当前位置:网站首页>How to upgrade high value-added links in the textile and clothing industry? APS to help

How to upgrade high value-added links in the textile and clothing industry? APS to help

2022-07-06 20:24:00 【andafa】

The global supply chain crisis under the epidemic has brought a large number of backflow orders to China's textile industry . Data from the General Administration of Customs shows ,2021 year , China's clothing exports increased by nearly 330 Billion dollars ( renminbi 2099 One hundred million yuan ) to 1702.6 Billion dollars , achieve 2015 A new high since . Before that , As the textile industry shifts to lower cost regions such as Southeast Asia , China's clothing exports have been declining year by year .

China is still the world's largest textile producer and exporter , But as domestic costs rise 、 International procurement trends shift , stay 2014 reach 1862.8 After the peak of billion dollars , China's clothing exports have been declining year by year ,2015-2020 The average growth rate during the year is -4%. Superimposed epidemic effects ,2020 The export volume in once fell to 1373.8 Billion dollars , Fall back 10 Year ago . The data of clothing export volume in recent ten years shows , Last year, foreign clothing orders returned more than 200 billion yuan , It means an increase of about 17 Million pieces . Under the influence of the epidemic , There are several reasons why China's textile industry has achieved good results ;

1. Institutional advantages : During the outbreak , China has controlled the epidemic of COVID-19 earlier , The industrial chain is basically restored , Relatively, Southeast Asia and other places have been affected by the epidemic ;

2. Obvious competitive advantage : After years of development , China's textile and clothing brands have a complete industrial chain 、 High processing supporting level , And there are many developed industrial clusters , This enables China's textile and clothing industry to show greater toughness and strong comprehensive strength .

However , Although I have more than 1700 Billion dollars of clothing exports , But data from the National Bureau of statistics shows ,2021 The operating profit margin of the export clothing industry in is less than 5%, Affected by factors such as rising raw material prices , In recent years, the overall profit level has continued to decline .

obviously “ China's textile industry is big but not strong ”. The epidemic will pass sooner or later , China has to develop towards the high-end environment of the industrial chain , Turn labor-intensive industries into technology-based industries , In the future, we will strengthen industrial upgrading , The pursuit of moderate profits is the king .

Textile and clothing value chain includes raw material production 、 Fabric production 、 Product design and textile and garment manufacturing , Among them, textile and clothing manufacturing has a low profit margin in the clothing value chain 、 The most competitive segment , It belongs to labor-intensive links . If you are immersed in the past development mode , Develop low value-added labor-intensive industries , It is a waste of national resources ,GDP And employment , But the profit added value did not stay in China , It was taken away by the upstream , At the expense of our environment and energy . The characteristics of products and orders in the textile and clothing industry , Determines the long delivery time ( Even as long as 40 God )、 There are a lot of WIP and finished products in stock and it is impossible to calculate the single piece cost ( Because the required quantity is not calculated ) Production scheduling features , This is for the textile and clothing industry to upgrade high value-added links , It's a big challenge .

According to the production scheduling characteristics of the textile industry , Andafa APS Advanced scheduling system goes through 18 Years of industry experience , Show the most advanced planning and scheduling technology in the industry today , Mainly in :

1. It can be delivered according to the sales order 、 Production plan 、 Purchase plan , this 3 They are seamlessly connected and quickly coordinated .

2. The constraints of various limited capacity resources can be considered synchronously to achieve a plan scheduling that is closest to the reality .

3. It can be used in the production environment with large amount of data , Calculate the desired result very quickly .

4. Multi task factory architecture .

Besides , As a local Chinese enterprise , It is more suitable for domestic enterprises , It's your best choice , Specifically, :

1. Easy to use ;

2. High technology content , Most commonly used functions are better than industry-leading products ;

3. Fast running speed ;

4. Fully functional , The amount of secondary development is very small , Easy to implement ;

Andafa APS The advanced scheduling system is complete 、 Networking 、 Management application system , Not plug-ins . It does not need to be applied to existing ERP Make any changes to the system , Can be implemented quickly .

5. Born online ; Multiple users through LAN 、 Even the remote Internet can be networked .

6. Use industry standard SQL Database and mainstream programming languages C# Development ;

7. Completely independent development , Own copyright , It can be customized and modified according to customer needs ;

8. Provide permanent original maintenance service .

边栏推荐

- Detailed introduction of distributed pressure measurement system VIII: basic introduction of akka actor model

- Tencent T4 architect, Android interview Foundation

- [network planning] Chapter 3 data link layer (4) LAN, Ethernet, WLAN, VLAN

- 5. 無線體內納米網:十大“可行嗎?”問題

- Unity making plug-ins

- Wonderful coding [hexadecimal conversion]

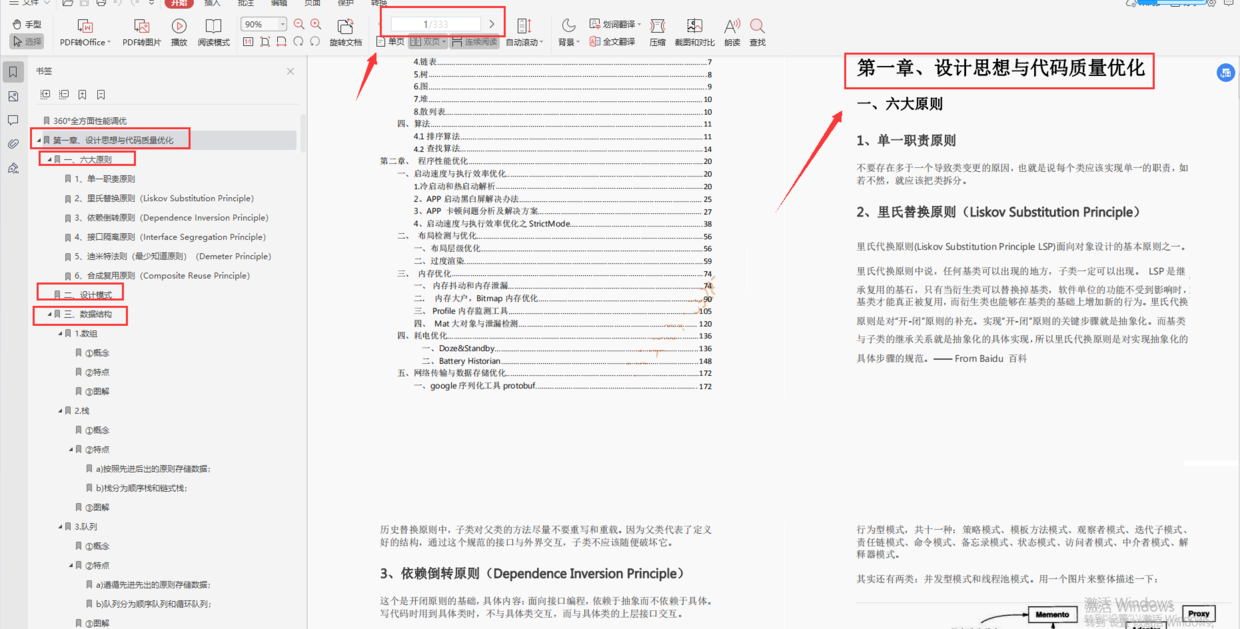

- 腾讯架构师首发,2022Android面试笔试总结

- Is it difficult for small and micro enterprises to make accounts? Smart accounting gadget quick to use

- 22-07-05 七牛云存储图片、用户头像上传

- B-jiege's tree (pressed tree DP)

猜你喜欢

Cesium Click to draw a circle (dynamically draw a circle)

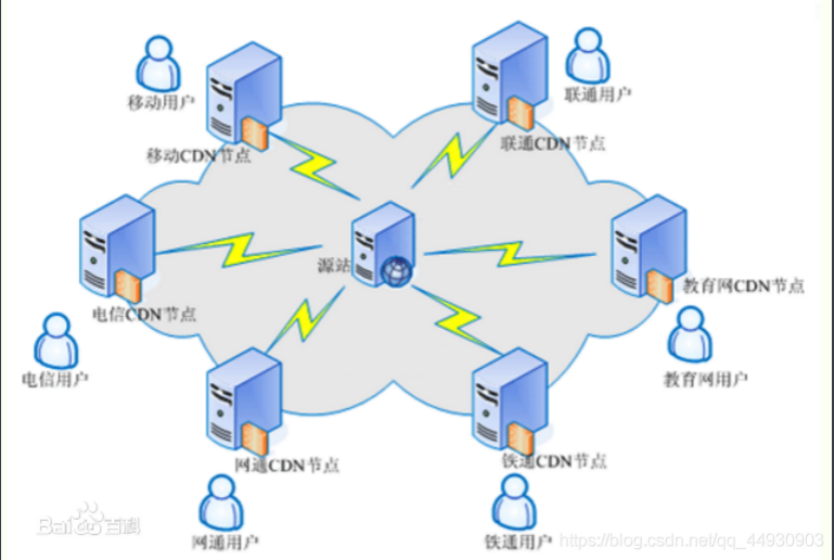

01 basic introduction - concept nouns

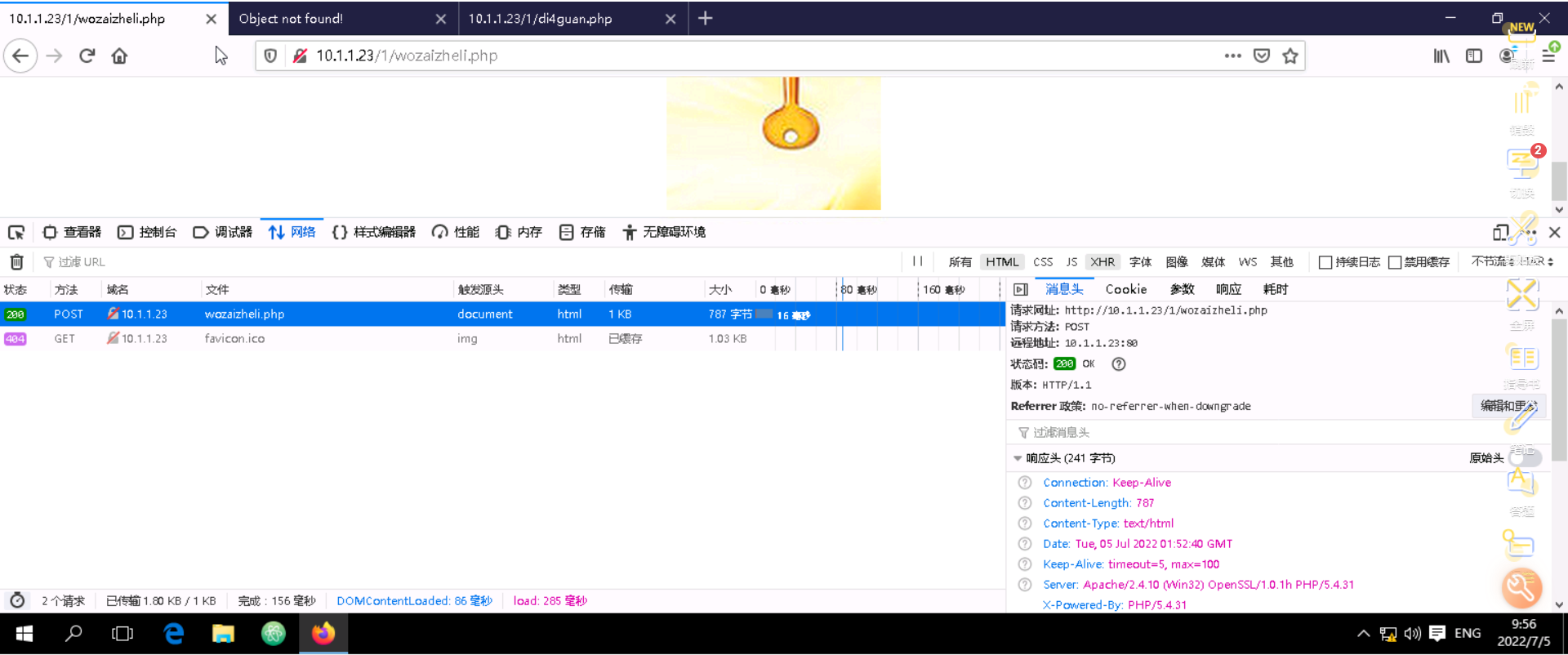

Learn to punch in Web

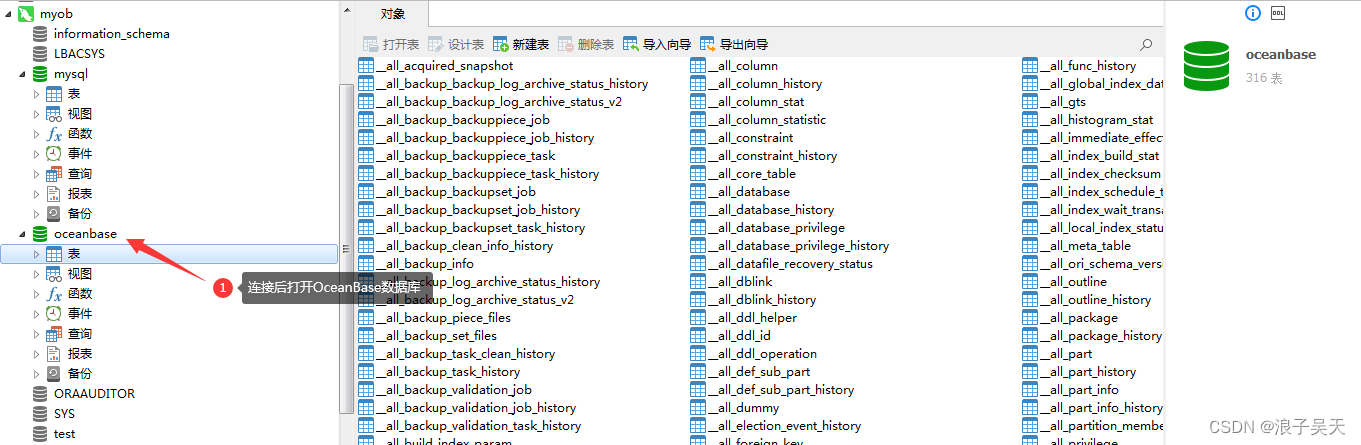

OceanBase社区版之OBD方式部署方式单机安装

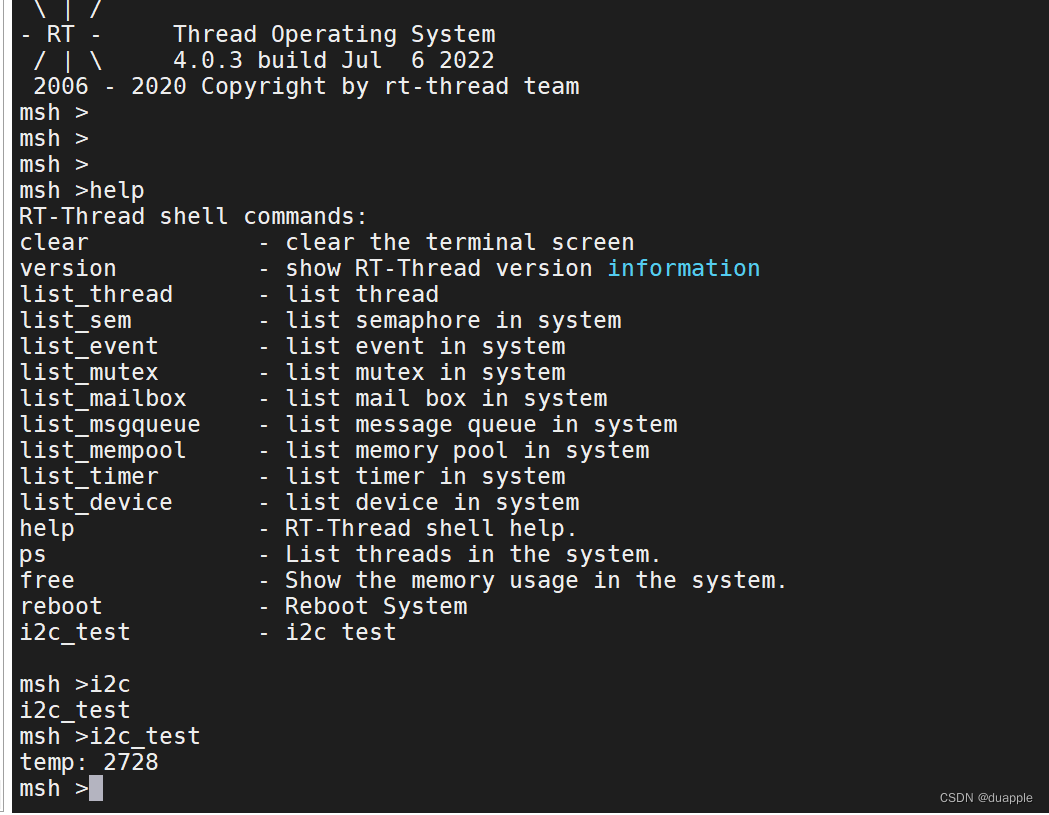

rt-thread i2c 使用教程

![[weekly pit] information encryption + [answer] positive integer factorization prime factor](/img/d8/a367c26b51d9dbaf53bf4fe2a13917.png)

[weekly pit] information encryption + [answer] positive integer factorization prime factor

Tencent T3 Daniel will teach you hand-in-hand, the internal information of the factory

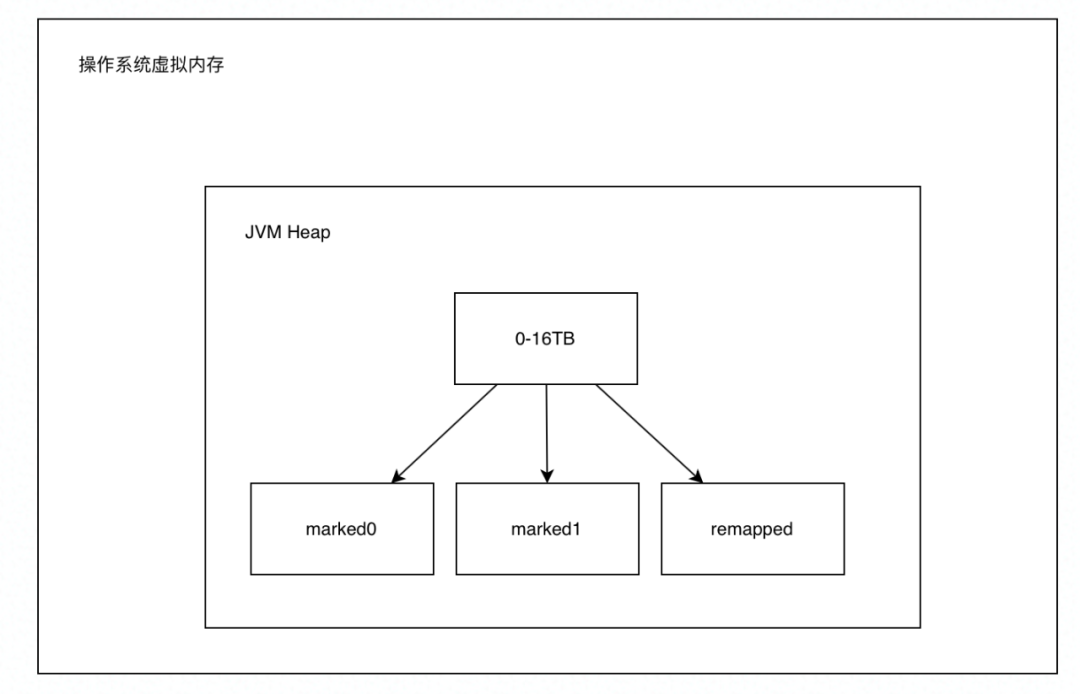

新一代垃圾回收器—ZGC

![[Yann Lecun likes the red stone neural network made by minecraft]](/img/95/c3af40c7ecbd371dd674aea19b272a.png)

[Yann Lecun likes the red stone neural network made by minecraft]

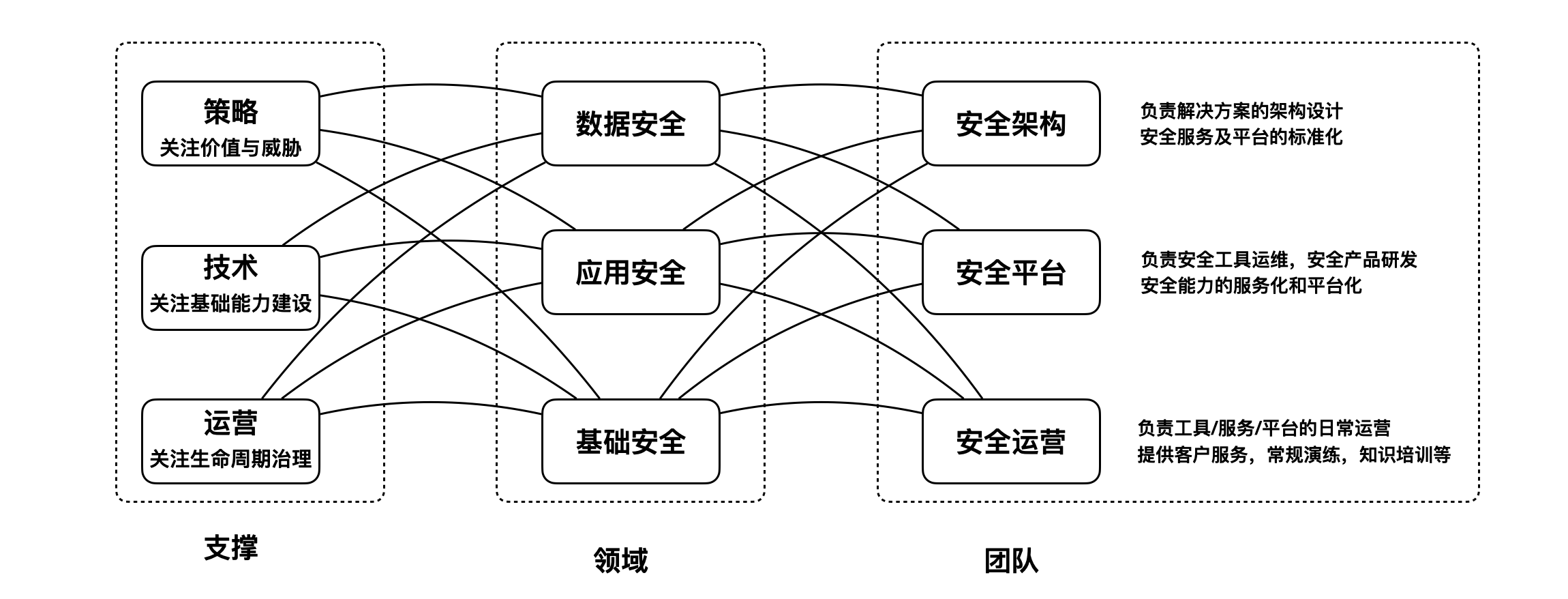

Design your security architecture OKR

随机推荐

Enumeration gets values based on parameters

Review questions of anatomy and physiology · VIII blood system

Special topic of rotor position estimation of permanent magnet synchronous motor -- fundamental wave model and rotor position angle

Rhcsa Road

[weekly pit] information encryption + [answer] positive integer factorization prime factor

BUUCTF---Reverse---easyre

HMS Core 机器学习服务打造同传翻译新“声”态,AI让国际交流更顺畅

B-jiege's tree (pressed tree DP)

Synchronization of data create trigger synchronization table for each site

某东短信登录复活 安装部署教程

js获取浏览器系统语言

JMeter server resource indicator monitoring (CPU, memory, etc.)

逻辑是个好东西

JS implementation force deduction 71 question simplified path

Tips for web development: skillfully use ThreadLocal to avoid layer by layer value transmission

Maximum likelihood estimation and cross entropy loss

recyclerview gridlayout 平分中间空白区域

8086 instruction code summary (table)

[weekly pit] positive integer factorization prime factor + [solution] calculate the sum of prime numbers within 100

Tencent Android development interview, basic knowledge of Android Development