当前位置:网站首页>EMC rectification cases of electronic equipment radiation

EMC rectification cases of electronic equipment radiation

2022-06-11 10:20:00 【Risehuxyc】

Preface :

The development of modern electronic products is faster and faster , The use environment faced by the product is becoming more and more complex , At present, all automobile manufacturers are focusing on electronization 、 automation 、 Intelligent development, etc , Electronic control systems are used more and more in automobiles , The electromagnetic compatibility of electronic products in the automotive system is becoming more and more important , To regulate the electromagnetic compatibility of electronic products , Most countries have formulated electromagnetic compatibility standards , Especially for military products . EMC standard is the basic requirement for products to work normally in the actual electromagnetic environment . So in order to meet the requirements of various electromagnetic compatibility standards , In the process of product development , We must do a good job in electromagnetic control and detection in every link , Then the spectrum analyzer has become an indispensable equipment in the laboratory . Automobile safety is one of the key problems facing the society today .

Next , This article is based on the problems in a product , The root cause of the problem can be found after the spectrum analyzer test , And go EMC The certification laboratory solves problems before certification , Make the product pass the certification smoothly .

1. Fault description

The system is a military automobile communication terminal product , Ask to pass GJB151A EMC test requirements for army ground equipment . Products in the EMC During laboratory testing ,CE102、CS101、CS114、RS103 All passed the test successfully , but RE102 The test results are shown in the figure 1 Shown :

chart 1 30MHz~200MHz Raw radiation emission

From the picture 1 It can be seen that , Radiation emission can only meet the requirements of fixed products , It can not meet the requirements of army ground electromagnetic radiation , Among them in 50MHz-120MHz Between , The maximum radiation emission exceeds the standard 20dB, Need to carry out EMC Rectification .

2. Cause analysis

View products , The whole system is a metal shielded case , The other system has 1 Shielded aerial plug-in power cord , Usually , The metal case and shielded cable have good shielding effectiveness , If you design it right , Can pass RE102 Radiation emission test , therefore , It is suspected that the metal case and shielded cable have electromagnetic leakage, which leads to the test failure .

So use the spectrum analyzer in the laboratory to diagnose the system and find the radiation source , The schematic diagram of the test system is shown in the figure 2 Shown :

chart 2 Schematic diagram of electromagnetic interference diagnosis system

The whole system test includes shielded chassis and cables tied as follows :

(1) It is Germany. ( Agilent ) Technology spectrum analyzer model :MXA N9020A ; Bandwidth range 20Hz~13.6GHz;

chart 3 Spectrum analyzer

(2)Langer amplifier : Amplify electromagnetic interference signal ;

(3)Langer Near field magnetic field probe : Measure and accept electromagnetic interference signal , There are many types of probes , Here's the picture 4 Shown , Generally, the probe is selected according to the measurement requirements , When you need to look in a wide range , Use a larger ring probe or a larger flat probe ; When precise measurement is required , Select a needle probe , The probe can measure every device or pin .

chart 4 Test probe

Set spectrum analyzer frequency band to 10MHz-1000MHz, Use the near-field probe to test the gap of the chassis 、 Vents 、 Shielded cable connector and cable , Find out 30MHz-200MHz There is great electromagnetic interference , Here's the picture 5 Shown , Therefore, it can be determined that the excessive electromagnetic interference is related to the chassis and cables .

chart 5 Higher radiation

Disassemble the chassis , Pictured 6 The schematic , It is found that the chassis is made of metal , There are no shielding measures at each gap of the chassis , And the seams of the chassis are painted , The gap of the chassis is not continuous , Shielding effectiveness decreases , So as to produce strong electromagnetic interference .

Check the termination of the power cord shield , It is found that the shielding layer is connected with the shell of the metal connector through a thin wire , Pig tail , Pictured 7 Shown :

chart 6 Unshielded chassis diagram

chart 7 Pigtail shielded cable

Shielded cables reduce cable radiation for two main reasons : First, the shielding layer can shield the differential mode radiation of the differential mode signal circuit in the cable ; The other is that the shielding layer can provide a return path for common mode current , Thus, the loop area of common mode current is reduced , In this sense , The smaller the impedance of the return path, the better , In this way, most of the common mode current can be bypassed back to the common mode noise source , The specific principle is shown in the figure 8 Shown :

chart 8 Principle of shielding cable to reduce radiation interference

The impedance of the common mode current return path consists of the self impedance of the shielding layer and the lap impedance between the shielding layer and the metal chassis .“ Pigtail ” The termination method of the is equivalent to connecting a series of the tens on the shielding layer nH The inductance of , It will increase the impedance of the common mode current return path of the shielding layer , This causes part of the common mode current to return from the earth , The loop area of common mode current is increased ; Second, common mode current will generate common mode voltage in shielding layer , This voltage will form a loop between the shield and the earth ( Distributed capacitance or ground wire formation ) A new common mode current is generated in , Cause greater common mode radiation , The specific principle is shown in the figure 9 Shown :

chart 9 “ Pigtail ” Principle of electromagnetic interference in termination mode

3. Improvement measures

Considering the poor shielding design of this chassis , And the electromagnetic interference exceeds the standard greatly , If the original chassis is changed , It can not meet the requirements of shielding effectiveness and is not conducive to mass production , therefore , Redesign the shielded chassis , In addition to ensuring that the gap of the chassis is well overlapped , The ventilation guide is also added to the vent , The final design of the shielding case is shown in the figure 10 Shown .

For shielded cables , To meet the shielding requirements , It is necessary to shield the cable 360 Degree termination , To form a good conductive bonding , At the clip of the aviation plug , Remove the cable insulation , Expose the shield , Then directly clamp the shielding layer with the clip at the end of the connector , Tighten the screws to secure , formation 360 Degree termination , Pictured 11 Shown .

chart 10 Redesigned shielded chassis

chart 11 Interconnecting cable shield termination

After the above rectification , Re use the spectrum analyzer and near-field probe to view the radiated emission of the chassis and interconnection cables , At this time, the radiation is much lower than before , Here's the picture 12 Shown , The rectification has achieved the expected effect .

chart 12 Lower radiation

4. Experimental verification

Check and install the equipment , Carry the product to the certification laboratory for radiation emission test of the system , The test results are shown in the figure 13 Shown :

chart 13 30MHz~200MHz Radiation emission after rectification

From the picture 13 It can be seen that , After rectification, the radiation emission margin reaches 10dB, The test passed .

5 summary

After the whole , This product has successfully passed the certification test . Explain that during product development , Try to test the products in the laboratory , The spectrum analyzer and near-field probe can be used to check the problems of the product , This is not only very convenient to find problems , It can also save the cost of certification laboratory testing , Therefore, spectrum analyzer has become an indispensable equipment in more and more laboratories .

边栏推荐

- C语言课程设计题目

- Browserfetcher class for getting started with puppeter

- 【高并发】关于线程池,蚂蚁金服面试官问了我这些内容!!

- Differences between beanfactorypostprocessor and beanpostprocessor

- 选择DC-DC开关电源控制器的实战过程

- 批量对数据添加噪声并生成新命名标注文件

- 科技云报道:Web3.0浪潮下的隐私计算

- Interview review - closure

- Initial deployment of Servlet

- 【bert】:在训练bert 语义相似的任务时,last ave state 的计算

猜你喜欢

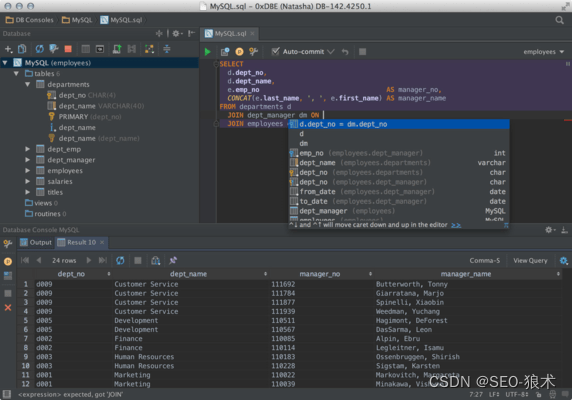

Datagrip 2022, datagrip function

图片规则翻页

【机器学习理论】True Positive, True Negative, False Positive, False Negative概念

Q1营收超华尔街预期,挚文集团的价值等待回归

Circuit board made of real gold -- golden finger

Vk2c22a/b anti-interference series electric meter, water meter segment code LCD driver chip data (customized dice/cog)

Introduction to steamvr

Q1 revenue exceeded expectations. Why did man Bang win headwind growth?

UGUI鼠标点击扩散UI效果

Internet of things security in the era of remote work

随机推荐

Review handwritten questions in interview -- function interception and jitter

rpc的正确打开方式|读懂Go原生net/rpc包

Servlet 的初次部署

puppeteer入门之 Browser 类

Ugui picture wall

C语言课程设计题目

TikTok在英国遭遇文化冲突,短期内众多员工离职

详解2.5G/5G/10G Base-T以太网接口物理层一致性测试!

Start jar

No more! The entry byte beat for a week and ran decisively.

Function and function of wandfluh proportional valve

Handwritten code call, apply, bind

[high concurrency] the interviewer of ant financial asked me about thread pool!!

How much do you know about the functions and functions of Rexroth solenoid directional valve

Mysql--事务

General idea of interface tuning

MySQL comparison

Q1营收超预期,满帮为何赢得逆风增长?

关于马格齿轮泵的应用领域都有哪些?总结一下

Wuenda machine learning course - week 7