当前位置:网站首页>Section III: structural characteristics of cement concrete pavement

Section III: structural characteristics of cement concrete pavement

2022-06-11 05:05:00 【Skill code brother】

Cement concrete pavement The structure consists of subgrade 、 Cushion 、 The basic level as well as Surface course .

1、 Structural characteristics

One 、 Cushion

In an environment with poor temperature and humidity , Cement concrete road shall be provided with cushion , To improve the pavement performance .

(1) stay Seasonally frozen areas , The total design thickness of the road structure is less than the minimum anti freezing thickness When required , according to Subgrade dry and wet type and Characteristics of subgrade filler Set cushion , The difference is the thickness of the cushion . Soil cutting with poor hydrogeological conditions , When the moisture of subgrade soil is high , Should be set Drainage cushion . The subgrade may cause uneven settlement or Uneven deformation when , It is advisable to add Semi rigid cushion .

(2) Width of cushion It should be the same as the subgrade width , Its minimum thickness is 150mm.

(3) Sand should be used for antifreeze cushion and drainage cushion 、 Granular materials such as gravel , Low dose cement should be used for semi-rigid cushion 、 Lime and other combined stable granular materials or soil materials .

Two 、 The basic level

(1) Function of cement concrete road base : To prevent or mitigate from pumping As a result of The bottom of the board is hollow and Staggered platform And other diseases ; Together with the cushion , It can control or reduce the adverse effect of uneven frost heave or volume deformation of subgrade on concrete surface ; Provide a stable and solid foundation for the concrete surface , and Improve the load transfer capacity of joints .

(2) Selection principle of base course materials : according to Road traffic grade and Anti scouring capacity of subgrade To select the base material . Lean concrete should be selected for special traffic 、 RCC or asphalt concrete ; Cement stabilized aggregate or asphalt stabilized macadam shall be selected for heavy traffic roads ; in 、 Cement or lime fly ash stabilized aggregate or graded aggregate shall be selected for light traffic roads . Humid and rainy areas , Drainage base course shall be adopted for heavy traffic sections .

(3) The width of base course shall be different according to the construction method of concrete surface course , At least... Wider than each side of the concrete surface course 300mm( During the construction of small machines and tools ) or 500mm( During the construction of rail mode paver ) or 650mm( During the construction of sliding mode paver ).

(5) To prevent the subgrade from being affected by water seepage , The drainage base course shall be provided with Cement stabilized aggregates or Dense granular material An impermeable subbase composed of , The top surface of subbase should be paved Asphalt seal coat or waterproof geotextile .

(6) RCC base course Joints corresponding to the concrete surface course shall be set .

3、 Surface course

(1) The surface concrete is usually divided into Ordinary ( plain ) concrete 、 reinforced concrete 、 Continuously graded concrete 、 Prestressed concrete etc. . At present, China mostly adopts Ordinary ( plain ) concrete . The cement concrete surface course shall have sufficient Strength 、 Durability ( Frost resistance )、 Surface skid resistance 、 wear-resisting 、 smooth .

(2) The plate length of each rectangular plate is as follows Type of finish 、 The thickness of the And by the Stress calculation determine .

(3) Longitudinal joints are based on Pavement width and Construction paving width Set up . When the one-time paving width is less than the pavement visibility , Should be set With pull rod In the form of flat seams Longitudinal construction joints . The one-time paving width is greater than 4.5m when , Should be set With pull rod In the form of a false seam Longitudinal contraction joint , The longitudinal joint shall be parallel to the centerline of the line .

Transverse joints can be divided into Transverse contraction joint 、 Expansion joint and Transverse construction joint . The transverse construction joint shall be selected at the contraction joint or expansion joint as far as possible . Expressway 、 Dowel bar shall be added to the transverse expansion joint of the main road ; Near bridges or other fixed structures 、 Where the plate thickness changes 、 Small radius horizontal curve, etc , Expansion joints shall be provided .

(4) about Special traffic grade concrete pavement , Transverse expansion joint 、 Dowel bar shall be set for contraction joint . stay At the free edge , Expansion joint bearing heavy traffic 、 Construction joints , Less than 90° The corner of the surface layer , Under the municipal pipeline pavement , as well as Around rainwater inlets and underground inspection wells , Reinforcement shall be provided .

(5) Anti sliding structure — The concrete surface shall have a large roughness , That is, it has high anti sliding performance , To improve the safety of driving . In this way Grooving 、 Pressure groove 、 Broaching or Roughening And other methods to form a certain structural depth .

2、 Selection of main raw materials

(1) Roads with heavy traffic or above 、 Urban Expressway 、 The trunk road shall adopt 42.5 Portland cement for roads above grade 、 Ordinary portland cement ; Other roads can use the same slag cement , Its strength grade should not be lower than 32.5 level .

Cement with a factory life of more than three months or affected with moisture , must After testing , It can be used only after it is qualified .

(2) Coarse aggregate shall be hard 、 Durable 、 Clean gravel 、 Gravel 、 Crushed gravel , The technical indicators shall meet the specification requirements , Coarse aggregate should be used Artificial grading , Maximum nominal size of coarse aggregate , Crushed gravel shall not be greater than 26.5mm, The crushed stone shall not be greater than 31.5mm, Gravel should not be larger than 19.0mm.

(3) Silhouette of the appropriate place , The fineness modulus is 2.5 above , Clean coarse sand conforming to the grading requirements 、 Medium sand . Sea sand shall not be used directly on the concrete surface . Desalinated sea sand should not be used in urban expressways 、 The main road 、 Secondary road , Available for branch .

(4) Admixtures shall undergo mixing test .

(5) Reinforcement Varieties 、 specifications 、 composition , It shall comply with the design and current national standards , Having a manufacturer Brand 、 Heat number , Inspection Report and Certificate , And by Second interview ( Including witness sampling ) qualified . The reinforcement shall not be rusted 、 Crackle 、 Defects such as cuts and nicks . Dowel bar ( Pull rod )、 Sliding sleeve material 、 The specifications shall comply with the regulations .

(6) The expansion joint plate should be thick 20mm, Good water stability , have A certain flexible sheet Make , And shall be approved by Antiseptic treatment . Caulking seasoning should be used Resin 、 Rubber 、 PVC mastic 、 Modified asphalt Caulking material , And should add Anti aging agent .

边栏推荐

- JVM tuning V: JVM tuning tools and tuning practice

- AAAI2022-ShiftVIT: When Shift Operation Meets Vision Transformer

- 华为设备配置BGP/MPLS IP 虚拟专用网

- Target detection - personal understanding of RCNN series

- How to choose a suitable optical network card?

- go单元测试实例;文件读写;序列化

- Let me tell you how to choose a 10 Gigabit network card

- Linked list de duplication

- Vins fusion GPS fusion part

- Unzip Imagenet after downloading

猜你喜欢

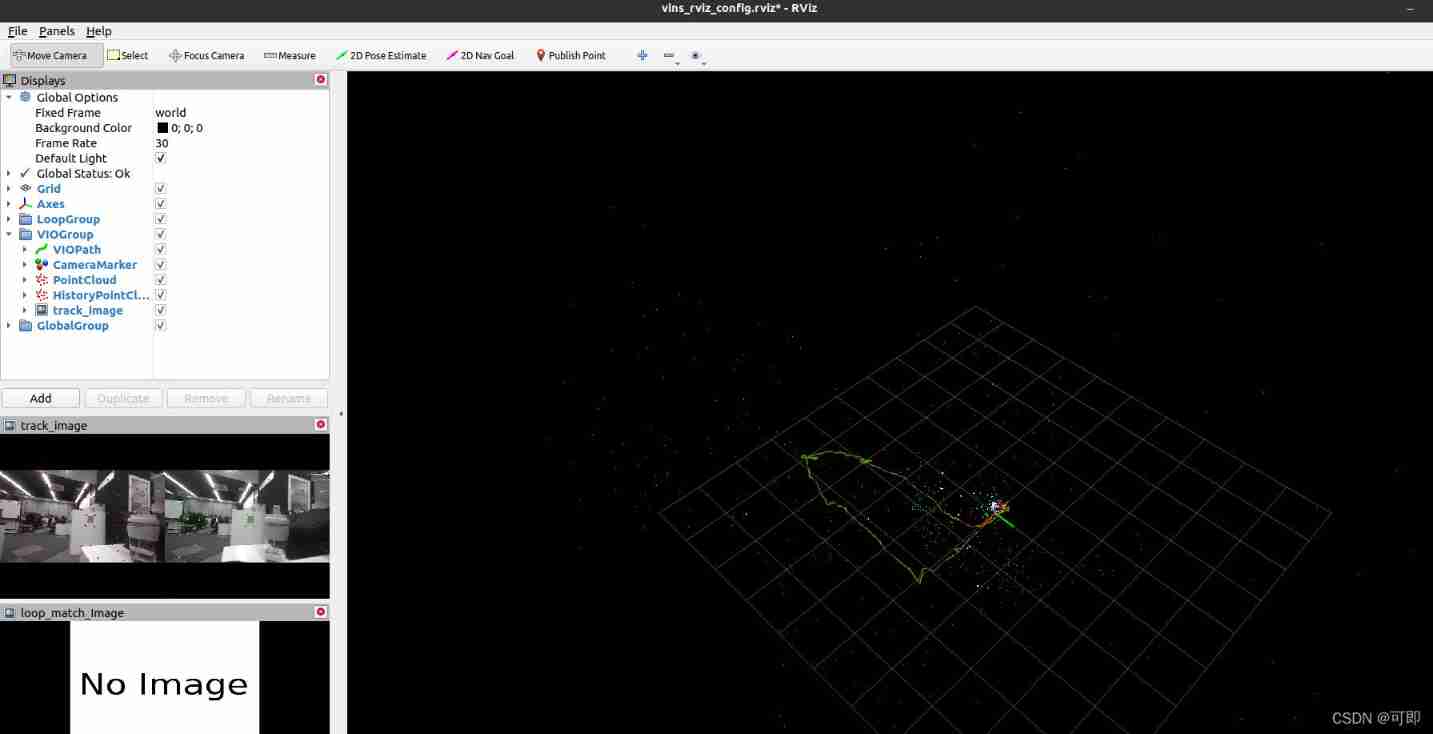

Preliminary test of running vins-fusion with zed2 binocular camera

Introduction to coordinate system in navigation system

华为设备配置BGP/MPLS IP 虚拟专用网地址空间重叠

Paper reproduction: pare

KD-Tree and LSH

Deep extension technology: intelligent OCR recognition technology based on deep learning has great potential

Differences between the four MQ

高斯白噪声(white Gaussian noise,WGN)

Emnlp2021 𞓜 a small number of data relation extraction papers of deepblueai team were hired

Zed2 camera calibration -- binocular, IMU, joint calibration

随机推荐

Detailed explanation of network security bypass network card

Possible errors during alphapose installation test

Relational database system

What is the difference between a wired network card and a wireless network card?

What is a smart network card? What is the function of the smart network card?

华为设备配置跨域虚拟专用网

Huawei equipment configures local virtual private network mutual access

How to purchase 25g optical network card

Oh my Zsh correct installation posture

Codesys get System Time

JVM tuning V: JVM tuning tools and tuning practice

Let me tell you how to choose a 10 Gigabit network card

Leetcode question brushing series - mode 2 (datastructure linked list) - 83:remove duplicates from sorted list

Course design summary

SAVING AND LOADING A GENERAL CHECKPOINT IN PYTORCH

华为设备配置BGP/MPLS IP 虚拟专用网

Cartographer learning record: cartographer Map 3D visualization configuration (self recording dataset version)

Google drive download failed, network error

Dongmingzhu said that "Gree mobile phones are no worse than apple". Where is the confidence?

Huawei device configuration bgp/mpls IP virtual private network command