当前位置:网站首页>What warehouse management problems can WMS warehouse management system solve in the electronics industry?

What warehouse management problems can WMS warehouse management system solve in the electronics industry?

2022-08-04 00:32:00 【Deep blue website,】

Electronic manufacturing enterprises often face the following problems in warehouse management:

How to effectively control multiple specifications of raw materials;

The inventory is not accurate, and there are often problems such as downtime and waiting for materials, unable to deliver on time;

The inventory turnover rate is low, resulting in a lot of sluggish materials and serious inventory backlog;

Manual work is inefficient, and errors often occur, requiring manual adjustment, which is time-consuming and labor-intensive;

Lack of batch management, material traceability is difficult;

The warehouse business is becoming more and more complex, and the management efficiency is getting lower and lower, which affects the development of the enterprise.

Electronic industry WMS warehouse management system integrates location, inbound, shelf, outbound, inventory, batch, transfer, inventory, strategy and reportManagement and other functions are integrated into one, simplifying the daily operation process and improving the operation efficiency.And through integration with the ERP system, it can achieve overall planning, data sharing, multi-dimensional management and control, eliminate information islands, and double the value of information construction.

The electronic industry WMS warehouse management system solution helps the electronic manufacturing industry to improve the efficiency of warehouse operations and enhance the intelligent and digital management of warehouses.WMS warehouse management system can bring the following benefits to electronic manufacturing enterprises:

1、reasonable layout of warehouse

Through the storage location management function, plan the warehouse site, divide the storage area and storage location, hang the sign, paste the QR code in the storage location,And organize it into an Excel table, import the WMS system to file with one key, and realize the systematic management and control of the warehouse location, which not only reduces the daily work of storage, search and inventory of warehouse management personnel, but also makes the monitoring of materials/finished products more convenient.A condition for an item/finished product occurs.

2, accurate inventory, clear accounts

Record and update inventory dynamic data in real time, so that inventory is controllable, checkable and traceable, so that inventory is accurate and accounts are clear.

3, solve the problem of downtime and wait for materials, and improve the timely delivery rate

Before the system is installed, when the production line reaches a certain stage, it is found that the material is insufficient and the line is stopped, which not only wastes man-hours, but also reduces production efficiency.After the WMS system is launched, it can solve the problems of buying less materials and waiting for materials during the production process, improve the timely delivery rate, greatly enhance the market competitiveness of enterprises, and improve customer adhesion.

4, warehouse process optimization

After launching the WMS system, the warehouse process has been optimized.It solves the problems of data confusion, inaccurate inventory, and difficulty in tracing the loss of goods before the system is installed.After going online, the accuracy of data has been improved, and the loophole of lost materials in warehouse management has been solved, and the cost has become clearer.

5, intelligent permission control, reduce operation errors

After the launch of the WMS system, the division of labor is clearer, and the system permissions are more detailed, which reduces operational errors caused by permission assignment problems and reduces communication costs..

6Reduce reliance on human experience

In the process of daily operation, the system will intelligently guide the warehouse clerk to work, such as which warehouse location of the material to be taken off the shelf, and the goods to be put on the shelf.Which warehouse location is better, plus the automatic error-proofing reminder of PDA scanning, reduces the dependence on manual experience, and improves the operation efficiency and accuracy.

边栏推荐

- RSS订阅微信公众号初探-feed43

- 孙宇晨:Web3.0和元宇宙将协助人类更加全面地进入网络世界

- Free自由协议系统开发

- 20年将投资美国约2000亿美元,三星电子财大气粗的样子真好看

- 【超详细教程】LVS+KeepAlived高可用部署实战应用

- 数据库扩容也可以如此丝滑,MySQL千亿级数据生产环境扩容实战

- 扩展卡尔曼滤波EKF

- Using matlab to solve the linear optimization problem based on matlab dynamic model of learning notes _11 】 【

- jmeter分布式压测

- 小身材有大作用——光模块基础知识(一)

猜你喜欢

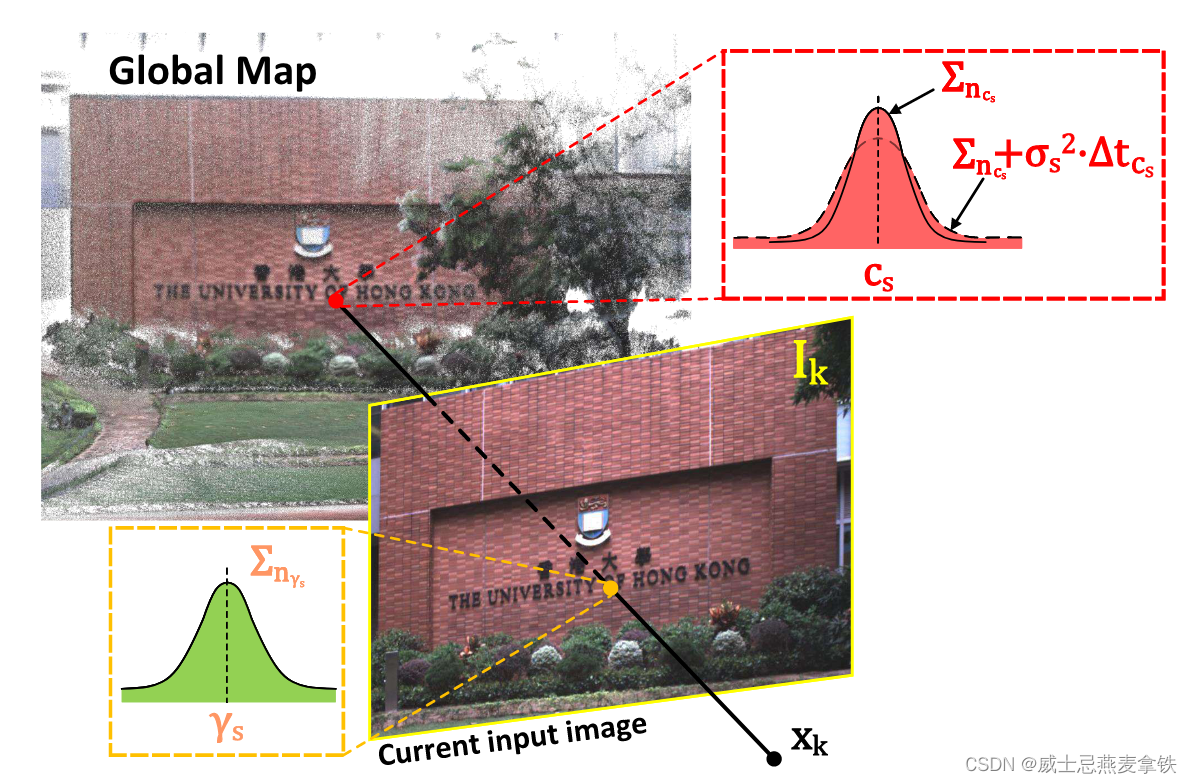

R3LIVE论文学习(二):VIO子系统

Justin Sun was invited to attend the 36氪 Yuan Universe Summit and delivered a keynote speech

孙宇晨受邀参加36氪元宇宙峰会并发表主题演讲

我的祖国

Nanoprobes 棕榈酰纳米金相关说明书

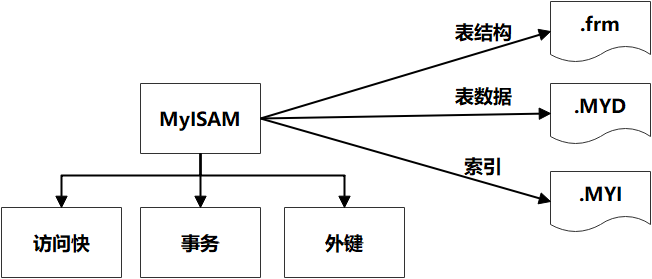

【性能优化】MySQL性能优化之存储引擎调优

The problem of disorganized data output by mnn model

Salesforce的中国区业务可能出现新变化,传言可能正在关闭

Web3 安全风险令人生畏?应该如何应对?

搭建好pytorch环境后,pip和conda指令不能用

随机推荐

第1章:初识数据库与MySQL----MySQL安装

c语言分层理解(c语言操作符)

600MHz频段来了,它会是新的黄金频段吗?

A Preliminary Study of RSS Subscription to WeChat Official Account-feed43

outputBufferIndex = mDecode.dequeueOutputBuffer(bufferInfo, 0) 一直返回为-1

扩展卡尔曼滤波EKF

BGP实验(含MPLS)

米哈游--测试开发提前批

Spinnaker调用Jenkins API 返回403错误

【每日一题】899. 有序队列

身为程序员的我们如何卷死别人?破局重生。

Read FastDFS in one article

状态机实验

Using matlab to solve the linear optimization problem based on matlab dynamic model of learning notes _11 】 【

Talking about the future development direction of my country's industrial parks

LeetCode第三题(Longest Substring Without Repeating Characters)三部曲之三:两次优化

跨域问题解决方式 代理服务器

教你如何定位不合理的SQL?并优化之

RSS订阅微信公众号初探-feed43

XSS - Bypass for loop filtering