当前位置:网站首页>PVL EDI project case

PVL EDI project case

2022-07-06 22:13:00 【Knowledge and practice EDI】

2021-2022 The first half of the fiscal year was seriously affected by the global shortage of electronic components , Many car manufacturers are forced to be in “ Shutdown ” period . This comes from raw materials 、 energy 、 The pressure of transportation cannot be underestimated . Under the influence of these external factors ,Plastivaloire The group ( hereinafter referred to as PVL) Although the sales volume of has declined, the business momentum is still good , Compared with the same period of the previous fiscal year , Order volume growth 16.6%.

Project background

PVL Attach great importance to the quality of cooperative relations , The requirements for its suppliers include : Network security 、 Innovation ability 、 Master new technology 、 Improve service efficiency . If the supplier wants to cooperate with PVL Further cooperation , You will definitely encounter people from PVL The question of : Do you have EDI Ability ?

EDI Electronic data interchange , Make the business data conform to the message format of international standards , Through the network , At suppliers and PVL Make long-term predictions 、 Electronic data transmission of business documents such as delivery notice and inventory report .PVL Hope the supplier can have EDI Ability , adopt EDI The transmission of business data not only improves the security of data transmission , It can also help suppliers quickly receive information from PVL The order of , So as to improve the response speed of suppliers to orders !

Project challenges

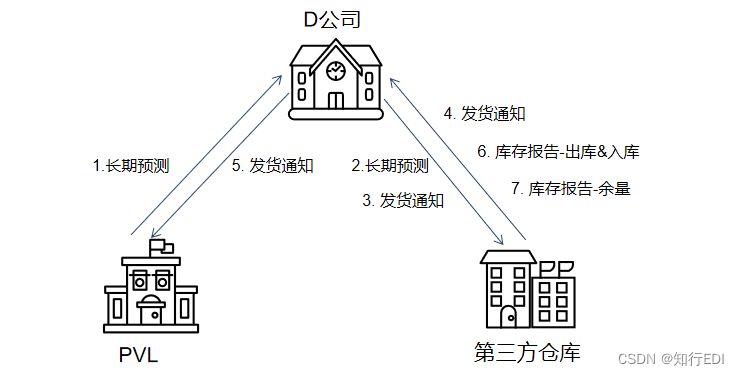

PVL Supplier D In order to meet the needs of its business development and business cooperation , Planning and PVL And its third-party warehouse 3PL Through between EDI Transfer order / Delivery and other business data . So as to realize the automatic transmission and processing of business data between enterprises , Reduce the error rate of manual operation , Improve work efficiency .

The difference between this project and previous projects is D In addition to PVL establish EDI Outside the connection , Also need to work with third-party warehouses 3PL establish EDI Transmission channel , Synchronous shipment 、 Inventory and other information . In the design EDI When it comes to solutions , Need to be clear D company 、PVL、 And third-party warehouses 3PL Data flow and goods flow , Ensure that the data can be transmitted accurately .

Project requirements

Transfer protocol :OFTP2

Message standard :EDIFACT

Business message :

docking PVL

| Business message code | Business implications | Transmission direction |

|---|---|---|

| Long term forecast | DELFOR(Firm & Forecast) | receive |

| Delivery notice | DESADV | send out |

Connect with the third-party warehouse

| Business message code | Business implications | Transmission direction |

|---|---|---|

| DELFOR(Firm & Forecast) | Long term forecast | send out |

| DESADV | Delivery notice | send out |

| DESADV | Delivery notice | receive |

| INVRPT(MVT-IN&OUT) | Inventory report - Out of stock & Put in storage | receive |

| INVRPT(BAL STOCK) | Inventory report - allowance | receive |

| Box Label | Box paste | Generate |

| Pallet Label | Tray sticker | Generate |

In order to maximize the automation of business processes ,D The company hopes to integrate its internal ERP The bridge between system and knowledge and action EDI The system is seamlessly integrated .

Solution

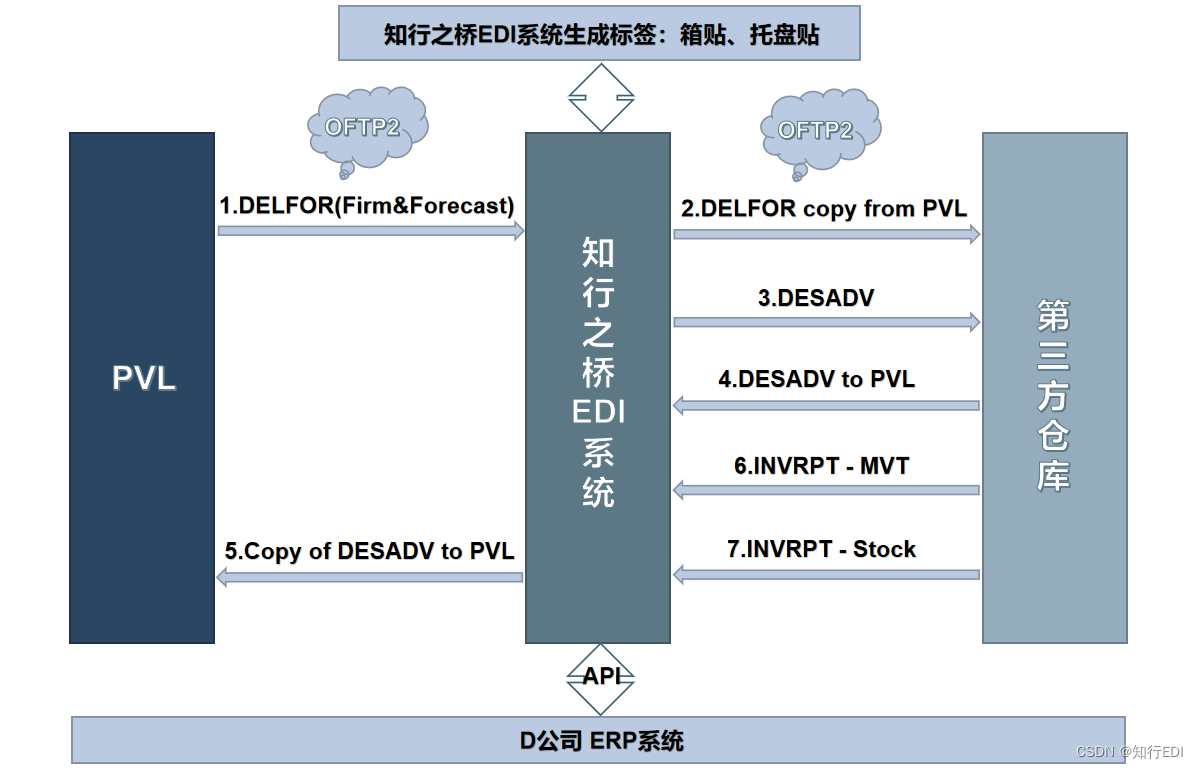

whole EDI The solution is shown in the figure below :

1.PVL adopt EDI send out DELFOR Long term material forecast to D company ,D The company uses the bridge of knowledge and action EDI System reception , Based on this, production scheduling can be carried out in advance .

2. Bridge of knowing and doing EDI The system will PVL It's from DELFOR A copy of the long-term material forecast is sent to the third-party warehouse .

3.D The company sends the goods to the third party warehouse , Send... At the same time DEASDV Delivery notice to warehouse . The delivery notice here is D Issued by the company based on the standards of the third-party warehouse .

4. The third-party warehouse is based on PVL Standard generation DESADV The delivery notice is sent to D company , Send goods synchronously .

5.D The company will receive DESADV Send a copy of the delivery notice to PVL, Let them know about the delivery .

6.INVRPT-MVT The inventory report is sent by the third party warehouse to D company , It mainly transmits stock out and stock in reports , The warehousing report here is equivalent to receipt confirmation .D The company can compare the delivery report with DESADV Combined with delivery notice .

7.INVRPT-Stock The inventory report is sent by the third party warehouse to D company , Mainly to D The company fed back the latest inventory level .

establish OFTP2 signal communication

Whether it's docking PVL Or connect with the third-party warehouse , You need to use OFTP2 Transfer protocol .D The company needs to cooperate with PVL Exchange with third-party warehouses OFTP2 Connection information , Send test files to each other to verify whether the connection is successful .

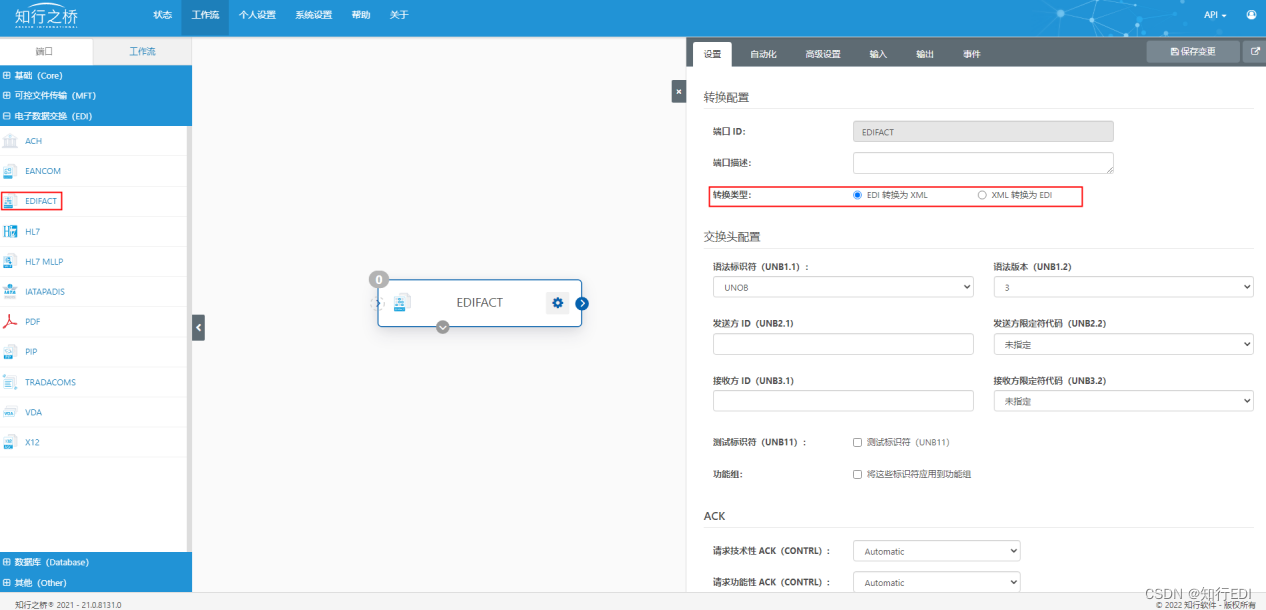

Data format conversion

Based on the bridge of knowledge and action EDI Systematic EDIFACT port , Realization EDI File with the XML Switch between , Reduce enterprise access / View the complexity of business data . Message processing needs to be divided into D company &PVL as well as D company & The third-party warehouse is completed in two parts .

1.D company &PVL

PVL Send to D company :

DELFOR: Delivery forecast (Delivery Instruction), According to the conditions specified in the purchase contract , Provide details of long-term material requirements to suppliers .

D The company sent to PVL:

DESADV: Delivery notice (ASN/Despatch Advice), According to the delivery plan or shipping schedule information received by the supplier , According to the contract or order , Deliver the goods to PVL.

DESADV Will contain different material information 、 Packaging information 、 Delivery instructions and inventory status information .

D In this part, the company needs to do format conversion in two different directions , namely : take EDIFACT DELFOR Convert to XML And will be XML Convert to EDIFACT DESADV. Here we need to pay attention to ,EDIFACT DESADV Need to meet PVL Specification requirements provided , Make sure that the sent file can be PVL Handle... Successfully .

2.D company & Third party warehouse

Third party warehouse sent to D company :

DESADV to PVL Delivery notice

INVRPT – MVT Inventory report - Out of stock & Put in storage

INVRPT – Stock Inventory report - allowance

D The company sends it to the third-party warehouse :

DELFOR copy from PVL Delivery forecast

DESADV Delivery notice

D The company also needs to do format conversion in two different directions in this part , namely : take EDIFACT DESADV、EDIFACT INVRPT – MVT as well as EDIFACT INVRPT – Stock Convert to XML. take XML Convert to EDIFACT DELFOR as well as EDIFACT DESADV. there DELFOR as well as DESADV It needs to meet the specification requirements provided by the third-party warehouse , Ensure that the sent documents can be successfully processed by the third-party warehouse .

Bridge of knowing and doing EDI The system can help D Besides the business documents sent and received by the company , You can also generate labels according to your needs , for example : Box paste 、 Tray stickers, etc .

Reference reading : How to use PDF Port generation label Label?

Business system integration

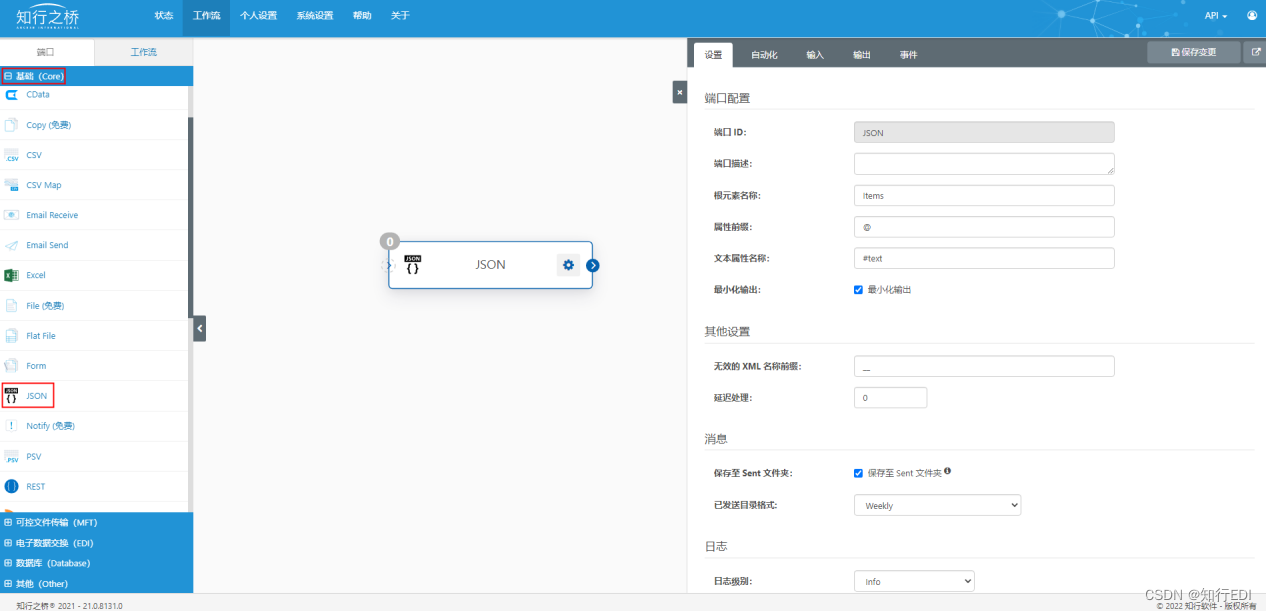

Bridge of knowing and doing EDI The system supports multiple integration modes , Common are :IDOC、REST API Or intermediate database .D Company chooses to use REST API To achieve its ERP System and EDI System integration .

Bridge of knowing and doing EDI Systems and D The company's ERP The system calls the document through the interface provided by the other party , Use REST API To call the other party's interface , With JSON perhaps XML Format to transmit business data .

Use REST API The way to integrate , It needs to be obtained in the process of format conversion XML The format file passes through the bridge of knowledge and action EDI Systematic Json The port is converted to Json Format .

EDI and ERP The integration of can be carried out according to the following example :

Through the bridge of knowledge and action EDI The system receives from the purchaser DELFOR After long-term material forecast , from EDI The system parses , And then call ERP Order receiving interface of the system , Change order data to Json or XML Format to ERP,ERP After the interface of receives the order data , Display in its order module , The business personnel complete the final order data check , complete EDI receive DELFOR Long term integration test of materials .

Bridge of knowing and doing EDI Introduction to system ports

In the process of file conversion, we mentioned two ports :EDIFACT Port and JSON port , The two ports are briefly introduced below :

EDIFACT port

EDIFACT Ports can be used to XML Document conversion to EDIFACT file , Can also be EDIFACT Document conversion to XML. We can still do that EDIFACT Configure the switching head in the port , The information that can be configured here usually includes :

Syntax identifier 、 Syntax version 、 The sender ID、 Sender qualifier 、 The receiving party ID And receiver qualifier .

JSON port

JSON Port support will XML Data to JSON, take JSON Data to XML. Ports support configurable syntax to distinguish attributes and ensure that the output is valid XML/JSON.

More about the bridge of knowledge and action EDI Please refer to The reference sample Demo

more EDI Information , see also : EDI What is it? ?

边栏推荐

- GPS from getting started to giving up (19), precise ephemeris (SP3 format)

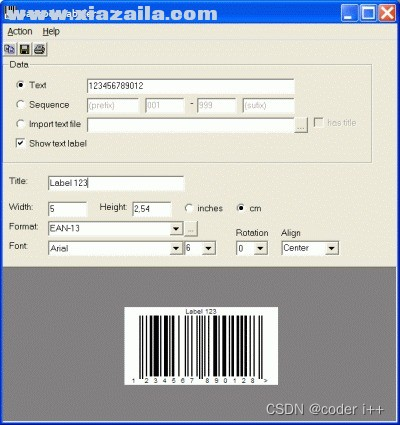

- BarcodeX(ActiveX打印控件) v5.3.0.80 免费版使用

- Assembly and interface technology experiment 5-8259 interrupt experiment

- 中国VOCs催化剂行业研究与投资战略报告(2022版)

- Codeforces Round #274 (Div. 2) –A Expression

- 经纪xx系统节点VIP案例介绍和深入分析异常

- GPS from getting started to giving up (XX), antenna offset

- Some problems about the use of char[] array assignment through scanf..

- GPS从入门到放弃(十三)、接收机自主完好性监测(RAIM)

- Maximum product of three numbers in question 628 of Li Kou

猜你喜欢

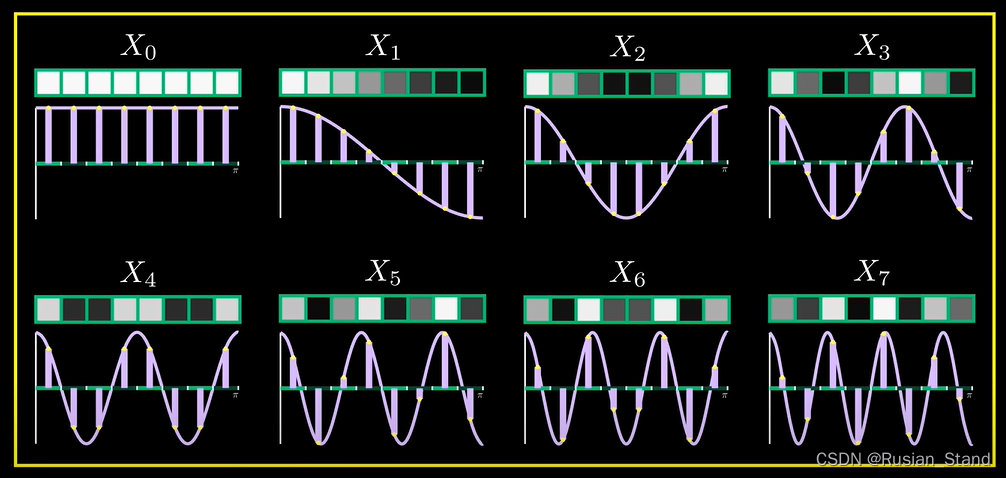

图像的spatial domain 和 frequency domain 图像压缩

BarcodeX(ActiveX打印控件) v5.3.0.80 免费版使用

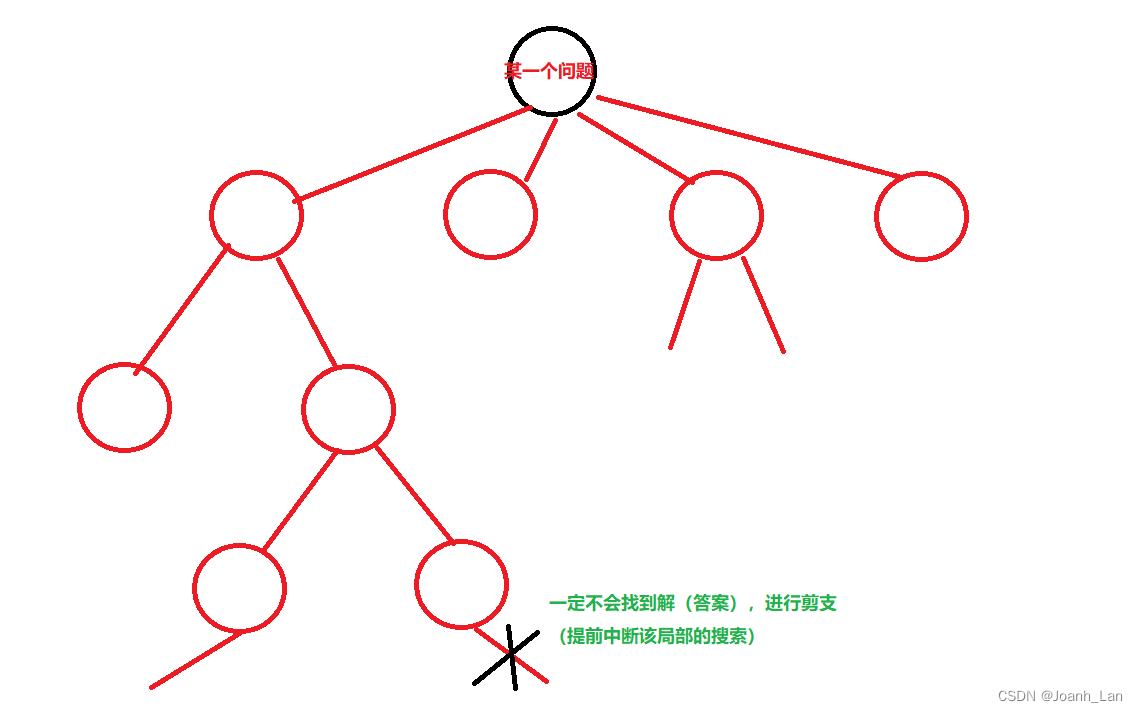

Search element topic (DFS)

Leetcode learning records (starting from the novice village, you can't kill out of the novice Village) ---1

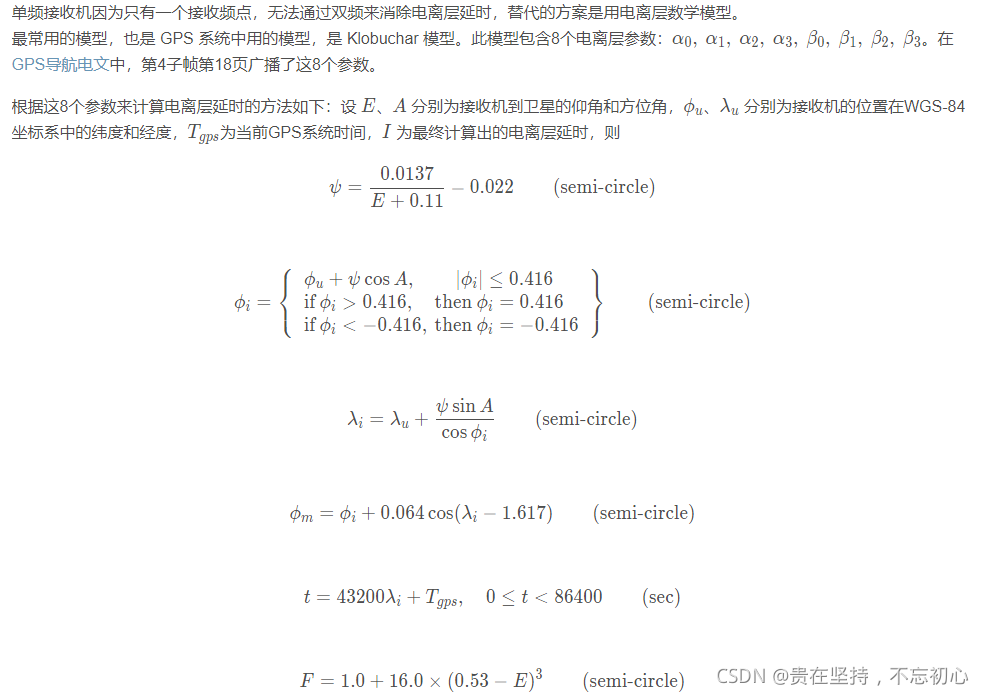

GPS from entry to abandonment (XIV), ionospheric delay

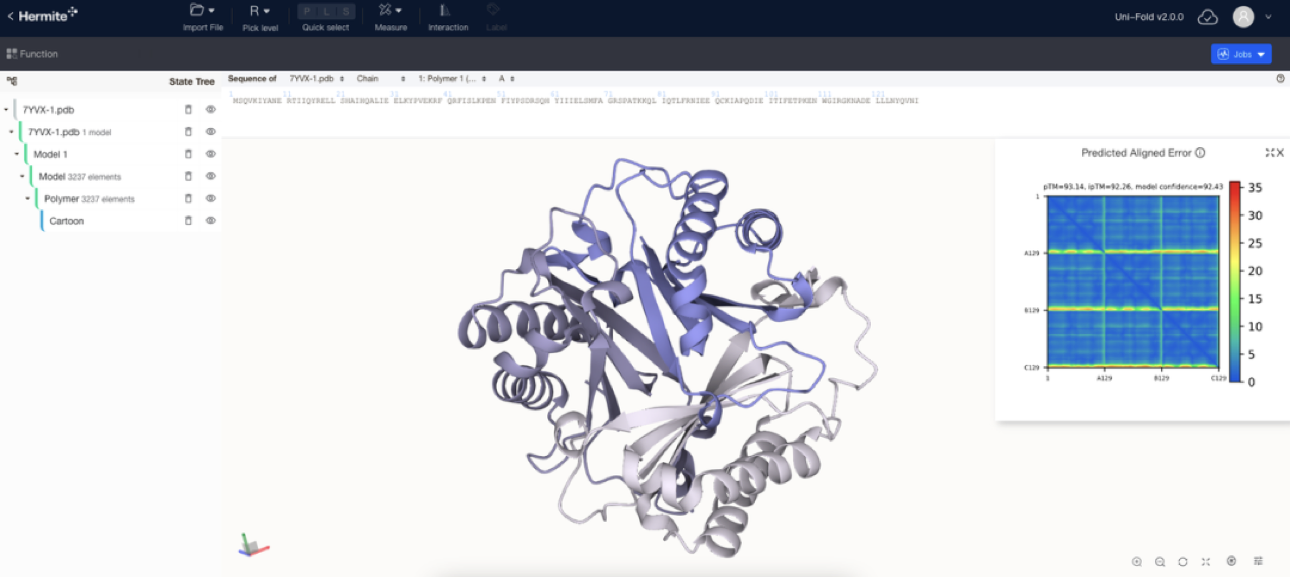

AI 企业多云存储架构实践 | 深势科技分享

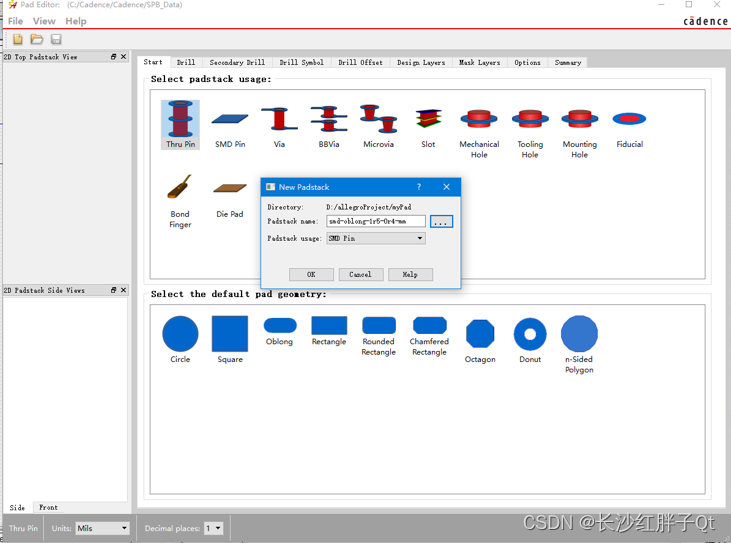

硬件开发笔记(十): 硬件开发基本流程,制作一个USB转RS232的模块(九):创建CH340G/MAX232封装库sop-16并关联原理图元器件

小常识:保险中的“保全”是什么?

Huawei has launched attacks in many industries at the same time, and its frightening technology has made European and American enterprises tremble

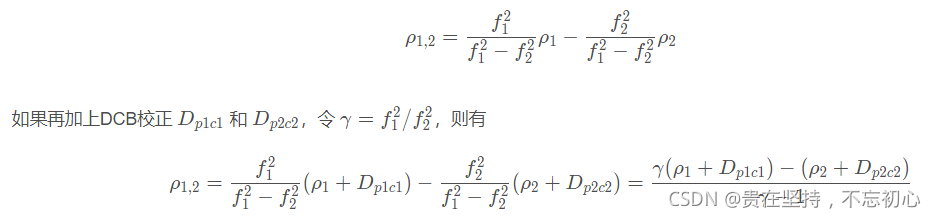

GPS from getting started to giving up (XV), DCB differential code deviation

随机推荐

墨西哥一架飞往美国的客机起飞后遭雷击 随后安全返航

数据处理技巧(7):MATLAB 读取数字字符串混杂的文本文件txt中的数据

Classic sql50 questions

Management background --1 Create classification

Assembly and Interface Technology Experiment 6 - ADDA conversion experiment, AD acquisition system in interrupt mode

Write a rotation verification code annotation gadget with aardio

Force deduction question 500, keyboard line, JS implementation

Persistence / caching of RDD in spark

GPS from getting started to giving up (XI), differential GPS

HDR image reconstruction from a single exposure using deep CNNs阅读札记

Assembly and interface technology experiment 5-8259 interrupt experiment

MySQL related terms

AI enterprise multi cloud storage architecture practice | Shenzhen potential technology sharing

MPLS experiment

The golden age of the U.S. technology industry has ended, and there have been constant lamentations about chip sales and 30000 layoffs

Codeforces Round #274 (Div. 2) –A Expression

关于程序员的职业操守,从《匠艺整洁之道》谈起

LeetCode刷题(十一)——顺序刷题51至55

HDU 2008 digital statistics

【10点公开课】:视频质量评价基础与实践