当前位置:网站首页>How to realize batch control? MES system gives you the answer

How to realize batch control? MES system gives you the answer

2022-07-08 01:43:00 【Huidu technology intelligent manufacturing】

In the process of enterprise production ,MES How does the system realize batch control ? It also needs to be discussed from the following aspects .

First , The objects of batch control mainly include raw materials 、 Supplementary material 、 Semi finished products and finished products , Involving procurement 、 machining 、 The whole process of assembly and other product production logistics . The quality characteristics of a batch of unit products are generally the same .

In the procurement phase , Usually, each supply of the supplier constitutes a batch ; In the process , A batch of semi-finished products 、 The production conditions of finished products shall be as same as possible , That is, the original 、 The batch of auxiliary materials is the same , There is little change in production staff , The production date is about the same, and the products produced under the production conditions consist of batches , Each production receipt can constitute a batch . Management comes from requirements , Batch management is no exception .

One 、 In manufacturing enterprises , Batch management mainly serves the following requirements :

1、 The need of enterprise cost accounting , For some price sensitive item numbers , When warehousing, different batches are distinguished according to different purchase prices .

2、 Industry or national mandatory regulations , For personal safety 、 Healthy products or dangerous goods must be subject to batch management . Such as medicine 、 food .

3、 For important materials that affect product quality 、 parts , Quality traceability is required in case of quality problems of production products , Find out the cause quickly and accurately , Limit the quantity of repair and scrap and the impact of user use to a minimum , It may also involve the recall of defective products , Batch management is a necessary condition for traceability .

4、 Item No. with shelf life requirements , Overdue needs to be handled . Such as rubber 、 Oils 、 food 、 Medicine, etc , All need batch management .

Two 、 Batch management runs through the whole process of manufacturing :

Enterprise procurement 、 Storage 、 production 、 There may be batch management requirements in the sales business , Batch management runs through the whole process of product manufacturing . In the purchase business , We pay attention to the batch number of incoming materials given within the supplier , So that quality problems can be traced back to the supplier .

In manufacturing , We pay attention to which supplier's materials are used in each batch of products , When will it be put into production 、 Which workshop processes , Quality inspection data at that time, etc . In sales , We pay attention to which customers each batch of products are sold to , When did you ship it . In the warehouse , It shall be isolated according to the item number and batch 、 identification 、 Record 、 Find inventory data .

3、 ... and 、 that , What are the major factors to realize batch control :

1、 Characteristics of Lot No

The batch number is a unique code that contains very little information , It is not our purpose to record the batch number , We need to determine the specific attribute information of the batch number according to the batch number , For example, who is the purchasing supplier , Date of supply , Inspection records , Internal production unit of the enterprise , Production personnel , Production date and other information . and MES The manufacturing execution system itself has detailed batch characteristic information .

MES In manufacturing execution system, different types of transaction records are used to express various businesses , Transaction records become the carrier of enterprise business information , Contains the most detailed feature information , For example, the purchase record contains suppliers 、 Date of supply 、 Supplier's product batch number 、 Quality certificates, etc , The production record contains the lot number of the material used 、 Date of manufacture 、 Production team 、 Production personnel 、 Process inspection data, etc .

2、 Batch traceability analysis

According to batch file , Perform batch traceability analysis , Including top-down and bottom-up approaches , It is also called batch forward query and reverse query . When quality problems are found in products sold to customers , The batch number of the product delivered to the customer is found in the sales record , The production record of this batch of products can be found in the batch file by the batch number of this product , Then, the production records can find out which batches of materials are used in the batch file , Check the purchase record from the material batch number , Suppliers can be found from the purchase records . When a batch of materials has quality problems , It can also be found from the batch file that this batch of materials are used in those products , To which customers .

3、 Determination and distribution of lot numbers

Material purchase warehousing or product production warehousing is the time when the batch number is generated , It is necessary to determine a batch number to assign to this batch item number , Lot numbers can be generated automatically or entered manually , The batch number can be a unique code without meaning , You can also include simple date information , However, the characteristic information of the batch number should not be set through complex coding rules , For example, when purchasing stock in , The lot number should not contain vendor information , Inspection information, etc . During production warehousing , The batch number should not include the production team , Processing personnel , Process quality information, etc .

4、 Establishment of batch file

The batch number is generated by a stock in , Store in warehouse , The process of warehouse out . For batch traceability , You need to create a batch file data , Reflect the source and destination of the batch , It is also convenient for later retrospective analysis . Purchase receipt or production receipt generates a new batch number , The corresponding relationship between the newly generated batch number and the source business should be recorded in the batch file ; When the production picking materials are issued or delivered to the customer for sales , In the batch file, the corresponding relationship between the used batch number and the destination business should be recorded . The batch file record shall be able to follow MES The establishment of transaction data is automatically generated .

5、 Determination of delivery batch

When the item No. managed by batch is issued, there is a problem to determine the batch , The system shall support the retrieval of qualified batch numbers according to the given conditions , You can set some usage policies , For example, it shall be determined according to FIFO or supplier , Set some batch number search rules . The delivery batch number can be determined according to the rules during delivery , And manual input shall be allowed .

边栏推荐

- Leetcode exercise - Sword finger offer 36 Binary search tree and bidirectional linked list

- NPM internal split module

- The beauty of Mathematics -- the principle of fine Fourier transform

- npm 内部拆分模块

- Codeforces Round #649 (Div. 2)——A. XXXXX

- 2022 low voltage electrician examination content and low voltage electrician simulation examination question bank

- 项目经理有必要考NPDP吗?我告诉你答案

- 如何制作企业招聘二维码?

- 滑环使用如何固定

- 能力贡献 GBASE三大解决方案入选“金融信创生态实验室-金融信创解决方案(第一批)”

猜你喜欢

用户之声 | 冬去春来,静待花开 ——浅谈GBase 8a学习感悟

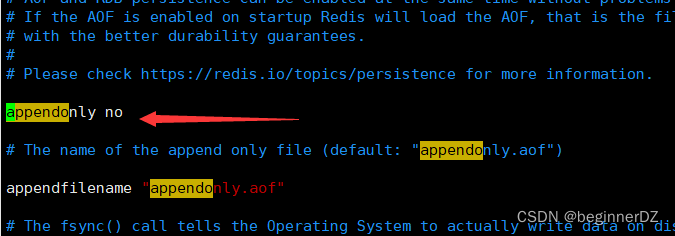

The persistence mode of redis - RDB and AOF persistence mechanisms

Qt - - Packaging Programs - - Don't install Qt - can run directly

滑环在直驱电机转子的应用领域

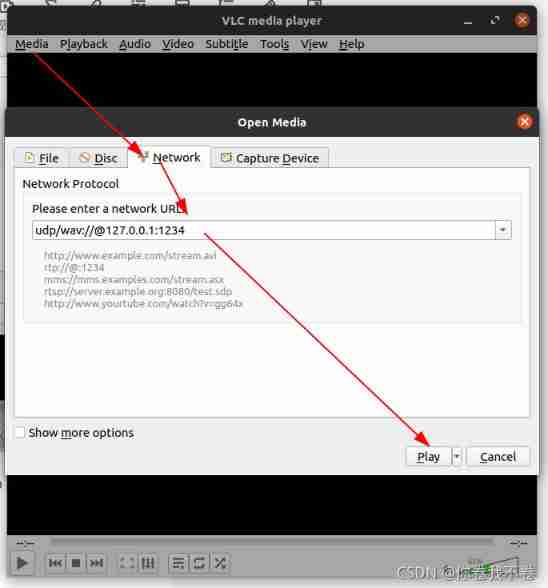

Gnuradio transmits video and displays it in real time using VLC

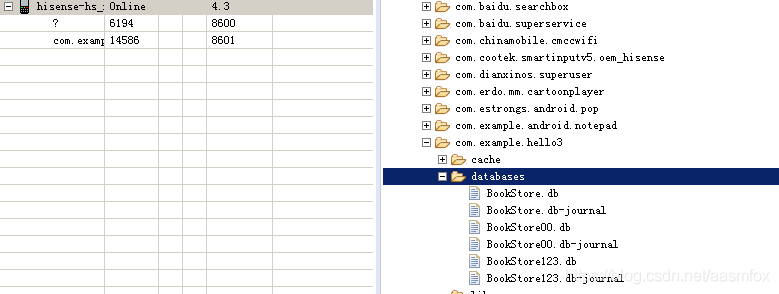

Android 创建的sqlite3数据存放位置

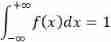

The difference between distribution function and probability density function of random variables

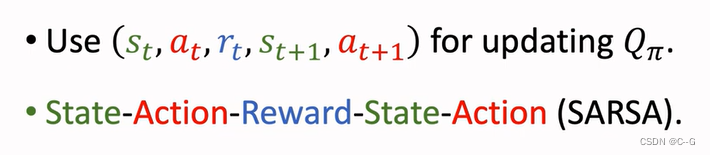

2、TD+Learning

2021 welder (primary) examination skills and welder (primary) operation examination question bank

qt--将程序打包--不要安装qt-可以直接运行

随机推荐

小金额炒股,在手机上开户安全吗?

Js中forEach map无法跳出循环问题以及forEach会不会修改原数组

能力贡献 GBASE三大解决方案入选“金融信创生态实验室-金融信创解决方案(第一批)”

COMSOL----微阻梁模型的搭建---最终的温度分布和变形情况----几何模型的建立

Common operations of numpy on two-dimensional array

Qt - - Packaging Programs - - Don't install Qt - can run directly

php 获取音频时长等信息

Is it safe to open an account on your mobile phone for small amount of stock speculation?

Android 创建的sqlite3数据存放位置

QT build with built-in application framework -- Hello World -- use min GW 32bit

regular expression

Kafka connect synchronizes Kafka data to MySQL

Break algorithm --- map

Leetcode exercise - Sword finger offer 36 Binary search tree and bidirectional linked list

2022 safety officer-a certificate free examination questions and safety officer-a certificate mock examination

About snake equation (5)

Guojingxin center "APEC investment +": some things about the Internet sector today | observation on stabilizing strategic industrial funds

腾讯游戏客户端开发面试 (Unity + Cocos) 双重轰炸 社招6轮面试

Getting started STM32 -- how to learn stm32

NPDP在国内有认可度吗?看一看就明白了!