当前位置:网站首页>Launch APS system to break the problem of decoupling material procurement plan from production practice

Launch APS system to break the problem of decoupling material procurement plan from production practice

2022-07-06 07:37:00 【Huidu technology intelligent manufacturing】

Recently, we have solved the problem of decoupling material procurement plan from actual production for a well-known customer in the sheet metal industry , And successfully achieve single purchase cost savings 30% The above remarkable results .

Before , Customer procurement 、 plan 、 production 、 Each department of material control mainly adopts traditional manual Excel Material collaboration management , The workload is huge and complicated , It often appears in the coordination of various departments “ Conflicts ”: For example, the material purchase cannot keep up with the production schedule , Lead to production delay ; Purchasing materials in an unnecessary period of time will increase the cost of a single purchase and overstock the warehouse ; It is impossible to accurately trace the purchased materials , The cost cannot be counted .

The key to conflict , In the final analysis, each department does its own thing , It is difficult to consider the company comprehensively “ capacity + materiel ” Key resources . actually APS Automatic scheduling system can easily solve this problem , because APS It is a medium and long-term planning and scheduling based on limited capacity and resources , Opened the MRP-MPS Complete planning process , Combined with inventory capacity and ( Lead time )leadtime, It can accurately calculate the net material demand of a single work order , Make the material purchase plan and production plan match accurately .

Traditional material requirement planning and purchasing methods , It is often disconnected from the actual production plan , Most manufacturing enterprises are used to Eexcel To maintain the MRP , use excel There is a large amount of data 、 Prone to error , And it can only realize order level material requirement planning , It is impossible to accurately trace the purchased materials , At the same time, the regular production and marketing coordination meetings also bring a lot of time waste , Lead to purchasing personnel 、 Material control personnel 、 The production personnel have different opinions , Internal conflicts occur frequently ;

Many times, in order to meet production needs, purchase in advance , This leads to an increase in the cost of a single purchase , And early purchase is also likely to cause factory warehouse explosion , Even cause the material quality to expire 、 Deterioration and other problems . Similar information is opaque 、 The complex procurement process not only brings great trouble to factory managers , At the same time, it also causes a lot of unnecessary cost waste .

that , How to solve these problems , In fact, it can be implemented APS Automatic scheduling system , Get through MRP-MPS Complete planning process , Realize medium and long-term planning and scheduling based on limited capacity , And use this to calculate the time when the materials of the corresponding production work order are complete , And take a single production work order as the dimension , Combined with inventory capacity and lead time , Accurately calculate the net material demand of a single work order , In this way, the accurate traceability of purchased materials can be realized , Realize accurate statistics of order costs , And it can greatly reduce the single purchase cost , Avoid long-term occupation of cash flow .

If you have MES/APS System related requirements , Pay attention to me , Get more details about smart manufacturing , Welcome to communicate !

边栏推荐

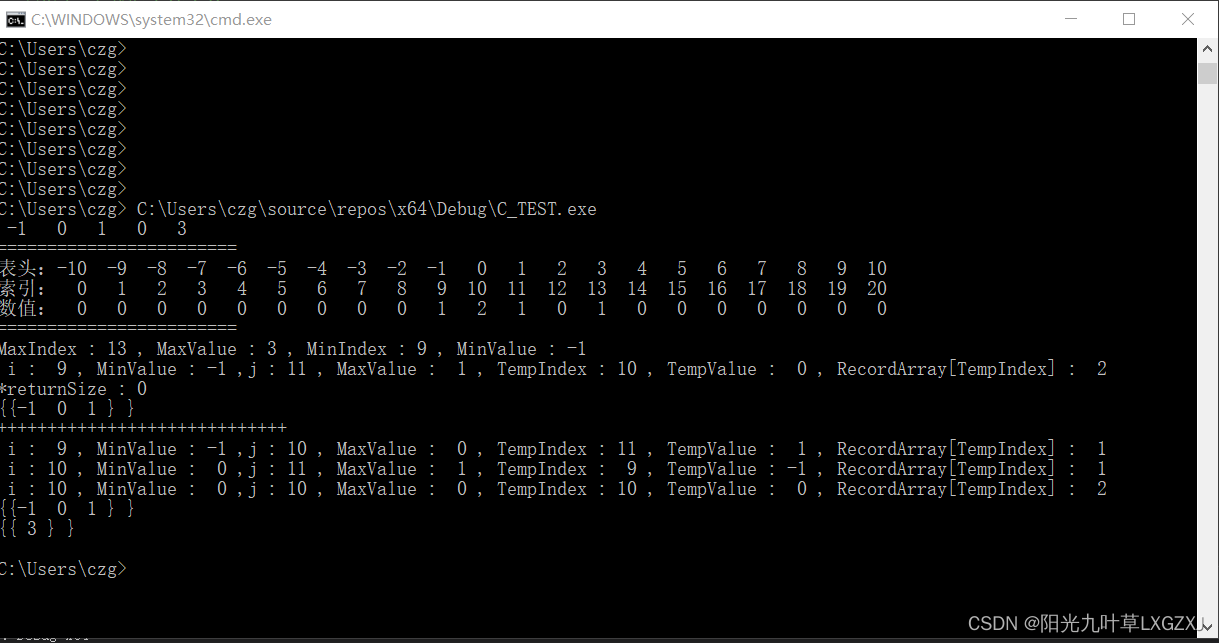

- Simple and understandable high-precision addition in C language

- 成为优秀的TS体操高手 之 TS 类型体操前置知识储备

- OpenJudge NOI 2.1 1661:Bomb Game

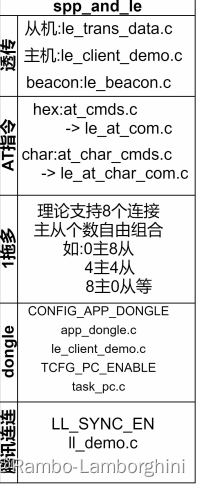

- Ble of Jerry [chapter]

- The ECU of 21 Audi q5l 45tfsi brushes is upgraded to master special adjustment, and the horsepower is safely and stably increased to 305 horsepower

- The ECU of 21 Audi q5l 45tfsi brushes is upgraded to master special adjustment, and the horsepower is safely and stably increased to 305 horsepower

- Games101 Lesson 7 shading 1 Notes

- 杰理之BLE【篇】

- Luogu p1836 number page solution

- TS 体操 &(交叉运算) 和 接口的继承的区别

猜你喜欢

Mise en œuvre du langage leecode - C - 15. Somme des trois chiffres - - - - - idées à améliorer

杰理之BLE【篇】

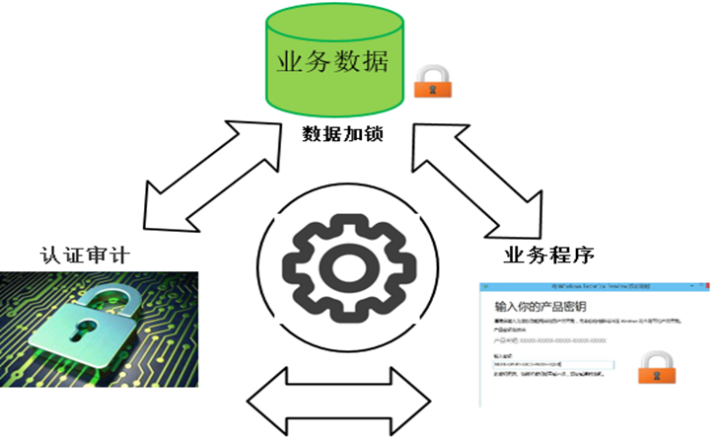

Significance and measures of encryption protection for intelligent terminal equipment

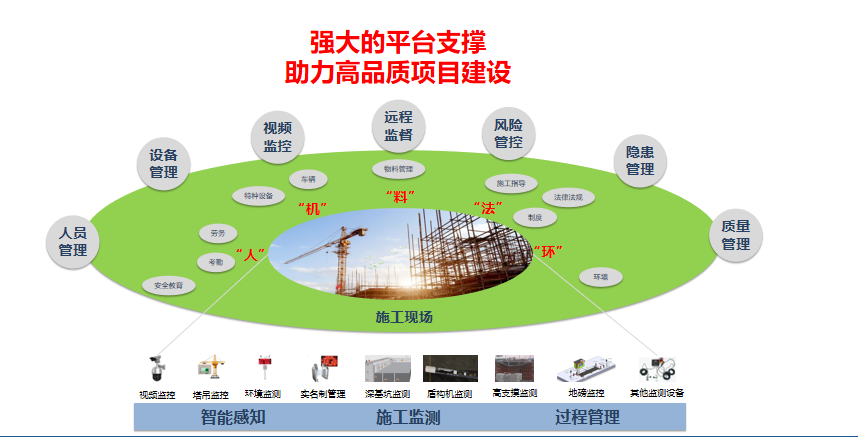

解决方案:智慧工地智能巡检方案视频监控系统

navicat如何导入MySQL脚本

Key value judgment in the cycle of TS type gymnastics, as keyword use

QT color is converted to string and uint

word中如何删除某符号前面或后面所有的文字

Twelve rules for naming variables

![Ble of Jerry [chapter]](/img/00/27486ad68bf491997d10e387c32dd4.png)

Ble of Jerry [chapter]

随机推荐

Ble of Jerry [chapter]

TypeScript void 基础类型

word设置目录

Bloom taxonomy

杰理之BLE【篇】

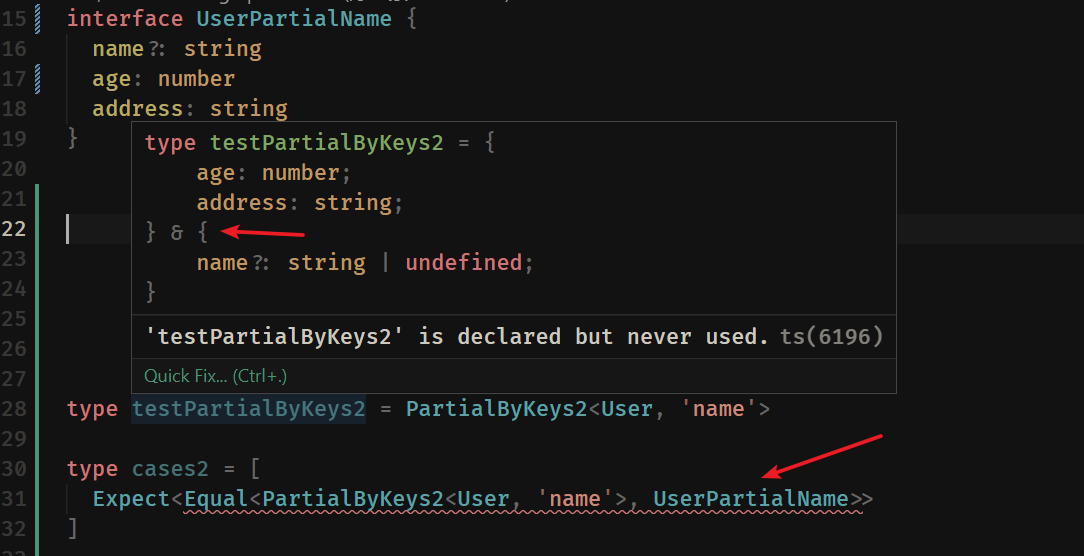

The difference between TS Gymnastics (cross operation) and interface inheritance

The way to learn go (I) the basic introduction of go to the first HelloWorld

Twelve rules for naming variables

opencv学习笔记八--答题卡识别

TypeScript接口与泛型的使用

杰理之BLE【篇】

Compliance and efficiency, accelerate the digital transformation of pharmaceutical enterprises, and create a new document resource center for pharmaceutical enterprises

Simulation of Teman green interferometer based on MATLAB

Memory error during variable parameter overload

Relevant introduction of clip image

Google可能在春节后回归中国市场。

edge瀏覽器 路徑獲得

软件测试界的三无简历,企业拿什么来招聘你,石沉大海的简历

[MySQL learning notes 32] mvcc

Comparison of usage scenarios and implementations of extensions, equal, and like in TS type Gymnastics