当前位置:网站首页>Pad printing process flow and application precautions

Pad printing process flow and application precautions

2022-06-11 23:18:00 【Double vision】

Pad printing technology first appeared in Europe , A dial for printing watches , In the last century 80 Introduced into China in the s , Because it can be used in a small area , Printing on irregular concave and convex products , Have a great advantage . With the continuous development of China's manufacturing industry , Pad printing technology is more and more widely used , Electronics , toy , The proportion of pad printing technology used in surface printing of various products such as plastics accounts for 50% about .

01

Introduce

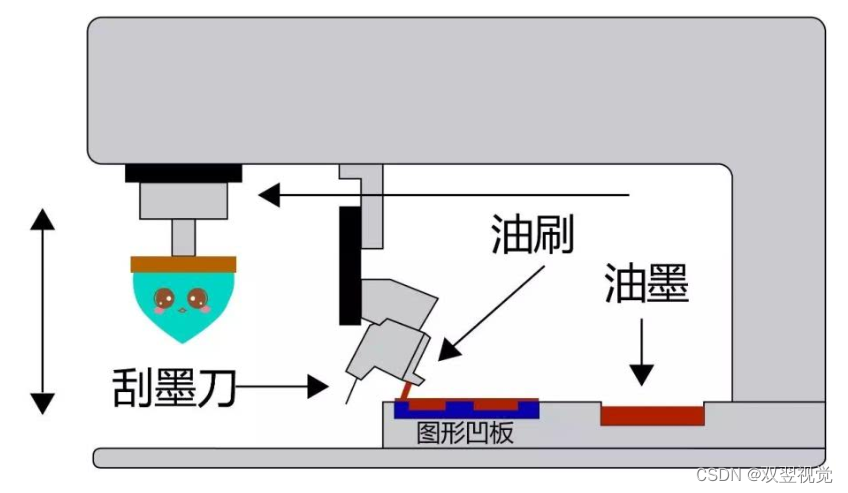

Pad printing is one of the special printing methods , That is, steel ( Or copper 、 Thermoplastics ) gravure , Curved surface pad printing head made of silicone rubber material , Dip the ink on the gravure plate onto the surface of the pad printing head , Then press it on the surface of the object you want to print 、 Patterns, etc .

02

Technological process

The graphic content of pad printing needs to be etched on the steel plate first , After cleaning the steel plate, evenly apply a layer of photosensitive adhesive , Stick a printed film with pictures and texts , Exposure to ultraviolet light will harden the image and text free area , Develop with developing water to present the pictures and texts on the film on the steel plate , Pour corrosive solution into the steel plate so that the depth of graphic corrosion on the steel plate does not exceed 0.5 mm . It can also be directly etched on the steel plate by laser .

The transfer head is made of elastic silicone , The shape is round , Rectangle and square , This kind of shape can better contact with the etched plate and the printed product , Transfer pictures and texts to products of different shapes on flat steel plates , In this process, the rubber head will be deformed due to different pressure and action surface of the rubber head , In order to make the transferred pictures and texts not deformed, we should choose different soft and hard according to the product shape , Big and small rubber heads , To adapt to the deformation of the rubber head to achieve the desired effect .

Apply the ink to the etch board , A telescopic scraper scrapes away the excess ink , The remaining ink will remain in the etch plate pit .

Pad printing head made of silica gel material , Stick the ink in the concave to the surface of the pad printing head .

Then press the surface of the product to be pad printed, and the graphics and text on the concave will appear , Finally dry , Check the packing .

03

Characteristics and application of pad printing

advantage :

1、 Wide application : Pad printing is generally used in grooves 、 Workpiece that cannot be processed by silk screen printing, such as the back of the workpiece . As the pad printing machine is an automatic equipment, its precision is high , Therefore, chromatic printing can be carried out , In theory, chromatic number can be infinite , But the actual operation will not exceed 7 color .

2、 Easy to operate : The equipment is fully automatic

3、 The cost is low : Except that the equipment is much more expensive than the screen printing machine , But other cost factors are the same as silk screen printing

shortcoming :

1、 The effect is ordinary : The visual effect of the finished product is slightly smoother than that of silk screen printing , But not far away

2、 Area limit : Because the silicone pad printing head works elastically , And the production size has an upper limit , Therefore, pad printing cannot produce patterns with too large area

3、 Color scale limits : Although pad printing can be chromatic operation , However, due to the corrosion of the steel plate, the edges of the machined grooves are clear , So you still can't make gradients

4、 Construction taboos : In the use of UV In case of ink construction , Need to use a dark room or pay attention to shading , prevent UV Ink curing damages pad printing die head and steel plate

application :

For vehicle interior ,3c Surface printing of electronic products and sports equipment

04

matters needing attention

1. Bubbles or sand holes

Pad printing head is too soft , The rubber head is flat and not easy to exhaust , The surface of the rubber head is damaged ; The steel plate is not etched properly ; The ink is too thick or dries too fast ; There is dust or oil stain on the product surface ; The ink has deteriorated or expired

resolvent : Replace the appropriate rubber head ; Redo the pad printing steel plate ; Add corresponding additives ; Clean the surface with alcohol ; Replace with new ink

2. Pad printing silicone head is not durable

① There is no problem with pad printing silica gel . The problem is that the silica gel is not filtered well , There are impurities ; Or during packaging , Manual subpackaging , Barrels or plastic bags are not cleaned , The pad printing silicone head is not durable

② It has a lot to do with the amount of silicone oil in silica gel , The more silicone oil is added , The softer the rubber head is , Because silicone oil will destroy the amount of silicone , Produce non durable , Easy to age, etc

③ Silicone application manufacturer , Do not understand the performance of silica gel , The service life of pad printing silica gel is closely related to the size of the pattern to be printed . If you're printing big pictures , Be sure to use a larger rubber head , If the pattern printing is small , You can use a small rubber head ( Adjust the size of the rubber head according to the pattern size , The ratio of the size of the glue head to the pattern 3:1)

3. Ink drawing

The ink viscosity is too high ; The rubber head rises too fast ; The surface of the rubber head is damaged or deteriorated after too long use

resolvent : Adjust the ink for the best viscosity or consistency ; Adjust the rising speed ; Replace the rubber head ; Add filler into the ink , Improve wire drawing

4. The pattern is blurred

Pad printing head is too soft ; The clamp is loose ; The rubber head falls too fast ; The steel plate is etched too deeply ; The ink is too thin or too thick ;

There is dust or oil stain on the product surface , Clean the surface with alcohol

resolvent : Replace the rubber head with suitable hardness ; Check whether the fixture for fixing the product is loose ; Adjust the descending speed of the rubber head ; Replace the steel plate with moderate depth ; Use additives to adjust the consistency

5. The rubber head is not stained with ink

There is oil stain on the surface of the rubber head ; The ink is too thick ; Ink drying speed is too fast ; The etched pattern is too shallow , Or defective printing plates ; The angle of the rubber head is too large ; The large pattern color block scraper scrapes away the ink in the middle of the pattern ; The ink taking pressure is too high

resolvent : Use alcohol tape to clean ; Add an appropriate amount of diluent ; Use a slow drying thinner ; Change the printing plate ; Use a rubber head with a slightly flat angle ; Add mesh or use thick steel plate ; Reduce the ink extraction pressure

边栏推荐

- 2022年安全員-A證考題模擬考試平臺操作

- Unity3d C # development of wechat games audio / sound playback problem solving process sharing

- PHP mkdir(): Permission denied上传文件会把文件夹权限改为411权限

- 2022年安全员-A证考题模拟考试平台操作

- Jetpack architecture component learning (3) -- activity results API usage

- 2022 safety officer-b certificate theoretical question bank and simulation test

- 2022年安全员-A证考题模拟考试平台操作

- 2022年高处安装、维护、拆除操作证考试题库模拟考试平台操作

- Lekao.com: what is the difference between Level 3 health managers and level 2 health managers?

- The latest "capsule Network Overview" paper of imperial technology, etc., 29 pages of PDF, expounds the concept, method and application of capsule

猜你喜欢

解决IDEA下载插件慢的问题

删除收货地址【项目 商城】

Leetcode must review 20 lintcode (5466421166978227)

Is it too troublesome to turn pages manually when you encounter a form? I'll teach you to write a script that shows all the data on one page

MySQL 8.0 decompressed version installation tutorial

【Day4 文献精读】Space–time interdependence: Evidence against asymmetric mapping between time and space

Jetpack architecture component learning (3) -- activity results API usage

mysql5和mysql8同时安装

A method of relay for ultra long distance wireless transmission of low power wireless module

2022 safety officer-b certificate theoretical question bank and simulation test

随机推荐

Solve the problem of slow downloading plug-ins for idea

Try catch

Recruitment of audio and video quality test and Development Engineer

2022 safety officer-b certificate theoretical question bank and simulation test

双向带头循环链表(C语言)

The top ten trends of 2022 industrial Internet security was officially released

【Day8 文献泛读】Space and Time in the Child‘s Mind: Evidence for a Cross-Dimensional Asymmetry

Altium designer工程下多个原理图和PCB图的一一对应

2022 low voltage electrician certificate and online simulation examination

【Day11-12 文献精读】On magnitudes in memory: An internal clock account of space-time interaction

Discrete mathematics attention points, priority problems

PHP mkdir(): Permission denied上传文件会把文件夹权限改为411权限

Some problems about Tencent domain name resolution and Alibaba cloud server

【delphi】判断文件的编码方式(ANSI、Unicode、UTF8、UnicodeBIG)

oracle中dblink操作

Unity3d C#开发微信小游戏音频/音效播放问题解决过程分享

【Day15 文献泛读】Numerical magnitude affects temporal memories but not time encoding

Games-101 闫令琪 5-6讲 光栅化处理 (笔记整理)

Solr之基礎講解入門

Method for debugging wireless data packet capturing of Internet of things zigbee3.0 protocol e18-2g4u04b module