当前位置:网站首页>MES system plays an important role in the factory production management

MES system plays an important role in the factory production management

2020-11-09 14:34:00 【Hongyun Zhizao】

MES It can provide enterprises with manufacturing data management 、 Schedule management 、 Production scheduling management 、 Inventory management 、 Quality management 、 Human resource management 、 Work center / Equipment management 、 Tooling management 、 purchasing management 、 Cost management 、 Project Kanban Management 、 Production process control 、 Bottom level data integration analysis 、 Upper data integration and decomposition management module , For the enterprise to create a solid 、 reliable 、 comprehensive 、 A feasible manufacturing collaborative management platform . For factories ,MES System The effect is undoubtedly enormous .

1. In terms of process control

MES Manage the whole production process of production order , Through the real-time monitoring of any emergency in the production process , The system can automatically correct errors in the production process or provide management decision support , In order to achieve production scheduling requirements ; In case of abnormality or deviation from production plan , Timely feedback relevant personnel to take corresponding measures .

2. In terms of task dispatch

MES After the production plan is finished , Automatically generate task dispatch list , According to the change of actual processing capacity of production equipment , Formulate and optimize the production process and detailed operation sequence of each equipment ; In order to enhance the flexibility of production , Production task according to the actual situation of production execution and the specific situation of equipment , Combined with resource allocation, dynamic allocation on the spot .

3. In terms of resource allocation

MES Through detailed data statistics and Analysis , Provide real-time status of various production site resources for enterprises , Coordinate closely with task allocation , Configure the corresponding tools for each production process 、 equipment 、 materiel 、 Documents and other resources , Ensure that all operations are prepared and executed according to the scheduling requirements .

4. In terms of capacity balance analysis

MES Analysis and comparison work center / Equipment task load 、 department / Team task load 、 Job type, task load, etc. and make corresponding assessment , Assist planning and scheduling personnel to coordinate and balance production tasks , And achieve the optimal production planning scheduling .

5. In terms of quality management

MES Track the whole production process from raw materials to finished products , For the raw material of the product 、 Production equipment 、 The operator 、 Process batch data collection in real time , For the use of the product 、 Provide basis for improving design and quality control ; Finally determine the product problem according to the test 、 Provide corresponding management decision support .

6. Production planning and inventory data

The production plan is in ERP Produced in , Write to through the interface MES perform , return when done ERP. If not ERP, Can be found in MES It is directly transformed into production plan .MES Integration with inventory management system , When the plan is generated, the system will automatically read the inventory data and deduct the available quantity , At the same time, specific guidance on site operation ingredients .

7. In terms of data collection

MES According to different data 、 Application scenarios 、 Personnel capability 、 Equipment investment and other aspects to take a different way of data acquisition , Get all processes in real time 、 equipment 、 materiel 、 Product data , And statistics 、 Analysis into other systems 、 Information that managers need .

8. Financial data

Financial data can lead to MES Accounting for production costs . From many From the working experience of enterprise informatization project implementation , Data has a great impact on the success of a project , It's not uncommon for projects to fail because of data problems , Therefore, it is very important to plan and prepare the data at the beginning of the project construction .

9. In terms of maintenance management

MES Record each device 、 Maintenance time per tool 、 Maintenance content 、 The cause of the failure, etc , And then calculate the most common devices / Tool maintenance and work experience accumulation , Manage and direct production equipment 、 Tool maintenance activities , And convert it into the corresponding maintenance work experience document , For browsing 、 Inquire about .

MES Record each device 、 Maintenance time per tool 、 Maintenance content 、 The cause of the failure, etc , And then calculate the most common devices / Tool maintenance and work experience accumulation , Manage and direct production equipment 、 Tool maintenance activities , And convert it into the corresponding maintenance work experience document , For browsing 、 Inquire about .

MES The system can make the management mode of the manufacturing workshop information 、 Standardization 、 The direction of standardization is upgrading , Realize enterprise management system 、 Manufacturing systems 、 Automation systems and information systems are interconnected !

Hongyun intelligent manufacturing is a leading intelligent manufacturing solution provider in China , stay MES/WMS System development 、 Production automation has 14 Years of industry experience , It is one of the top three intelligent manufacturing solution providers in China .

Hongyun Zhizao has an experienced professional consultant team , The technical team accounts for 70%, And absorbed a number of university professors and doctors , As a high-level intellectual resource support . future , Hongyun Zhizao will be ready to go , Focus on intelligent manufacturing and control , Realize information 、 equipment 、 Intelligent integration of three aspects of Logistics , Promote industry in an all-round way 4.0 manufacture , help “ Made in China ” March towards “ China smart ”.

版权声明

本文为[Hongyun Zhizao]所创,转载请带上原文链接,感谢

边栏推荐

- Put method of immutablemap

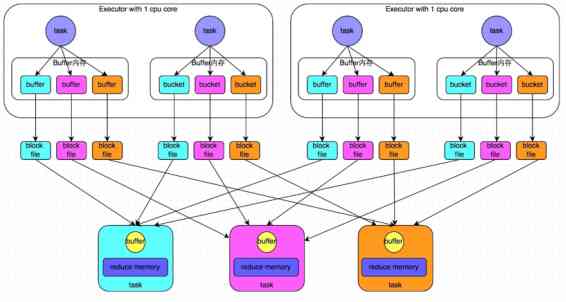

- spark学习(二)--作业调度和shuffle解析

- Embedded assembly in IOS

- 导师制Unity网课 双十一优惠报名进行中

- 【亲测有效】Github无法访问或者访问速度的解决方案

- Explain three different authentication protocols in detail

- 百万年薪架构师之路:谈应用系统架构设计

- cad教程 cad2016安装教程

- MES系统在工厂生产管理起到9大很重要的作用

- Application and practice of native map and web fusion technology

猜你喜欢

c语言小白学习历程第六篇

spark学习(二)--作业调度和shuffle解析

导师制Processing网课 双十一优惠进行中

博士在读时,把暗恋的师兄变成了老公是种怎样的体验?

A letter to myself

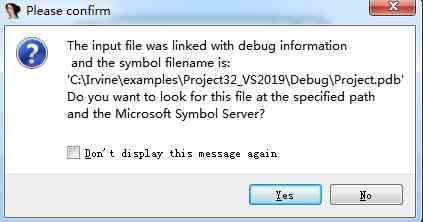

Viewing PDB files from the angle of assembly

03. Priority link model

How to download and install autocad2020 in Chinese

Object oriented magic method collection

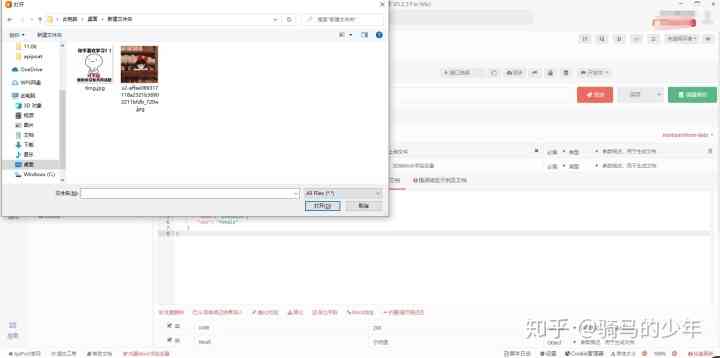

Interface tests how to pass files in post requests

随机推荐

Guest interview: Wang Jian

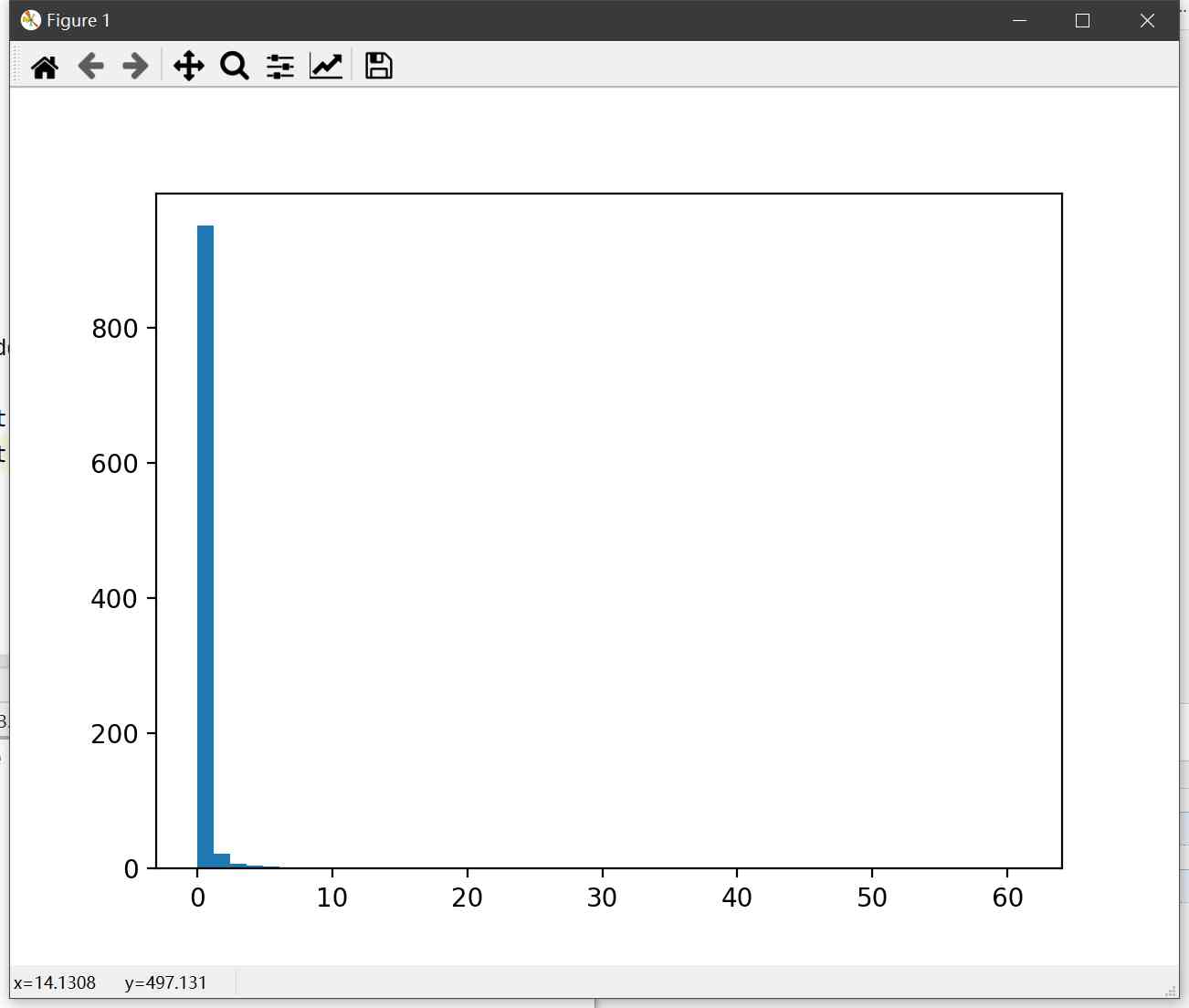

Python loading voice class custom dataset

融云完成数亿人民币 D 轮融资,将持续打造全球云通信能力

决策树算法-理论篇

CSP-J/S 2020考前注意事项

Infrastructure testing based on chef inspec

Several methods of initializing singleton variable in go language

Full link stress testing of moral integrity -- the evolution of corpus intelligence

基于synchronized锁的深度解析

How can you be a big data worker with an annual salary of 40W if you don't work hard?

要我说,多线程事务它必须就是个伪命题!

To me, multithreading transaction must be a pseudo proposition!

Depth analysis based on synchronized lock

jackson、fastjson、kryo、protostuff等序列化工具性能对比

Embedded assembly in IOS

SEO builders, what are the unspeakable hardships?

H5 official account listens to events in the closed browser (left fork).

Learning history of C language

Put method of immutablemap

CAD2016下载AutoCAD2016下载安装详细教程CAD下载