当前位置:网站首页>MES system is different from traditional management in industry application

MES system is different from traditional management in industry application

2020-11-09 14:34:00 【Hongyun Zhizao】

MES Three key factors should be paid attention to in system selection

For the manufacturing industry , Although there is no easy way , But it's still amazing , How to maintain the entanglement of enterprises . Too much time and energy is focused on functionality and character – More time should be spent to master the industry knowledge of every potential distributor , Strategic partner ecosystem and with your own IT System architecture and staffing correspond one by one . Only so , In order to implement reasonable and effective MES Systems software Pick the link .

The cost of poor analysis is likely to last for years . I've seen such a situation , Just for a new MES It took almost five years to select the product . in addition , Production and old , The elimination and poor integration of system software to fight . In other cases , Even if For many relevant departments of the enterprise , It's all the wrong solutions , But people who have the best solution push it across the enterprise .

Here you are 3 There are two important factors to consider , To help circumvent MES The result of the puzzle caused by the analysis link .

factors 1: Try to specify each existing functional provision

When setting up the analysis phase , Focusing too much on existing links and functionality may be MES Serious shortcomings of the analysis link . ad locum , Manufacturers don't know how to improve business processes as part of a new solution , For example, depending on current paper system software or obsolete technology applications . If they don't take advantage of advances in innovative technology , So these are probably not current best practices . What's happening is that these companies are just making sub optimal steps intelligent . When you intelligentize bad steps , You just “ cannot do well , Make it bigger , faster ”.

factors 2: Too much concern about the ultimate state of Utopia

in addition , Some companies try to imagine a better way to do things , And design a concept for the future , It can be impossible or difficult to achieve . then , Many people seek to implement this vision MES resolvent . Functional steps that have not been tested are required to produce the desired results . ad locum , The key to the challenge is , Focus only on the desired state , Manufacturers are likely to struggle with the transition from the current state without complete elimination and replacement .

factors 3: Fall into the trap of finding “ perfect ” The trap of the solution

Once the appropriate list of functional provisions has been established , The list of dealers meeting these conditions will be listed . The next step will be functional baking . Companies are likely to spend months piloting conference rooms or in-depth product analysis , It turns out that there is no one solution that can go all the way further . At this point , Internal politics can be involved in lobbying, management and decision-making of various schools , To find solutions that meet their specific needs , Even if This can lead to not being the best solution in general . It took a lot of time and resources , Lead to management decision delay and economic cost – All of this happened , Instead of solving the original problem of the startup step !

版权声明

本文为[Hongyun Zhizao]所创,转载请带上原文链接,感谢

边栏推荐

- c语言小白学习历程第六篇

- Rainbow sorting | Dutch flag problem

- Go语言初始化单例变量的几种方法

- IDEA解决yml配置文件中文输出乱码问题

- JS design pattern

- AutoCAD 2020 installation package & Installation Tutorial

- Several methods of initializing singleton variable in go language

- What is website [new four modernizations]?

- Clock service Android implementation of alarm clock

- H5 official account listens to events in the closed browser (left fork).

猜你喜欢

彩虹排序 | 荷兰旗问题

The way of a million year salary Architect: on the architecture design of application system

The technology masters who ride the wind and waves gather again | Tencent cloud TVP continues to sail

What kind of experience does a doctor have when he turns his secret love brother into a husband?

C language -- game of Sanzi

Chinese programmer vs Japanese programmer, full screen shame!

CAD2016下载AutoCAD2016下载安装详细教程CAD下载

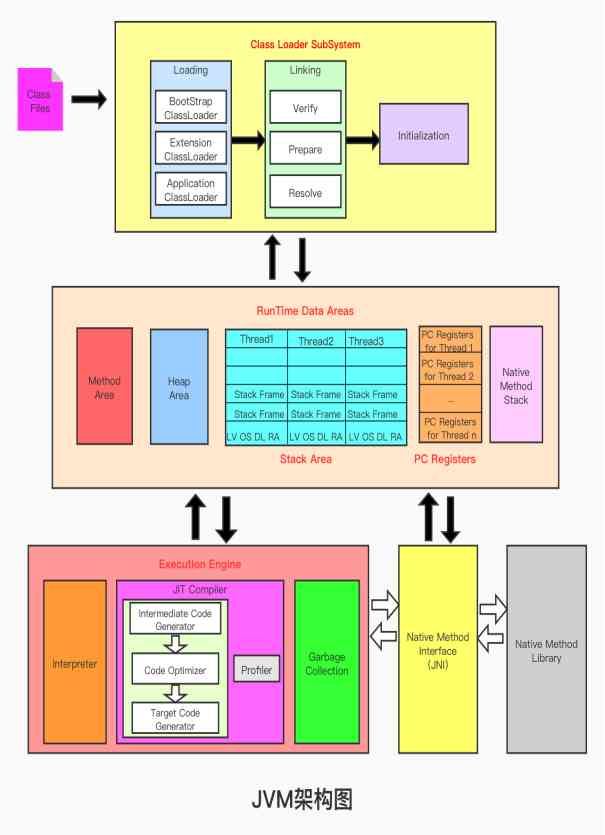

JVM learning (5) - execution subsystem

Get this template, double your salary

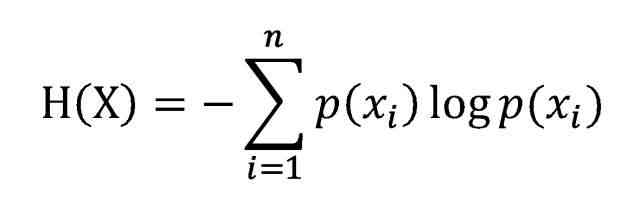

决策树算法-理论篇

随机推荐

IDEA rest-client,会了它我还没打开过postman

Android字节跳动一面,被面试官吊打!幸得美团内推,三面拿到offer

使用art-Template模板获取天气预报信息

腾讯云服务器搭建wordpress网站的两种方式(详细图文新手版)

Do programmers pay too much to work overtime? Should programmer's salary be reduced? Netizen: let go of other hard pressed programmers

CSP-J/S 2020考前注意事项

EMQ X 在中国建设银行物联网平台中的应用EMQ X 在中国建设银行物联网平台中的应用

shell脚本快速入门----shell基本语法总结

高德全链路压测——语料智能化演进之路

面试了一位33岁Android程序员,只会面向百度编程,居然要25k,被我一顿怼

The technology masters who ride the wind and waves gather again | Tencent cloud TVP continues to sail

Hadoop学习(三)-YARN

MES系统在行业应用里区别于传统式管理

决策树算法-理论篇

Several methods of initializing singleton variable in go language

7-10倍写入性能提升:剖析WiredTiger数据页无锁及压缩黑科技

为什么我强烈建议要定制开发小程序,这些好处你需要了解

大厂面试系列(二):并发编程

基于Chef InSpec的基础设施测试

嘉宾专访|2020 PostgreSQL亚洲大会阿里云数据库专场:王健