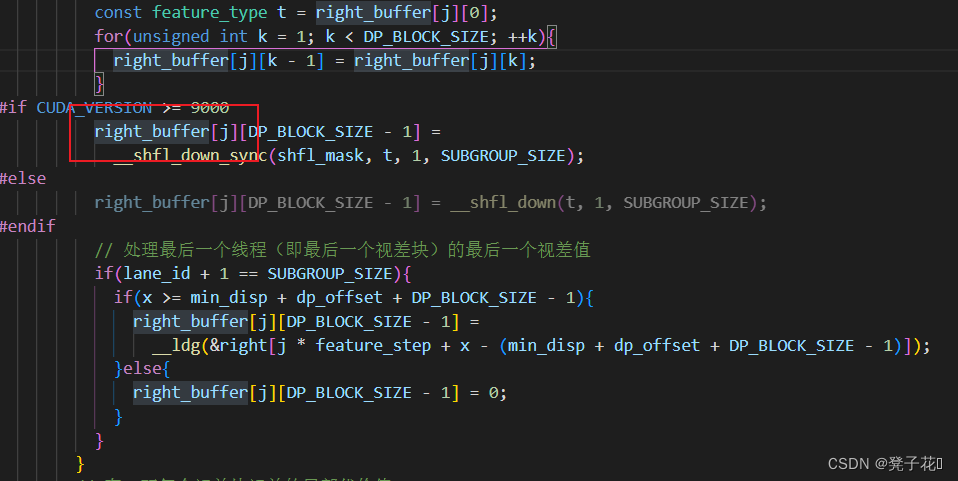

There are many common points between the faults of the mechanical part of CNC machine tools and those of ordinary machine tools , Therefore, when diagnosing and repairing mechanical faults , Many places are interlinked . however , The mechanical structure of CNC machine tools is greatly simplified , The failure of its mechanical structure presents some new features , For example, the transmission chain is shortened , High accuracy of transmission components , Mechanical maintenance covers a wider range .

1、 Mechanical structure of CNC machine tool

1.1 Main components

(1) Main drive system ;

(2) Feed transmission system ;

(3) System and device for realizing automatic action and auxiliary functions of some parts of machine tool , Such as chip removal 、 Protective devices , Tool holder and automatic tool changing device , Automatic workbench switching device ;

(4) Special function device , Such as tool breakage monitoring 、 Precision detection and monitoring device .

1.2 Main mechanical components

⑴ Spindle components : Provide cutting power 、 It also has C Axis function and orientation function

⑵ Feed part : The positioning of linear motion is completed under the drive of servo motor 、 feed .

⑶ Rotating moving parts : Refers to the rotating shaft, such as :B Axis 、A Axis

⑷ Automatic tool change device : Turret tool rest of CNC lathe 、 Tool magazine and tool changing mechanism of Machining Center

2、 Mechanical fault diagnosis of CNC machine tools

Diagnosis technology of mechanical faults of CNC machine tools , It is divided into simple diagnosis technology and precision diagnosis technology

2.1 Simple diagnostic technology : Also known as mechanical inspection technology . Ask about the machine tool 、 see 、 listen 、 feel 、 Smell, wait .

2.2 Precision diagnostic technology : According to the difficult faults proposed in the simple diagnosis , The full-time fault precise diagnosis personnel use advanced testing means to carry out accurate quantitative detection and analysis , Find out the fault location 、 reason 、 data , Determine the repair method and time

2.2.1 Common fault diagnosis methods

(1) Intuitive method ( look , listen , question and feel the pulse -- four ways of diagnosis )

ask — Malfunction of machine tool 、 Processing status, etc

see —CRT Alarm information 、 Alarm indicator 、 Whether the fuse is broken 、 Components are smoked and charred 、 Capacitor expansion deformation 、 Crack 、 The protector trips 、 Contact sparks, etc

listen — Abnormal sound ( Iron core 、 Undervoltage 、 Vibration etc. )

smell — Burnt smell and other peculiar smell of electrical components

feel — fever 、 Vibration 、 Poor contact, etc

(2)CNC Self diagnosis function of the system

(3) Data and status check

(4) The alarm indicator shows fault

(5) Plate replacement method ( Alternative law )

(6) Exchange templates or units with the same function , Observe the failover , Can quickly determine the fault location .

(7) Percussion

CNC system is composed of various circuit boards , On the circuit board 、 Faulty soldering or poor contact of the interface slot at the connector will

Cause trouble . Gently tap the doubtful point with insulation , If it appears , Then the striking part is likely to be the fault part .

(8) Heating method

When the equipment operates for a long time or the ambient temperature is high , The machine tool will fail , Use a hair dryer 、 Infrared light

Shoot suspicious components or components . Determine the fault point .

(9) Functional program testing

(10) Segregation

The isolation method is to disconnect some control circuits , So as to achieve the purpose of narrowing the fault area .

(11) Measurement comparison method

For the convenience of detection , A detection terminal is set on the template or unit , With a multimeter 、 Oscillograph and other instruments test the level or waveform of these terminals , Compare the test value with the normal value , It can analyze and judge the cause and location of the fault . Various fault diagnosis methods have their own characteristics , Flexible combination and application should be carried out according to the characteristics of fault phenomena .

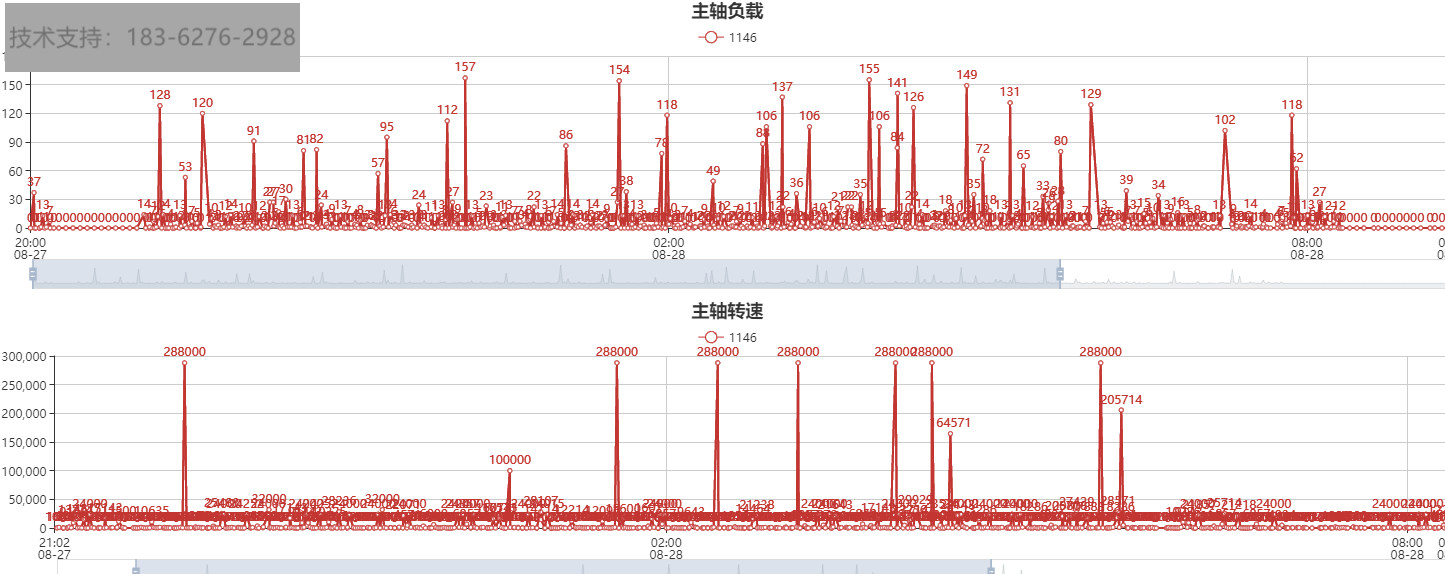

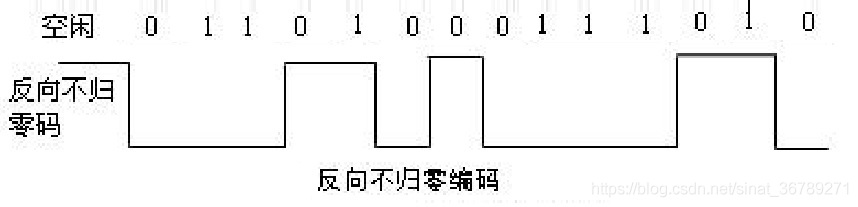

2.2.2 Mechanical vibration detection and diagnosis

Take machine tool vibration as information source , Obtain signals during the operation of the machine tool , Make various processing and analysis of signals , Judge whether there is a fault through the change of some characteristic quantities 、 Determine the nature of the fault according to some criteria formed by previous diagnosis experience, and further determine the location of the fault based on some other basis . It is practical and reliable 、 The characteristics of accurate judgment

This paper is written by Yunwojia digital chemical plant service provider Release ,[ Click here ] (https://www.yun-360.com) You can find me

![SSRF vulnerability file pseudo protocol [netding Cup 2018] fakebook1](/img/10/6de1ee8467b18ae03894a8d5ba95ff.png)