当前位置:网站首页>Visubit "ai+3d vision" product series | loading assembly workstation

Visubit "ai+3d vision" product series | loading assembly workstation

2022-06-28 17:04:00 【3D vision workshop】

Automobile manufacturing is one of the industries with the highest degree of Automation , But automobile OEMs 、 More than half of the loading and unloading of parts factories 、 The assembly process is manual , Work hard 、 High repeatability 、 Recruitment difficulties ; And because there are thousands of kinds of auto parts 、 The deviation of manual feeding leads to irregular incoming materials, which makes the traditional automation unable to cope with the flexible production mode , More and more automobile OEMs and parts manufacturers began to layout AI Visual intelligence loading and unloading 、 Assembly robots .

Loading and unloading of auto parts 、 assembly

Visual recognition pain points

In the actual production process , Auto parts include exterior parts 、 Interior trim 、 Engine accessories 、 Different types of power train accessories , Their shapes are different and their sizes vary greatly .

Loading and unloading of most auto parts 、 Manual operation is adopted for assembly , And rely on “AI Machine vision ” And “ Industrial robot ” Loading and unloading of parts in combination 、 The assembly has the following pain points :

► There are many kinds of parts : The wide variety of parts makes it impossible to grasp through simple suction cups and fixtures , It is not allowed to scratch or scratch the surface of parts during grasping , Therefore, it is necessary to specially design flexible fixtures and realize grasping with ultra-high visual recognition accuracy in a specific attitude ;

► Part reflection 、 Easy to deform : The exterior decoration parts are mostly high reflective parts , Yes 3D Visual imaging and recognition are easy to cause interference , And it is easy to deform in the process of grasping , It is very difficult for robots to place fixtures or assemble ;

► The position of incoming materials is unstable : Manual material placement deviation 、 Accuracy deviation of hopper car 、AGV Feeding deviation will lead to great changes in the incoming position and attitude of parts ,AI It is more difficult to locate parts by machine vision ;

► High placement accuracy is required : After blanking, parts shall be subject to multiple assembly processes , It needs to be placed on the blanking fixture with a very accurate attitude , The deformation of parts leads to the error of robot placement .

△ Black and highly reflective

△ Parts are easily deformed 、 Scratch

Loading assembly workstation

SpeedLoader-M

The visual bit robot faces the automobile main engine factory 、 Loading and unloading of Auto Parts Factory 、 sorting 、 Assembly and other scenes , Independent research and development based on “AI+3D Vision ” Robot Loading assembly workstation (SpeedLoader-M), Depending on the 3D Visual high-precision positioning algorithm 、3D Visual high-precision deviation correction algorithm , It realizes multi category 、 Disorderly incoming auto parts High precision positioning and grasping and high-precision deviation correction , The system can be used in the automatic flexible robot production line of automobile agile development 、 Rapid deployment .

Besides , Loading assembly workstation (SpeedLoader-M) can docking MES、SCADA Such as system , And AGV And other downstream equipment linkage , Realize different categories 、 High precision flexible grasping and placement of parts with multi posture .

△ Product information sheet

△ Accurately locate the deep frame and grab the parts

△ Accurately correct the deviation and place the parts

Core strengths

► Initiate 3D Registration cloud algorithm

The first groundbreaking will Transformer The network is applied to 3D Point cloud processing , Realization Efficient real-time point cloud registration algorithm ; Through this registration algorithm , The accurate posture of the part to be grasped can be obtained , Provide high-precision grasping information and placement information for the robot ; Besides , Point cloud registration algorithm based on deep learning network , have Strong anti-interference ability 、 High stability 、 Strong real time Characteristics , And for the missing point cloud caused by part reflection , There is a certain degree of compatibility .

► be based on 3D High precision positioning and grabbing of point cloud

The 3D model of the part is accurately registered with the 3D point cloud photographed in real time , It can guide the robot to accurately grasp the highly reflective parts stacked in the material box ; Besides , The robot driver independently developed by visual bit can plan the robot trajectory in real time , In the deep 1.5m While grasping the parts in the material frame , Actively avoid the metal column fixing the workpiece and the four walls of the material box , In this process, the visual recognition accuracy can reach 0.1mm~0.2mm.

△ Point cloud imaging effect

△ Point cloud extraction effect

△ Point cloud matching effect

△ Accurately grasp the real object with deep frame

► be based on 3D High precision correction and placement of point cloud

utilize 3D The recognition and location algorithm realizes the inverse operation of the grasping process , The parts on the robot end fixture shall be installed according to the process requirements Place exactly In the fixture , And the parts are processed with high precision 3D rectifying , The visual recognition accuracy of this process can also reach 0.1mm~0.2mm.

△ Point cloud imaging effect

△ Point cloud extraction effect

△ Point cloud matching effect

△ 3D Accurate deviation correction and placement

► Customized flexible fixture

The workstation adopts the flexible fixture independently designed by visual bit , can It is compatible with flexible grasping of various specifications of automobile exterior trim parts , And integrated into the stripper mechanism , Ensure that the upper and lower parts are effectively separated , And ensure that the parts are not scratched .

► 3D Visual software interface

The application case

Batch landed in a future factory of auto parts

In the black light factory of a leading auto parts enterprise , Dozens of them AGV、 Industrial robots work together to complete the exterior decoration of many models “ Automatic injection molding —AGV Transport — Set up a warehouse for temporary storage —AGV Transport — Visual loading and unloading — Automatic assembly — Quality testing — Packing ” Fully automated production . Most of the exterior ornaments are highly reflective 、 Deformable plastic parts , And the automatic production line must be compatible with the flexible production of parts of different specifications .

In the black light factory , Independent research and development workstation (SpeedLoader-M) It realizes the Multiple specifications 、 High reflection 、 Large deformation Accurately identify and grasp the exterior trim of the , Re pass 3D Visual finish with high accuracy 3D Place it in the secondary fixture after correction . Besides , Automated production lines can be based on MES Place orders and switch to automatic production and assembly of different products accurately and quickly , In a real sense Realize flexible production .

Promote the deep integration of technology , Continue to promote the upgrading of Intelligent Manufacturing in the industry

When the manufacturing model starts to change ,“AI Machine vision ” It can give full play to the advantages of flexible production . Cibit robot and its holding subsidiary minshi Qiyuan continue to launch a number of products for the automotive intelligent manufacturing industry Efficient 、 Flexible and cost-effective Of AI Machine vision product line , Include Special machine for ultra-high precision measurement of large-size workpieces 、 Special machine for defect detection 、 Vision guided robot loading and unloading 、 assembly etc. , Continuously promote the transformation and upgrading of the automobile industry .

future , Visual bit will always adhere to “ Software defines industrial intelligence ” The core mission of , Create a multi-dimensional product matrix , Push AI More scene products with machine vision , Foundry enterprises with hard core ability “ The moat ”.

边栏推荐

- RHEL6.4中使用Cacti+Spine监控远程主机

- 彻底凉了!腾讯知名软件全线下架,网友一片唏嘘。。。

- From five capabilities to "1+5+n", Huawei makes the transformation of government and enterprises more stable

- 基于Krack的网络攻击「建议收藏」

- "Popular science leaders say" intelligent bionic robot fish

- EasyCVR接入Ehome协议的设备,无法观看设备录像是什么原因?

- C#/VB. Net to convert PDF to excel

- 免费、强大、高颜值的笔记软件评测: OneNote、Heptabase、氢图、FlowUs

- PotPlayer播放百度云盘视频

- 基数排序——【常见排序法(2/8)】

猜你喜欢

This simple little function saves 213 hours for our production research team in half a year

Cardinality sorting - common sorting method (2/8)

MATLB|电力系统优化运行与市场化

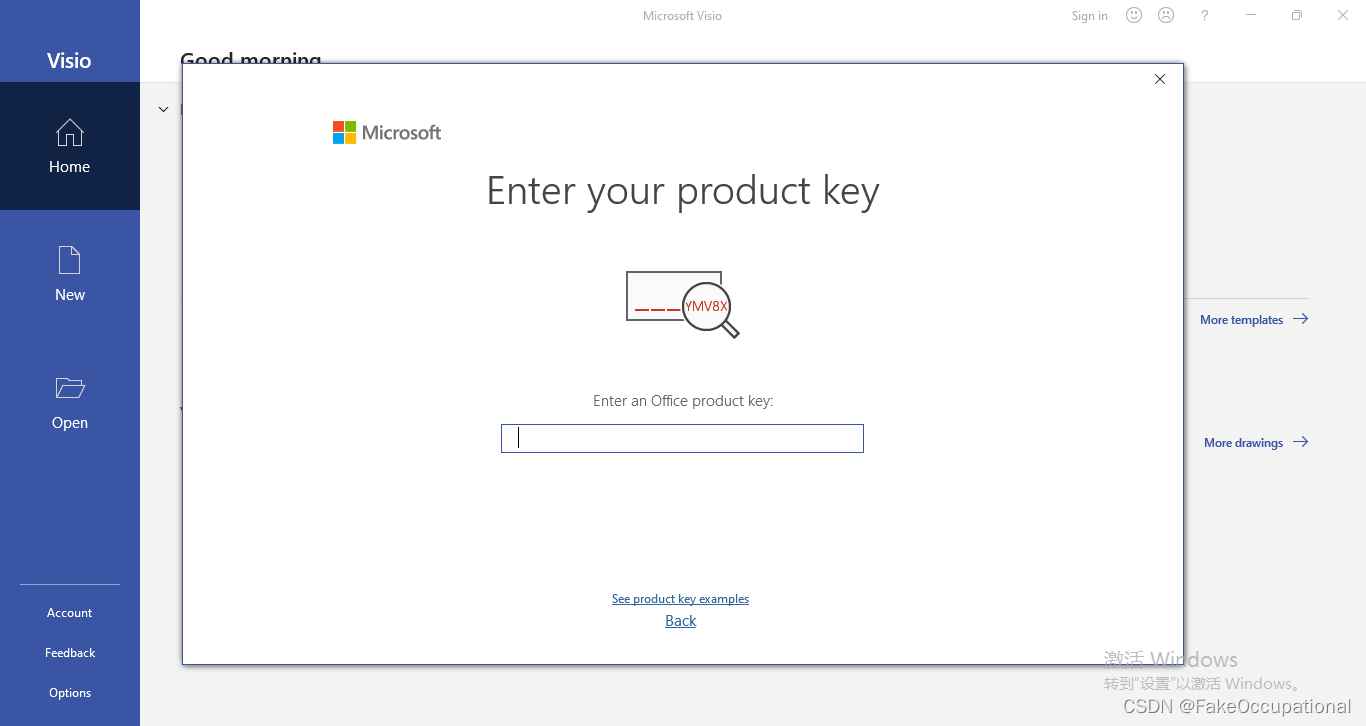

visio 使用

关于接口测试自动化的总结与思考

AutoSAR 软件开发培训

![[golang] how to install iris](/img/c6/842c4e920a74f9a07c2f6a82bb0cc1.png)

[golang] how to install iris

This simple little function saves 213 hours for our production research team in half a year

Fs2k face sketch attribute recognition

大型体育赛事与犯罪风险

随机推荐

np tips: random 创建随机矩阵 sample = np.random.random([19, 64 , 64, 3])

Cross cluster deployment of helm applications using karmada

"Popular science leaders say" intelligent bionic robot fish

ICML 2022 | 基于解耦梯度优化的可迁移模仿学习方法

Noip2011-2018 problem solving report of improvement group

NOIP普及组2006-2018初赛 2019 CSP-J1 2020 CSP-J1 完善程序题

本地部署Confluence遇到的问题:MySQL数据库编码、隔离级别、验证码不显示

EasyCVR播放视频出现卡顿花屏时如何解决?

MySQL中的日志管理 日志備份與恢複

China energy integration and Tianyi cloud create an "energy brain"

大促场景下,如何做好网关高可用防护

After the first failure, AMEC rushed to the Hong Kong stock exchange for the second time, and the financial principal changed frequently

Langqing and Langchao, an ecological model from OEM to value symbiosis

Gartner announces five privacy trends from today to 2024

Coding Devops helps Sinochem information to build a new generation of research efficiency platform and drive the new future of "online Sinochem"

Noip1998-2018 popularization group csp-j2 2019 2020 problem solving report and video

MATLB|可视化学习(plot和bar)

软件快速交付真的需要以安全为代价吗?

NOIP1998-2018 CSP-S2 2019 2021提高组解题报告与视频

Potplayer play Baidu Cloud disk video