当前位置:网站首页>Industry where edge gateway strong?

Industry where edge gateway strong?

2022-08-02 04:33:00 【Hewo IoT】

What is an Industrial Edge Gateway?

The industrial edge gateway is an industrial-grade intelligent gateway designed to meet industrial-grade standards and the needs of industrial users. It is also called an industrial IoT gateway, a data acquisition gateway, and a PLC wireless gateway. It is capable of mining industrial equipment data and accessing the cloud.Platform for intelligent embedded network devices.Support data collection, protocol analysis, edge computing, and use 4G/5G/Wifi network/wired to provide users with wired and wireless long-distance big data transmission functions and access to industrial cloud platforms.

What is the power of the industrial edge gateway?

- Data Collection

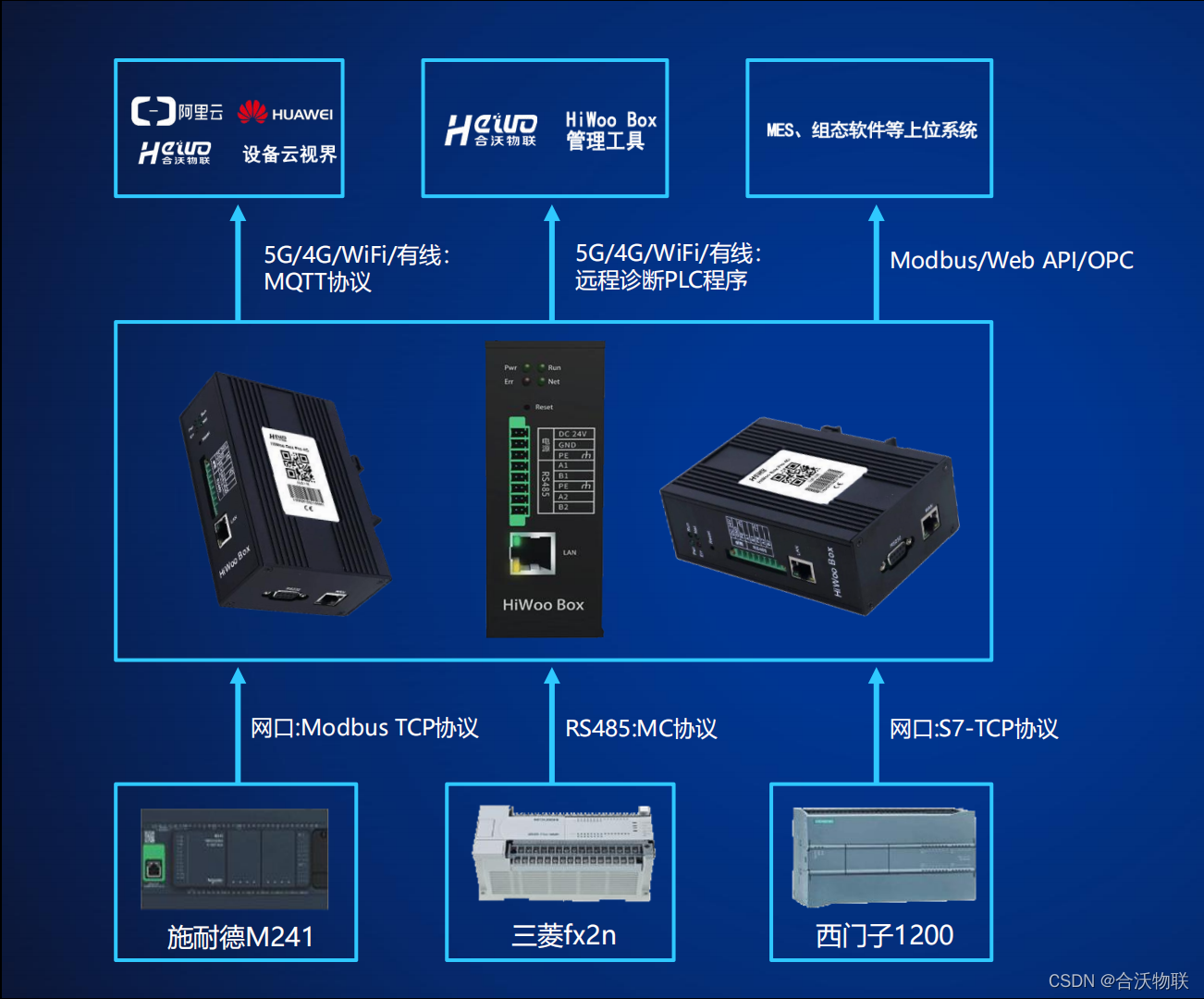

Internet of Things applications in various fields such as the Industrial Internet, Smart City, and Smart Agriculture are facing difficulties in data collection. How to analyze complex equipment protocols and how to overcome equipment knowledge barriers have become the biggest challenges for project implementation.The industrial edge gateway has a powerful protocol conversion function, which can meet the data collection requirements of most devices in the market.Realize remote monitoring and maintenance of equipment, and technicians can access equipment in other places with full authority, thereby significantly improving monitoring and maintenance efficiency, effectively saving maintenance costs, and pre-monitoring and eliminating mechanical failures.

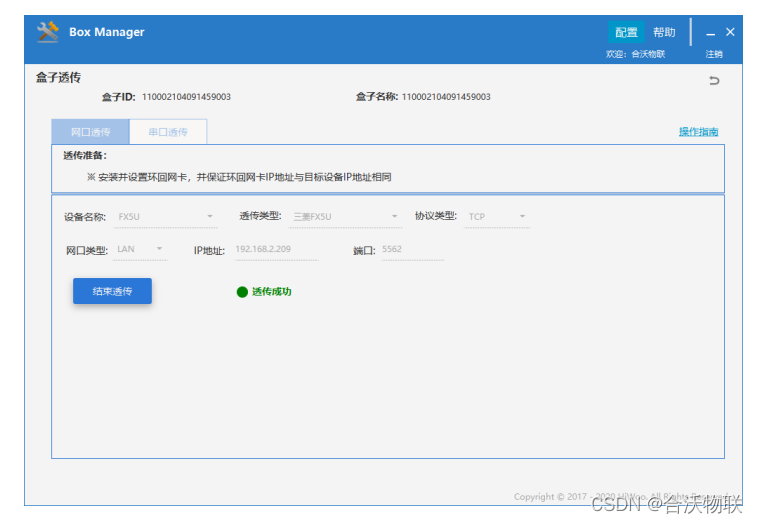

- Remote passthrough

Automated equipment such as packaging machines, printing machines, and dynamic balancing machines are distributed remotely across the country and around the world, making it difficult for equipment manufacturers to provide after-sales services.When customers apply for repairs, engineers often need to travel to the site, and after-sales service costs are high; it is impossible to know the situation of on-site equipment in time, the problem is not handled in time, and customer satisfaction is low.As equipment accessories, the industrial edge gateway can be repaired by customers, remotely diagnose PLC and touch screen programs, and grasp the repair status in time. If there is a fault, remotely update the PLC program, reduce business trips, improve after-sales service efficiency, and reduce after-sales service costs.

- Edge Computing

A large amount of data is transmitted to the cloud for processing, with poor data privacy, high network bandwidth requirements, and heavy cloud computing pressure; special equipment and special protocols make data collection difficult; various northbound systems are difficult to connect.The industrial edge gateway can perform single-point formula calculation for single data, sink business processing logic into the box, and reduce cloud computing pressure; support Python script programming, user-defined north-south protocols, custom business processing logic, and flexible access to special equipment, seamlessly connect various systems.

- Northbound protocol interface open

For customers who already have MES, configuration software and other host computer systems or build their own IoT cloud platform, there is no need to customize and develop complex protocols, and device data can be quickly obtained through industrial gateways.Industrial edge gateway, southbound device access, northbound open protocol interface, northbound interface protocols include: HTTP protocol, MQTT protocol, Alibaba Cloud MQTT protocol, Modbus protocol, OPC UA protocol, etc.

- Remote lock

When the equipment is sold, the customer pays in installments, and the payment is not timely, which affects the business operation and customer relationship; for equipment leasing, the customer pays according to the usage of the equipment, etc., and it is impossible to grasp the usage of the equipment status, output, etc., which affects the collection.As an equipment accessory, the industrial edge gateway has the anti-dismantling function. If the customer does not pay in time, the machine can be locked remotely. It monitors the running status of the leased equipment in real time, automatically counts the output of the equipment, grasps the usage of the equipment, and collects payments in a timely manner.

- Resume upload

The industrial edge gateway is flexible in networking and supports 2G/3G/4G/5G/WiFi/Ethernet multiple networking methods, enabling easy networking both indoors and outdoors.However, in practical applications, it is inevitable that wifi will be dropped, the Internet of Things card will run out of traffic, and the wired network port will be disconnected. The loss of data may have a significant impact on the production or business of the enterprise.The industrial edge gateway supports the function of resuming transmission from a breakpoint, and continues to work during the network disconnection. When the network is restored, all the data during the disconnection period will be transmitted to the platform to ensure that the data is not lost.

…

HiWoo Box, an industrial edge gateway of HiWoo IoT, covers all the above functions, and is easy to configure and operate remotely.It is widely used in environmental protection, water affairs, energy, production lines and other fields, and can meet the needs of most industrial equipment IoT.

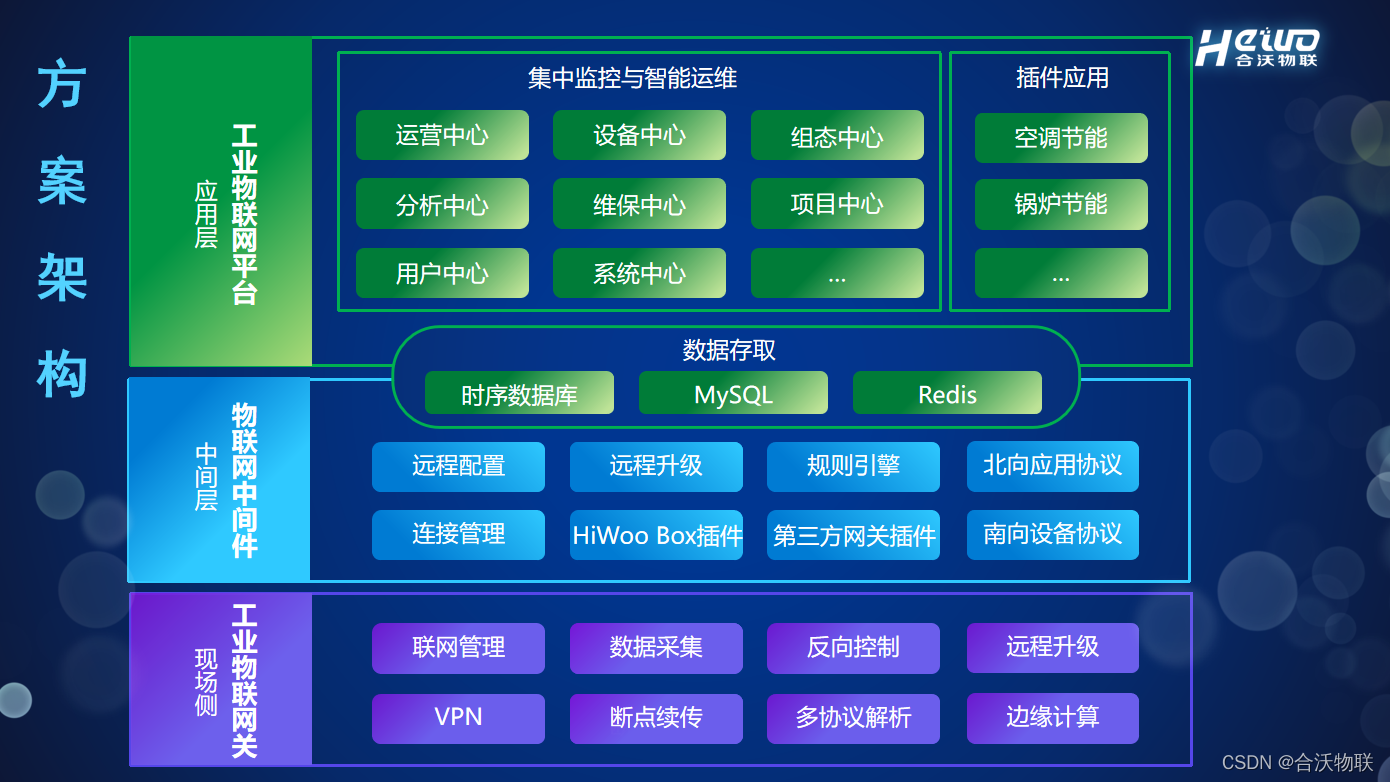

Using industrial edge gateways to realize equipment IoT is the first step for enterprises to take equipment digitization. The edge computing capabilities of gateways help enterprises to further improve equipment operation and management efficiency.In the practice of equipment digitization, the industrial edge gateway is often combined with the IoT middleware and the industrial IoT cloud platform to form an overall solution for the industrial IoT, helping enterprises to seize the opportunity of digital transformation.

The overall solution of the Industrial Internet of Things makes it easier to digitize equipment!

边栏推荐

猜你喜欢

随机推荐

无向图的连通分支数(并查集)

TimeSformer视频理解框架:视频理解中的Transformer

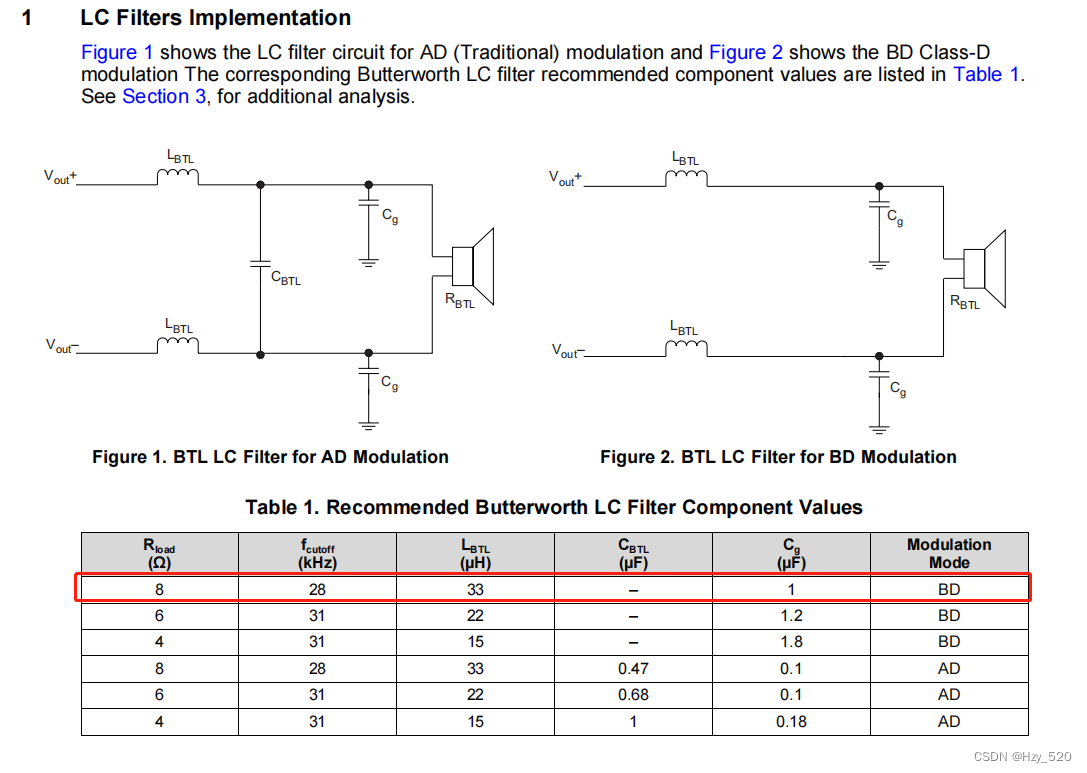

为什么D类音频功放可以免输出滤波器

属性动画的使用和原理解析

移动云物联网预研及阿里云开发对比分析

flutter 国内镜像源列表

写博客的原因。

基于阿里云OSS+PicGo的个人图床搭建

【Arduino connects DHT11 humidity and temperature sensor】

Spark MLlib特征处理 之 StringIndexer、IndexToString使用说明以及源码剖析

Case | industrial iot solutions, steel mills high-performance security for wisdom

PCIE电路设计

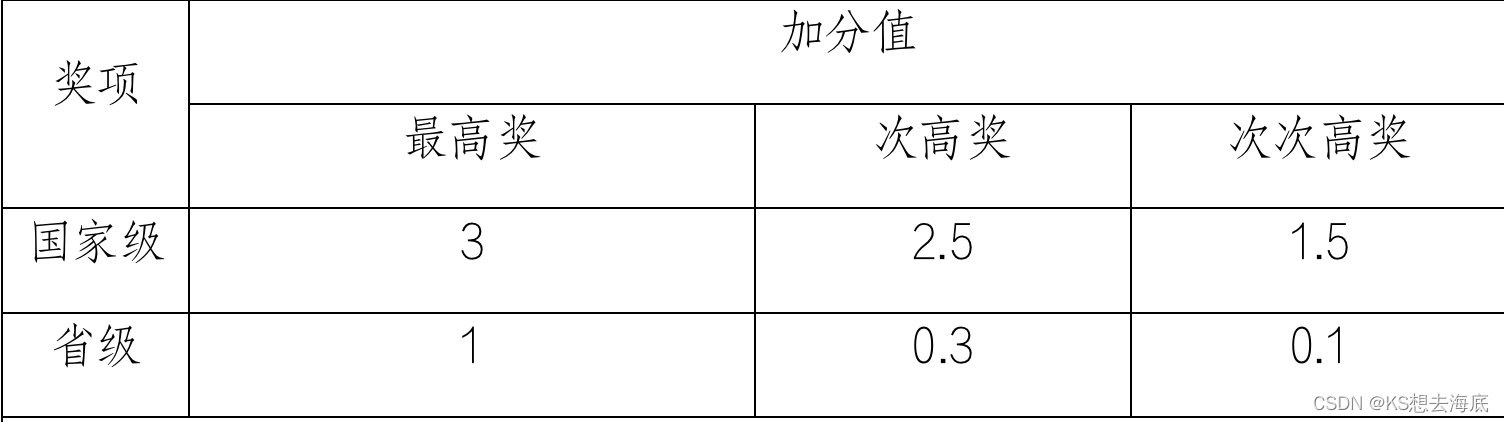

蓝桥杯:国二选手经验贴 附蓝桥杯历年真题

【Arduino 连接 SD 卡模块实现数据读写】

Acwing:哈夫曼树(详解)

Vision Transformer(ViT)论文精读和Pytorch实现代码解析

无源域适应(SFDA)方向的领域探究和论文复现(第二部分)

whistle 手机调试代理工具

kotlin语法总结(一)

【TCS3200 颜色传感器与 Arduino 实现颜色识别】