当前位置:网站首页>How to deal with these problems in the factory production process?

How to deal with these problems in the factory production process?

2022-06-11 09:07:00 【Digital processing technology Jason】

When the factory gets better and better , When the scale gets bigger , More and more problems will be handled , In the factory production process , Often presents some problems , For example, the production schedule is a formality 、 The semi-finished products of each production department are piled up 、 Low compliance rate of production plan 、 The raw materials or semi-finished products of the previous and subsequent processes are not connected .

Production plans are often added or cancelled 、 Urgent orders appear frequently 、 The original production plan has been disrupted 、 Product quality cannot be controlled 、 The raw materials in the warehouse are overstocked 、 A series of problems such as the delay of delivery date . How to deal with these difficult problems ?

1. Integrated management of production resources

In the process of factory production, we often encounter the waste of production parts , Excessive accumulation of warehouse data , stay ERP These problems in the software can be easily handled , Be able to establish standards in the system 、 Unified 、 Good production database , The regional 、 Each system 、 Data interconnection of all links , Real time control of production trends .

Quickly increase collaboration power , It is useful to prevent production problems and failures , Be able to integrate multi production mode 、 Multiple production lines 、 Multisectoral 、 Multi person collaboration , Machinery and equipment involved in production 、 Work center 、 Process 、 Manufacturing process, etc , To prevent idle resources and waste from causing problems of enterprise funds .

2. Production active scheduling

The production schedule is often presented in the production process , The bill of materials is not clear , A situation in which urgent orders or orders are frequently inserted , In order to prevent these situations , In Zhibang world ERP In the software, the production plan and the bill of materials can be automatically matched for accounting , Purchase the organization that generates a guess for the material , After production order accounting .

Take the initiative to calculate the time and balance the production capacity , Quick response to orders 、 Urgent order , Actively follow the scheduling rules , Start time of organizing production order 、 Production workshop 、 Production line and end time , Active scheduling replaces manual scheduling , Higher power , Less corruption , Prevent confusion in the workshop .

3. Production process control

Different management problems often appear in various links of factory production , The production cannot be completed within the specified time , Delay the delivery date , The company's reputation will be affected , These problems always perplex the factory production management , But if we use the production management system , Then these problems will be handled easily , such as ERP The software can assist the factory to complete the whole process of integrated processing .

from BOM、 process 、 guess 、 plan 、 Order 、 workshop 、 Outsourcing , To quality inspection 、 by the piece 、 Cost accounting , Information is highly shared , Process active connection , The process is easily controlled , Provide a simple process 、 Intermediate process 、 Complete process , Fully meet the needs of the production process , Custom approval process , Carefully control each link of the production process , Continue to optimize product line functions , Prevent danger ahead of time , Deal with all kinds of problems in the production process of the factory .

4. Production progress can be seen

The factory production manager is able to ERP Check the production progress and specific production status in the production management software , stay ERP The production progress report in the software is actively related to the production data , One click Check all the execution processes of the production order , Release from production task 、 Send workers 、 picking 、 The loading 、 Material return 、 rework 、 You can see the details of the process from subcontracting to quality inspection .

Real time tracking 、 Control order progress , Adjust in time 、 Organize production activities , Progress is clear at a glance , Powerful progress query function , The order no. 、 Start date 、 Closing date 、 Production progress 、 Man hour progress 、 Order status 、 Product information 、 Order process 、 Piece rate wage and payment status , In control .

5. Production quality control

The factory is in the process of practical production , Once the production process cannot be strictly controlled , The quality inspection process is very simple to present unqualified products , In order to handle these products reasonably , Can go through ERP Software classifies products , Provide production quality inspection and outsourcing quality inspection , Customize the quality inspection fields 、 Number 、 type 、 Grade , Quality inspection document follow-up is supported 、 Warehousing of qualified products 、 Repair of nonconforming products , Reduce the scrap rate , Save the cost for the enterprise .

Establish a unique symbol for each product , Support sampling inspection and full inspection , Support each process and product quality inspection , Strictly control product quality , Cut returns 、 Claim risk , Help you trace the origin of product problems , Improve in time .

6. Take the initiative to calculate the cost

stay ERP Software sofastsoft.com To establish scientific and comprehensive cost accounting rules , Take the initiative to calculate the indirect costs related to production , Simultaneously verify the direct costs related to production , The cost accounting of production order is finished , Real time synchronization of order related transaction data . Fully record all kinds of consumption in the order production process , Comprehensive coordination of production data , The order cost is actively updated , One key calculation of production cost , Ensure that the product cost is accurate and timely , It really reflects the profit level of the enterprise , Effectively improve the efficiency of the enterprise .

The factory passes by ERP Software to handle production , In order to effectively improve their own handling level , Continue to make a living in the fierce market , A suitable ERP Software can not only improve enterprise efficiency , It can better deal with all kinds of problems in the process of factory production ! So the factory ERP Software is very necessary for the factory !

边栏推荐

猜你喜欢

![[FAQ for novices on the road] about data visualization](/img/a1/d15e286c3c886a8d3a4ac3eb165748.png)

[FAQ for novices on the road] about data visualization

What software is required to process raw format images?

Android interview transcript (carefully sorted out)

Matlab learning 8- linear and nonlinear sharpening filtering and nonlinear smoothing filtering of image processing

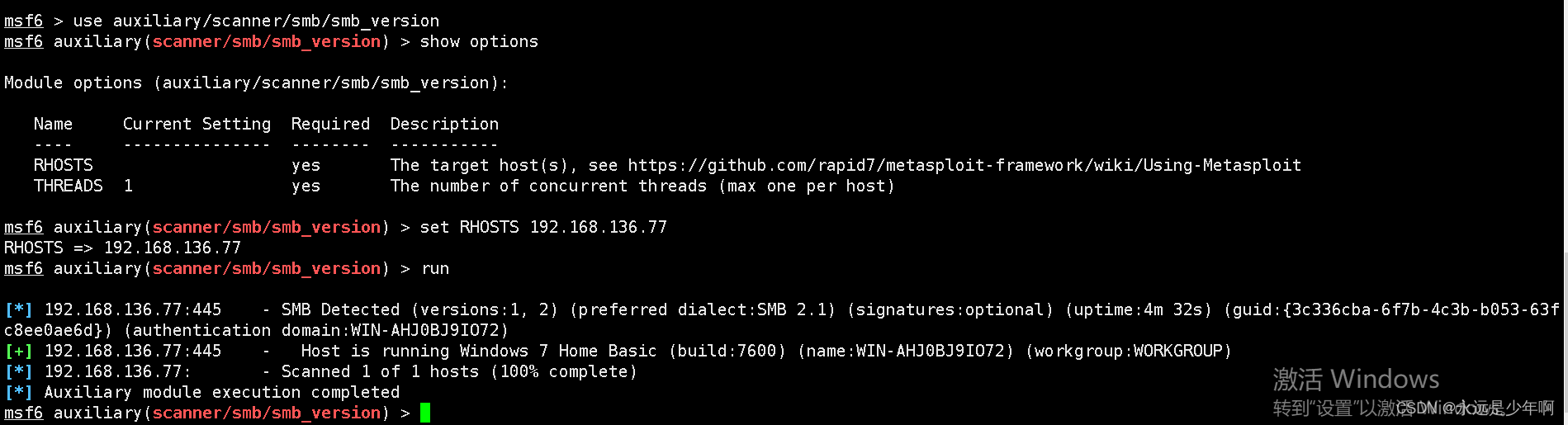

MSF基于SMB的信息收集

Redis source code analysis hash object (z\u hash)

Blinn Phong reflection model

山东大学项目实训(四)—— 微信小程序扫描web端二维码实现web端登录

Pytorch installation for getting started with deep learning

Intelligent control theory question bank

随机推荐

Notes on MySQL core points

2130. 链表最大孪生和

Screening frog log file analyzer Chinese version installation tutorial

19. 删除链表的倒数第 N 个结点

【方案开发】红外体温计测温仪方案

Sword finger offer 06 Print linked list from end to end

【分享】企业如何进行施行规划?

1400. 构造 K 个回文字符串

CUMT学习日记——ucosII理论解析—任哲版教材

2095. 删除链表的中间节点

Why is the string class final decorated

[C language - function stack frame] analyze the whole process of function call from the perspective of disassembly

机器学习笔记 - Kaggle大师Janio Martinez Bachmann的故事

Talk about reading the source code

机器学习笔记 - 使用TensorFlow的Spatial Transformer网络

19. delete the penultimate node of the linked list

【分享】企業如何進行施行規劃?

SAP material master data archiving

2130. maximum twin sum of linked list

Success and failure of ERP software from the perspective of enterprise evaluation