Machining industry MES System mold industry MES System CNCl China industry MES System MES Code scanning and work reporting MES Data collection

1、 Traceability management

1. Material level traceability

2. Product level traceability

3. Quality level traceability

4.4M trace ( people , machine , material , Law ) trace

2、 Superior scheduling

1. Obtain real-time production performance

2. Support ERP Interface , The schedule information is updated synchronously

3. Real time output Gantt Chart , Automatically analyze the status of plan achievement

4. Real time reminder and alarm

5. Intelligently adjust production scheduling

6. Intelligently decompose front and back work orders 、 Assembly work order 、 Pre processing work order

3、 Material management

1. Intelligent collection of materials P/N、 supplier 、 specifications 、 Number 、DC、LOT Etc

2. Each small packaging material automatically generates a label

3. Perfect ERP Interface , Synchronize material data in real time

4、 Warehouse management

1. fifo ( Batch or production date ) Control and control

2. Cancel multi warehouse circulation operation , Realization JIT Feeding mode

3. Mobile data terminal is adopted for mobile operation , Real time data interaction

4. Automatically analyze the remaining quantity of materials after the order is completed , Calculate material loss

5. Paperless work

5、 Visual Management

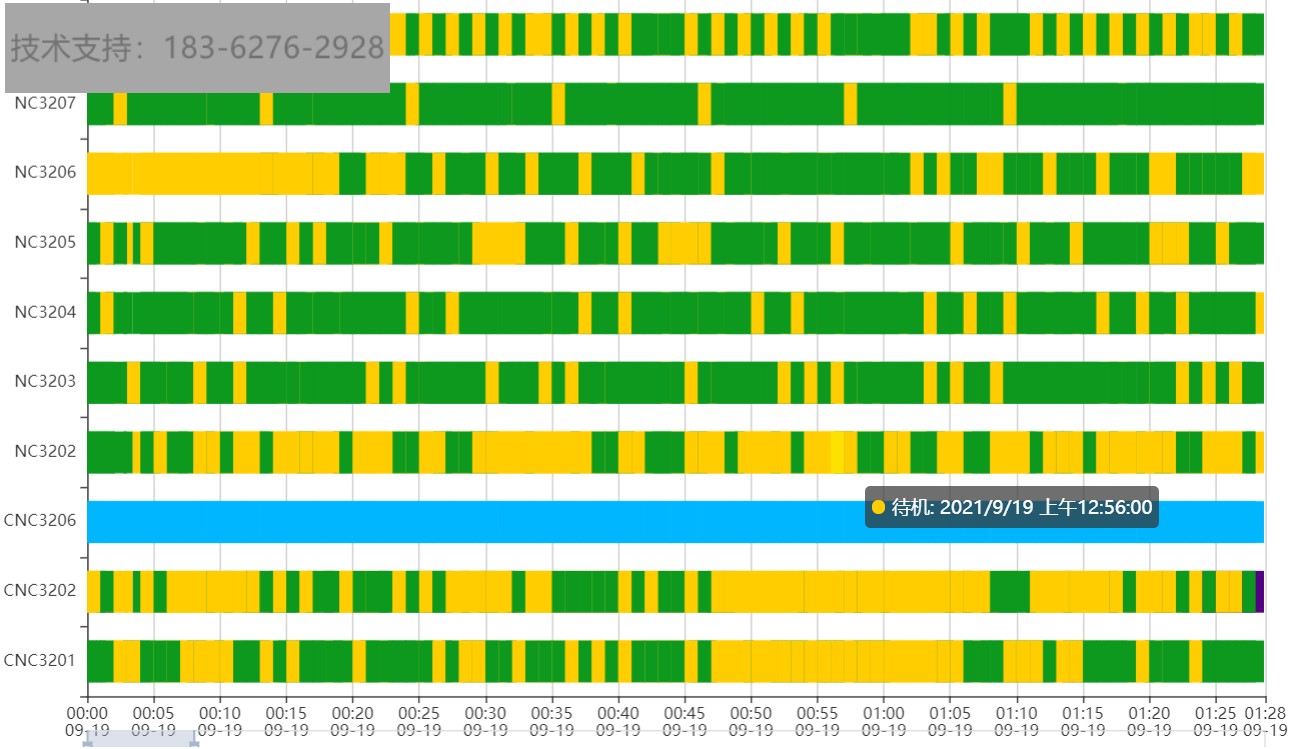

1.IMS Application MDC Technology automatically collects original information and makes statistical analysis ;

2. Management by objectives 、 Uncontrolled conditions automatically trigger , By text 、 Email feedback , Realize early warning management

3. Real time monitoring of equipment operation , And count its operation data , Convenient line body balance optimization ;

4. all KPI Statements and related records , Are directly generated by the system , You can restrict the query and export at any time ;

5. Complete paperless operation , Completely cancel the paper report operation ;

6. Can be realized WIP Real time analysis , Stop line early warning and fool proof mechanism ;

6、 Process flow management

1. Different technological processes and processes can be set according to different products ;

2. The system automatically controls the actual product production process ;

3. Call the police : For products not produced according to the product process flow , The system alarms in real time ( mail & SMS notification )

4. Guard against stupidity : Prevent the phenomenon of missing the process and not following the process flow , And Realize line stop processing .

5. Product process parameter setting and product design SN Process flow tracing is realized by association ;

7、PCBA management

1. Full closed loop process control

2.KPI Real time monitoring of indicators

3.JIT Feeding mode

4. The device is online

5. materiel ** Error proofing

6. Manpower reduction

7. Reduce inventory

8. Paperless workshop

8、 Assembly management

1. Flexible feeding mode

2. Test equipment online

3. Kanban management

4. Optimized process design

5. Personnel performance management

6. finished product / Semi finished product management

9、 maintenance management

1. Real time collection of maintenance data ( Bad information , Service information )

2. No repair area 、 Intelligent management and control of scrap disposal process

3. Graphical analysis and generation of repair data , Paperless work

4. Experience summary of maintenance methods , Reduce maintenance time

5. maintenance MEMO Record

6. Management and control of re running process of maintenance products

7. The whole process of maintenance is under the control of error prevention and stupidity prevention

8. The maintenance report is customized and automatically generated

10、 performance management

1. Set performance management indicators

2. The system provides comprehensive performance data of employees during their personal work

3. To achieve equity , Fair performance management

11、 Personnel management

1. Job skill setting

2. Employee qualification verification

3. Employee skill radar chart

4. New employee induction variation tracking

5. Employee induction training course tracking record

6. Record the working time and work content of each employee in real time

7. Realize quantifiable management of employees' work

12、 Quality management

1.IQC Incoming inspection management ,IQC The inspection process is systematic

2.IPQC Spot check 、 Full test 、 Patrol management

3.FQA Inspection process management

4.OQA Process control records

5. materiel 、 Partially Prepared Products 、 Finished product red card management ( Ban 、 lock )

6.ECN, Combined material management

7. Production quality data 、 Quality error shutdown mechanism and fool proof management

8. Automatic generation of quality report , Paperless management

13、 Packaging management

1. Collect products SN, Packaging accessories Reel ID,BOX ID Corresponding association ;

2. Anti stupidity treatment , Avoid less packages 、 Wrong package 、 Leak package ;

3. Prevent bad products from shipping ;

14、 Shipment management

1. docking ERP Customer shipping information ;

2. Automatically generate the serial number label of the corresponding product in the printing box ;

3. Collect shipping pallets ID With the outer box BOX ID relation

4. docking ERP Information , Automatically record the account value of shipment data ;

5. Prevent bad products from shipping , Prevent shipping errors ;

6. Automatically generate shipping order ;

7. Traceability control .

————————————————

Copyright notice : This paper is about CSDN Blogger 「 Taoyuan shopping mall 」 The original article of , follow CC 4.0 BY-SA Copyright agreement , For reprint, please attach the original source link and this statement .

Link to the original text :https://blog.csdn.net/baina666/article/details/123755481

This paper is written by Yunwojia digital chemical plant service provider Release ,[ Click here ] (https://www.yun-360.com) You can find me

![[leetcode] understanding and usage of map[key]+](/img/f5/9718f1020bddf913c09592697eb903.jpg)