当前位置:网站首页>Panel display technology: LCD and OLED

Panel display technology: LCD and OLED

2022-07-07 08:54:00 【Hardware bear】

Panel display technology (FPD) There are roughly three stages :CRT( crt )、LCD Liquid crystal display 、OLED( Organic light emitting semiconductors ), The technologies that are expected to develop in the future are Mini-LED、Micro-LED.

In the past 20 For many years, the display panel industry has experienced Japan --> South Korea --> Taiwan, China --> There are four stages in Chinese Mainland , At present, Chinese Mainland has the largest production capacity , And drive IC、 Polarizer 、 Backlight module 、 Color filters 、 Liquid crystal materials are in the strategic opportunity period of domestic substitution .

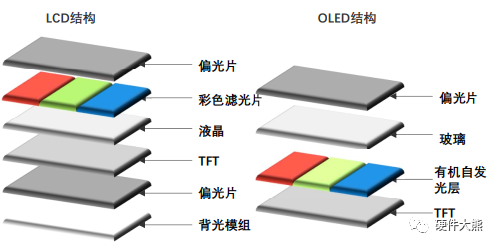

Current mainstream display technologies include LCD And OLED display technique ,LCD The panel is illuminated by the backlight module , and OLED No need for backlight modules , It has self luminous characteristics .

LCD The market has now entered the stock stage , and OLED Panel demand is gradually released , and LCD comparison ,OLED The panel has faster response speed 、 A broader perspective 、 Higher color saturation , And OLED The structure is relatively simple , weight 、 Thickness comparison TFT-LCD Lighter , At the same time, it has the advantages of flexibility and low power consumption .

( The picture is quoted from 《2020 Overview of China's display panel industry in 》www.leadleo.com)

TFT LCD working principle

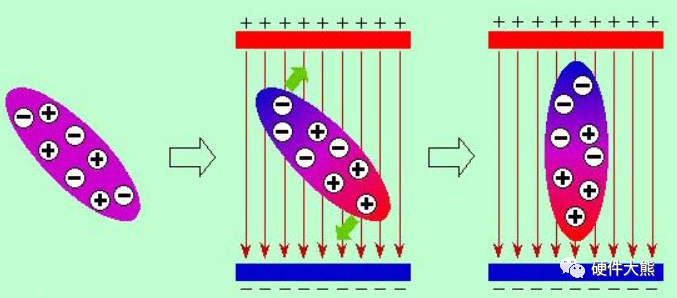

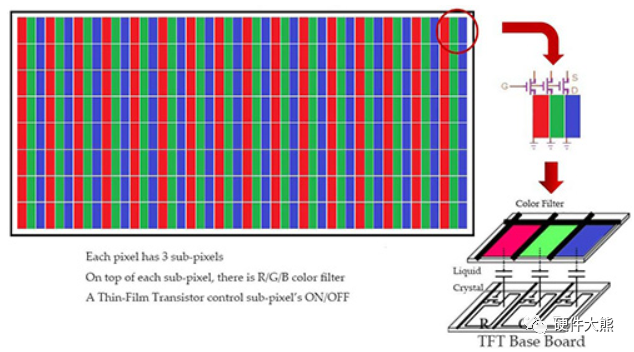

TFT yes “ Thin film transistor ” It means ,TFT LCD Also known as active matrix display , namely : stay TFT A glass substrate formed with transparent pixel electrodes and another with a color filter (RGB) There is a liquid crystal layer between the glass substrate and the transparent counter electrode , When an electric field in the opposite direction is applied to the liquid crystal , Liquid crystal molecules will change the arrangement angle due to torque .

( The picture is quoted from :https://hr-inoue.net/zscience/topics/liquidcrystal/liquidcrystal.html)

The deflection of liquid crystal changes the polarization direction of light , Through color filters and polarizers , Thus forming a single pixel color .

( The picture is quoted from :https://www.topwaydisplay.com/cn/blog/how-tft-lcd-works-explained)

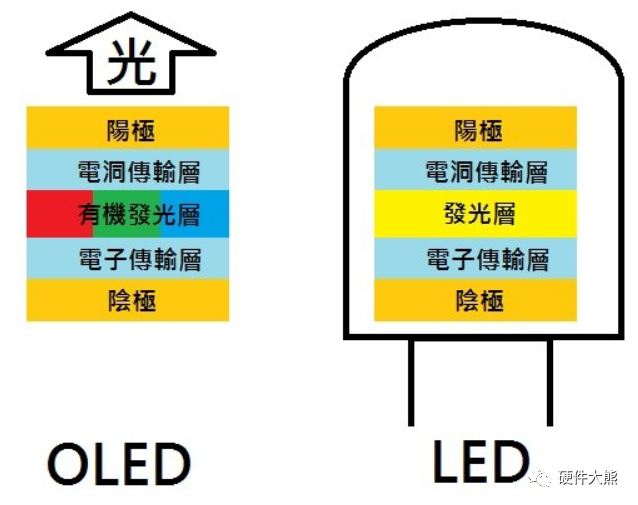

OLED working principle

OLED yes “Quantum Dotlight Emitting Diode” Abbreviation , Quantum dot light emitting diode .OLED The simplest form is a layer of luminescent material , Embedded between two electrodes , Carrier motion at input voltage , It is released in the form of light pulses through the organic layer , Through blue LED Light source irradiates quantum dots to excite red and green light .

( The picture is quoted from :https://hr-inoue.net/zscience/topics/liquidcrystal/liquidcrystal.html)

manufacturing process

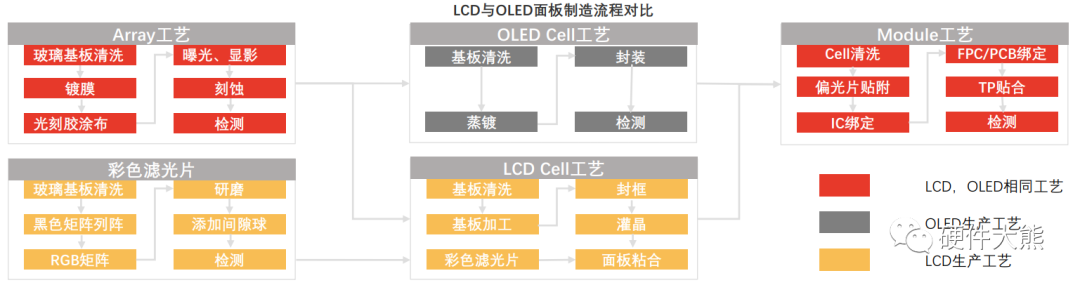

OLED Use self luminous organic materials , and LCD The backlight module is used to illuminate the rectification substrate , Therefore, the process flow will be different . But neither LCD still OLED, The panel manufacturing process can be divided into three stages :Array( array )、Cell( Box )、Module( module ).

LCD Technological process :

Array Process : Produce on glass substrate TFT Thin film transistor array , complete ITO Production of conductive glass ;

Cell Process : An empty liquid crystal cell is formed on the glass substrate , For example, liquid crystal molecules are divided according to the size required , It is formed after pasting the polarizer and loading the electrical signal to check the display LCD panel ;

Module Process : take LCD Panel and drive IC Connected with the signal base plate , Finally, assemble the backlight and protective cover to form a complete LCD module

OLED In the above process Cell Add evaporation and packaging process in the stage , The process is more difficult , At present, the evaporation equipment is used by Japan Canon Tokki The company monopolizes the high-end market , therefore OLED The construction cost of the production line far exceeds LCD The production line .

( The picture is quoted from 《2020 Overview of China's display panel industry in 》www.leadleo.com)

LCD The main application market of is TV market , and OLED Its main application market is smart phones , In the display panel industry chain , Upstream materials such as backlight module 、 Color filters 、 The polarizer has Jufei 、TOPPAN、 Shengbo optoelectronics and other manufacturers ; In the middle LCD The panel has BOE 、 Huike Co., Ltd ,OLED Youhehui photoelectric 、ROYOLE etc. ; The downstream application market is Samsung 、 hisense 、 lenovo 、 Huawei 、 Xiaomi and many other manufacturers .

( The picture is quoted from 《2020 Overview of China's display panel industry in 》www.leadleo.com)

Recommended reading :

Original collection of hardware bear (2022/06 to update )

Originality is not easy. , If there is a need to reprint , Be sure to inform !

If my words inspire or help you ,

“ give the thumbs-up \ forward ” It was my greatest support

边栏推荐

- How to integrate app linking services in harmonyos applications

- Recommended by Alibaba P8, the test coverage tool - Jacobo is very practical

- 調用華為遊戲多媒體服務的創建引擎接口返回錯誤碼1002,錯誤信息:the params is error

- Shell script for changing the current folder and the file date under the folder

- Digital triangle model acwing 1027 Grid access

- Analysis of using jsonp cross domain vulnerability and XSS vulnerability in honeypot

- 年薪50w阿裏P8親自下場,教你如何從測試進階

- GoLand set goproxy

- Problems encountered in the use of go micro

- 2022-06-30 Unity核心8——模型导入

猜你喜欢

![Data analysis methodology and previous experience summary 2 [notes dry goods]](/img/e1/643e847a777e1effcbd39f8b009e2b.png)

Data analysis methodology and previous experience summary 2 [notes dry goods]

![[Yugong series] February 2022 U3D full stack class 005 unity engine view](/img/19/dc1b2f74b9ec5f5808de3049793862.jpg)

[Yugong series] February 2022 U3D full stack class 005 unity engine view

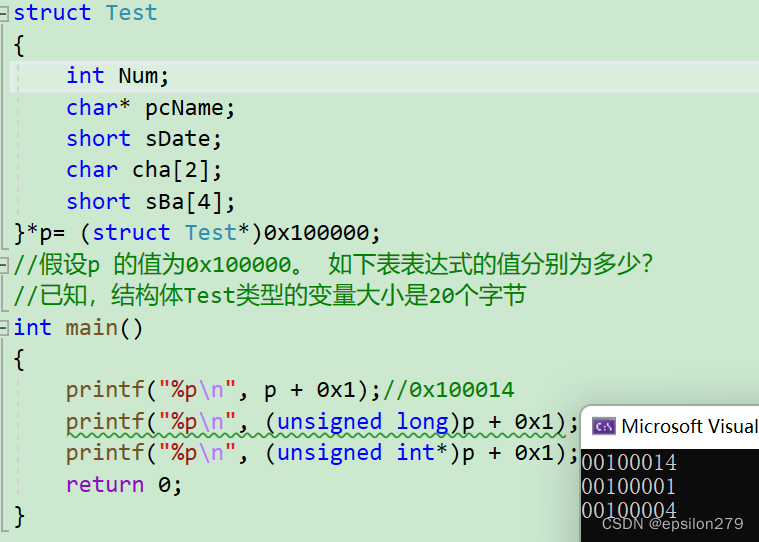

指针进阶,字符串函数

ncs成都新電面試經驗

About using CDN based on Kangle and EP panel

The longest ascending subsequence model acwing 1017 Strange thief Kidd's glider

Interpolation lookup (two methods)

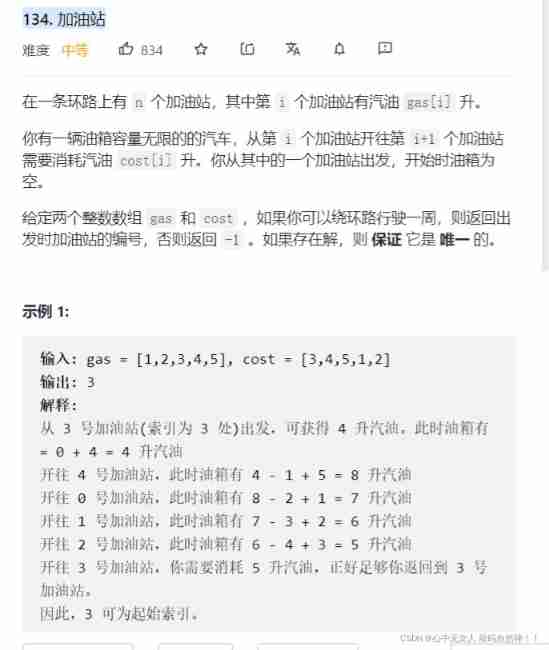

leetcode134. gas station

idea里使用module项目的一个bug

【MySQL】数据库进阶之触发器内容详解

随机推荐

Mock. JS usage details

leetcode135. Distribute candy

Calf problem

systemd

Greenplum6.x搭建_环境配置

2022-06-30 Unity核心8——模型导入

Rapid integration of authentication services - harmonyos platform

ncs成都新電面試經驗

对API接口或H5接口做签名认证

[Yugong series] February 2022 U3D full stack class 006 unity toolbar

Gson converts the entity class to JSON times declare multiple JSON fields named

数据分片介绍

2022-07-06 Unity核心9——3D动画

Greenplum 6.x reinitialization

leetcode134. gas station

let const

阿里p8推荐,测试覆盖率工具—Jacoco,实用性极佳

如何在图片的目标中添加目标的mask

Digital triangle model acwing 1027 Grid access

Vagrant failed to mount directory mount: unknown filesystem type 'vboxsf'