当前位置:网站首页>Production scheduling status of manufacturing enterprises and solutions of APS system

Production scheduling status of manufacturing enterprises and solutions of APS system

2022-06-12 08:22:00 【Intelligent manufacturing of Huidu Technology】

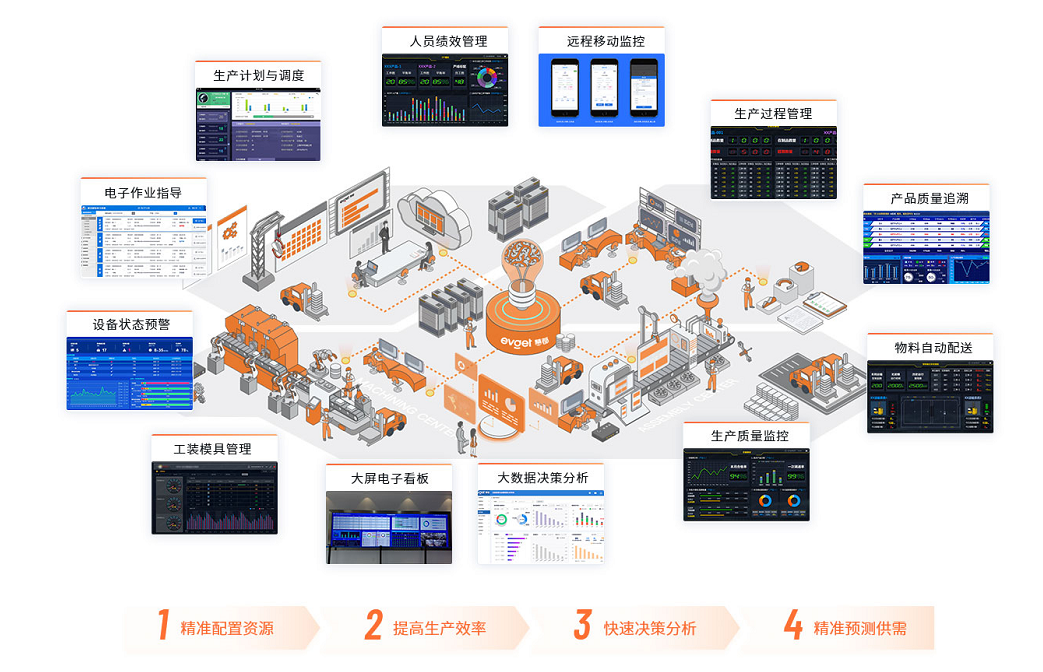

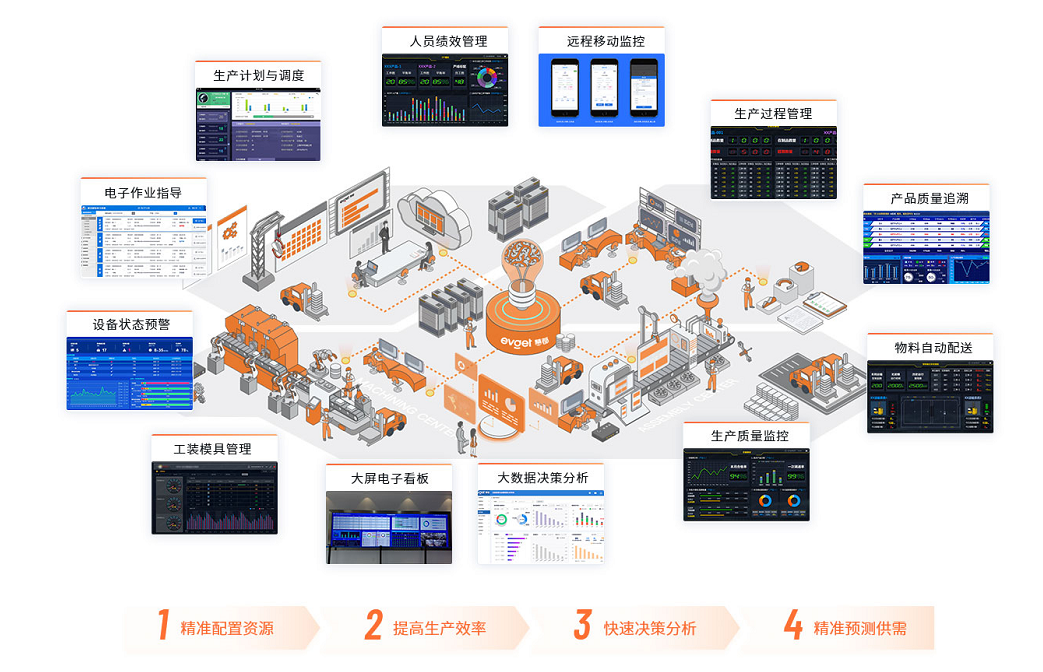

One 、 What is? APS Advanced planning and scheduling system

APS Advanced planning and scheduling is to solve the problems of production scheduling and production scheduling , It is often called scheduling problem or resource allocation problem .

at present , The market is gradually becoming personalized 、 The mode of setting production by sales ; Production is gradually formed in multiple varieties and small batches . For discrete manufacturing industries ,APS It is to solve the problem of multiple processes 、 Multi resource optimal scheduling problem , For the process industry ,APS Is to solve the sequence optimization problem .APS By solving the optimization problem of sequence and scheduling for process and discrete hybrid model at the same time , So as to minimize the critical chain and cost time of project management and project manufacturing , Of great significance .

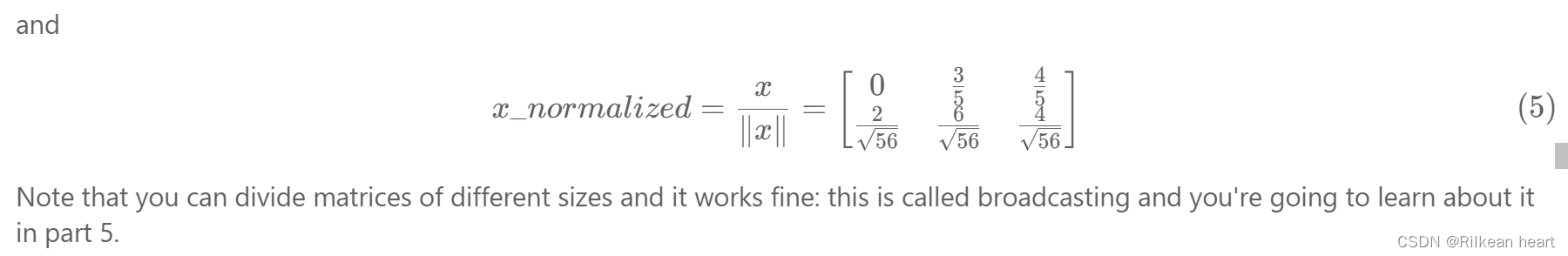

Sum up ,APS The system is based on comprehensive consideration of production capacity 、 work clothes 、 equipment 、 Human resources 、 shift 、 Work calendar 、 The mould 、、 Outsourcing resources 、 Processing batch and other constraints , Main solution “ With limited capacity , Accurate forecast of delivery capacity 、 The problem of optimal detailed planning of process production and material supply .

APS The production scheduling system makes a reasonable and optimized detailed production plan , And it can also combine actual performance with plan , receive MES Manufacturing execution system or other process completion feedback information , So as to completely solve the difficult problem of process production planning and material demand planning ,APS Software integration ERP、MES、PLM And other systems to provide data support , Efficiently realize the rolling scheduling of production plan , It is the implementation of JIT The most effective tool of lean manufacturing system .

Two 、 Current situation of the industry and pain points of manufacturing enterprises

Many varieties 、 Small batch 、 Discrete manufacturing , Single factory and multiple workshops 、 Group multi factory manufacturing enterprise , Whether big factories or small companies , No matter it's already on ERP, Still on MES System , No matter how high the degree of informatization is , They are basically using traditional EXCEL Manual scheduling .

Traditional manual scheduling has the following pain points :

1、 Multi person scheduling

Slow efficiency : It needs more than one person to divide the work , use Excel Way to make a rough schedule

2、 Human resource analysis

Waste of capacity : Judge by experience 、 Low equipment utilization , Manufacturing costs continue to increase

3、 Material planning

High stock : Supply and demand are out of sync , Cause shutdown and waiting for materials , Material preparation cannot be purchased on demand

4、ERP Derived data

Great error :ERP Low real-time performance of exported data , Manual scheduling cannot be performed in real time , The error of production scheduling is large

5、 customer demand

Order loss : Unable to determine the delivery date , Don't dare to answer urgent orders , Unable to insert the order urgently , Low customer satisfaction

3、 ... and 、APS The role and value of automated scheduling

1、 Improve the enforceability of production plan

2、 Reduce the difficulty and intensity of production scheduling

3、 Shorten the manufacturing cycle , lower production cost

4、 Reduce material lead time , Realize on-demand material preparation

5、 Improve the on-time delivery rate of orders , Improve customer satisfaction

6、 Reduce staff 、 The manpower demand of production management , Reduce personnel expenses

7、 Reduce material 、 Warehouse inventory of semi-finished products and finished products , Reduce capital occupation

8、 Improve equipment utilization , Reduce line change 、 Change the mold and stop the machine 、 Waiting time

Four 、APS Operation process of advanced planning and scheduling system

1、 Input master data through the production scheduling software system , Or by ERP、MES System API Interface to import master data , Like the work center 、 workshop 、 Production line 、 equipment 、 Human resources 、 The mould 、 The calendar 、 Basic data such as shifts and working hours .

2、 After the master data import is set , You need to enter or import synchronously through the planning and scheduling software ERP、MES Sales orders in the system 、 Production work order 、 Warehouse stock 、BOM、 Process 、 Process route 、 Purchase order and other related data , The sales order contains materials 、 Number 、 Delivery date ; The production work order contains materials 、 Number 、 Starting time 、 End time, etc ;

3、 One click automatic scheduling : After the master data and business document data are imported and set ,APS Advanced planning and scheduling system , You can set it according to the system , adopt APS Genetic algorithm in engine 、 Neural network algorithm , and APS Unique equalization algorithm for splitting orders and changing lines 、 Demand rolling scheduling algorithm 、 Unique advanced scheduling algorithms such as material integration algorithm and line change algorithm , Automatic discharge : Order delivery schedule 、 Purchase demand schedule 、 Production work order schedule 、 Production process schedule 、 Equipment resource use schedule, etc .

4、 When the scheduling results come out ,APS The system can export EXCEL Scheduling results , Or the system will automatically pass... With one key confirmation API Interface synchronization to ERP、MES、WMS and PLM Such as system , Automatically write order delivery date , Automatically create purchase requisition , Automatically jump to work order start date and finish date , Work order material staging plan 、 Production dispatch 、 Warehousing plan, etc .

5、APS The advanced planning and scheduling system provides multiple Gantt charts at the same time , You can intuitively get the scheduling results , Gantt chart of equipment resources 、 Order Gantt Chart 、 Work order Gantt Chart 、 Capacity load Gantt Chart 、 Inventory Gantt chart, etc , Know the plan data at a glance through the Gantt Chart .

If you have MES/APS System related requirements , You can leave a message by private mail , Get more case details , Welcome to communicate !

边栏推荐

- MES helps enterprises to transform intelligently and improve the transparency of enterprise production

- (P21-P24)统一的数据初始化方式:列表初始化、使用初始化列表初始化非聚合类型的对象、initializer_lisy模板类的使用

- Vscode的Katex问题:ParseError: KaTeX Parse Error: Can‘t Use Function ‘$‘ In Math Mode At Position ...

- Ceres optimizer usage (self use)

- Group planning chapter I

- MYSQL中的触发器

- Hands on deep learning -- concise implementation code of weight decay

- (p33-p35) lambda expression syntax, precautions for lambda expression, essence of lambda expression

- Xiaomi mobile phone recording data set software operation

- visual studio2019的asp.net项目添加日志功能

猜你喜欢

Vscode的Katex问题:ParseError: KaTeX Parse Error: Can‘t Use Function ‘$‘ In Math Mode At Position ...

MES helps enterprises to transform intelligently and improve the transparency of enterprise production

Hands on deep learning -- implementation of multi-layer perceptron from scratch and its concise implementation

智能制造的时代,企业如何进行数字化转型

ctfshow web 1-2

企业上MES系统的驱动力来自哪里?选型又该注意哪些问题?

Vision Transformer | CVPR 2022 - Vision Transformer with Deformable Attention

ctfshow web3

Vision Transformer | Arxiv 2205 - TRT-ViT 面向 TensorRT 的 Vision Transformer

Scope of bean

随机推荐

Project sorting of niuke.com

Gtest/gmock introduction and Practice

ctfshow web 1-2

GTEST/GMOCK介绍与实战

Group planning chapter I

vm虛擬機中使用NAT模式特別說明

超全MES系统知识普及,必读此文

The residual pressure monitoring system ensures the smoothness of the fire evacuation passage in case of fire, and protects the safe operation of large high-rise buildings and the safety of people's l

制造企业生产排产现状和APS系统的解决方案

FPGA generates 720p video clock

Vision Transformer | Arxiv 2205 - TRT-ViT 面向 TensorRT 的 Vision Transformer

Py & go programming skills: logic control to avoid if else

You get download the installation and use of artifact

模型压缩 | TIP 2022 - 蒸馏位置自适应:Spot-adaptive Knowledge Distillation

Bean的作用域

安科瑞消防应急照明和疏散指示系统

ctfshow web4

js中的数组

ctfshow web3

Vscode download slow solution