当前位置:网站首页>What is the relationship between digital transformation of manufacturing industry and lean production

What is the relationship between digital transformation of manufacturing industry and lean production

2022-07-02 11:33:00 【51CTO】

After decades of rapid development, China's manufacturing industry , Has owned every year 30 Trillions more GDP,670 More than 10000 manufacturing enterprises , But still face low profit margins 、 The dilemma of poor core competitiveness . But as one of the pioneers of the global Internet , The digital transformation in the industrial field has begun to take shape . The transformation exploration of many leading enterprises and the rapid development of many enterprise software suppliers , Led the goal for the transformation of manufacturing 、 Provides an effective solution .

Connected CRM Fanxiang salesmen are based on their intensive experience in the manufacturing industry in the past few years , Summarize a new path to enhance the core competitiveness of Chinese manufacturing enterprises : Lean manufacturing is the bone , Digital transformation into muscle . Enjoy the products produced by customers 《2022-B2B Enterprise new growth Orange Book 》 in , Interpret the methods and successful cases of digital transformation in manufacturing industry in detail .

One 、 Lean manufacturing is the bone : The foundation of digital transformation

All the growth must finally be reflected in the improvement of enterprise profit level . Manufacturing as a real industry , Its profit growth will inevitably come from the outflow of higher value products and lower costs . therefore ,QCD( quality 、 cost 、 deliver ) Management has always been the core of manufacturing enterprise management : Ensure the highest product quality 、 Lowest cost 、 Shortest lead time , So as to realize lean manufacturing .

To achieve QCD management , We must avoid all kinds of waste , Is to reduce costs through lean management , Improve the efficiency of the whole business system , Get best practices for business processes . Then these best practices are solidified into the system by digital means , Continuously improve the process with intelligent analysis , Finally, sustainable high-quality growth .

therefore , Lean manufacturing 、 Lean management thinking is the basic skeleton of the digital transformation of manufacturing industry , We should integrate the logic of lean manufacturing into the system algorithm , In order to reduce costs and increase efficiency 、 Demand for high-quality output .

Two 、 Digitize to tendon : Full link digitalization promotes the upgrading of lean manufacturing

The traditional manufacturing system is product centered , Pay attention to the improvement of product quality and manufacturing efficiency , With the business model becoming platform 、 Shared transformation , The internal logic of products and services has changed , Product as a service , The mode of service as product is more prominent . And the market for product diversification 、 The promotion of personalized needs , Enterprises are required to have real-time insight and meet customer needs , From scale to personalization . therefore , From a product centric operation to a customer-centric operation , It is the starting point and foothold for manufacturing enterprises to carry out digital transformation , It is also the direct embodiment of transformation value .

To truly achieve customer focus , You need to input the front-end customer information to the back-end production QCD Full link digitization . This is why manufacturing enterprises need the new growth of lean manufacturing and digital double helix .

On the other hand , With the continuous application of digital tools in lean manufacturing , Lean management methods are also constantly upgrading , For example, become standardized 、 visualization 、 Intelligent . The concept of lean production was born in Toyota of Japan , Internet age , Many Japanese enterprises still maintain their traditional business operation . Some leading manufacturing enterprises in China integrate lean production and digitalization , A new growth path has been found , Improve efficiency and product quality to a greater extent .

Lean manufacturing and digitalization complement each other 、 Mutual strength , Have a common starting point , That is to help enterprises better manage 、 cost reduction 、 Avoid waste 、 Increase profits . The two push each other 、 Grow up together . Lean thinking runs through the whole business , Is the premise of digitalization ; Digitalization feeds lean manufacturing , Provide it with a more efficient implementation platform and a more perfect upgrade . For more analysis and practical cases of digital transformation in manufacturing industry, please download and check the products of Fanxiang salesmen 《2022-B2B Enterprise new growth Orange Book 》.

边栏推荐

- Never forget, there will be echoes | hanging mirror sincerely invites you to participate in the opensca user award research

- C# 文件与文件夹操作

- From the perspective of attack surface, see the practice of zero trust scheme of Xinchuang

- js中给数组添加元素的方法有哪些

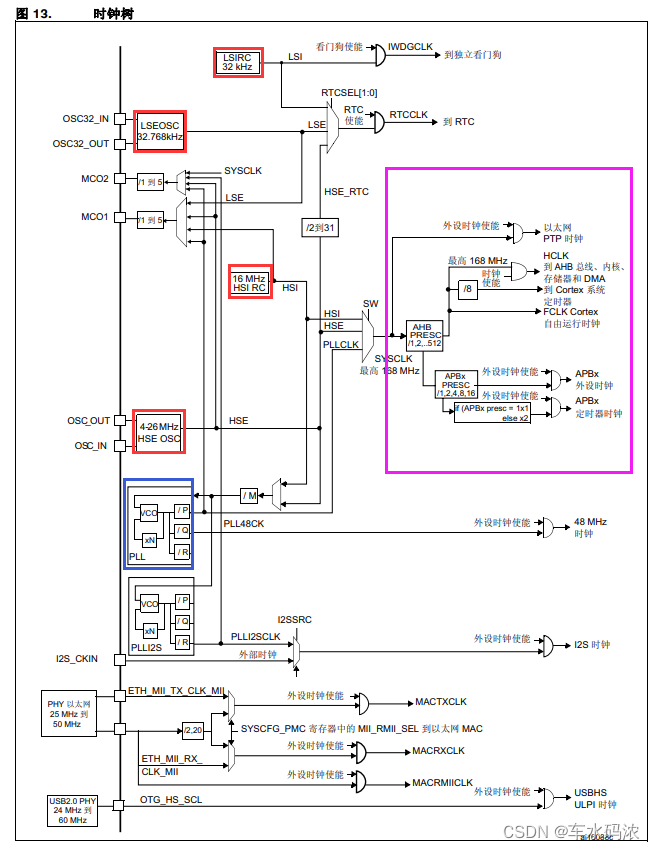

- 三.芯片啟動和時鐘系統

- Internship report skywalking distributed link tracking?

- TIPC addressing 2

- Tick Data and Resampling

- spritejs

- Resources reads 2D texture and converts it to PNG format

猜你喜欢

Never forget, there will be echoes | hanging mirror sincerely invites you to participate in the opensca user award research

III Chip startup and clock system

Wechat applet uses Baidu API to achieve plant recognition

【IDEA】使用插件一键逆向生成代码

flink二開,實現了個 batch lookup join(附源碼)

Tdsql | difficult employment? Tencent cloud database micro authentication to help you

ImportError: cannot import name ‘Digraph‘ from ‘graphviz‘

TDSQL|就业难?腾讯云数据库微认证来帮你

MySQL比较运算符IN问题求解

CentOS8之mysql基本用法

随机推荐

Redis超出最大内存错误OOM command not allowed when used memory > 'maxmemory'

Calculate the sum of sequences

在连接mysql数据库的时候一直报错

Order by注入

亚马逊云科技 Community Builder 申请窗口开启

二.Stm32f407芯片GPIO编程,寄存器操作,库函数操作和位段操作

程序员成长第六篇:如何选择公司?

Summary of data export methods in powerbi

三.芯片启动和时钟系统

Order by injection

Skills of PLC recorder in quickly monitoring multiple PLC bits

TIPC messaging3

Attribute acquisition method and operation notes of C # multidimensional array

C#多维数组的属性获取方法及操作注意

webauthn——官方开发文档

抖音海外版TikTok:正与拜登政府敲定最终数据安全协议

CTF record

【IDEA】使用插件一键逆向生成代码

map集合赋值到数据库

Multi line display and single line display of tqdm