当前位置:网站首页>Methods of improving machine vision system

Methods of improving machine vision system

2022-07-04 21:21:00 【Double vision】

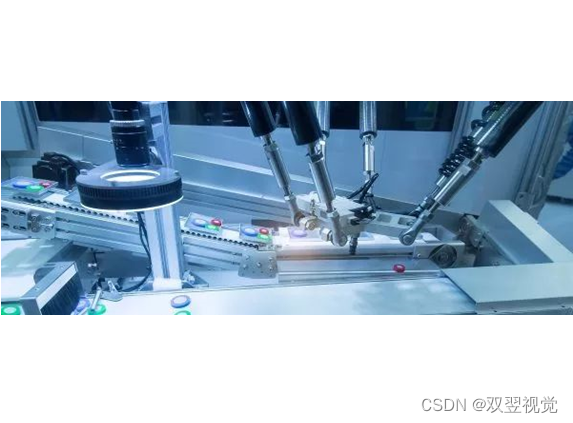

With the increasingly fierce competition in the global manufacturing market , It is important for enterprises to ensure that they operate with the highest efficiency . Downtime due to process related failures is considered non value added downtime , Directly affect the profitability of the company . Machine vision is a new field , If the settings are correct , It can reduce the inefficiency of the process . Any facility that uses machine vision as robot guidance or inspection should pay attention to this field , To seek possible improvements . If there is no appropriate setting in the machine vision system , It may cause non value-added downtime of machine vision process , Here are ten areas that need special attention for improvement :

1) Lighting technology - The correct lighting technology should be used to illuminate the area to be detected . Backlight 、 Bright field 、 grazing 、 Low angle linear array and dark field illumination technology are the most critical aspects of machine vision robustness . According to the surface finish and contour of the part , Correct lighting technology can enhance defects or remove image noise , Improve the efficiency and stability of the system . The purpose of this is to choose a method that can produce the maximum contrast ( From black to white pixels ) Lighting technology . Besides , Contrast needs to be directly related to what is being measured or checked .

2) Lighting color - The light color used for each specific part or application should be considered . The frequency is the number of oscillations per second , And the wavelength is the distance between two points on the same position . Each kind of different UV 、 blue 、 green 、 yellow 、 red 、 Infrared spectra have different illumination frequencies and wavelengths . These changes will affect the response of objects and camera surfaces when light enters . Its purpose is to use the optical frequency that can produce the maximum contrast and eliminate the noise in the image . for example , Metal parts can sometimes be introduced into a system , The system has a thin layer of oil or a slight oxidation on the surface , It depends on how they are stored . When both types of parts are introduced into the inspection system , It is important to use the frequency of light to reduce fluctuations .

3) Use a filter filter , Eliminate serious environmental interference such as background and overhead lighting noise . By simply placing a filter on the camera lens that matches the frequency of the light illuminating the component , It can eliminate the interference of ambient lighting .

4) The lens - field (FOV) And regions of interest (ROI), Including the required pixel accuracy , It plays an important role . The correct focal length lens will determine the size of the area that the machine vision system can see , And finally decide all the information collected . Calculation is too large FOV Will result in less detail and accuracy , And the calculation is too small FOV It may cause the inspection to fail , Because parts or objects are out of the line of sight of the camera . In the calculation FOV when , It is important to decide which focal length lens is best for the application , First determine the maximum of the part or object ROI And the maximum acceptable error in this area . Sometimes these factors may be limited by the working distance or height from the camera to the object , So all these factors need to be considered before building the system .

5) location —— It is important to know that the tolerance of a part or application is too wide , Repeated inspection of components is not allowed . When a component moves out of the camera's field of view , It will lead to system instability . Some type of physical fixture should be used to limit the movement of objects or parts of interest . If the part moves out of the camera view , It's going to break down , Increase unnecessary downtime . By providing a rough location of the part , This instability can be eliminated , Ensure that the parts can appear repeatedly in the machine vision system every time .

6) calibration - Have master fixture or calibration program , The system can be properly calibrated , Ensure that it meets the quality standards of the equipment .

Features and datums —— In order to check the image correctly , The benchmark —— The only feature found in each inspection —— It can be used as a reference point for visual tools during inspection , Or it can be used to detect whether there are correct parts in the image .

8) The resolution of the - The resolution determines the repeatability of the visual system ; It allows the size of pixels to be quantified into measured values . It is important to determine the resolution of the system , Because it determines the accuracy and repeatability of the inspection . In particular, solutions that need to be considered in quality measurement and detection and robot guidance . Some software can improve the resolution , The accuracy can reach sub-pixel .

9) stability —— When setting up the machine vision sensor , It is important to protect the camera system and light from moving . These items are the goals of system calibration . To minimize movement or interference , It is wise to place the camera and lighting lamp in a place with little or no vibration and traffic .

10) test —— Check the system regularly , Confirm whether the defective parts are captured and rejected by the system . You can build a test process directly in the system , To simplify the process . Defective test parts can be placed in the system at any time , To verify the proper function of the system .

边栏推荐

猜你喜欢

【观察】联想:3X(1+N)智慧办公解决方案,释放办公生产力“乘数效应”

heatmap.js图片热点热力图插件

Leetcode+ 81 - 85 monotone stack topic

接口設計時的一些建議

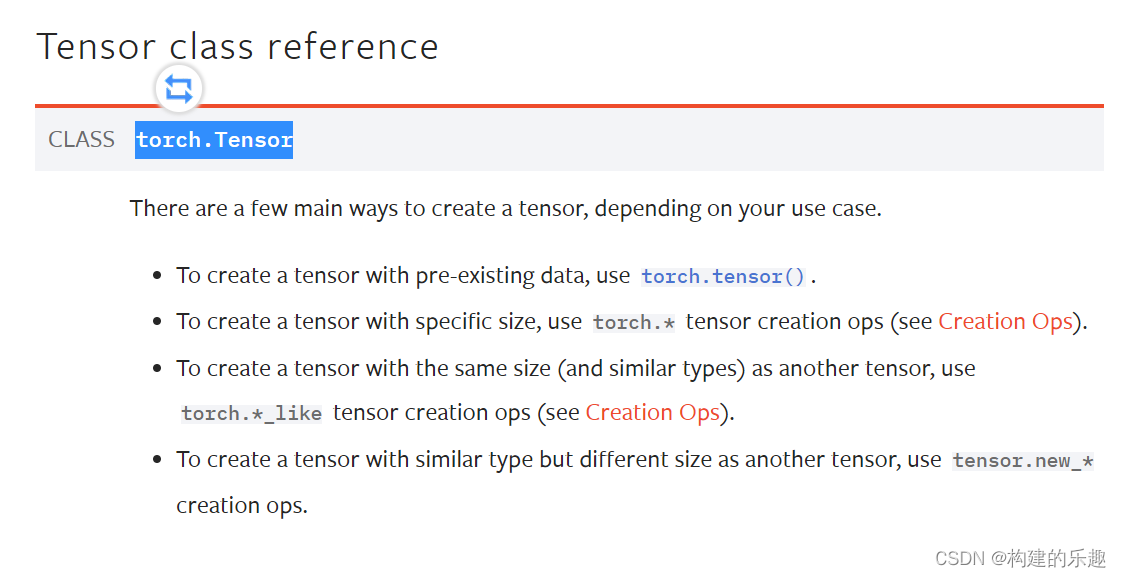

torch. Tensor and torch The difference between tensor

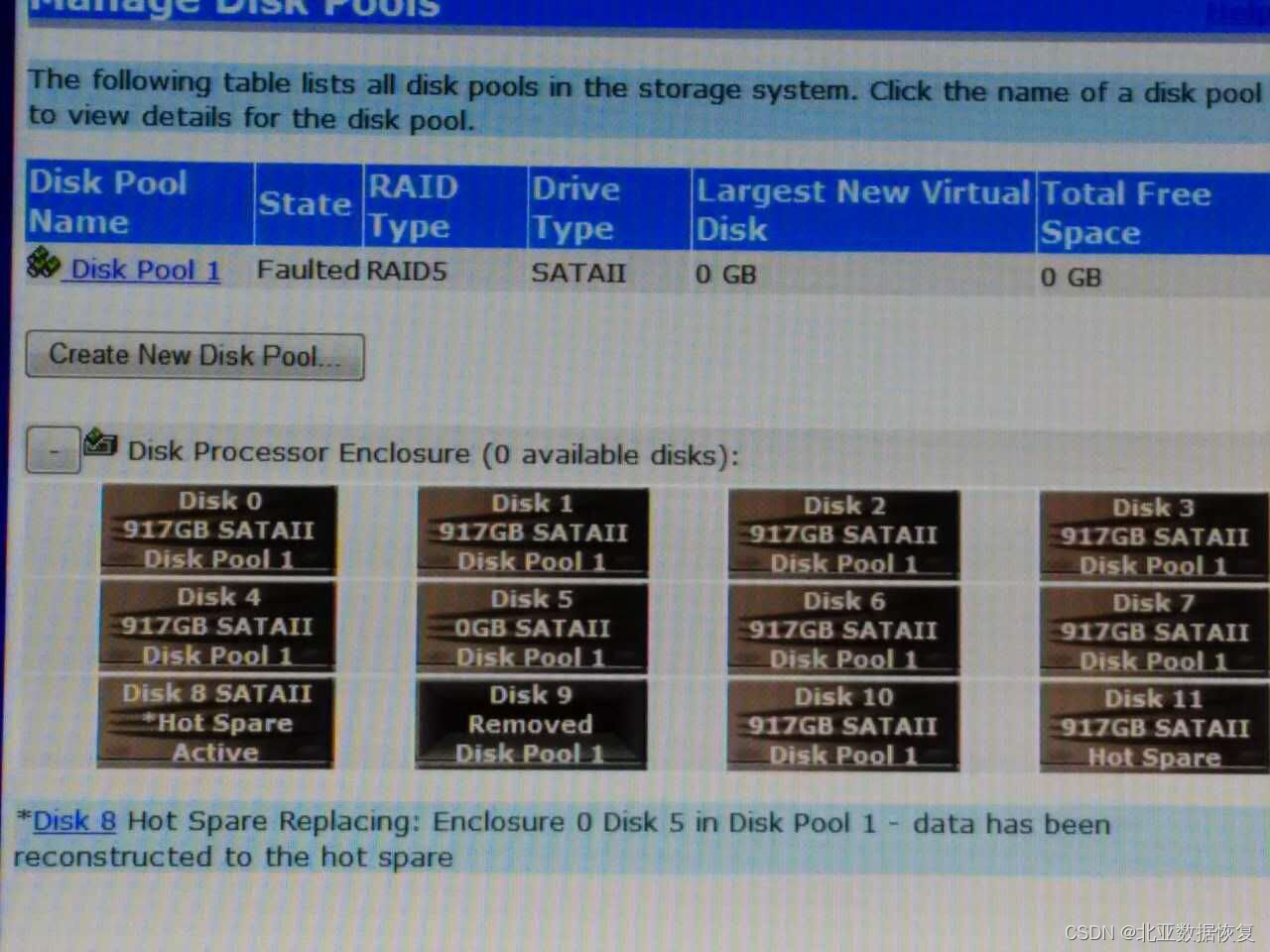

【服务器数据恢复】某品牌服务器存储raid5数据恢复案例

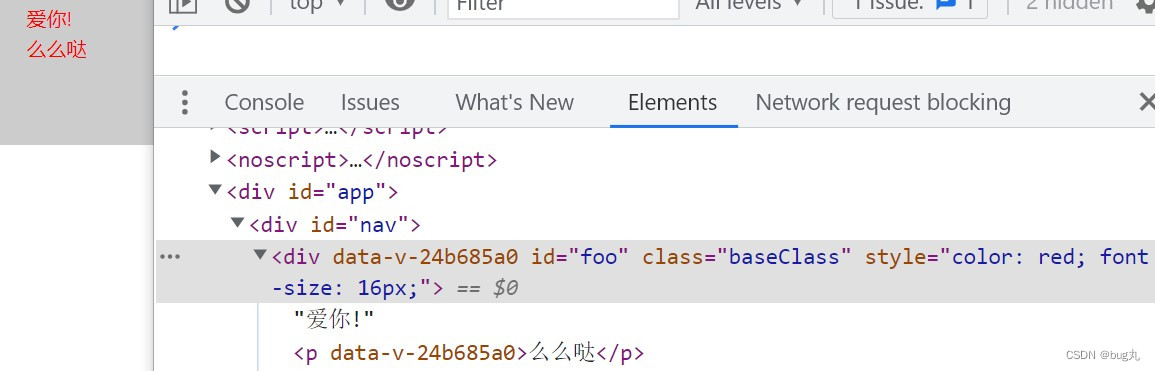

Render function and virtual DOM

Advantages of RFID warehouse management system solution

Maya lamp modeling

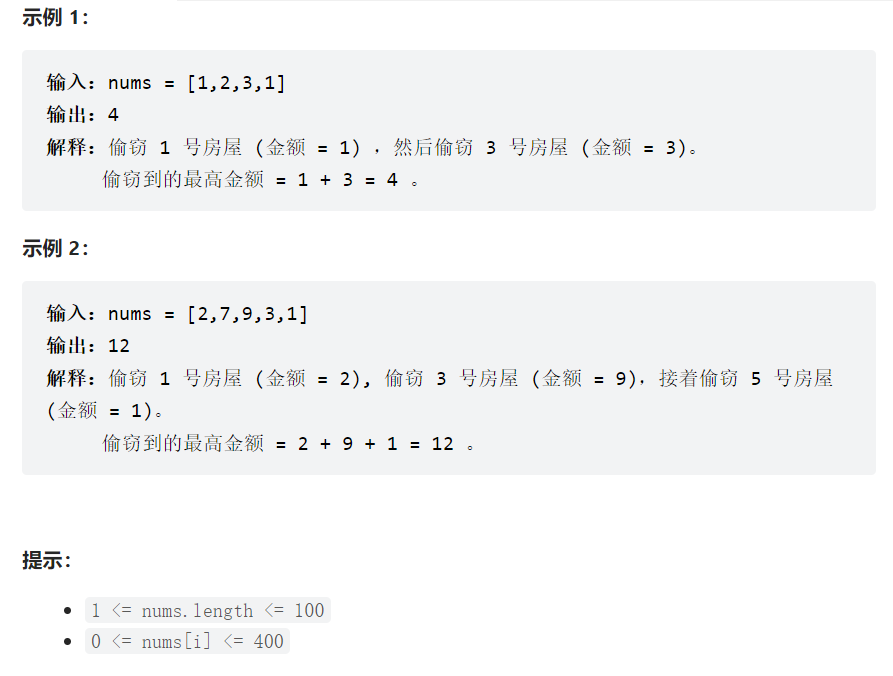

Sword finger offer II 80-100 (continuous update)

随机推荐

nmap扫描

Android原生数据库的基本使用和升级

c语言函数形参自增自减情况分析

杰理之AD 系列 MIDI 功能说明【篇】

redis布隆过滤器

Configuration of DNS server of Huawei ENSP simulator

Huawei ENSP simulator layer 3 switch

Huawei ENSP simulator enables devices of multiple routers to access each other

[buuctf.reverse] 151_ [FlareOn6]DnsChess

Pytorch---使用Pytorch实现LinkNet进行语义分割

maya灯建模

Use of redis publish subscription

改善机器视觉系统的方法

What are the functional modules of RFID warehouse management system solution

admas零件名重复

吐槽 B 站收费,是怪它没钱么?

[observation] Lenovo: 3x (1+n) smart office solution, releasing the "multiplier effect" of office productivity

redis发布订阅的使用

redis RDB AOF

HMS Core 机器学习服务