当前位置:网站首页>Quick completion guide of manipulator (10): accessible workspace

Quick completion guide of manipulator (10): accessible workspace

2022-07-07 04:00:00 【Lie on me】

Directory :

Quick completion guide of mechanical arm ( zero ): Main contents and analysis methods of the guide

Quick completion guide of mechanical arm ( One ): The development of manipulator

Quick completion guide of mechanical arm ( Two ): Application of mechanical arm

Quick completion guide of mechanical arm ( 3、 ... and ): Mechanical structure of mechanical arm

Quick completion guide of mechanical arm ( Four ): Reducer of key components of mechanical arm

Quick completion guide of mechanical arm ( 5、 ... and ): End actuators

Quick completion guide of mechanical arm ( 6、 ... and ): Stepper motor driver

Quick completion guide of mechanical arm ( 7、 ... and ): Description method of robot arm posture

Quick completion guide of mechanical arm ( 8、 ... and ): Kinematic modeling ( standard DH Law )

Quick completion guide of mechanical arm ( Nine ): Forward kinematics analysis

Quick completion guide of mechanical arm ( Ten ): Reachable workspace

******************** Here is the main body ********************

stay guide ( Nine ) in , We have obtained a six degree of freedom manipulator Forward kinematics equation , By substituting joint variables into the equation, the position and posture of the end of the manipulator can be obtained . Now we know the rotatable range of each joint , that , At the same time, we can also get all the positions that the end of the manipulator can reach , We call this set of possible locations as Reachable workspace , And this is also an important parameter index of the manipulator .

Used in the guide MATLAB Medium Robotic Toolbox hold-all ( It's not official Robotics System Toolbox ) Kinematic simulation of the manipulator , The reachable workspace of the manipulator is obtained by Monte Carlo method, which is easy to implement and runs fast .

One 、 Joint space and drive space

Joint space description and driver space description are two methods used to describe the pose of manipulator .

1. Joint space

For one with n For a manipulator with three degrees of freedom , The positions of all its connecting rods can be determined by a group n Joint variables are confirmed

set . Such a set of variables is often called nx1 Joint vector . The space composed of all joint vectors is called Joint space .

2. Drive space

up to now , We have always assumed that every joint is directly driven by some kind of driver . However , This is not the case for many industrial robots , Sometimes we also use two drivers to drive a joint in a differential way , Sometimes, a linear driver is used to drive the rotating joint through a four-bar linkage .

In these cases , You need to consider the drive space . Because the sensor that measures the joint change of the manipulator is usually installed on the driver , Therefore, in some calculations, the joint vector must be expressed as a set of driver functions , Drive vector . The space composed of all drive vectors is called Drive space .

Two 、 working space (workspace)

working space (workspace) It is when all the joints of the manipulator perform all the possible movements , A collection of the origin positions of the end effector coordinate system . The workspace can be divided into Can be up to (reachable) working space And flexible (dexterous) working space .

Workspace is Co., LTD. 、 closed 、 coherent Of . Because joints are rotating or moving , It is easy to know that the workspace is composed of a plane 、 spherical 、 Composed of surface elements such as ring and cylinder . Manipulator manufacturers will give the workspace of the manipulator in the form of top view and flat view in the data manual , It is the basic element needed to evaluate the performance of the robot in the expected application .

1. Reachable workspace

The set of target points reached by the manipulator end effector in more than one direction is Reachable workspace .

2. Flexible workspace

The set of target points that the manipulator can reach in any direction is Flexible workspace .

3. Programming realization of reachable workspace calculation of manipulator

% Monte Carlo method simulates the reachable workspace of the manipulator

% Liu lie

radian1 = pi/180;

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% Definition DH Parameters %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%% Liu lie %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

d1 = 169.77;

d2 = 0;

d3 = 0;

d4 = -222.63;

d5 = 0;

d6 = -36.25;

% Mechanical arm link length parameter a

a1 = 64.2;

a2 = 305;

a3 = 0;

a4 = 0;

a5 = 0;

a6 = 0;

% Parameters of joint deflection angle of manipulator alpha

alpha1 = -90 * radian1;

alpha2 = 0 * radian1;

alpha3 = 90 * radian1;

alpha4 = -90 * radian1;

alpha5 = 90 * radian1;

alpha6 = 0 * radian1;

% Define joint angle limits

lim1_min = -170 * radian1; lim1_max = 170 * radian1; % The joints 1(-170,170)

lim2_min = -132 * radian1; lim2_max = 0 * radian1; % The joints 2(-132,0)

lim3_min = 1 * radian1; lim3_max = 141 * radian1; % The joints 3(1,141)

lim4_min = -165 * radian1; lim4_max = 165 * radian1; % The joints 4(-165,165)

lim5_min = -105 * radian1; lim5_max = 105 * radian1; % The joints 5(-105,105)

lim6_min = -155 * radian1; lim6_max = 155 * radian1; % The joints 6(-155,155)

% Define the range of joint rotation

lim1 = lim1_max - lim1_min;

lim2 = lim2_max - lim2_min;

lim3 = lim3_max - lim3_min;

lim4 = lim4_max - lim4_min;

lim5 = lim5_max - lim5_min;

lim6 = lim6_max - lim6_min;

% Define each link and joint type , The default is to rotate the joint

% θ d a α Angle limit Joint offset

L(1)=Link([ 0 d1 a1 alpha1]); L(1).qlim=[lim1_min,lim1_max];

L(2)=Link([ 0 d2 a2 alpha2]); L(2).qlim=[lim2_min,lim2_max];

L(3)=Link([ 0 d3 a3 alpha3]); L(3).qlim=[lim3_min,lim3_max]; L(3).offset=-pi/2;

L(4)=Link([ 0 d4 a4 alpha4]); L(4).qlim=[lim4_min,lim4_max];

L(5)=Link([ 0 d5 a5 alpha5]); L(5).qlim=[lim5_min,lim5_max];

L(6)=Link([ 0 d6 a6 alpha6]); L(6).qlim=[lim6_min,lim6_max]; L(6).offset=pi;

% Combine the above connecting rods

AR3=SerialLink(L,'name','AR3');

% Displays the number of manipulator joints and D_H parameter list

%AR3:: 6 axis, RRRRRR, stdDH, slowRNE

AR3.display();

% Use Monte Carlo method to draw the workspace of the manipulator

N=15000;

theta1 = ( lim1_min + (lim1 * rand(N,1)) );

theta2 = ( lim2_min + (lim2 * rand(N,1)) );

theta3 = ( lim3_min + (lim3 * rand(N,1)) );

theta4 = ( lim4_min + (lim4 * rand(N,1)) );

theta5 = ( lim5_min + (lim5 * rand(N,1)) );

theta6 = ( lim6_min + (lim6 * rand(N,1)) );

for n = 1:N

theta = [theta1(n),theta2(n),theta3(n),theta4(n),theta5(n),theta6(n)];

workspace = AR3.fkine(theta);

plot3(workspace.t(1),workspace.t(2),workspace.t(3),'b.','markersize',1);

hold on;

end

AR3.plot(theta); % Animation display

% Real time display of robots

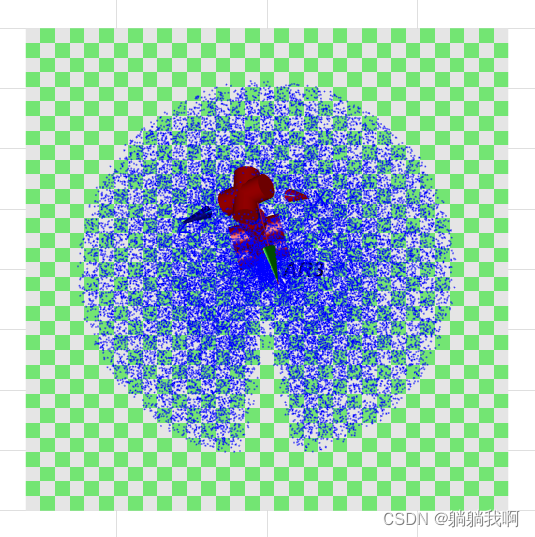

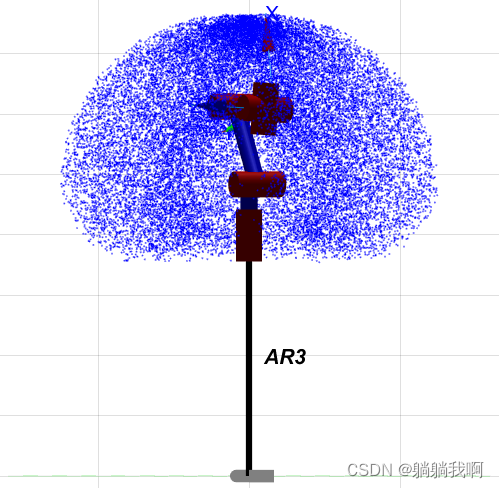

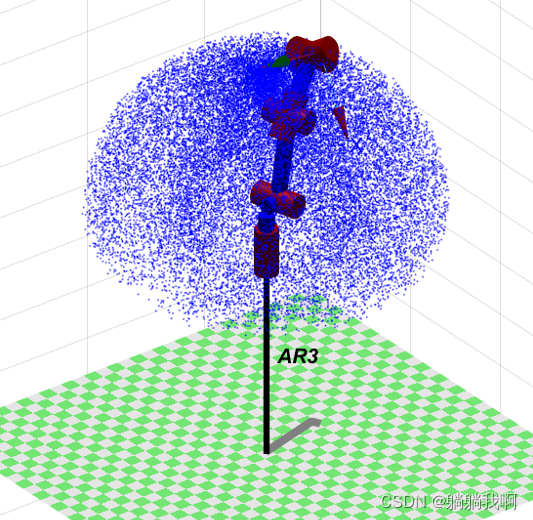

AR3.teach();The specific programming process is : First, according to the definition in the previous chapter Kinematic parameters of manipulator Yes Robotic Toolbox Assignment of relevant parameters of the manipulator in the toolbox , In order to build the simulation model of the manipulator ; next , Generate 30000 Random joint variables , Substitute Forward kinematics equation To solve the ; Last , Mark the points representing the reachable position of the end effector in three-dimensional space , The dot matrix formed can represent the Reachable workspace , The running effect of the program is shown in the figure below .

|  |  |

边栏推荐

- Allow public connections to local Ruby on Rails Development Server

- 手机号国际区号JSON格式另附PHP获取

- Antd Comment 递归循环评论

- 如何检测mysql代码运行是否出现死锁+binlog查看

- Delete data in SQL

- Enter the rough outline of the URL question (continuously updated)

- ABAP dynamic inner table grouping cycle

- 23. (ArcGIS API for JS) ArcGIS API for JS ellipse collection (sketchviewmodel)

- Free PHP online decryption tool source code v1.2

- VHDL implementation of arbitrary size matrix multiplication

猜你喜欢

一些常用软件相关

My brave way to line -- elaborate on what happens when the browser enters the URL

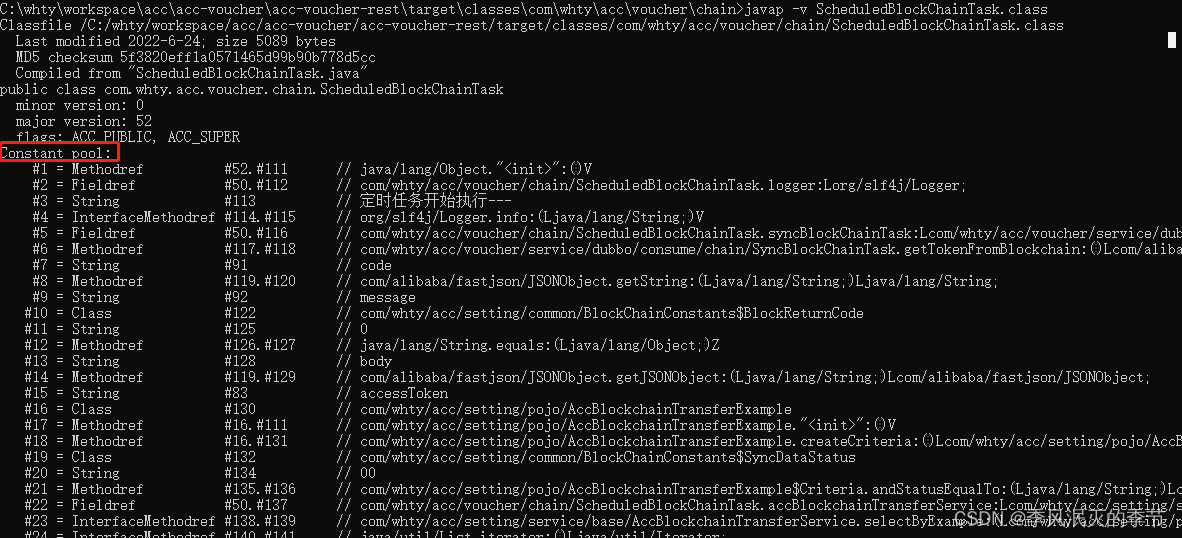

Class constant pool and runtime constant pool

维护万星开源向量数据库是什么体验

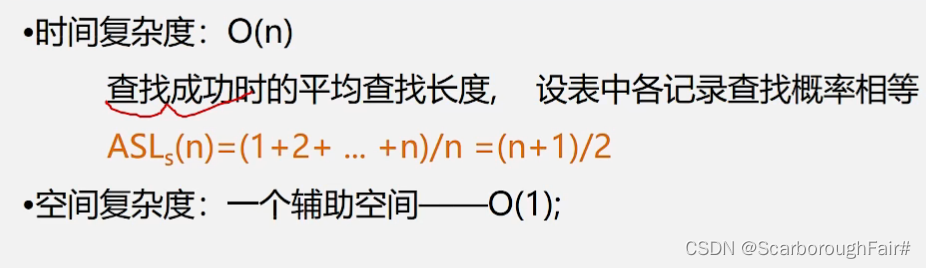

Search of linear table

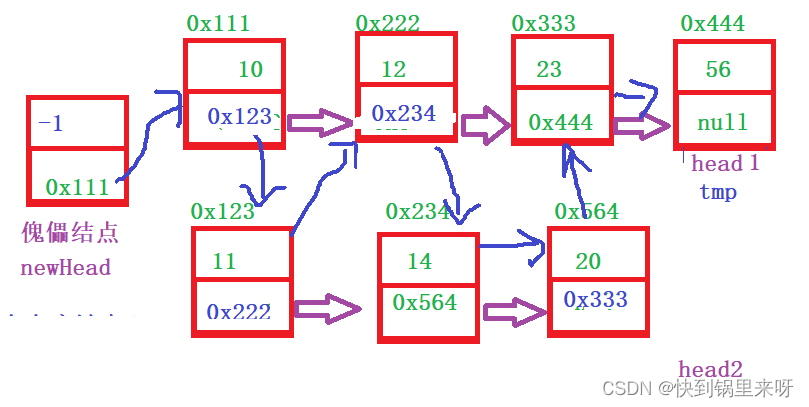

链表面试常见题

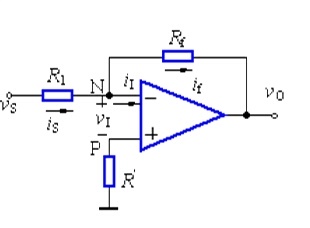

Operational amplifier application summary 1

![[leetcode] 700 and 701 (search and insert of binary search tree)](/img/b0/6aa9185f02fb1905fc59e6b329f7c3.jpg)

[leetcode] 700 and 701 (search and insert of binary search tree)

数据的存储

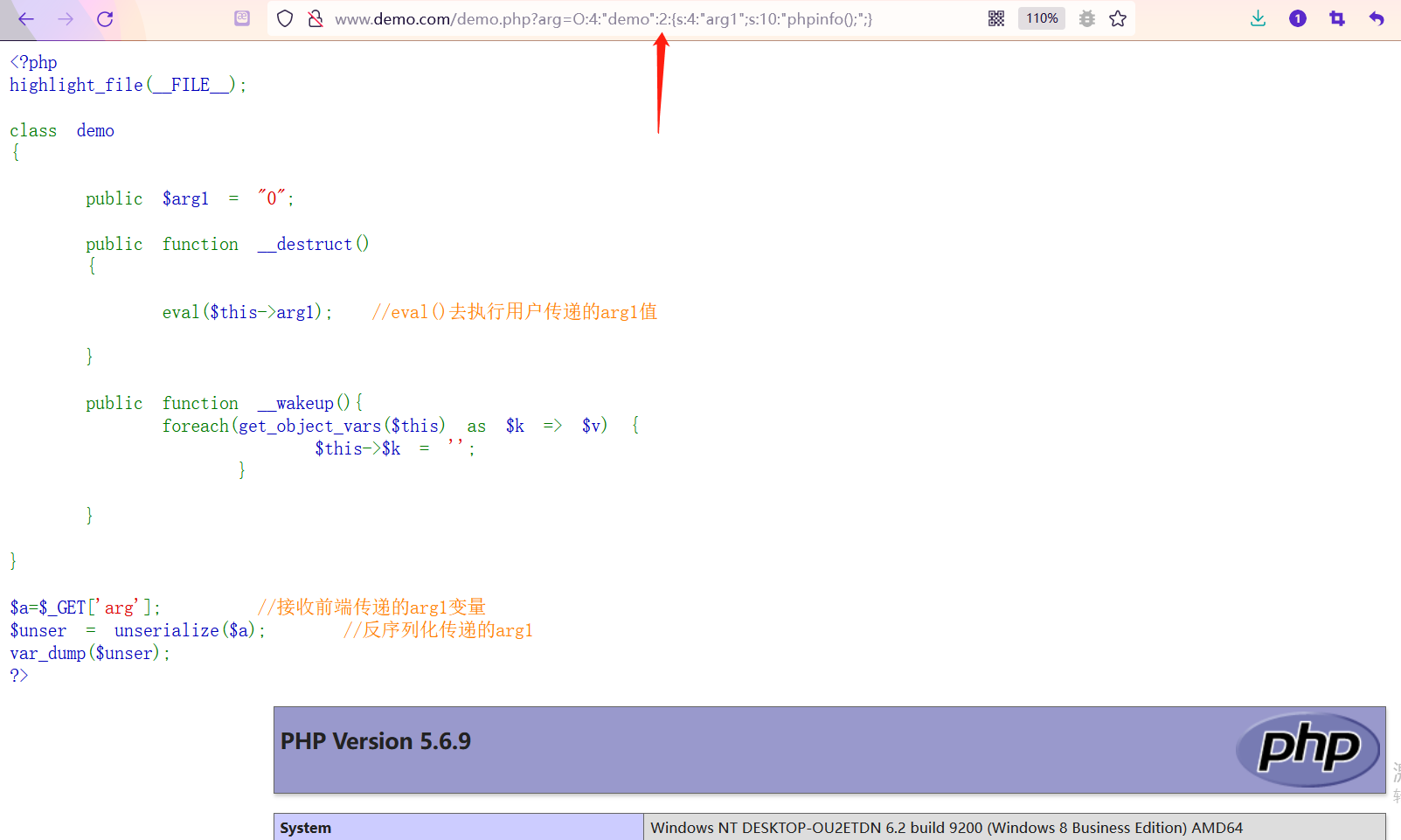

【安全攻防】序列化与反序列,你了解多少?

随机推荐

PHP 实现根据概率抽奖

Force buckle ----- path sum III

Construction of Hisilicon universal platform: color space conversion YUV2RGB

Enter the rough outline of the URL question (continuously updated)

map和set的实现

The true face of function pointer in single chip microcomputer and the operation of callback function

Top 50 hit industry in the first half of 2022

codeforces每日5题(均1700)-第七天

termux设置电脑连接手机。(敲打命令贼快),手机termux端口8022

一些常用软件相关

浅谈网络安全之文件上传

VHDL implementation of arbitrary size matrix addition operation

【安全攻防】序列化與反序列,你了解多少?

When QT uses qtooltip mouse to display text, the picture of the button will also be displayed and the prompt text style will be modified

Redis configuration and optimization of NoSQL

再AD 的 界面顶部(菜单栏)创建常用的快捷图标

Codeworks 5 questions per day (1700 average) - day 7

Antd Comment 递归循环评论

AVL树插入操作与验证操作的简单实现

It's too convenient. You can complete the code release and approval by nailing it!