当前位置:网站首页>[follow Jiangke University STM32] stm32f103c8t6_ PWM controlled DC motor_ code

[follow Jiangke University STM32] stm32f103c8t6_ PWM controlled DC motor_ code

2022-07-07 15:06:00 【Related to the sun_】

Code :

PWM.h

#ifndef __PWM_H

#define __PWM_H

void PWM_Init();

void PWM_SetCompare3(uint16_t Compare);

#endif

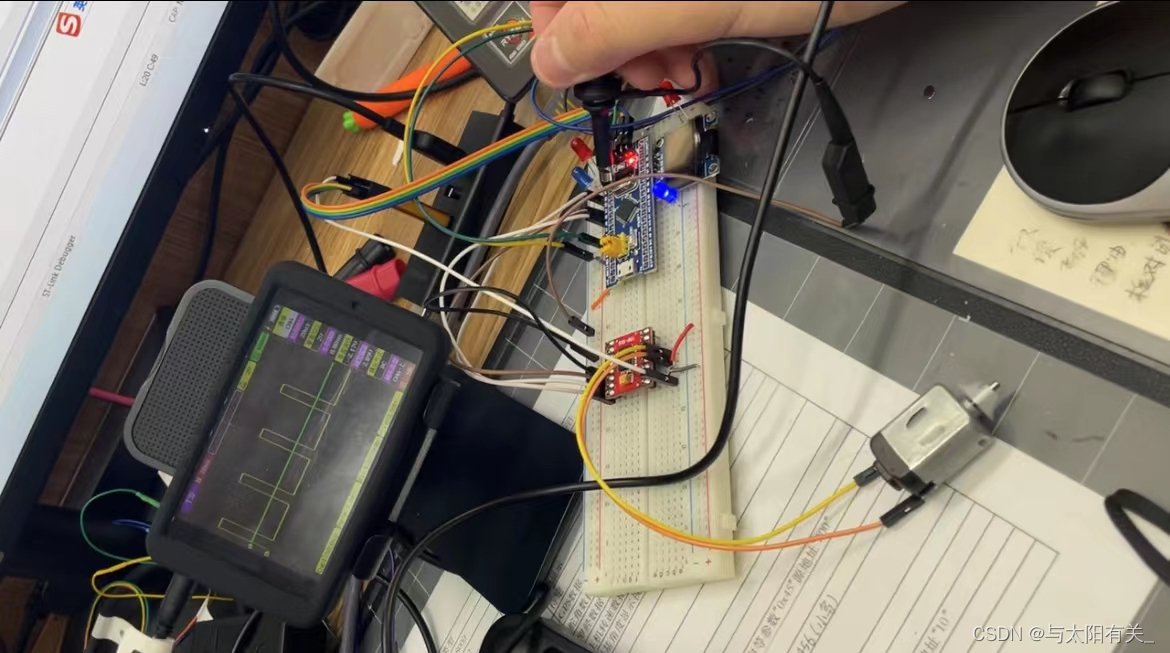

Inside the motor Coil and magnet , So in PWM Driven by , The buzzer will sound

When the SCM is set PWM When the frequency is within the range that our human ears can receive , We press and hold the rotating motor , You will hear an obvious buzzing ( The sound of buzzer )

Methods of elimination : enlarge PWM frequency , When PWM When the frequency is large enough , Beyond the scope of human ears , I can't hear it .Reduce prescaler , This will not affect the duty cycle

The radio frequency range of the human ear :20Hz To 20kHz.

It is amended as follows :TIM_TimeBaseInitStructure.TIM_Prescaler =36- 1; // The frequency changes to 20kHz

PWM.c

#include "stm32f10x.h" // Device header

void PWM_Init()

{

RCC_APB1PeriphClockCmd(RCC_APB1Periph_TIM2,ENABLE); // Turn on timer 2

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA,ENABLE);// passageway 2 Clock enable function

GPIO_InitTypeDef GPIO_InitStructure; // Definition GPIO Initializing structure variables

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP; // Set up GPIO For push-pull output mode

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_2;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz; // The speed is set to 50MHz

GPIO_Init(GPIOA, &GPIO_InitStructure); // Proceed according to the above parameters GPIO The initialization

TIM_InternalClockConfig(TIM2);//TIM The time base unit of is controlled by the internal clock

TIM_TimeBaseInitTypeDef TIM_TimeBaseInitStructure;

TIM_TimeBaseInitStructure.TIM_ClockDivision = TIM_CKD_DIV1;

TIM_TimeBaseInitStructure.TIM_CounterMode = TIM_CounterMode_Up;

TIM_TimeBaseInitStructure.TIM_Period = 100 - 1; //ARR The value of the automatic reloader

TIM_TimeBaseInitStructure.TIM_Prescaler = 720 - 1; //PSC Prescaler value Yes 72M(720000000) Conduct 720 frequency division namely 1K At different frequencies meter 1000 Number 1s Time for

TIM_TimeBaseInitStructure.TIM_RepetitionCounter = 0;// Repeat counter value

TIM_TimeBaseInit(TIM2,&TIM_TimeBaseInitStructure);

TIM_OCInitTypeDef TIM_OCInitStructure;

TIM_OCStructInit(&TIM_OCInitStructure);

TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM1;

TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_High;// Output polarity selection

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable;// Output status enable

TIM_OCInitStructure.TIM_Pulse = 10;//CCR, That is, the duty cycle is 10%

TIM_OC3Init(TIM2,&TIM_OCInitStructure);

TIM_Cmd(TIM2,ENABLE);

}

void PWM_SetCompare3(uint16_t Compare)

{

TIM_SetCompare3(TIM2, Compare);

}

Motor.h

#ifndef __MOTOR_H

#define __MOTOR_H

void Motor_Init();

void Motor_SetSpeed(int8_t Speed);

#endif

Motor.c

#include "stm32f10x.h" // Device header

#include "PWM.h"

void Motor_Init()

{

RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA,ENABLE);// passageway 2 Clock enable function

GPIO_InitTypeDef GPIO_InitStructure; // Definition GPIO Initializing structure variables

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP ; // Set up GPIO For push-pull output mode

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_4|GPIO_Pin_5;// Motor direction control foot

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz; // The speed is set to 50MHz

GPIO_Init(GPIOA, &GPIO_InitStructure); // Proceed according to the above parameters GPIO The initialization

PWM_Init();

}

void Motor_SetSpeed(int8_t Speed)

{

if(Speed >= 0) // Positive rotation ( Turn clockwise )

{

GPIO_SetBits(GPIOA, GPIO_Pin_4);

GPIO_ResetBits(GPIOA, GPIO_Pin_5);

PWM_SetCompare3(Speed);

}

else// reverse ( Turn counter clockwise )

{

GPIO_ResetBits(GPIOA, GPIO_Pin_4);

GPIO_SetBits(GPIOA, GPIO_Pin_5);

PWM_SetCompare3(-Speed);

}

}

main.c

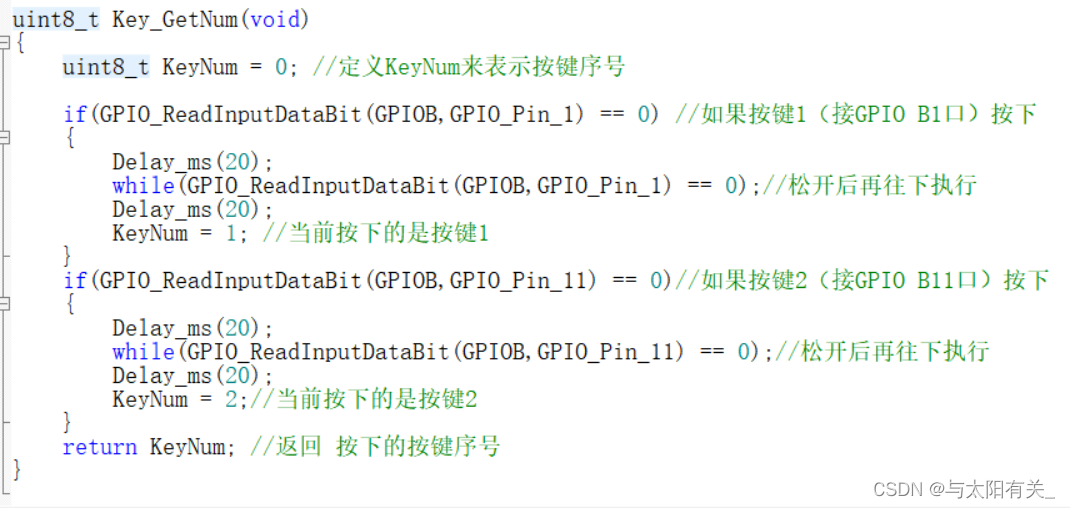

Press the key to control the motor speed

Code here shows KeyNum = Key_GetNum(); What you get isB1Pin value , So I put the button on this foot .

#include "stm32f10x.h" // Device header

#include "Delay.h"

#include "LED.h"

#include "Key.h"

#include "OLED.H"

#include "Motor.H"

uint8_t KeyNum,Speed;;

int main(void)

{

OLED_Init();

Motor_Init();

Key_Init();

OLED_ShowString(1,1,"Speed:");

while (1)

{

KeyNum = Key_GetNum();

if(KeyNum == 1)

{

Speed += 20;

if(Speed > 100)

{

Speed = -100;

}

}

Motor_SetSpeed(Speed);

OLED_ShowNum(1,7,Speed,3);

}

}

Work hard Grow slowly

边栏推荐

- Lidar knowledge drops

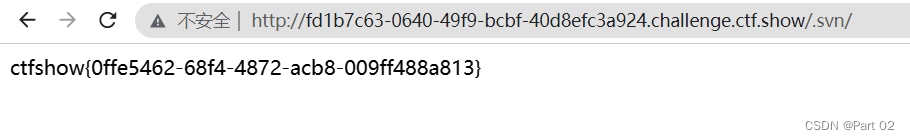

- CTFshow,信息搜集:web4

- Zhiting doesn't use home assistant to connect Xiaomi smart home to homekit

- CTFshow,信息搜集:web3

- Discussion on CPU and chiplet Technology

- Niuke real problem programming - Day11

- Webrtc audio anti weak network technology (Part 1)

- Ascend 910 realizes tensorflow1.15 to realize the Minist handwritten digit recognition of lenet network

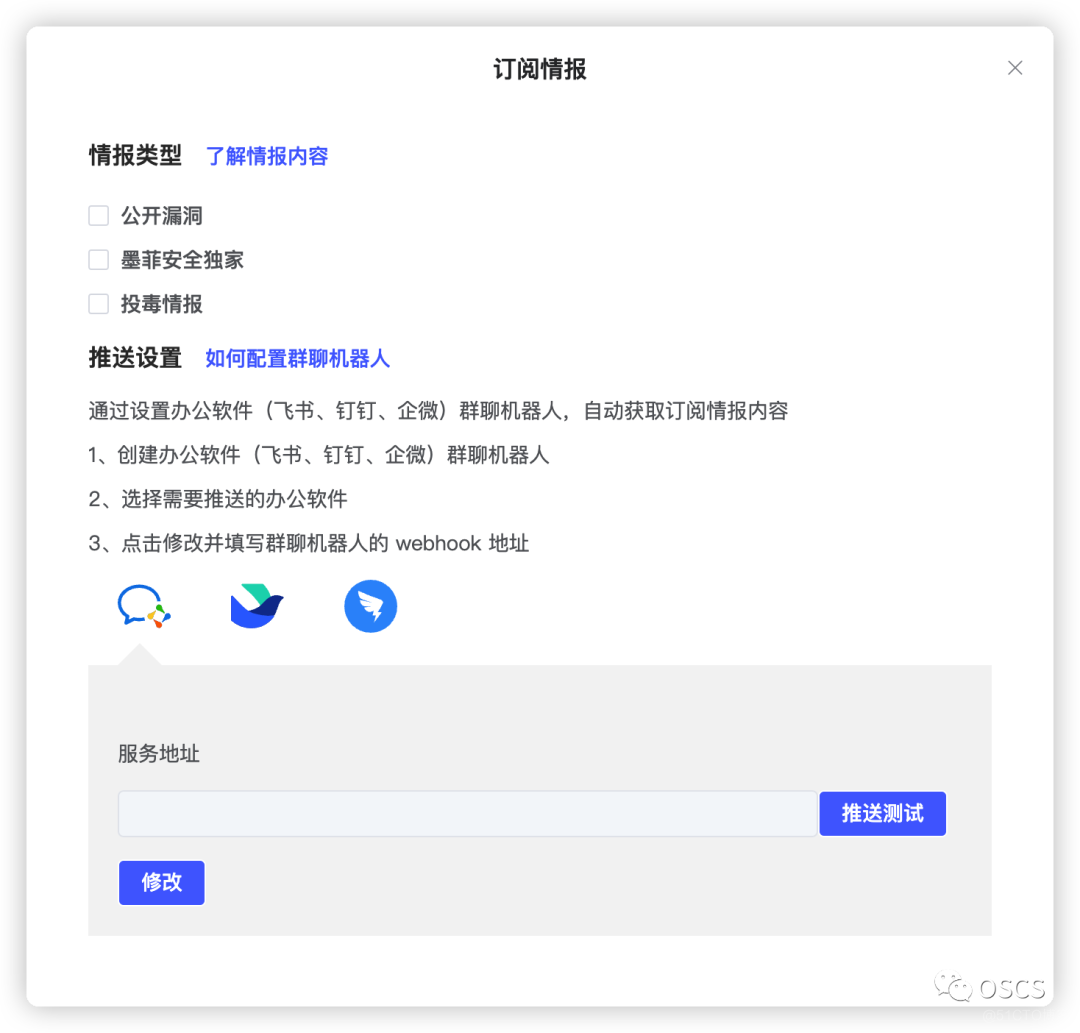

- Apache多个组件漏洞公开(CVE-2022-32533/CVE-2022-33980/CVE-2021-37839)

- 简述keepalived工作原理

猜你喜欢

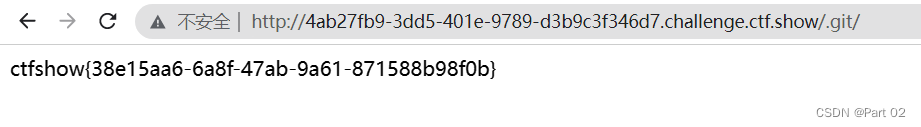

CTFshow,信息搜集:web8

In the field of software engineering, we have been doing scientific research for ten years!

Change win10 Screensaver

Ctfshow, information collection: web7

拜拜了,大厂!今天我就要去厂里

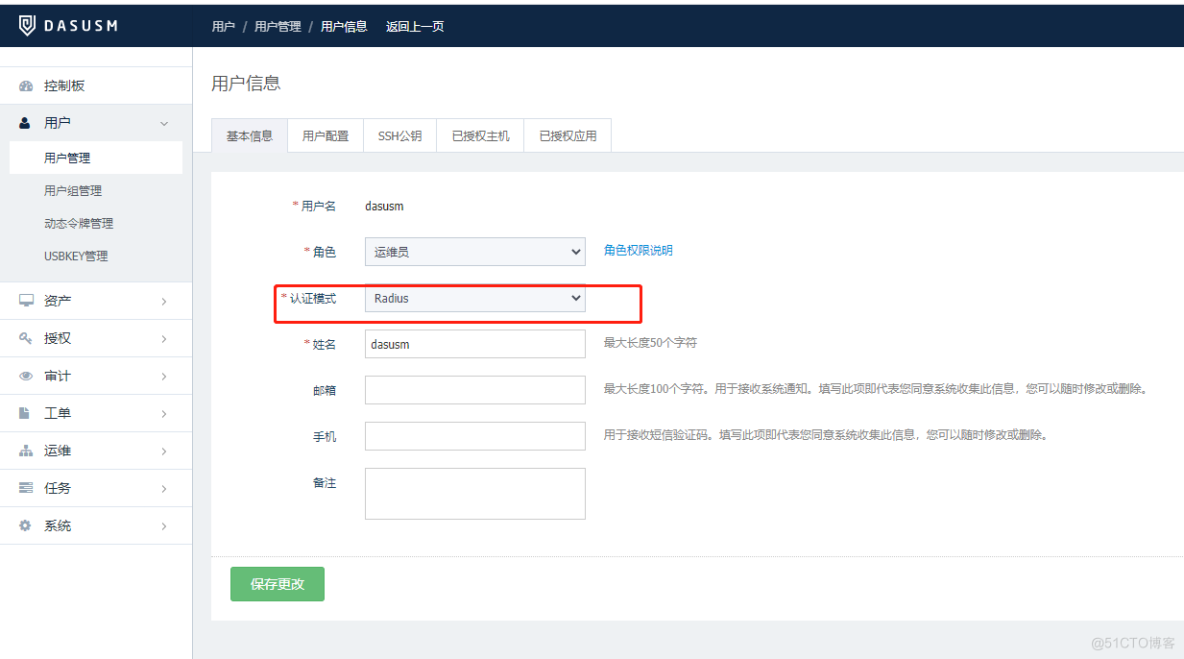

How to enable radius two factor / two factor (2fa) identity authentication for Anheng fortress machine

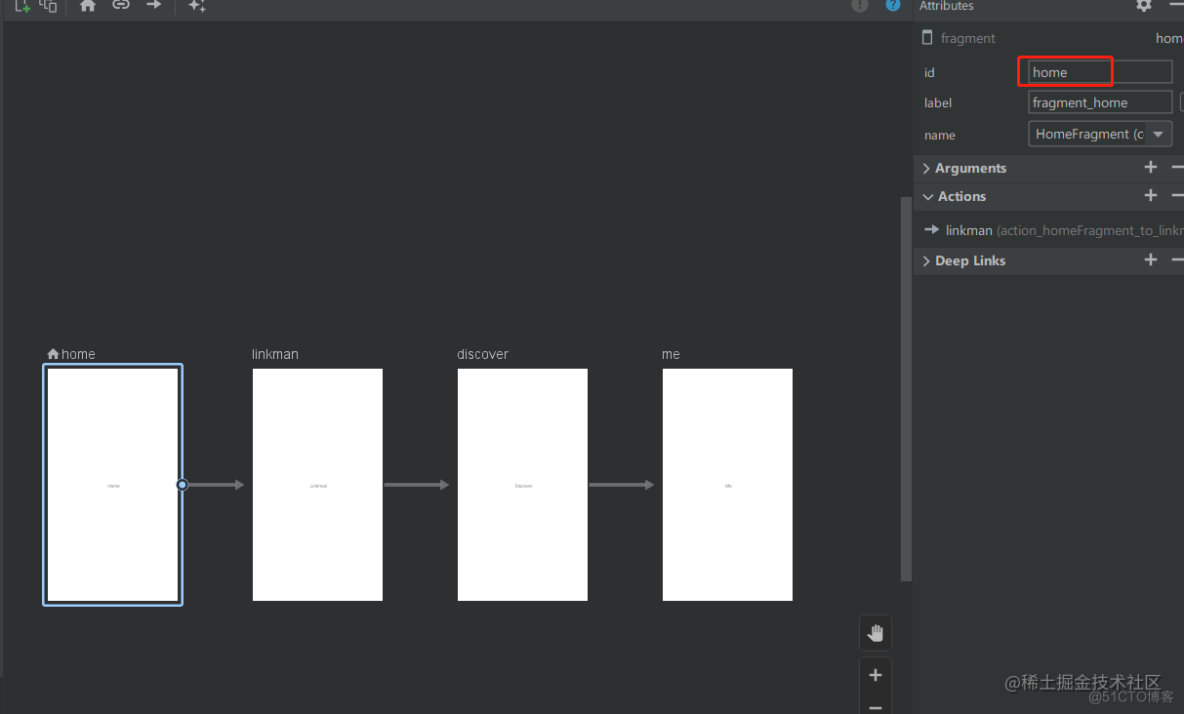

Navigation — 这么好用的导航框架你确定不来看看?

Apache multiple component vulnerability disclosure (cve-2022-32533/cve-2022-33980/cve-2021-37839)

JSON解析实例(Qt含源码)

![leetcode:648. Word replacement [dictionary tree board + find the shortest matching prefix among several prefixes]](/img/3e/cdde4b436821af8700eb65d35e8f59.png)

leetcode:648. Word replacement [dictionary tree board + find the shortest matching prefix among several prefixes]

随机推荐

PG基础篇--逻辑结构管理(锁机制--表锁)

Cocoscreator operates spine for animation fusion

最安全的证券交易app都有哪些

Read PG in data warehouse in one article_ stat

Deformable convolutional dense network for enhancing compressed video quality

Find your own value

Qu'est - ce qu'une violation de données

Lidar Knowledge Drop

IDA pro逆向工具寻找socket server的IP和port

What is cloud primordial? This time, I can finally understand!

Niuke real problem programming - Day17

JSON parsing instance (QT including source code)

Apache multiple component vulnerability disclosure (cve-2022-32533/cve-2022-33980/cve-2021-37839)

leetcode 241. Different Ways to Add Parentheses 为运算表达式设计优先级(中等)

Ctfshow, information collection: web6

What is the process of ⼀ objects from loading into JVM to being cleared by GC?

CTFshow,信息搜集:web5

Data Lake (IX): Iceberg features and data types

什麼是數據泄露

Niuke real problem programming - day13