当前位置:网站首页>Electronic Industry Inventory Management Pain Points and WMS Warehouse Management System Solutions

Electronic Industry Inventory Management Pain Points and WMS Warehouse Management System Solutions

2022-08-02 21:03:00 【Deep Blue Easy Network】

In recent years, with the continuous development and popularization of smart electronic products, the speed of product replacement is getting faster and faster, and the number of customer orders is small,There are many varieties and short order delivery times, which leads to increasing pressure on inventory, which further reduces the profit and income of electronic enterprises.

In order to carry out refined management of inventory, electronic companies began to introduce WMS warehouse management system solutions, and solve existing inventory problems with the help of warehouse barcode management system, to ensure accurate inventory, no backlog, and improve inventory turnover.

Electronic Enterprise Inventory Management Pain Points

1. There are many types and specifications of materials for electronic products, which are difficult to distinguish and find. As a result, many products are piled up in the corners and cannot be found, increasing the inventory backlogrisk.

2. The accuracy and timeliness of receipt and delivery basically depend on the experience and judgment of the warehouse clerk.situation occurs.

3. After the event, manually record the inbound and outbound data, and then enter it into the computer. There are errors in the recording and entry in the whole process, and the consumption ofThe time is long, and the inventory data is not accurate and real-time enough.

4. Sometimes due to changes in customer orders, product version updates, and oversupply from suppliers, a lot of sluggish materials are generated.

5. It is difficult to implement FIFO. There are many sluggish materials that are about to expire, and the inventory cost is high.

6. Manual inventory is time-consuming and labor-intensive, and the data is inaccurate, making it difficult to keep accounts consistent.

7. Lack of batch management and difficulty in material/product traceability.

WMS for electronics industryWarehouse management system solutions

1. Divide the warehouse location according to the SKU of the product, scan the code to make the goods correspond to the location, and carry out the location when putting on the shelf and picking.The prompt, "Where should I put it and where should I get it?" is clear at a glance, reducing the difficulty of identification, shortening the search path, and improving work efficiency and accuracy.

2. The whole process of code scanning operation can be realized in production picking, production warehousing, sales and warehousing, and real-time operation data can be automatically collected, so that warehouse managers can understand the progress of the operation in real time and make better adjustments.At the same time, the workload of employees can be greatly reduced.

3. After the products are put in and out of the warehouse, the inventory will be dynamically updated to ensure the real-time and accurate inventory quantity.At the same time, a complete inventory log is provided to record system operation traces and inventory changes to ensure that inventory traceability is well documented.

4. Scan the inventory through the PDA, and the data will be sent back to the PDA interface in real time, and it will be automatically checked in the system task. If there is an error, an early warning will be issued, therebyEnsure accuracy and ease in the inventory process.The inventory report can also be generated after the event, so that the accounts are consistent.

5. The existing inventory quantity can be set. When a certain inventory quantity is lower than a certain value, an early warning will be issued.Restock as soon as possible to avoid losses.

6. First-in, first-out strategy, giving priority to materials/finished products earlier in storage, reducing sluggish materials and improving inventory turnover.

7. You can query the number of materials/finished products in the warehouse, so that you can accurately grasp the existing inventory of each material/finished product.

8. It can be seamlessly integrated with external information systems, such as SAP, ERP, SRM, MES, etc.Office efficiency, optimize supply chain management.

Through the application of the WMS system, it can provide managers and employees of electronic enterprises with effective tools for warehouse management to achieve standardization, informatization,Refined warehouse management and information sharing in all aspects of the supply chain ensure the consistency of logistics and information flow and improve corporate profits.

边栏推荐

猜你喜欢

随机推荐

百问百答第49期:极客有约——国内可观测领域SaaS产品的发展前景

How Tencent architects explained: The principle of Redis high-performance communication (essential version)

Remember the stuck analysis of an industrial automation control system in .NET

千万级别的表分页查询非常慢,怎么办?

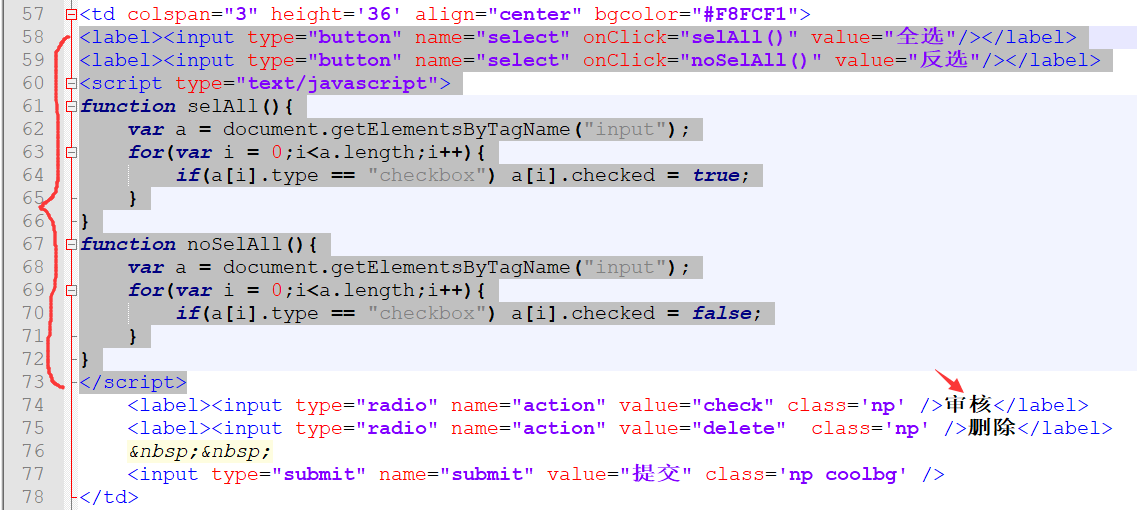

2022安全员-C证考试题库模拟考试平台操作

魔豹联盟:佛萨奇2.0dapp系统开发模式详情

什么是会话劫持以及如何阻止它

LeetCode 2336. 无限集中的最小数字(SortedSet)

MySQL LIKE – 语法和用法示例教程

千万级QPS下服务如何才能平滑启动

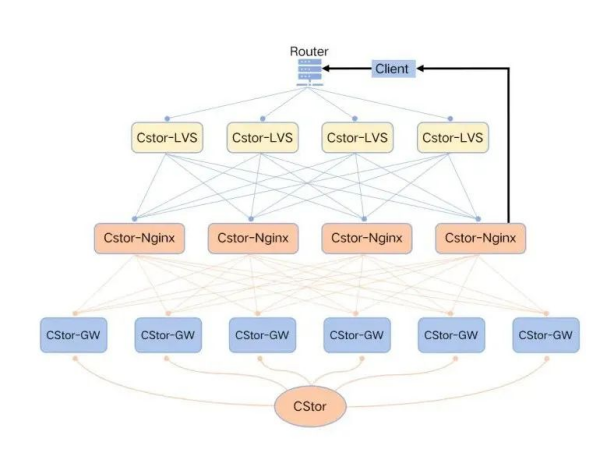

Playing in the cloud | The key technology of Tianyi cloud object storage ZOS high availability is revealed

在线文档Sheet技术解析

golang源码分析(19)简单编译器-计算器

全面认识二极管,一篇文章就够了

golang源码分析(33)pollFD

Data Governance: The Evolution of Data Integration and Application Patterns

天翼云4.0来了!千城万池,无所不至!

宝塔搭建实测-基于ThinkPHP5.1的wms进销存源码

vulnhub W34kn3ss: 1

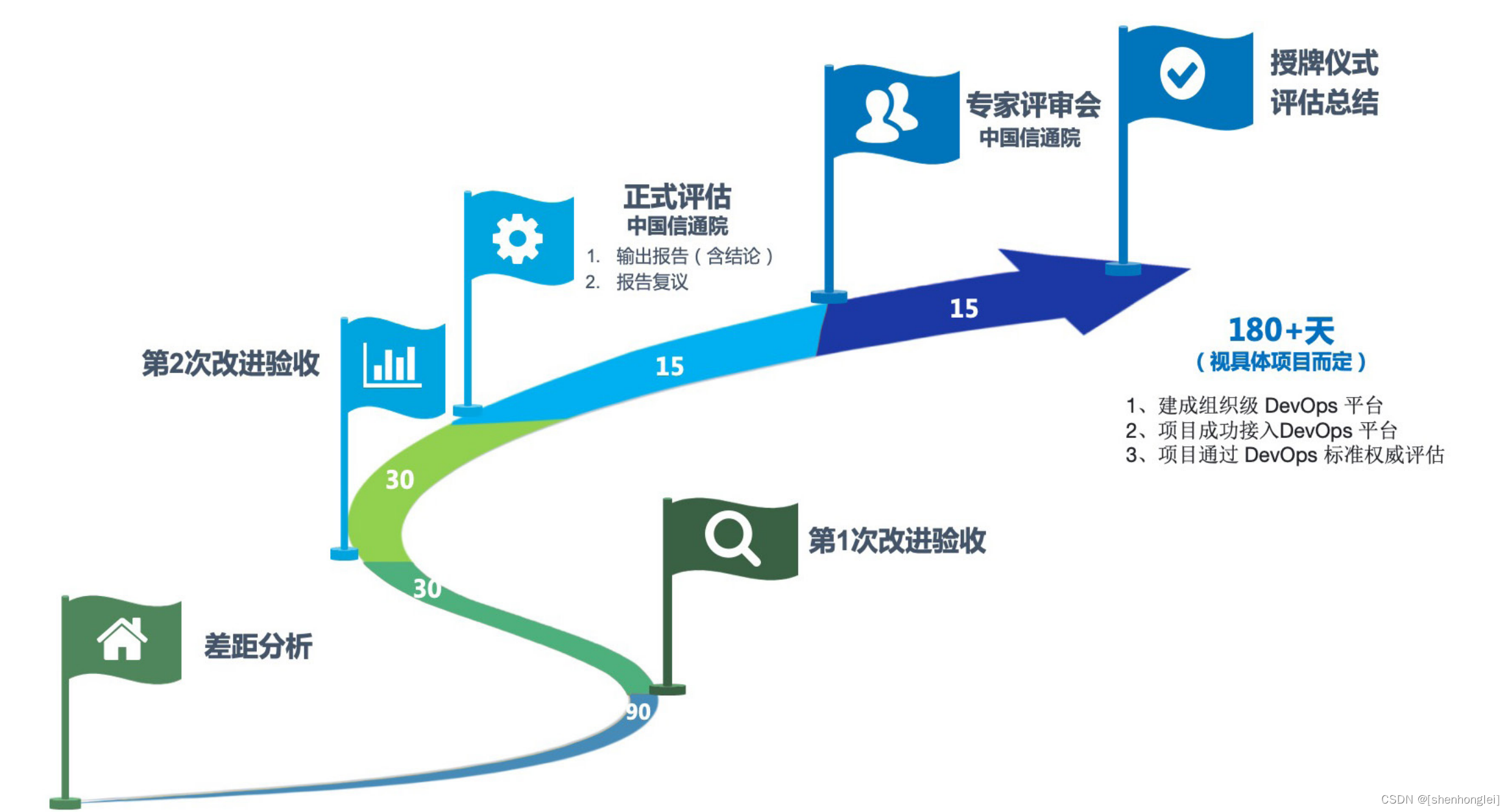

如何构建准实时数仓?