当前位置:网站首页>Detailed explanation | detailed explanation of internal mechanism of industrial robot

Detailed explanation | detailed explanation of internal mechanism of industrial robot

2022-07-06 07:10:00 【Xiaobai learns vision】

Reading guide

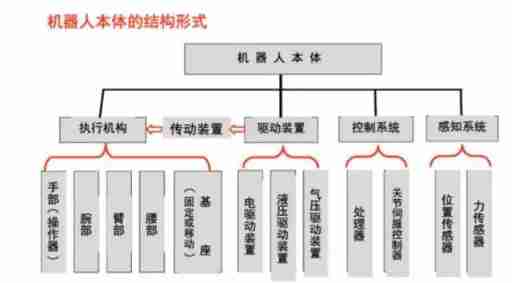

Xiaobian will tell you about the internal structure of industrial robots today , Teach everyone to control 、 drive 、 Transmission 、 Execution and other basic knowledge about robots .

Don't underestimate this basic content , As the saying goes, sharpening a knife is not a mistake for cutting firewood , With a solid foundation , It is very helpful for future study and development .

Before understanding the construction of general industrial robots

Let's first look at the animation simulation of robot arm joints

Germany kuka Industrial robots

Main internal structure

One 、 Robot drive

Concept : To make the robot run , It is necessary to place the transmission device for each joint, that is, each degree of freedom of motion .

effect : Provide all parts of the robot 、 The motive force of each joint action .

Drive system : It can be hydraulic transmission 、 Pneumatic transmission 、 Electric drive , Or an integrated system that combines them ; It can be driven directly or through the synchronous belt 、 chain 、 gear train 、 Harmonic gear and other mechanical transmission mechanisms for indirect drive .

1、 Electric drive

The energy of the electric drive is simple , The speed variation range is large , Efficient , High speed and position accuracy . But they are mostly connected with the speed reducer , Direct drive is difficult .

The electric drive device can be divided into DC (DC)、 communication (AC) Servo motor drive and stepping motor drive . The brush of DC servo motor is easy to wear , And easy to form sparks . Brushless DC motor has also been more and more widely used . Stepper motor drive is mostly open-loop control , Simple control but low power , It is mostly used in low precision and low power robot systems .

The following checks shall be made before the electric motor is powered on for operation :

1) Whether the power supply voltage is appropriate ( Overvoltage is likely to cause damage to the drive module ); For DC input +/- The polarity must not be connected wrong , Whether the motor model or current setting value on the drive controller is appropriate ( Don't be too big at first );

2) The control signal line is firmly connected , It is best to consider shielding in industrial sites ( If twisted pair is used );

3) Don't connect all the wires you need to connect at the beginning , Only connect into the most basic system , After running well , Then gradually connect ;

4) Be sure to find out the grounding method , Still use floating without receiving ;

5) The state of the motor shall be closely observed within half an hour of starting operation , If the movement is normal , Sound and temperature rise , If any problem is found, stop the machine immediately and adjust it .

2、 Hydraulic drive

Through high-precision cylinder and piston to complete , The linear motion is realized through the relative motion of the cylinder block and the piston rod .

advantage : High power , The speed reducer can be omitted and directly connected with the driven rod , Compact structure , Good stiffness , Fast response , Servo drive has high precision .

shortcoming : Additional hydraulic source is required , Prone to liquid leakage , Not suitable for high 、 Low temperature occasions , Therefore, hydraulic drive is mostly used in super high-power robot systems .

Choose the right hydraulic oil . Prevent solid impurities from mixing into the hydraulic system , Prevent air and water from invading the hydraulic system . Mechanical operation shall be gentle and smooth, and rough operation shall be avoided , Otherwise, shock load will inevitably occur , Make mechanical faults occur frequently , Greatly shorten the service life . Pay attention to cavitation and overflow noise . Pay attention to the sound of hydraulic pump and overflow valve during operation , If the hydraulic pump appears “ cavitation ” noise , It cannot be eliminated after exhaust , Find out the cause and eliminate the fault before using . Maintain proper oil temperature . The working temperature of the hydraulic system is generally controlled at 30~80℃ In between .

3、 Air pressure drives

The structure of pneumatic drive is simple , clean , Quick action , It has a buffering effect . But compared with hydraulic drive , Less power , Poor stiffness , It's noisy , Speed is not easy to control , Therefore, it is mostly used for point control robots with low precision .

(1) Fast speed 、 The system structure is simple , Easy to maintain 、 Low price characteristics . Suitable for 、 In small load robots . But because it is difficult to realize servo control , It is mostly used in robot controlled by program , As on 、 It is widely used in blanking and stamping robots .

(2) In most cases, it is used to realize two position or finite point position control 、 In small robots .

(3) At present, most control devices choose programmable controller (PLC controller ). It's flammable 、 In explosive situations, pneumatic logic elements can be used to form a control device .

Two 、 Linear transmission mechanism

The transmission device is the key part connecting the power source and the moving connecting rod , According to the joint form , The commonly used transmission mechanisms include linear transmission and rotary transmission .

The linear transmission mode can be used in the design of rectangular coordinate robot X、Y、Z To drive , Radial drive and vertical lifting drive of cylindrical coordinate structure , And the radial telescopic drive of spherical coordinate structure .

Linear motion can be achieved through rack and pinion 、 Transmission elements such as lead screw and nut convert rotary motion into linear motion , It can also be driven by linear drive motor , It can also be directly generated by the piston of the cylinder or hydraulic cylinder .

1、 Rack and pinion unit

Usually the rack is fixed . The rotational motion of the gear is converted into the linear motion of the supporting plate .

advantage : Simple structure .

shortcoming : The return difference is large .

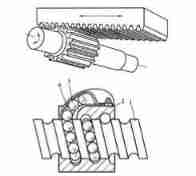

2、 Ball screw

Insert the ball into the spiral groove of the lead screw and nut , The ball can circulate continuously through the guide groove in the nut .

advantage : Little friction , High transmission efficiency , No crawling , High precision .

shortcoming : High manufacturing cost , Complicated structure .

Self locking problem : In theory, the ball screw pair can also be self-locking , However, this self-locking is not used in practical application .

The main reason is the poor reliability , Or the processing cost is very high ; Because the diameter is much larger than the lead , Generally, a set of self-locking device such as worm gear and worm is added .

3、 ... and 、 Rotary transmission mechanism

The purpose of adopting the rotary transmission mechanism is to convert the higher speed output by the driving source of the motor into a lower speed , And obtain a larger torque . The most widely used rotary transmission mechanism in robot is gear chain 、 Synchronous belt and harmonic gear .

1、 Gear chain

(1) Speed relationship

(2) Moment relation

2、 Synchronous belt

A synchronous belt is a belt with many teeth , It meshes with the synchronous belt pulley with the same profile teeth . It works like a soft gear .

advantage : No sliding , Good flexibility , Cheapness , High accuracy of repeated positioning .

shortcoming : It has certain elastic deformation .

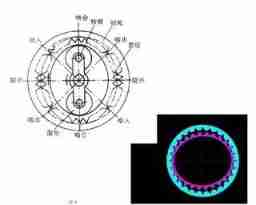

3、 Harmonic gear

Harmonic gears consist of rigid gears 、 Harmonic generator and flexible gear are three main parts , Generally, rigid gears are fixed , The harmonic generator drives the flexible gear to rotate .

The main features :

(1) High transmission ratio , Single stage is 50—300;

(2) Smooth transmission , High bearing capacity ;

(3) High transmission efficiency , Can be up to 70%—90%;

(4) High transmission accuracy , Higher than ordinary gear transmission 3—4 times ;

(5) The difference is small , Less than 3’;

(6) Cannot get intermediate output , The flexspline has low stiffness .

Harmonic drive has been widely used in countries with advanced robot technology . In Japan alone , Design of robot driving device 60% All adopt harmonic drive .

Robots sent to the moon by the United States , Each joint part of the utility model adopts a harmonic drive device , One of the upper arms is used 30 A harmonic drive mechanism .

The mobile robot sent to the moon by the former Soviet Union “ Lunar lander ”, They are installed in pairs 8 All wheels are driven separately by closed harmonic drive mechanism . Developed by Volkswagen AG ROHREN、GEROT R30 And the robot developed by Renault of France VERTICAL 80 All robots adopt harmonic transmission mechanism .

Four 、 Robot sensing system

1、 The sensing system is composed of internal sensor module and external sensor module , To obtain meaningful information in the internal and external environmental state .

2、 The use of intelligent sensors improves the mobility of the robot 、 The level of adaptability and intelligence .

3、 For some special information , Sensors are more effective than human sensory systems .

5、 ... and 、 Robot position detection

Rotary optical encoder is the most commonly used position feedback device . Photodetectors convert light pulses into binary waveforms . The rotation angle of the shaft is obtained by calculating the number of pulses , The direction of rotation is determined by the relative phases of the two square wave signals .

The inductosyn outputs two analog signals —— Sine signal and cosine signal of shaft rotation angle . The rotation angle of the shaft is calculated from the relative amplitude of the two signals . Inductosyn is generally more reliable than encoder , But its resolution is low .

Potentiometer is the most direct form of position detection . It's connected in a bridge , It can generate a voltage signal proportional to the shaft angle . however , Due to low resolution 、 Poor linearity and sensitivity to noise .

The tachometer can output an analog signal proportional to the speed of the shaft . If there is no such speed sensor , The speed feedback signal can be obtained by the difference between the detected position and time .

6、 ... and 、 Machine manpower detection

The force sensor is usually installed in the following three positions of the operating arm :

1、 Mounted on the joint drive . Measurable drive / The output of the torque or force of the reducer itself . However, the contact force between the end effector and the environment cannot be well detected .

2、 It is installed between the end effector and the end joint of the operating arm , It can be called wrist force sensor . Usually , Three to six forces applied to the end effector can be measured / Moment component .

3、 Installed on the end effector “ Fingertips ” On . Usually , These forceful fingers have built-in strain gauges , You can measure one to four components acting on your fingertips .

7、 ... and 、 robot - Environmental interaction system

1、 robot - Environmental interaction system is a system that realizes the interaction and coordination between industrial robots and equipment in the external environment .

2、 Industrial robots are integrated with external equipment into a functional unit , Such as processing and manufacturing unit 、 Welding unit 、 Assembly unit, etc ; It can also be multiple robots 、 Multiple machine tools or equipment 、 Integration of multiple parts storage devices, etc .

3、 It can also be multiple robots 、 Multiple machine tools or equipment 、 Multiple parts storage devices are integrated into a functional unit to perform complex tasks .

8、 ... and 、 Human computer interaction system

Human computer interaction system is a device that enables operators to participate in robot control and contact with robots . The system can be divided into two categories : Instruction setting device and information display device

download 1:OpenCV-Contrib Chinese version of extension module

stay 「 Xiaobai studies vision 」 Official account back office reply : Extension module Chinese course , You can download the first copy of the whole network OpenCV Extension module tutorial Chinese version , cover Expansion module installation 、SFM Algorithm 、 Stereo vision 、 Target tracking 、 Biological vision 、 Super resolution processing And more than 20 chapters .

download 2:Python Visual combat project 52 speak

stay 「 Xiaobai studies vision 」 Official account back office reply :Python Visual combat project , You can download the Image segmentation 、 Mask detection 、 Lane line detection 、 Vehicle count 、 Add Eyeliner 、 License plate recognition 、 Character recognition 、 Emotional tests 、 Text content extraction 、 face recognition etc. 31 A visual combat project , Help fast school computer vision .

download 3:OpenCV Actual project 20 speak

stay 「 Xiaobai studies vision 」 Official account back office reply :OpenCV Actual project 20 speak , You can download the 20 Based on OpenCV Realization 20 individual Actual project , Realization OpenCV Learn advanced .

Communication group

Welcome to join the official account reader group to communicate with your colleagues , There are SLAM、 3 d visual 、 sensor 、 Autopilot 、 Computational photography 、 testing 、 Division 、 distinguish 、 Medical imaging 、GAN、 Wechat groups such as algorithm competition ( It will be subdivided gradually in the future ), Please scan the following micro signal clustering , remarks :” nickname + School / company + Research direction “, for example :” Zhang San + Shanghai Jiaotong University + Vision SLAM“. Please note... According to the format , Otherwise, it will not pass . After successful addition, they will be invited to relevant wechat groups according to the research direction . Do not Send ads within the group , Or you'll be invited out , Thanks for your understanding ~

边栏推荐

- kubernetes集群搭建Zabbix监控平台

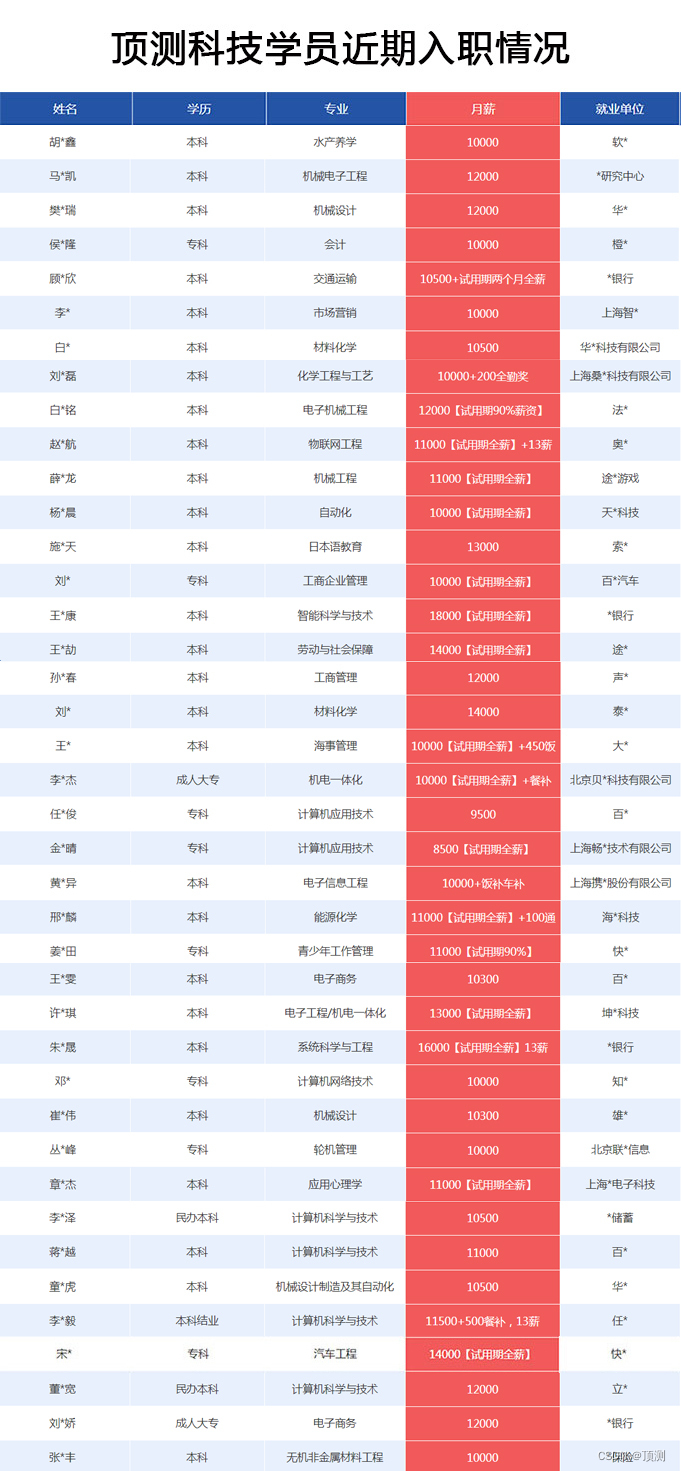

- 顶测分享:想转行,这些问题一定要考虑清楚!

- 3. Business and load balancing of high architecture

- 巴比特 | 元宇宙每日必读:中国互联网企业涌入元宇宙的群像:“只有各种求生欲,没有前瞻创新的雄心”...

- Cookie Technology & session Technology & ServletContext object

- 数据仓库建设思维导图

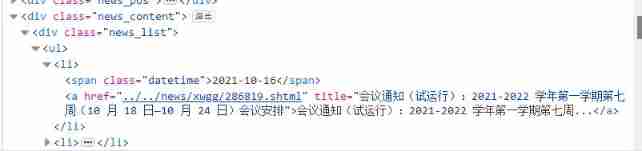

- Crawling exercise: Notice of crawling Henan Agricultural University

- 作者已死?AI正用艺术征服人类

- 18.多级页表与快表

- Project GFS data download

猜你喜欢

Blue Bridge Cup zero Foundation National Championship - day 20

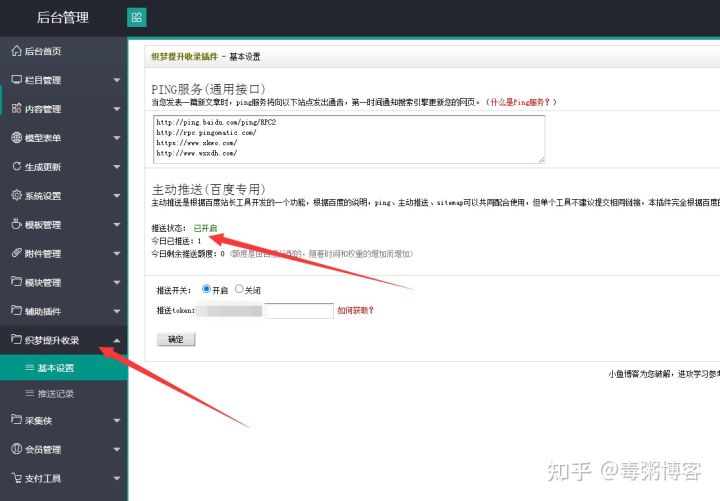

The first Baidu push plug-in of dream weaving fully automatic collection Optimization SEO collection module

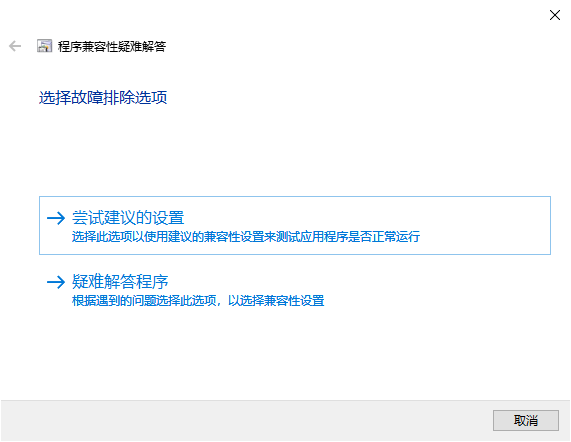

Win10 64 bit Mitsubishi PLC software appears oleaut32 DLL access denied

巴比特 | 元宇宙每日必读:中国互联网企业涌入元宇宙的群像:“只有各种求生欲,没有前瞻创新的雄心”...

L'auteur est mort? Ai utilise l'art pour conquérir l'humanité

C - Inheritance - polymorphism - virtual function member (lower)

Supporting title of the book from 0 to 1: ctfer's growth road (Zhou Geng)

Top test sharing: if you want to change careers, you must consider these issues clearly!

Cookie Technology & session Technology & ServletContext object

Crawling exercise: Notice of crawling Henan Agricultural University

随机推荐

Leetcode35. search the insertion position (simple, find the insertion position, different writing methods)

Practical guidance for interface automation testing (Part I): what preparations should be made for interface automation

Uni app third party package configuration network request

配置树莓派接入网络

【服务器数据恢复】IBM服务器raid5两块硬盘离线数据恢复案例

How to configure GUI guide development environment

Path analysis model

#systemverilog# 可綜合模型的結構總結

What does UDP attack mean? UDP attack prevention measures

漏了监控:Zabbix对Eureka instance状态监控

简单描述 MySQL 中,索引,主键,唯一索引,联合索引 的区别,对数据库的性能有什么影响(从读写两方面)

[daily question] 729 My schedule I

Cookie Technology & session Technology & ServletContext object

ROS学习_基础

chrome查看页面fps

Configure raspberry pie access network

A brief introduction of reverseme in misc in the world of attack and defense

You deserve this high-value open-source third-party Netease cloud music player

PCL实现选框裁剪点云

从autojs到冰狐智能辅助的心里历程