当前位置:网站首页>Advantages and Disadvantages of Blind and Buried Via PCB Stacked Via Design

Advantages and Disadvantages of Blind and Buried Via PCB Stacked Via Design

2022-08-03 20:10:00 【edadoc2013】

Author: Wang Huidong, member of Mr. Yibo Technology High Speed

Maomao said that his recent life is like a weather forecast, sunny, cloudy, rainy, and if it rains, it will rain. It is still a violent storm, with thunder and lightning.

This is not just the design of a second-order HDI, and it was put into the board factory for two weeks, and it will be delivered soon. The factory suddenly called and said that there was an open circuit between the blind and buried holes on the board.I'm confused, what's the problem? No, I'm going to call Ruyan from Company E and talk to her about this PCB.

Ruyan received the call and saw Maomao's design. There are blind holes and buried holes stacked on the board. Haha, Maomao, let's talk about it today, this is the cornerstone of PCB wiring.Magical technology - stacked via design of blind and buried vias.

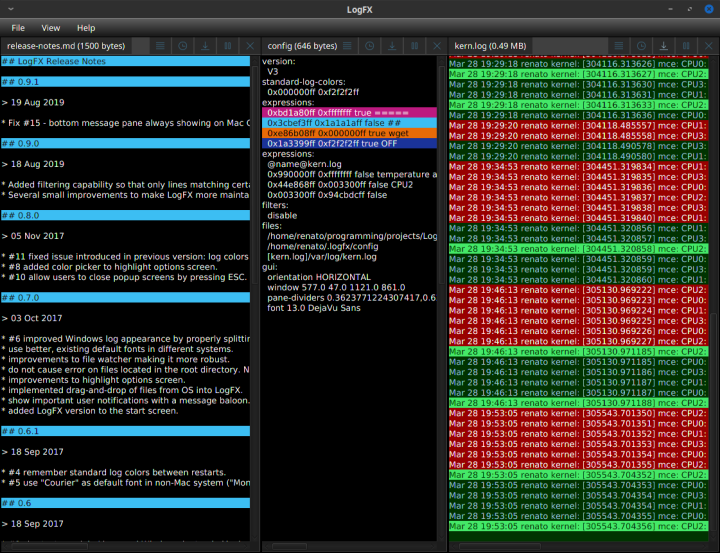

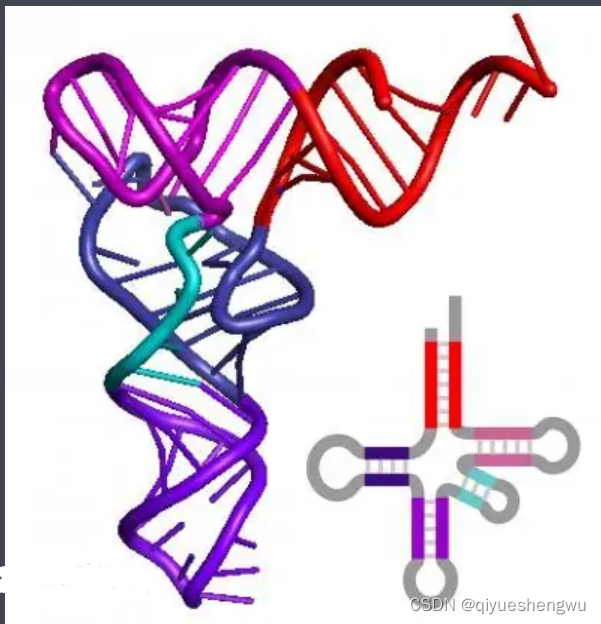

From the picture above, can you see how many levels of HDI the PCB is?

With the development of the electronic industry, electronic products are developing towards high density and high precision, and there are relatively strict requirements for the wiring space of circuit boards.The most effective way to increase the density of PCB wiring is to reduce the number of through holes. The design of blind and buried vias is no longer out of reach, but is integrated into the PCB design bit by bit and becomes within reach.

Usually, there are two types of blind holes of second order or above. One is wrong holes. As the name suggests, wrong holes are two blind holes that are staggered.

Another design is the stacking design of blind vias, that is, two blind vias are overlapped.As shown below:

Can you tell which is the wrong hole and which is the stacked hole design?

So what are the advantages of the stacked hole design?

Blind and buried vias can provide more space and options to the PCB.The buried via design will help free up space on the board without affecting surface devices or traces on the upper and lower layers.Stacked vias of blind vias and stacked vias of blind-buried vias help free up more space.

The following is a production flow chart of a second-order HDI:

We can see from the above picture that the blind hole in the inner layer must be filled with electroplating once after the stacked hole design is made, so the flatness of the blind hole filled electroplating is more stringent.If the bottom of the blind hole is filled with uneven electroplating, after the second blind hole is drilled, there is no conduction of the copper plated layer below, and there is a floating between the layers, and an open circuit appears.

So for the blind via stack, the first blind via should be filled and electroplated, and the wrong via does not need to be done.Therefore, the process is longer, the time is longer, and the requirements for the process are also stricter.

The method of filling blind holes by electroplating is used to realize the stacking method of blind holes and blind holes. Due to its advantages of high reliability and simple process, it has become the most ideal filling method at present.Most of the manufacturing technologies of second-order or multi-level HDI boards use the methods of laser drilling blind holes and electroplating blind holes to realize the interconnection between layers. The manufacturing difficulties are blind hole processing, electroplating and blind hole filling, and alignmentAccuracy control, the blind holes are stacked and then filled and electroplated has the following advantages:

1. It saves more wiring space than wrong holes

2. It increases the reliability of heat conduction

3.Increase the current carrying capacity

4. Make the surface pad more flat and make the welding more reliable.

If the blind hole and the buried hole are stacked, a POFV process (resin plug hole electroplating and leveling) process for the inner layer is required.

Blind hole and blind hole stacking process, the flatness of the resin plug hole becomes the key point for the success or failure of the process.The key point of resin plug holes is that if the buried resin plug holes are not plated flat, everything is designed to be empty.

Ruyan said: "Maomao, there is nothing wrong with your design, but the key depends on the craftsmanship of the factory."

Maomao said I understand, next time I will go to Ruyan to make a board.

Summary:

The stacking design of blind vias and blind vias, the process increases the inner layer blind via filling and electroplating, the process increases, and the cost increases.

The stacking design of blind vias and buried vias, the process increases the POFV process of the inner layer, the process increases, and the cost increases.

The through-hole design should try not to have blind holes, and the blind holes should not be stacked as much as possible.

边栏推荐

- 力扣203-移除链表元素——链表

- Matlab paper illustration drawing template No. 42 - bubble matrix diagram (correlation coefficient matrix diagram)

- 高位套牢机构,用友网络的信任危机是如何产生的?

- Statistical machine learning 】 【 linear regression model

- 高效目标检测:动态候选较大程度提升检测精度(附论文下载)

- YARN功能介绍、交互流程及调度策略

- 一种能有效缓解环境噪声对音频质量干扰的方案

- In-depth understanding of JVM-memory structure

- Kubernetes资源编排系列之三: Kustomize篇 作者 艄公(杨京华) 雪尧(郭耀星)

- NNLM、RNNLM等语言模型 实现 下一单词预测(next-word prediction)

猜你喜欢

不要再用if-else

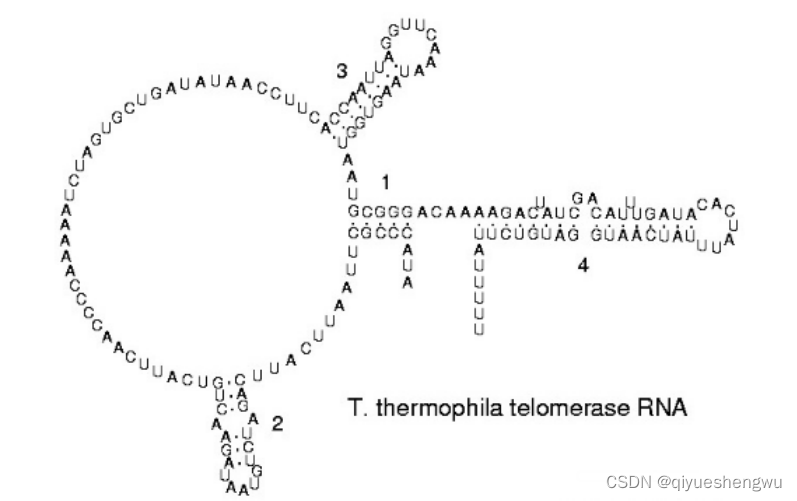

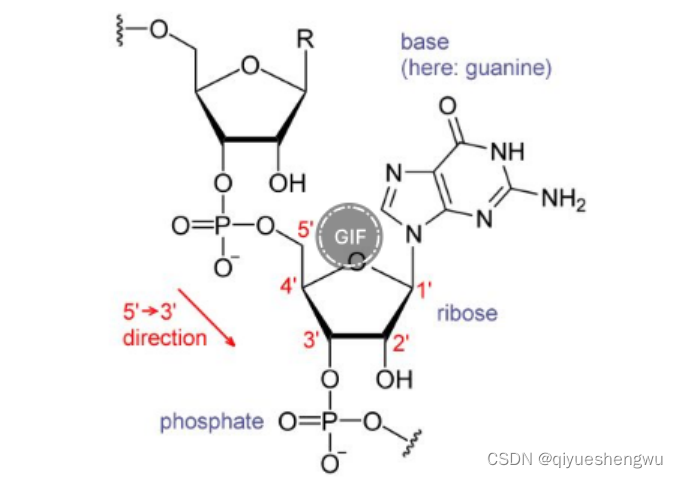

RNA核糖核酸修饰RNA-HiLyte FluorTM 405荧光染料|RNA-HiLyte FluorTM 405

化算力为战力:宁夏中卫的数字化转型启示录

开源生态研究与实践| ChinaOSC

1161 最大层内元素和——Leetcode天天刷【BFS】(2022.7.31)

转运RNA(tRNA)甲基化修饰7-甲基胞嘧啶(m7C)|tRNA-m7G

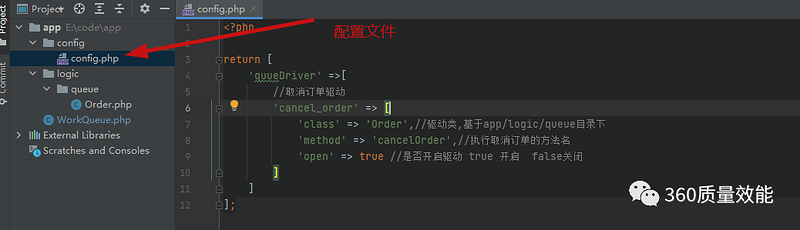

利用 rpush 和 blpop 实现 Redis 消息队列

信使mRNA甲基化偶联3-甲基胞嘧啶(m3C)|mRNA-m3C

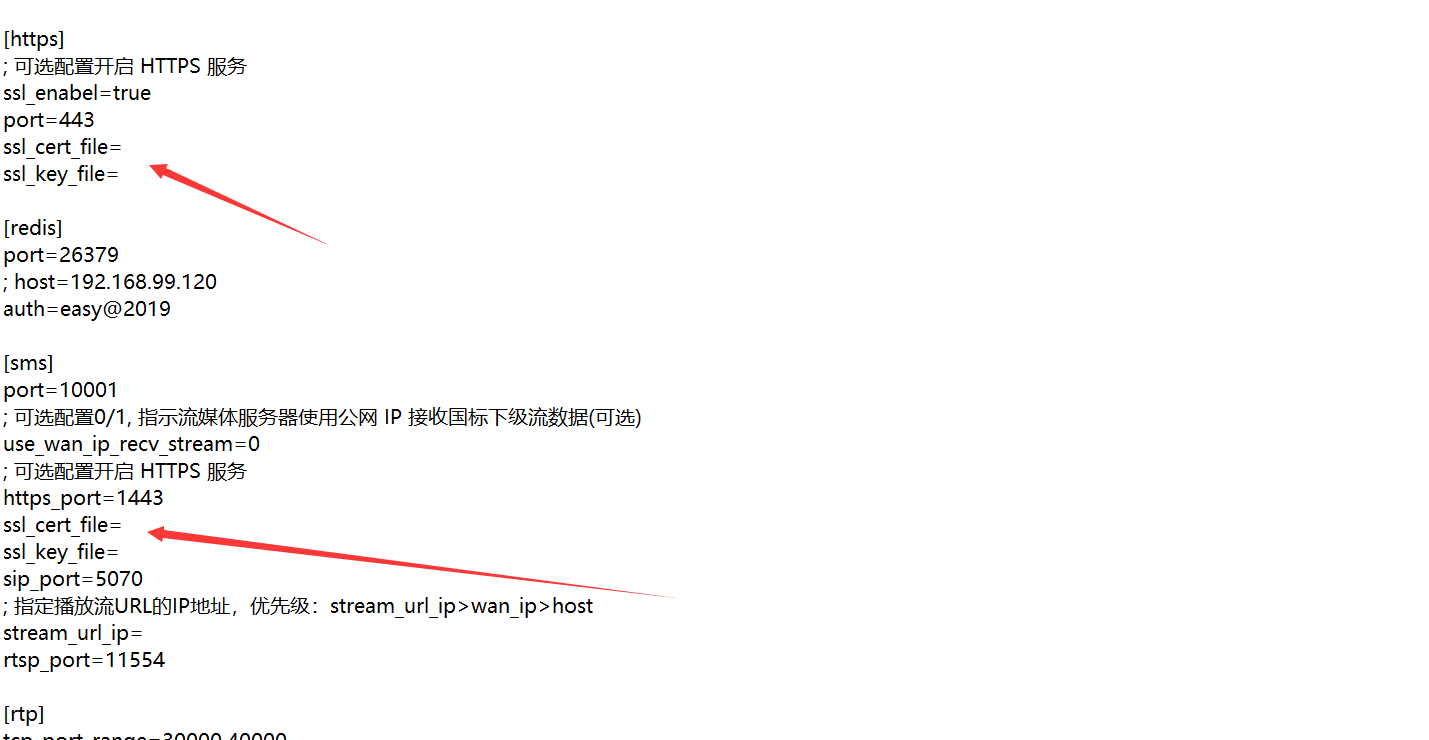

EasyCVR平台海康摄像头语音对讲功能配置的3个注意事项

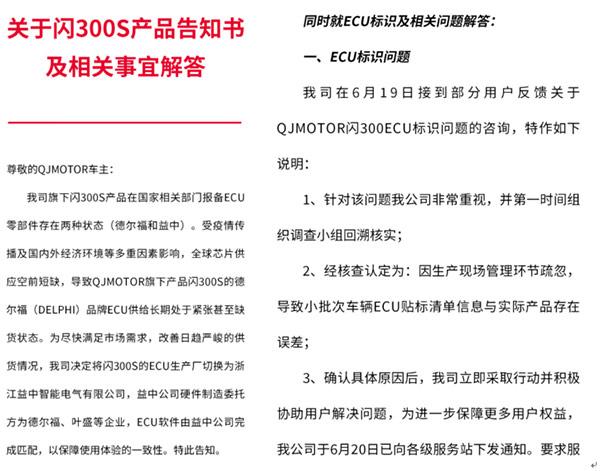

钱江摩托某型号产品ECU货不对版 消费者知情权应如何保障?

随机推荐

开源教育论坛| ChinaOSC

揭秘5名运维如何轻松管理数亿级流量系统

多模态 参考资料汇总

WPF .cs中使用资源文件中的ControlTemplate或Style并找到控件

glide set gif start stop

YARN功能介绍、交互流程及调度策略

信使mRNA甲基化偶联3-甲基胞嘧啶(m3C)|mRNA-m3C

极验深知v2分析

LeetCode 622. 设计循环队列

若依集成easyexcel实现excel表格增强

Mapper输出数据中文乱码

不要再用if-else

【leetcode】剑指 Offer II 009. 乘积小于 K 的子数组(滑动窗口、双指针)

详解AST抽象语法树

消除对特权账户的依赖使用Kaniko构建镜像

危化企业双重预防机制数字化建设进入全面实施阶段

ECCV 2022 Oral | 满分论文!视频实例分割新SOTA: IDOL

RNA核糖核酸修饰荧光染料|HiLyte Fluor 488/555/594/647/680/750标记RNA核糖核酸

使用 ReportLab 绘制 PDF

若依集成browscap读取浏览器用户代理